Second page of instructions To complete R0015278 assembly mounting

Introduction

Tools Required

Standard Hex key set

Standard spanner set

300 mm rule

1000mm rule

Parts Required

D0008288 Takeup Pad Left (D7339) (Wet/P F Matt) x 1

D0015583 Take Up Beam Joiner x 1

D0015598 Datum Flag: Saw Infeed x 1

D0015717 Energy Chain Angle Bracket Lower x 5

D0015718 Energy Chain Angle Bracket Upper x 2

D0015718B Energy Chain Angle Bracket Double Deck x 3

D0015720 Carriage Bracket x 1

D0015721 Energy Chain Tray Deep Long x 1

D0015723 Energy Chain Tray Shallow x 1

D0015724 Energy Chain Tray Deep x 2

D0015725 Energy Chain Tray Shallow Medium x 1

D0015742 Takeup Pad Right ZX5 x 1

D0015862 Energy Chain Tray Deep Long x 1

E0000336 Sensor: M8; 2mm, PNP N/O, M8 conn x 1

R0015011 Bench Assemble Gripper

R0015063 Bench Assemble Roller Tables

R0015096 Bench Assemble Transfer Drive Assembly

R0015101 Bench assembly take up assembly

R0015286 Bench Assemble X axis components and energy chainÉtape 2 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all fasteners to show finalised

Étape 3 - Quality check

Please quality check finish on below channel bars .

Paint work should match on both bars in regards to colour and finish (ie matt /gloss)

Report any discrepancy to supervisor

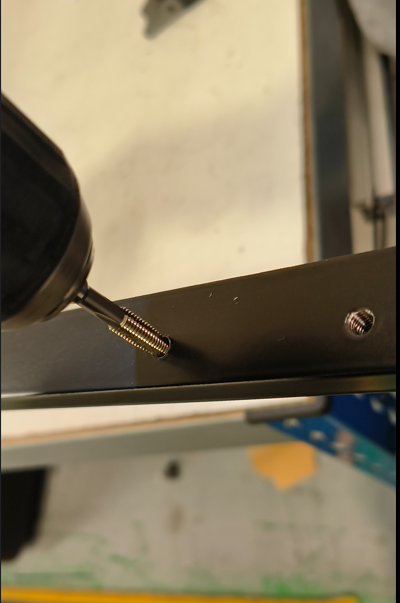

Étape 4 - Clean threads

Clean threads in parts

D0015742 Takeup Pad Right ZX5 x 1

D0008288 Takeup Pad Left (D7339) (Wet/P F Matt) x 1

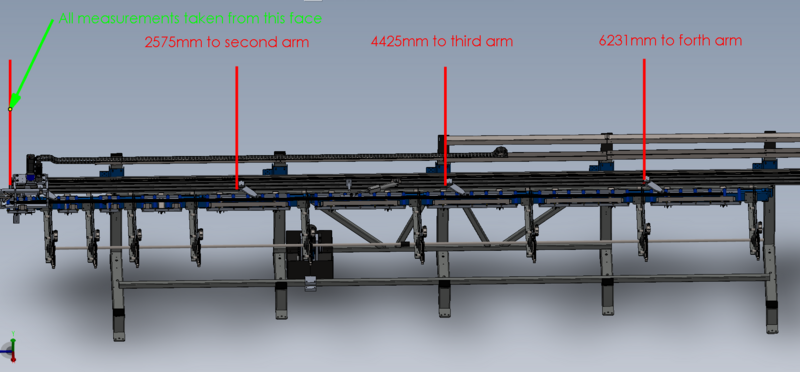

Étape 5 - Mount 1st take up arm

Use 4 off F0000299 M6 d nuts and 4 off M6 x 20 socket caps and M6 penny washers to mount takeup arm at position shown

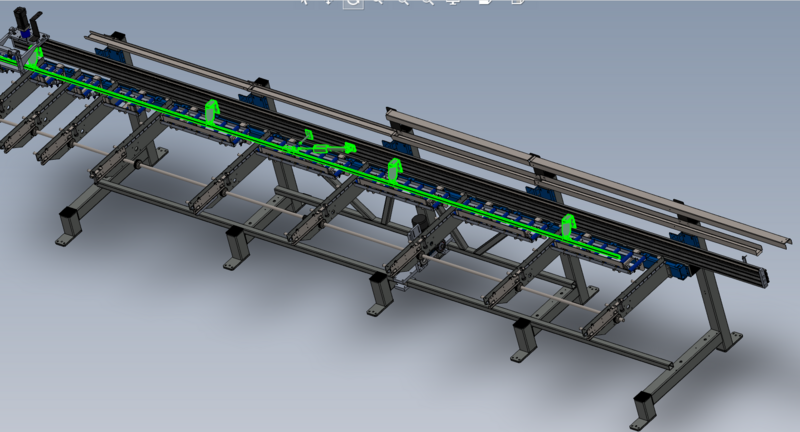

Étape 6 - Mount 2nd,3rd and 4th arms

Mount remaining 3 take up arms as shown using fasteners stated in previous step

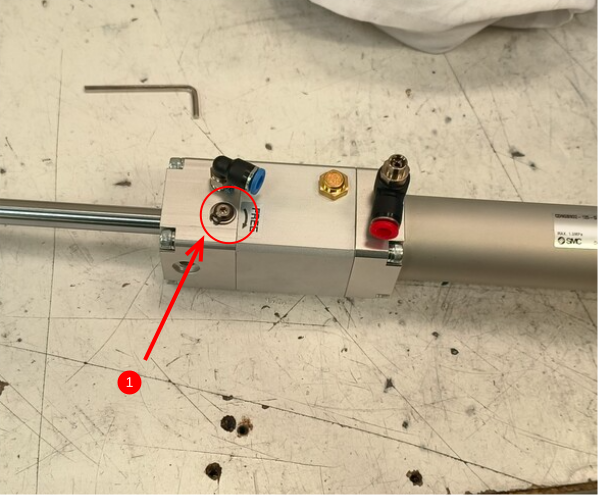

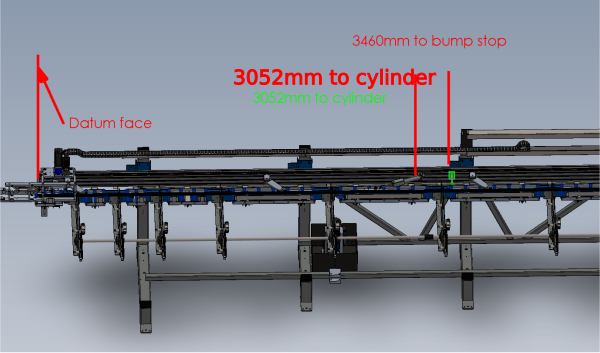

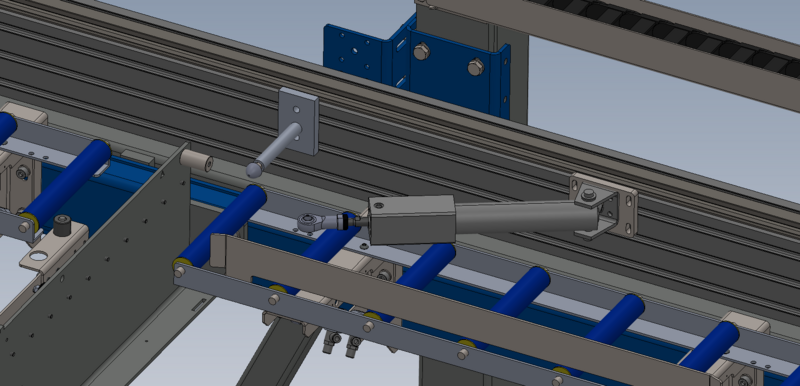

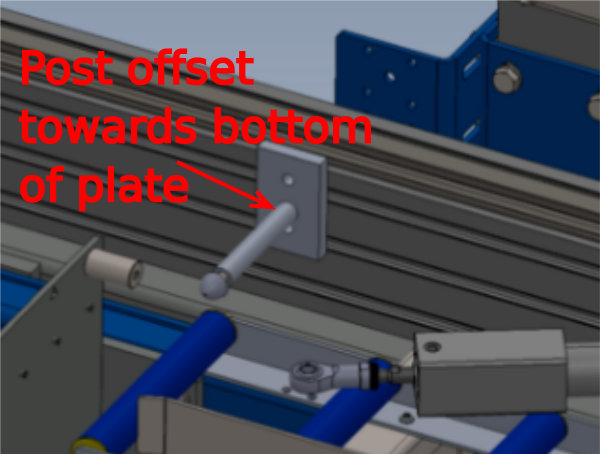

Étape 7 - Mount cylinder assembly and hard stop

1 Over ride lock function so piston on cylinder can move freely

2 Mount cylinder in position shown . Do Not apply adhesive to these fasteners yet .

use M6 x 20 socket caps and penny washers to secure cylinder assembly

3 Mount hard stop as shown using M6 x 20 socket caps and 20mm diameter washers at top position , Bottom position uses M6 x 20 socket caps and A form washers

Étape 8 - Note

Black take up pads D0008288 and D0015742 are not fitted at this point .

These will be fitted at a later stage of build

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português