Assembly details for 1st stage fitting

Sommaire

Introduction

Tools Required

Standard Hex key set

Standard HSS Drill Set

Standard spanner set

Standard Tap set

Standard 5mm straight hex key ( non ball point )

Hex key extension bar

Parts Required

D0004583 Outfeed Long Rest (5354) x 1

D0004584 Outfeed Side Rest x 4

D0005127 Outfeed Welded Frame (5356) x 1

H0005136 Outfeed Top Tray (5355) x 1

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 570 on all threaded pneumatic connections

Pen mark all bolts when finalised

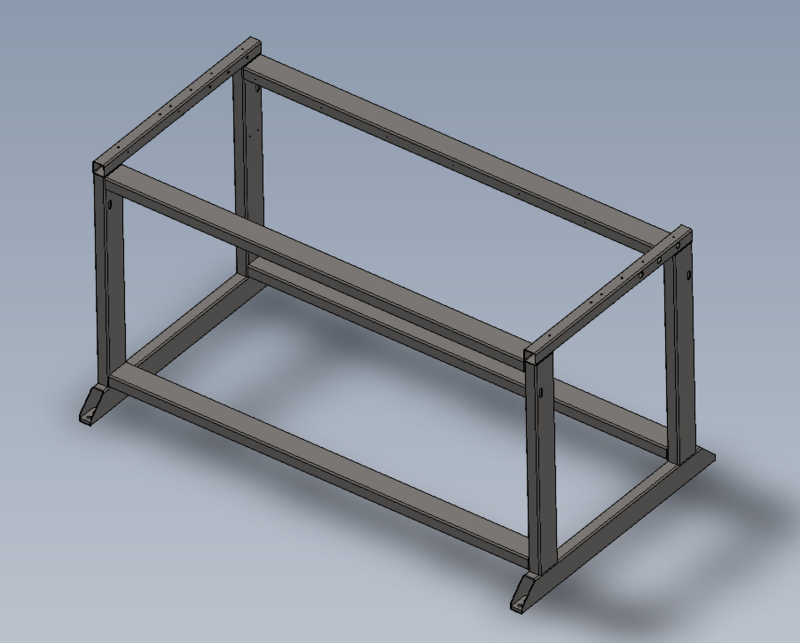

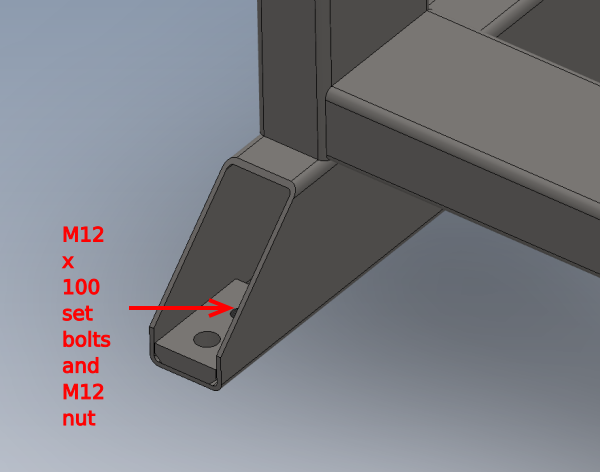

Étape 2 - Clean and tap

Use taps to clean all threads present on frame .

Add 4 off m12 x 100 set bolts with M12 nuts and fit to adjusting points

Use 4 off levelling pads (workshop stock ) to sit beneath adjustment bolts

(pictures required please)

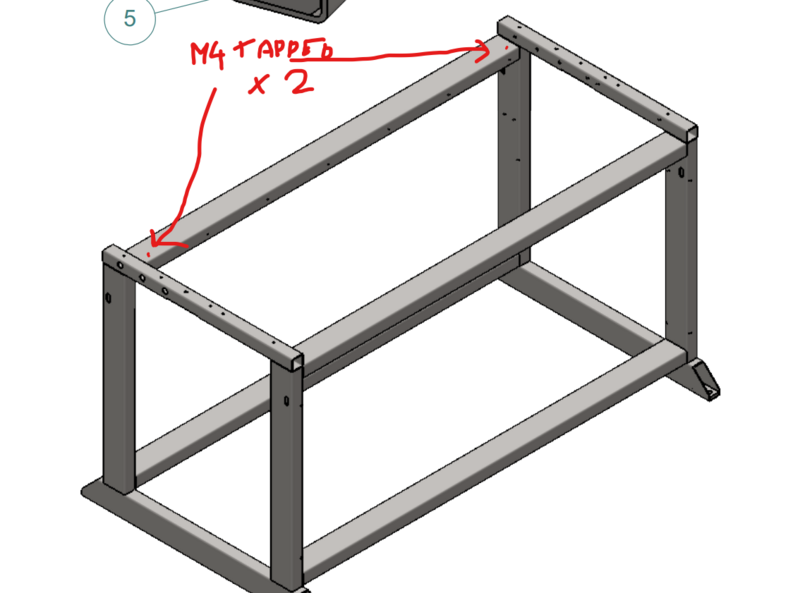

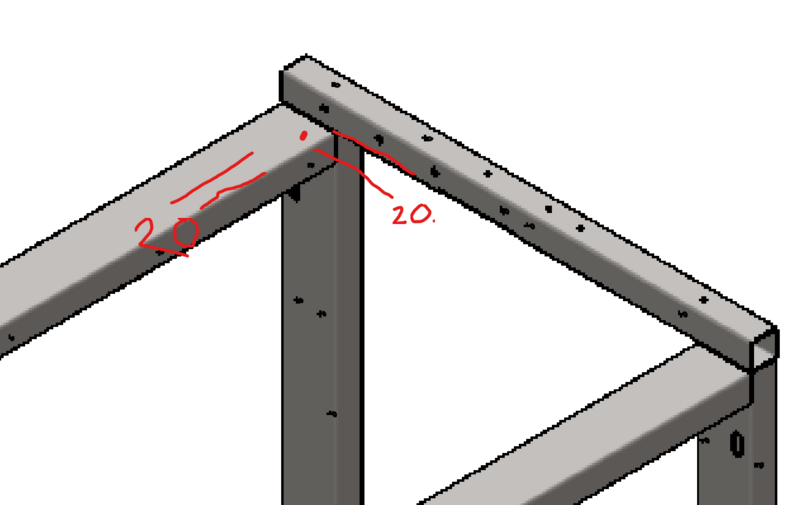

Étape 3 - Ecr work

Ecr raised 10/10/23 to add 2 off M4 tapped holes to frame.

Until processed add by hand as shown

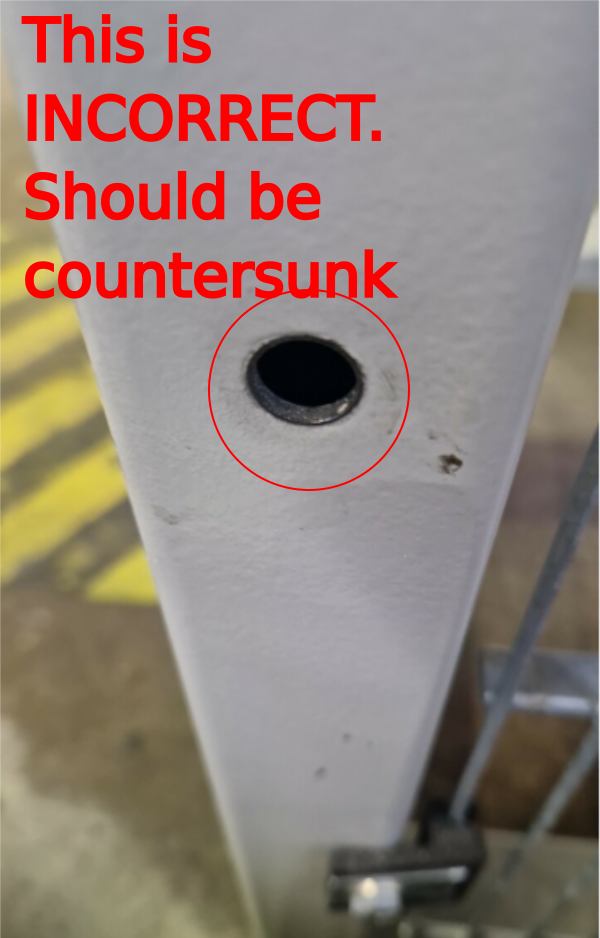

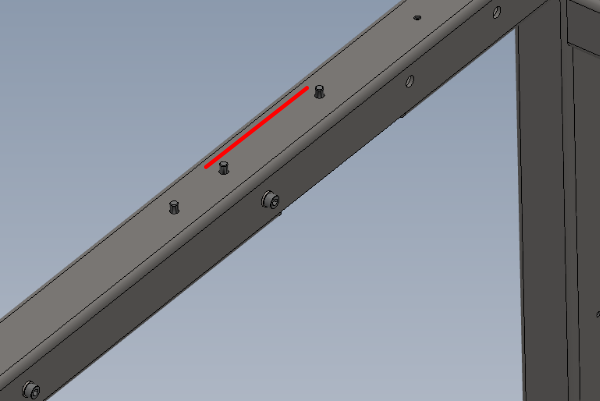

Étape 4 - Check and fit M8 rivnuts

Fit 2 off rivnuts to required mounting points for conveyor .

2 off M8 rivnuts must be installed correctly

1 Face of frame must be countersunk to allow flush fitment and full contact of rivnut shoulder.

2 Rivnuts must be tensioned correctly when installed. If in doubt, please request information from supervisor for the correct fitting of rivnuts.

3 Rivnuts should have a solid fixed into frame and not be able to rotate . To check this, bolt a component to the rivnut and tighten. Then undo fastener and remove component. Rivnut should not move during this process and remain solid

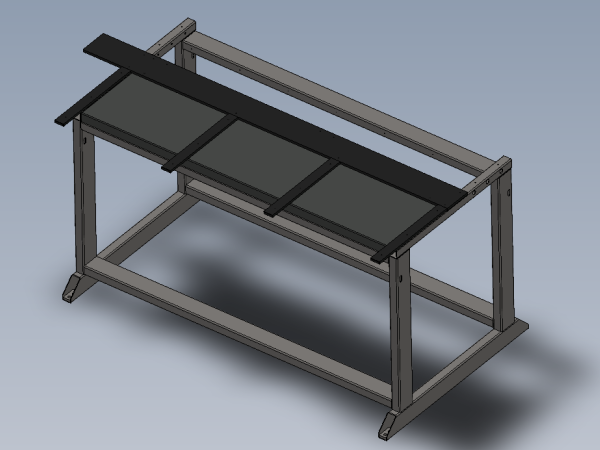

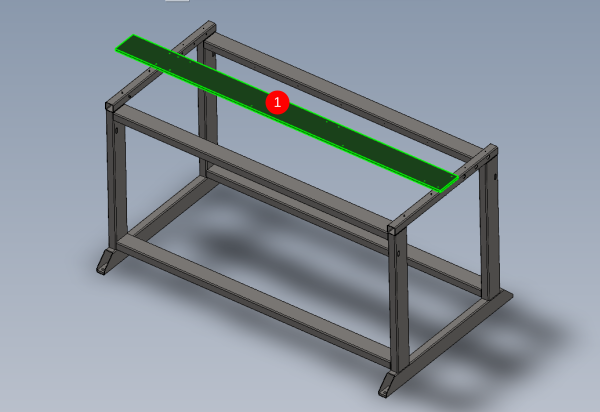

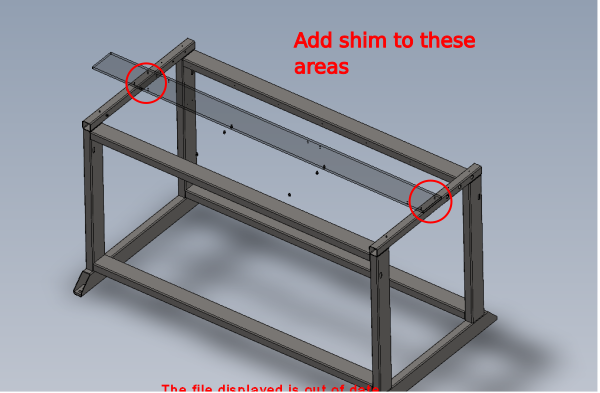

Étape 5 - Mount and check long rest plate

Fit D0004583 Outfeed Long Rest orientated as shown

Tap all holes in long rest before fitting . Only use a plug tap to clean threads in long rest

1 Use 4 off M6 x 12 socket caps with M6 A washers and fix to frame

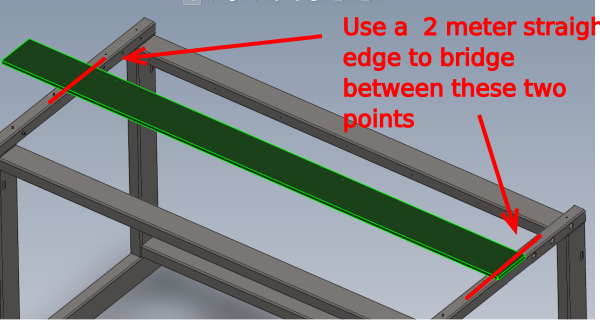

2 Check flatness with 2 meter straight edge across 2 indicated points.

Straight edge will show a gap in the centre section of the long rest bar

Étape 6 - Adjust Outfeed long rest

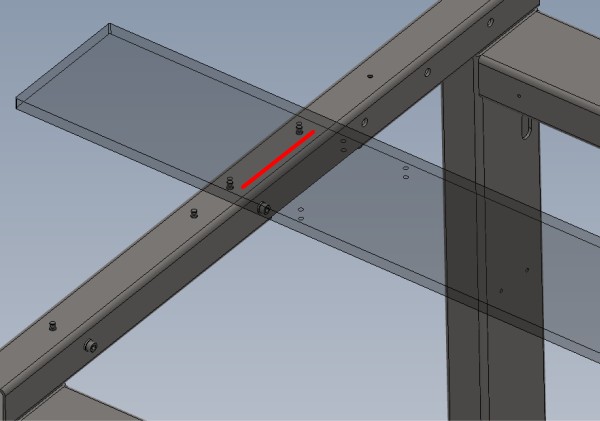

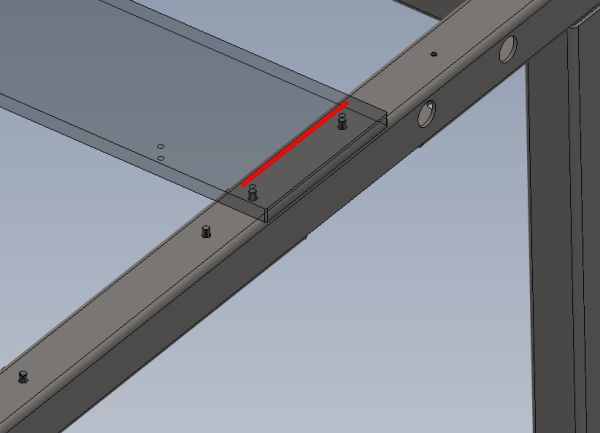

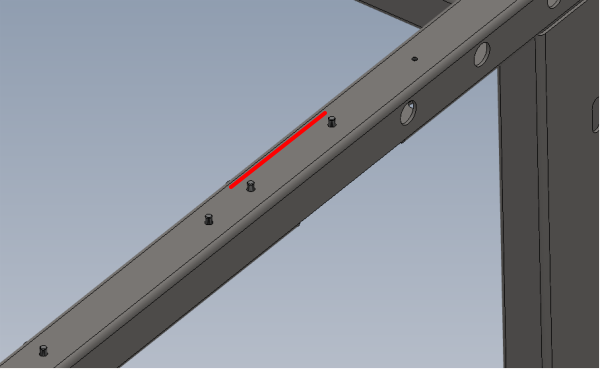

Shims can be used to adjust the flatness of the long rest plate

Cut shims to 10mm x 140mm

Place at indicated points between frame and long rest bar .

Re tension bolts once shim is added to show true reflection of change made by shim added

Adjust until long rest bar is flat to straight edge

Tolerance + - 1mm

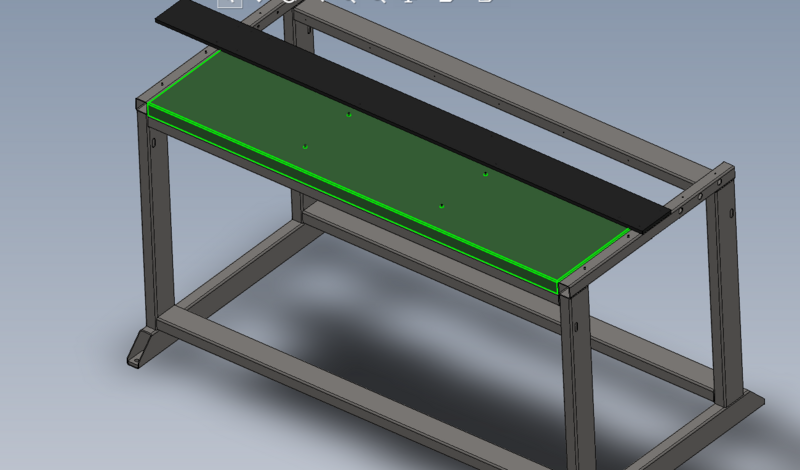

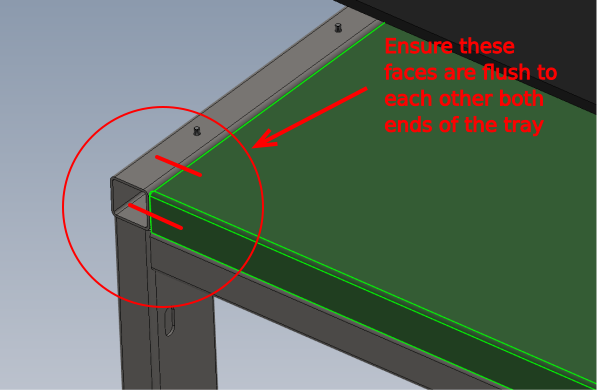

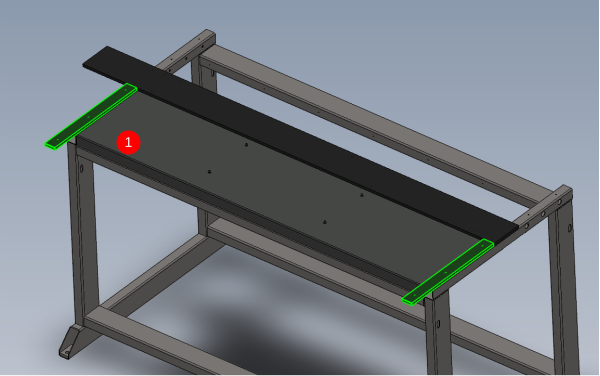

Étape 7 - Fit outfeed top tray

Fit H0005136 Outfeed Top Tray as shown

Ensure indicated faces are set flush to frame

Use 8 off M6 x 12 socket caps and heavy M6 washers to fix to frame

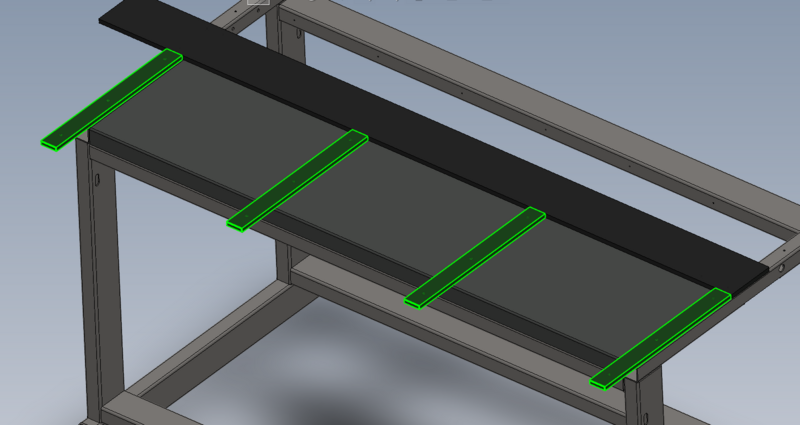

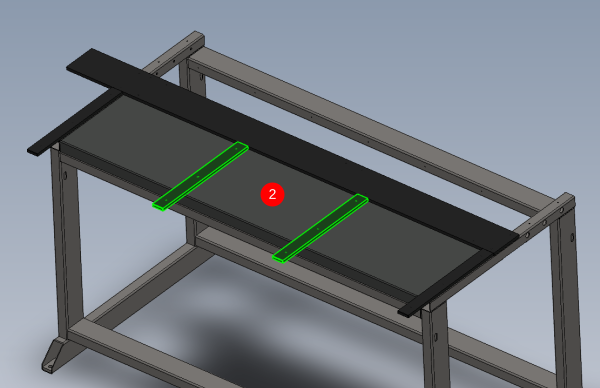

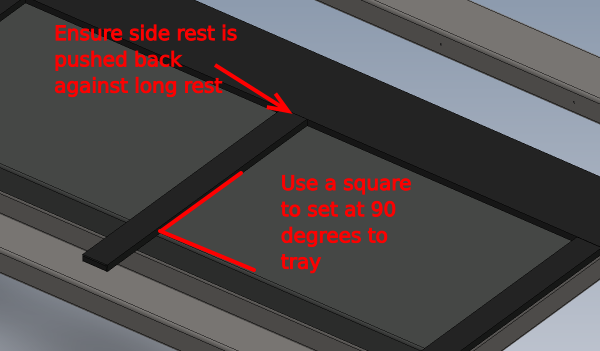

Étape 8 - Fit side rests

Fit 4 of D0004584 Outfeed Side Rest to positions indicated

When fitting side rests ensure that they are set as shown S

1 Use M6 x 10 socket caps (4 off) to fit indicated arms to frame

2 Use M6 x 12 socket caps and penny washers (4 off) to fit indicated side rests

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português