Instructions to install pneumatic connections to main frame

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - mount pneumatic rail

- 4 Étape 3 - Valve Bank Connections

- 5 Étape 4 - Y239 Material blower

- 6 Étape 5 - Y231, Y230 and Y299 Pop up feeds

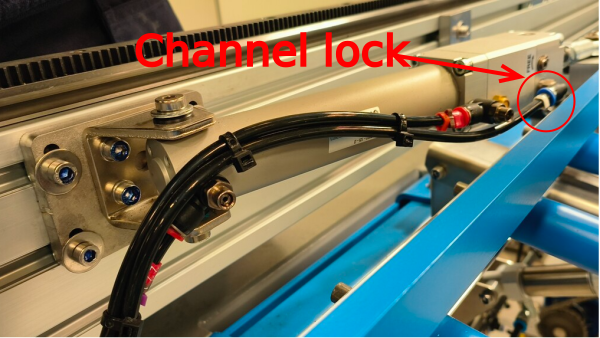

- 7 Étape 6 - Y221 channel

- 8 Étape 7 - Y220 channel lock

- 9 Étape 8 - Y147 pop up E

- 10 Étape 9 - Y146 Roller Bed

- 11 Étape 10 - Important

- 12 Étape 11 - Y131 Grip Height

- 13 Étape 12 - Y241 Rack blower

- 14 Étape 13 - Cable looms

- 15 Étape 14 - Connect ring main

- 16 Commentaires

Introduction

Tools require

Pipe cutters

Number identification

Flush cutters

Parts required

P0000010 Elbow Adaptor 6mm - 1/8 BSPT (Taper thread) x 8

P0000160 Fitting: Flow Controller In Line 6mm x 2

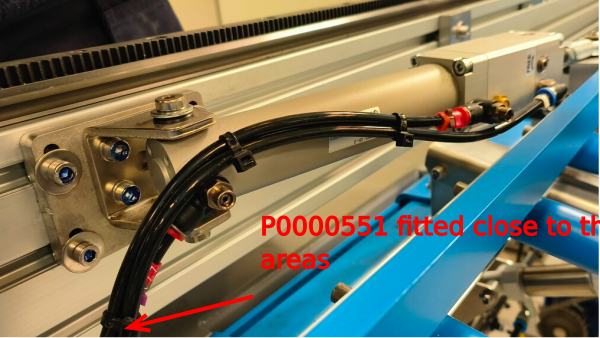

P0000551 6mm inline Quick Exhaust Fitting x 7

P0001008 Regulator: ARG20 0 - 8.5 Bar c/w Gauge x1

P0001022 Regulator Bracket: to suit P0001008 x 1

A0000343 energy chain x 1

A0000344 energy chain bracket set x 1

D0015577 Fixed energy chain bracket x 1

P0001030 6mm compact tee x 12

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

Étape 2 - mount pneumatic rail

Mount pre assembled pneumatic rail with 2 off M8 x 20 socket cps. Use 1 off M8 A Form washer on slotted end of rail

Étape 3 - Valve Bank Connections

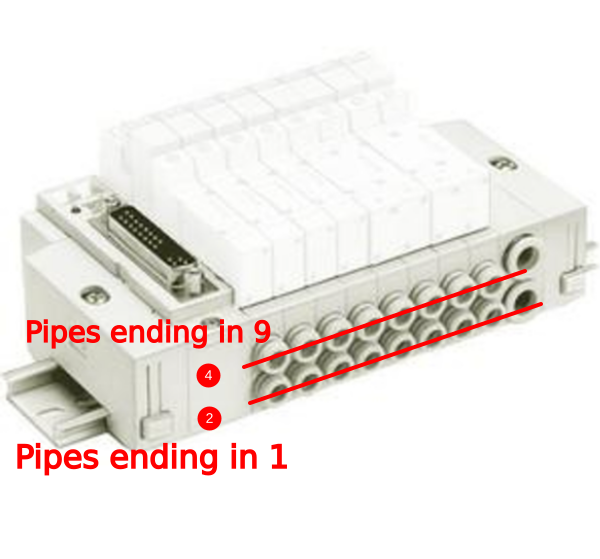

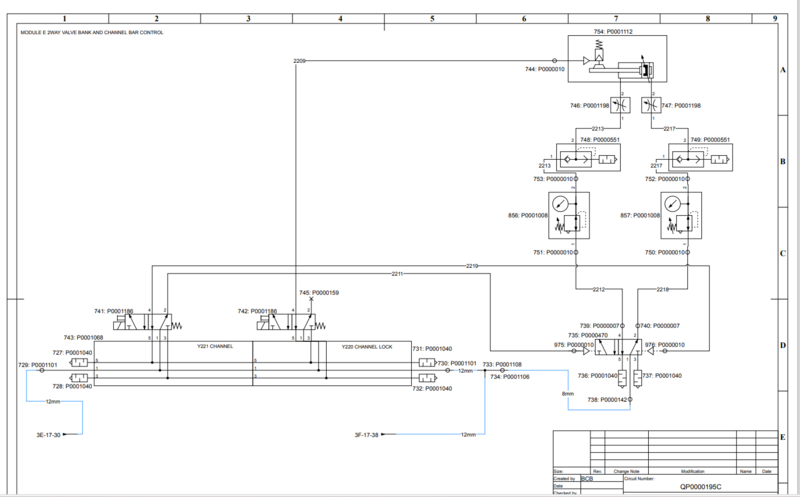

Valve bank connections are as follows

Front row of valve bank (4) is the active ports, These will all be connected with suffix 9 pipe identifications

Back row (2) is the home position , these will always be connected with suffix 1 pipe identifications

Étape 4 - Y239 Material blower

Material blower should be identified as 2399

Located on roller assembly close to saw unit

P0000160 flow reg required to control flow onto sensors, this should be pre fitted to roller assembly at bench assembly stage

Connect to active port ln valve bank (4)

Étape 5 - Y231, Y230 and Y299 Pop up feeds

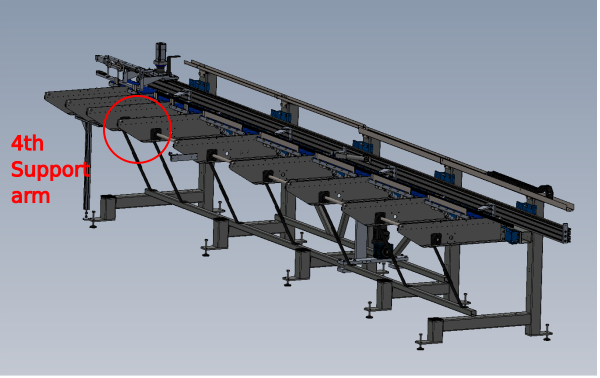

Feed pipes from valve bank should be run to transfer arm location 4

Identifications will be

2319

2309

2299

Connect to active port on valve bank (4)

Fit A000343 energy chain @40 links

A0000344 energy chain brackets as shown

Mount to D0015577 fixed bracket with M3 x 6 panhead screws and attach to support arm as shown using M4 x 16 socket caps, A form washers and M4 nyloc nuts .

Must have a P0000551 Q.E.V fitted to each line

Ensure 1.5 m of pipe is left exiting the end of the energy chain

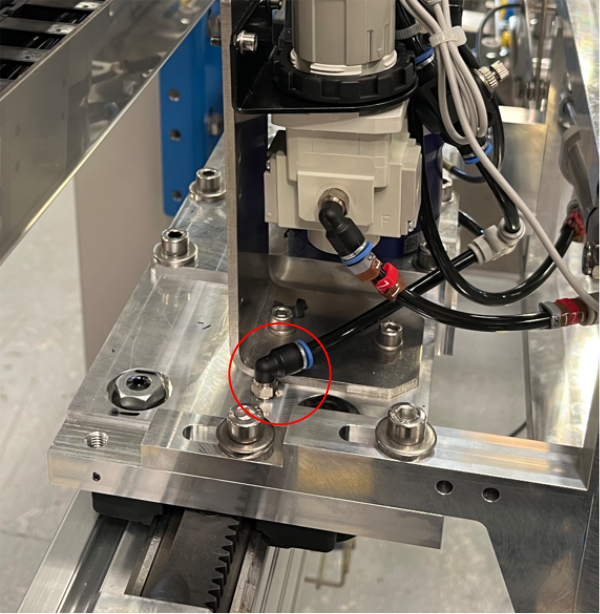

Étape 8 - Y147 pop up E

Identification 1479

Connects to active port on valve bank (4)

Use P0001030 compact tee to connect

Ensure enough loom to allow full range of movement

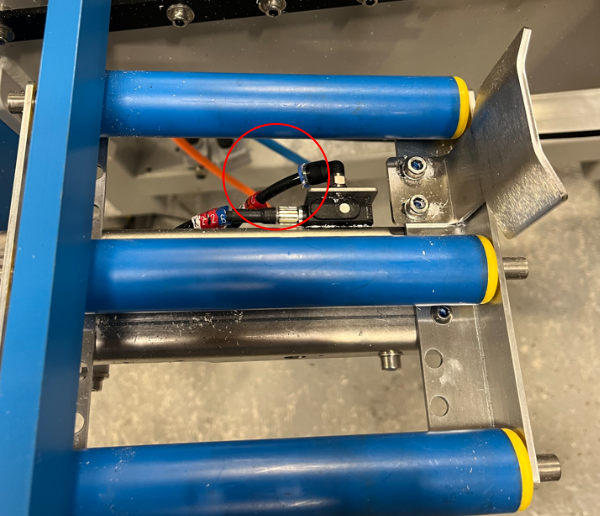

Étape 9 - Y146 Roller Bed

Identification

1461 and 1469

Roller bed is lifted at home position

Use P0001030 6mm tee for connections

1461 to home port on valve bank (2)

1469 to active port on valve bank (4)

Étape 10 - Important

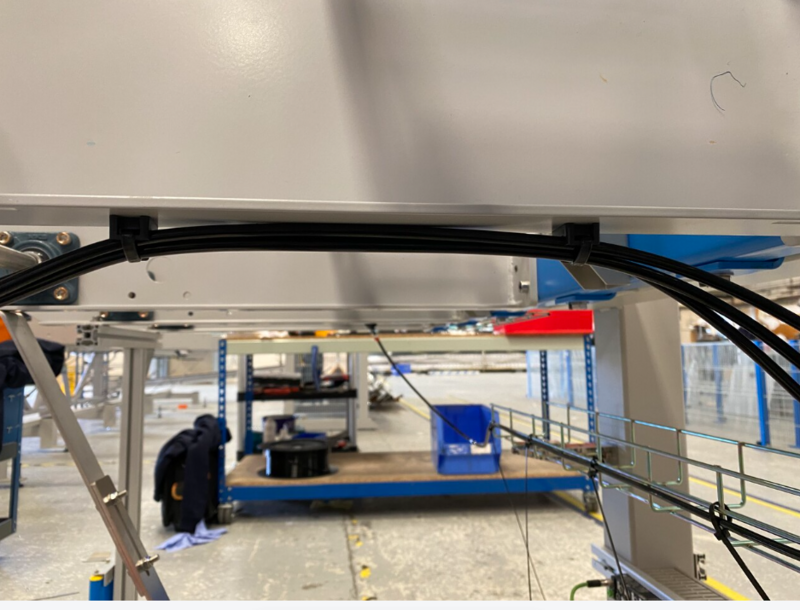

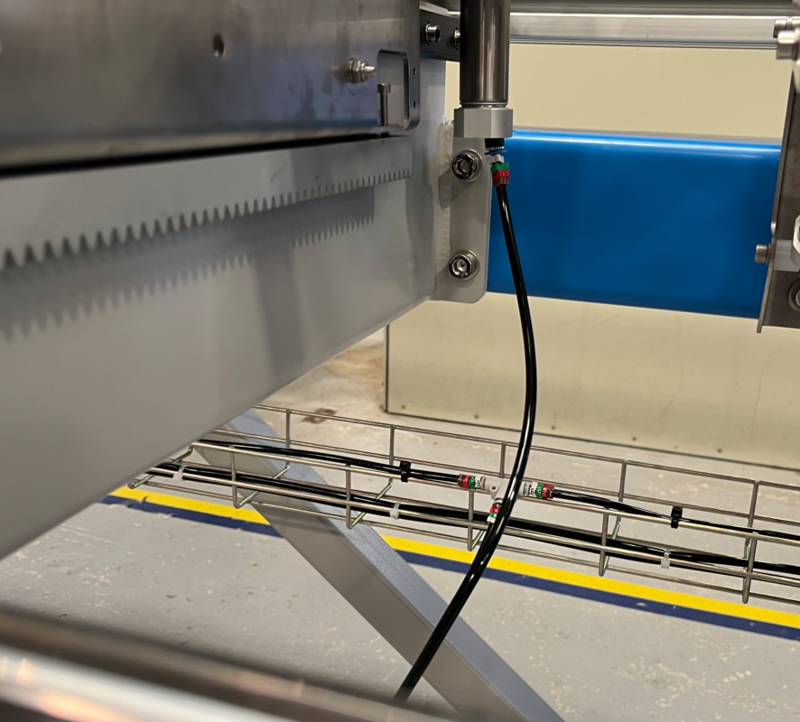

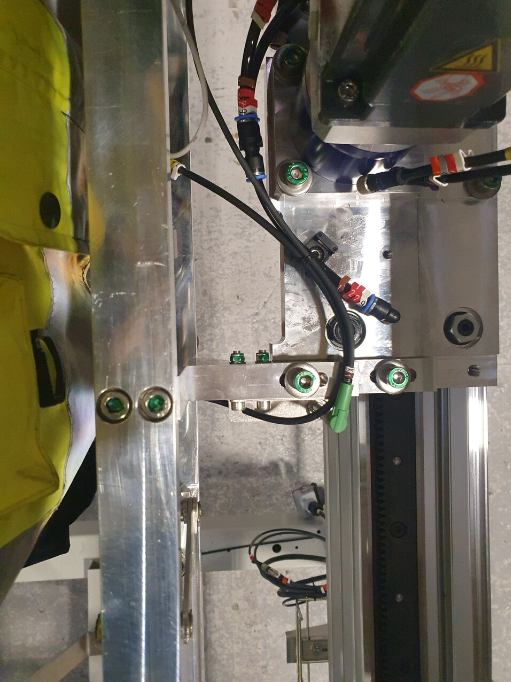

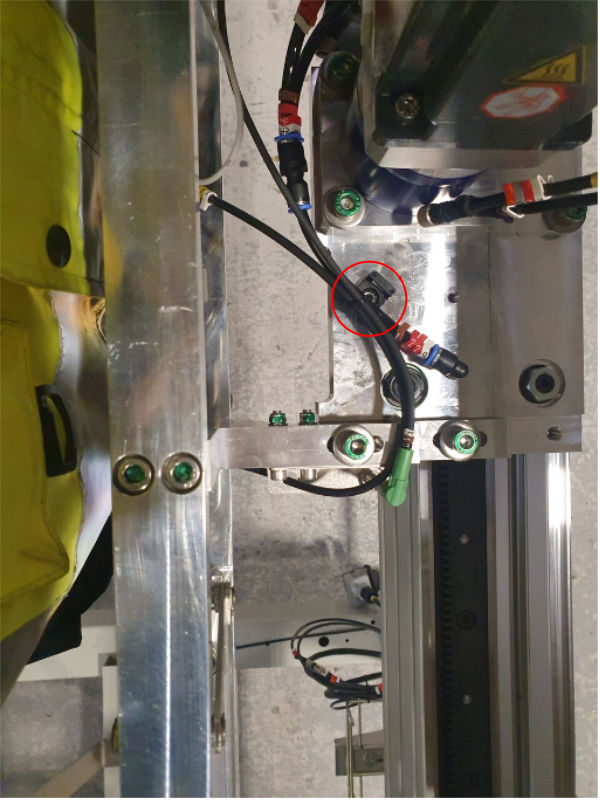

It is vital that when installing pipes into the main X axis energy chain, that cable retaining points are used

All cables and pipes should be secured with tie wraps to the 'fingers' on the energy chain brackets at BOTH ends

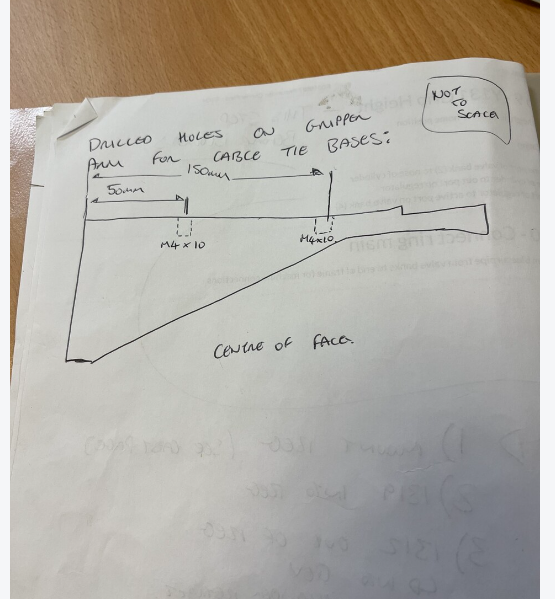

Étape 11 - Y131 Grip Height

Fit tie bases as shown to gripper support arms .

Ecr raised to add holes to drawing 06/11/23

Fit P0001008 Regulator: ARG20 0 - 8.5 Bar c/w Gauge x1

P0001022 Regulator Bracket: to suit P0001008 x 1 to bracket shown

Gripper height is lifted for home position

identification

1311 Home port of valve bank (2) to nose of cylinder

1312 base of cylinder to out port on regulator

Ensure P0000551 Q.E.V are fitted to both grip height cylinder ports

1319 In port of regulator to active port on valve bank (4)

Étape 12 - Y241 Rack blower

Identification 2419

Must have flow regulation P0000160

Split feed with P0001030 6mm tee

Connect to active port (4) on valve bank

Étape 13 - Cable looms

Install 1 off cable tie base as shown

Run cable X44 and X10 as shown

Leave loops of excess cable tied off ready for electrical termination

Leave cable X283 tied off in a loop on cylinder

Étape 14 - Connect ring main

Connect 12mm blue airpipe from valve banks to end of frame for machine connections

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português