Bench assembly details for Ecoline clacker

Introduction

Tools Required

10mm spanner

5mm punch

Ball pein hammer

Parts Required

D0003196 Dipper Arm ( Ecoline) x 1

D0003197 Dipper Base ( Ecoline) x 1

D0003894 Flapper pivot pin x 1

M0000101 Compression Spring 11 D 15 D 25 Long x1

F0000185 M6 x 16 Hex set S/S x 1Étape 1 - M000101 Compression spring

M0000101 is not required for bench assembly , and will not be shown within the work instruction .

Ensure this part is issued with each assembled clacker

Étape 2 - Components

D0003196 Dipper Arm ( Ecoline) x 1

D0003197 Dipper Base ( Ecoline) x 1

D0003894 Flapper pivot pin x 1

F0000185 M6 x 16 Hex set S/S x 1

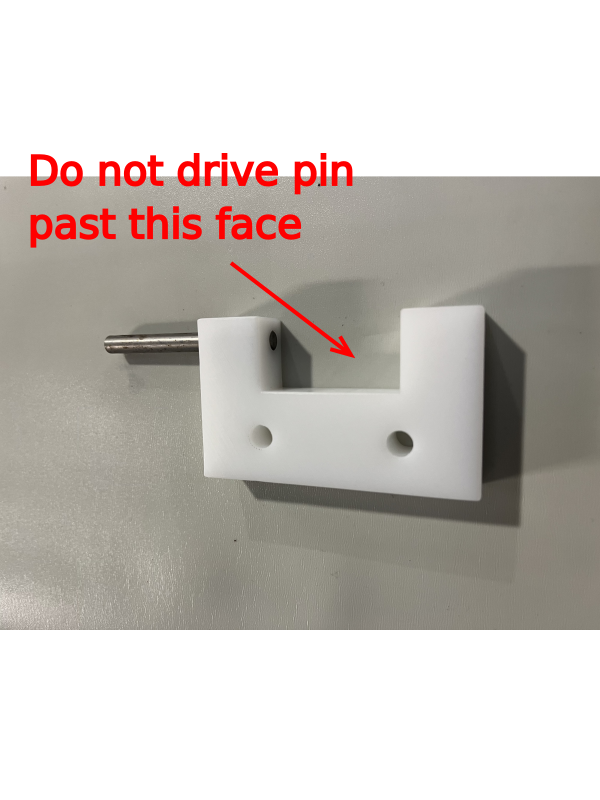

Étape 3 - Fit D0003894 Flapper pivot pin

Use ball pein hammer to locate D0003894 Flapper pivot pin into D0003197 Dipper Base as shown

Ensure pin does not go past indicated face

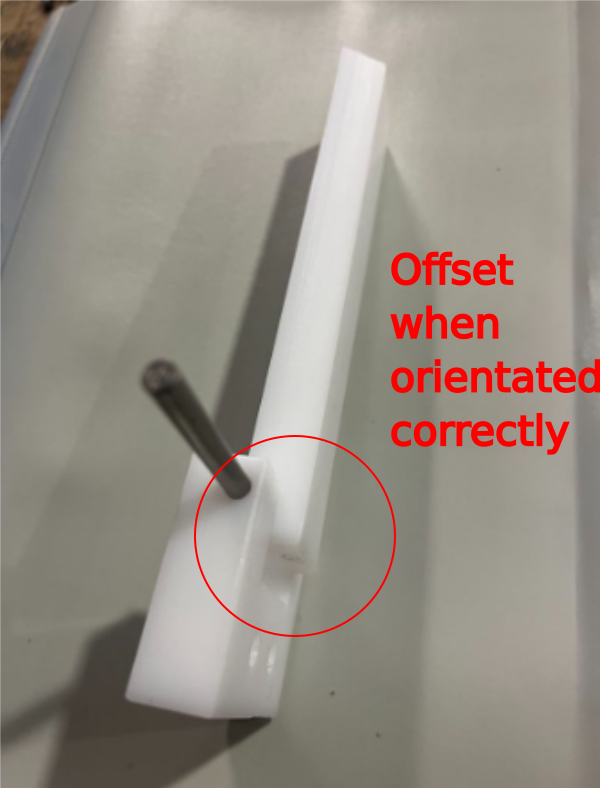

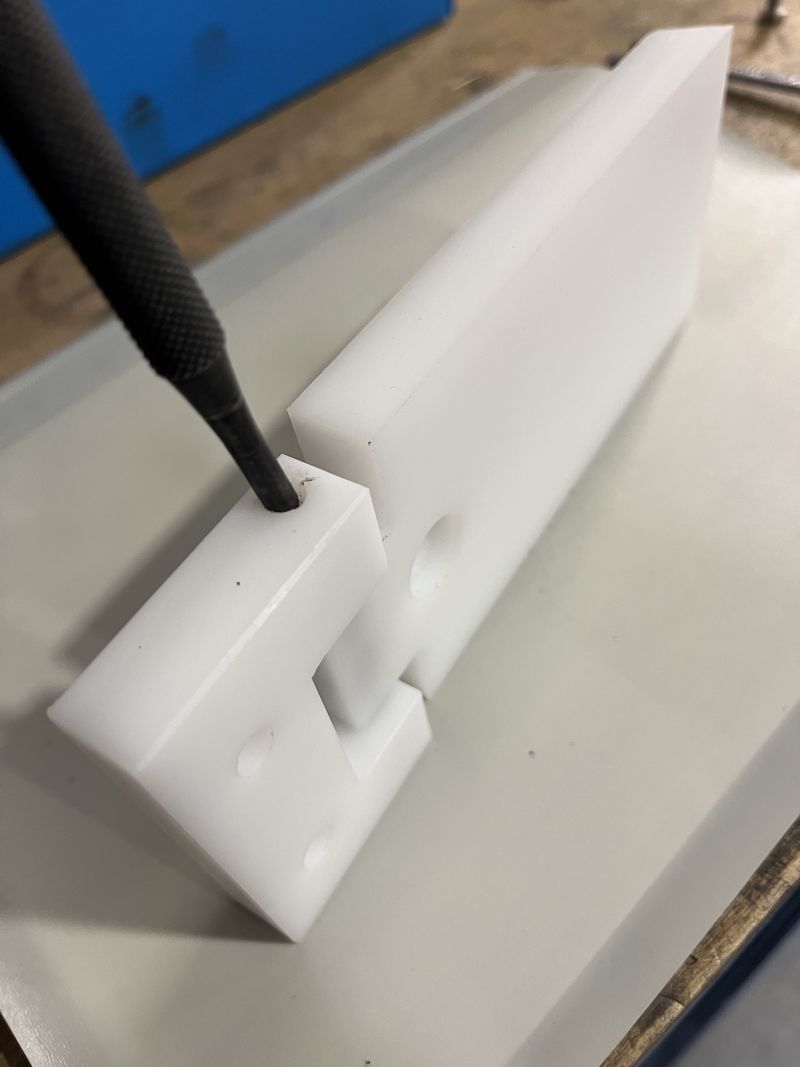

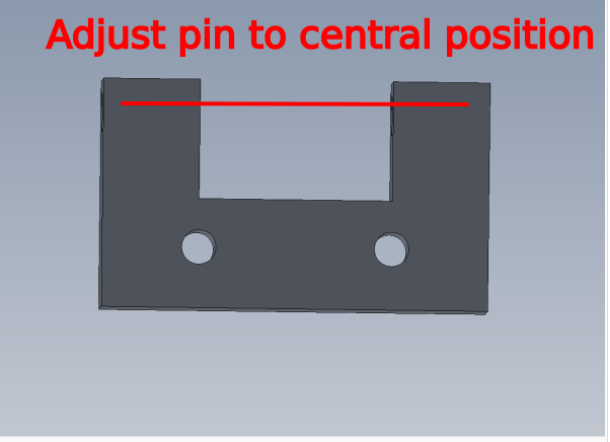

Étape 6 - Centralise pin

Use a 5mm punch and ball pein hammer to centralise pin between the 2 outer faces of D0003197 Dipper Base

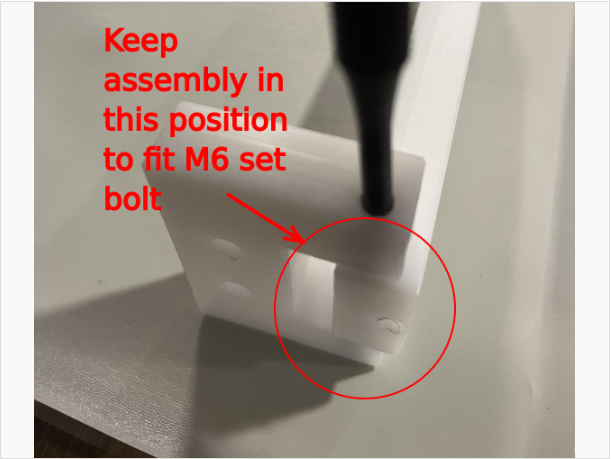

Étape 7 - Fit stop

Position assembly as shown

Fit M6 set bolt by hand

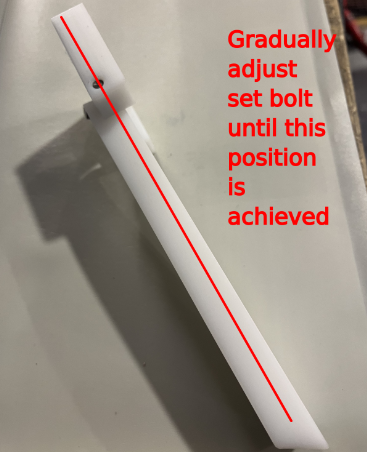

Slowly adjust set bolt by winding into the assembly until the shown position is achieved by the base and arm when Head of set bolt contacts the clacker base

DO NOT SET ANY FURTHER THAN THIS POSITION

Étape 8 - Finish

Check list

Pin centralised

Set bolt adjusted

Clacker arm and base pivots on pin by hand

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português