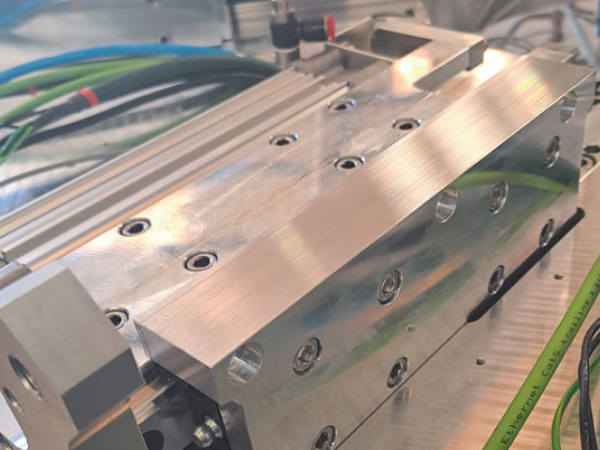

2nd stage of assembly of spindle assemblies

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Important Information

- 4 Étape 3 - Adjustable P bracket only Mount single plunge spindle cylinder 2,4,6 and 8

- 5 Étape 4 - Adjustable P Bracket only Align components and set position

- 6 Étape 5 - Fixed P bracket only Mount single plunge spindle cylinder 2,4,6 and 8 Adjustable P bracket

- 7 Étape 6 - Check D0007649

- 8 Étape 7 - Adjustable P Bracket only Mount double plunge spindle cylinder 1,3,5 and 7

- 9 Étape 8 - Adjustable P Bracket only Align components and set position

- 10 Étape 9 - Fixed P Bracket only Mount double plunge spindle cylinder 1,3,5 and 7

- 11 Étape 10 - Adjustable P Bracket only Attach single plunge motor plate

- 12 Étape 11 - Fixed P Bracket only Attach single plunge motor plate

- 13 Étape 12 - Double plunge assembly motor mount

- 14 Étape 13 - Mounting double plunge motor

- 15 Étape 14 - Mount double plunge cylinder

- 16 Étape 15 - Mount hard stops

- 17 Commentaires

Introduction

Tools Required

0.05mm feeler gauge

Standard hex key set

Standard spanner set

Rule

6mm punch

Ball pien hammer

Parts Required

D0007990 cylinder anchor x 7

D0007648 end plate x 4

D0007649 Double slide end plate x 4

D0007686 single motor plate x 4

D0007723 Double slide motor mount x 4

D0007687 Motor mount x 4

D0007600 Cylinder anchor x 4

D0015856 hard stop x 4

Étape 2 - Important Information

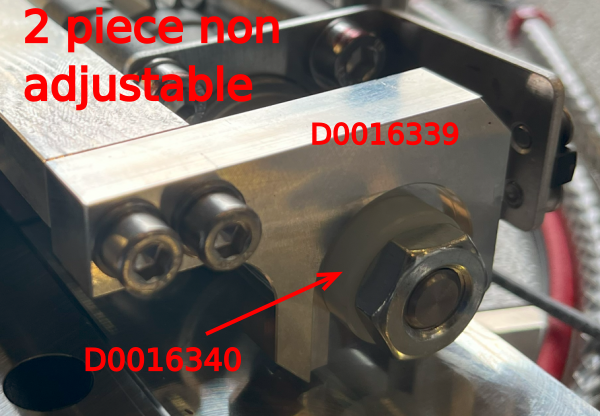

This instruction covers the fitting of 2 different styles of cylinder P bracket sets

Please see photos for clarity on differences

Steps will detail if any specific settings are required for the appropriate style of P bracket being fitted

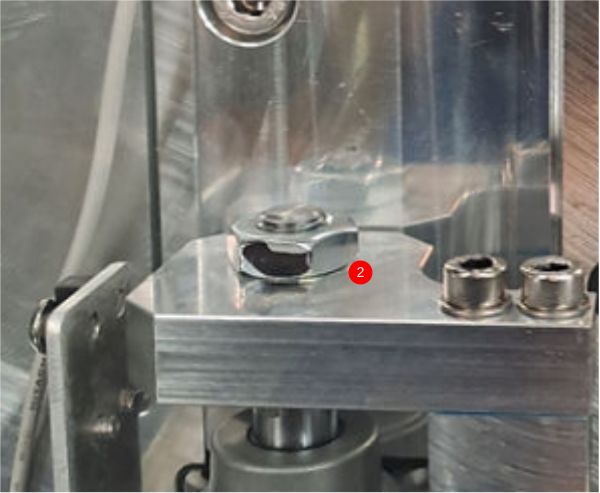

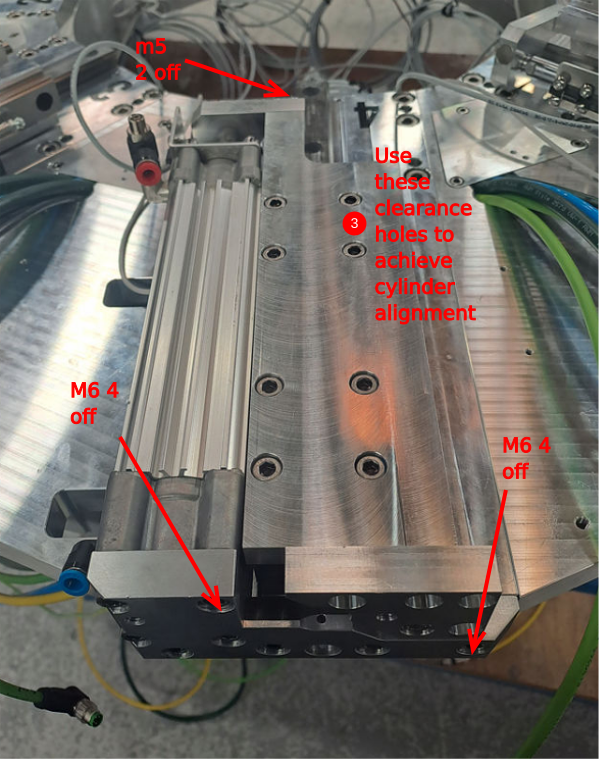

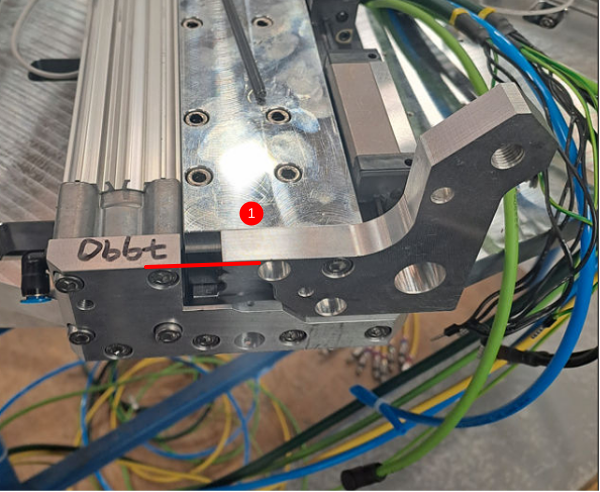

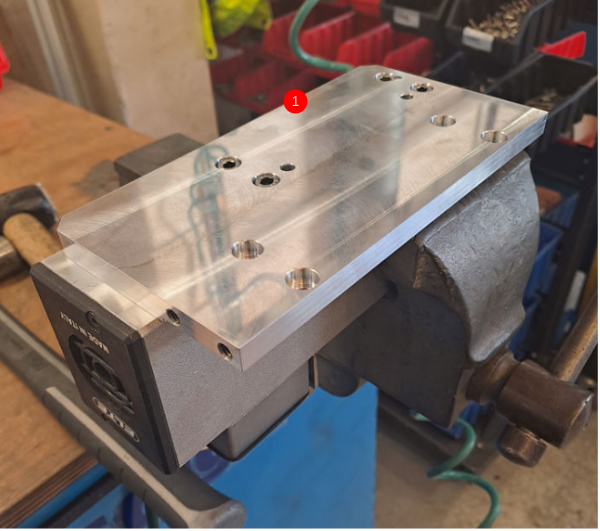

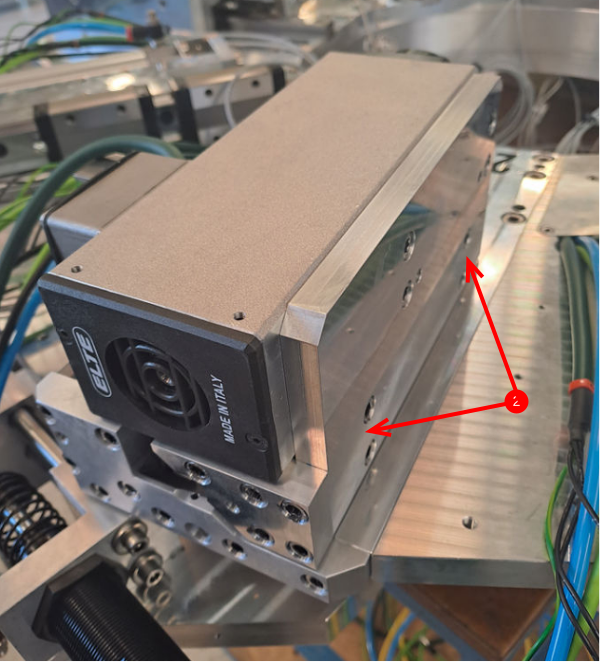

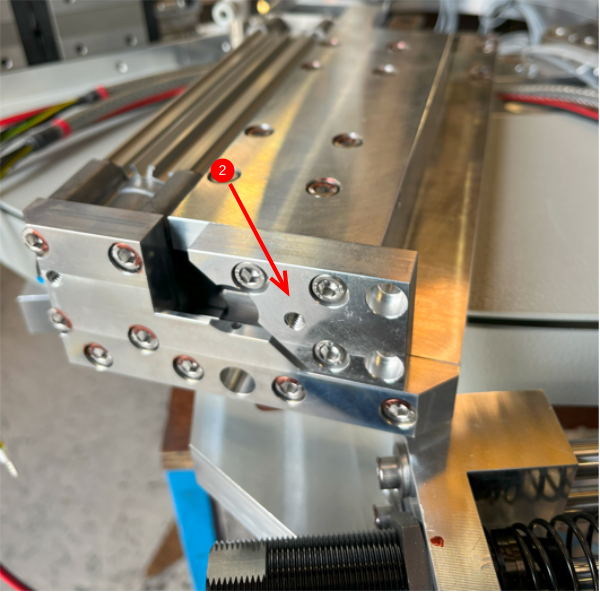

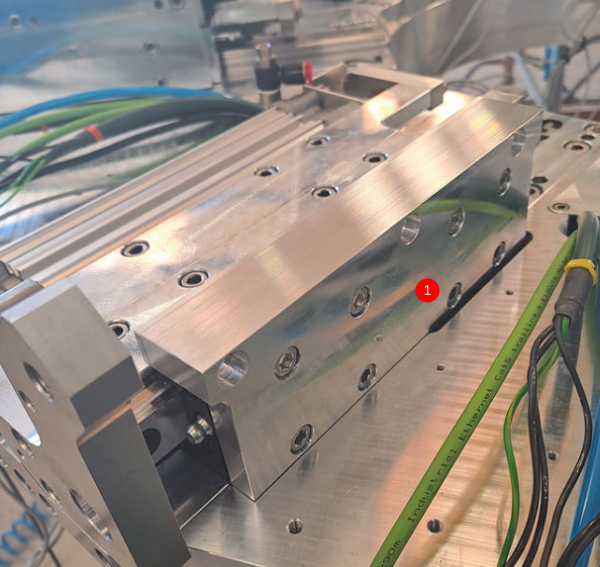

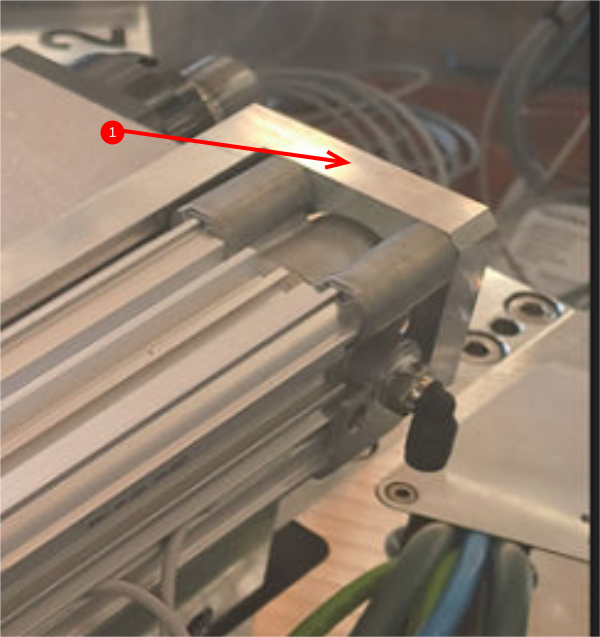

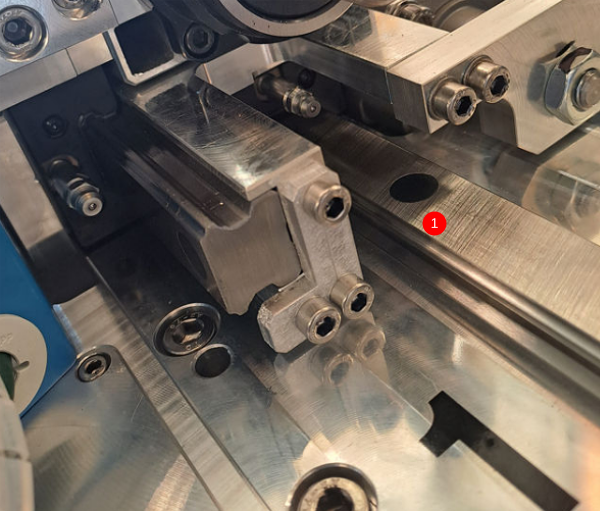

Étape 3 - Adjustable P bracket only Mount single plunge spindle cylinder 2,4,6 and 8

Adjustable P bracket only

Do not add final tension to bolts until alignment has been achieved

1 Attach pre built cylinder anchor to end of cylinder

2 Position pre built cylinder on slide base assembly as shown

3 Use 2 off m5 x 25 socket caps with A form washers to attach to slide base

4 Temporarily mount D0007648 with 1 off m6 x 20 socket cap

5 Attach D0007790 cylinder anchor with 4 off M6 x 20 socket caps

6 Attach Cylinder base to anchor with 4 off M6x 20 socket caps

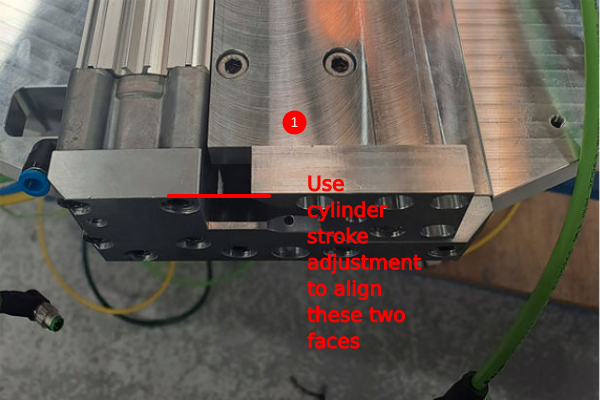

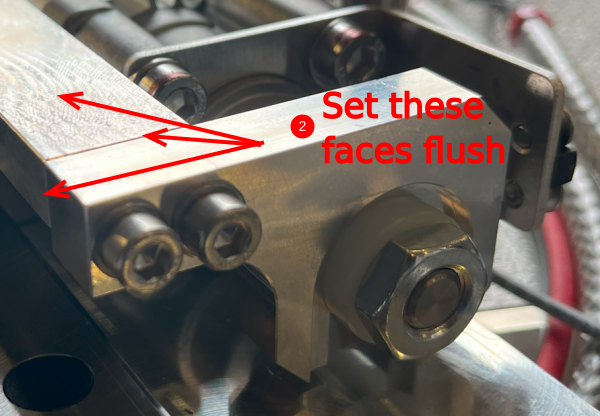

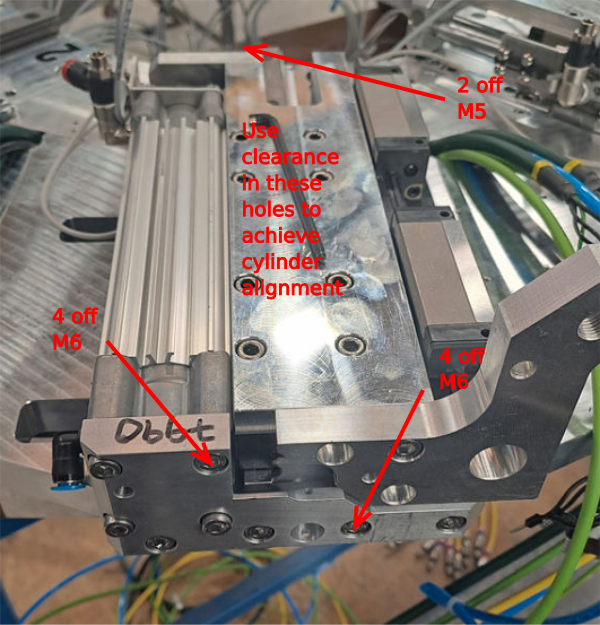

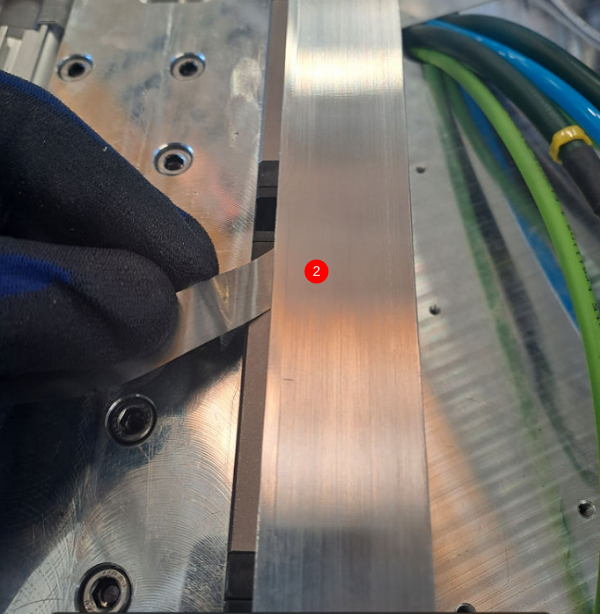

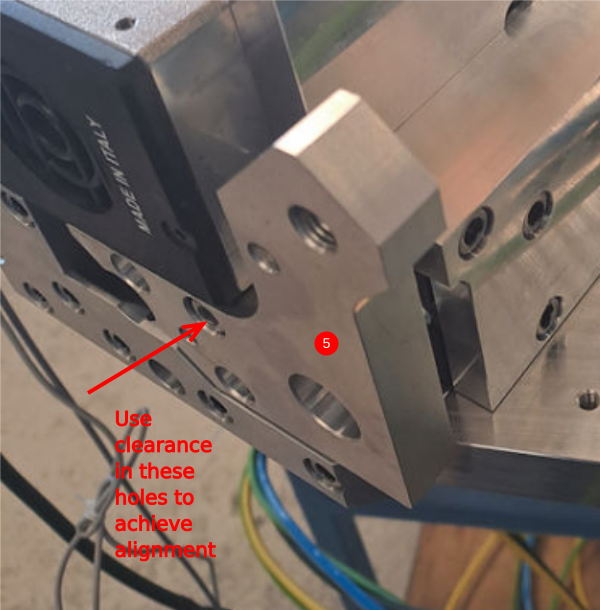

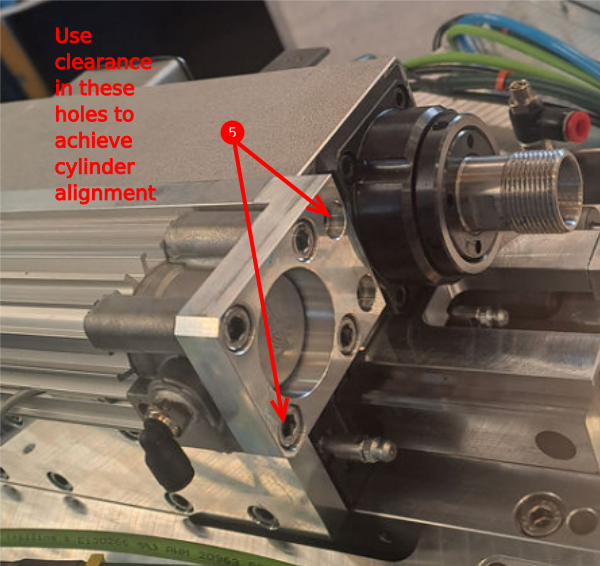

Étape 4 - Adjustable P Bracket only Align components and set position

Adjustable P Bracket only

1 Use cylinder stroke adjustment to align these two faces

2 Apply Loctite 243 to cylinder nut and tighten

3 Use clearance in holes for mounting at points indicated to achieve cylinder alignment. Cylinder stroke should be even and free along entire stroke

4 Finalise bolts

Repeat on all four single spindles (2,4,6 and 8)

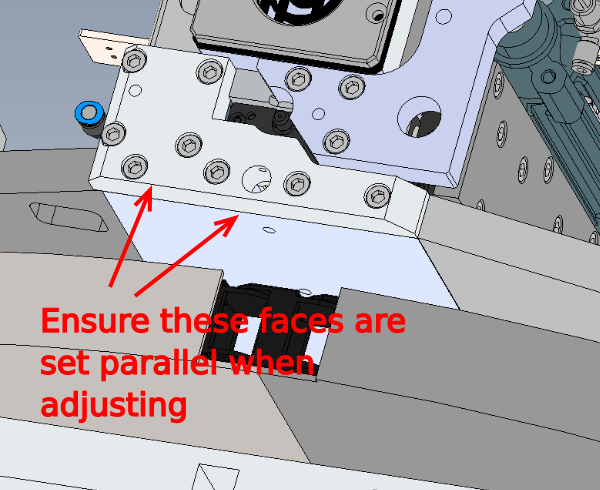

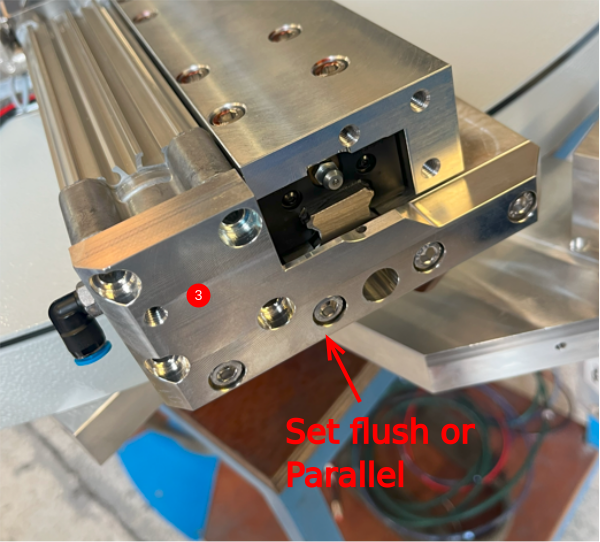

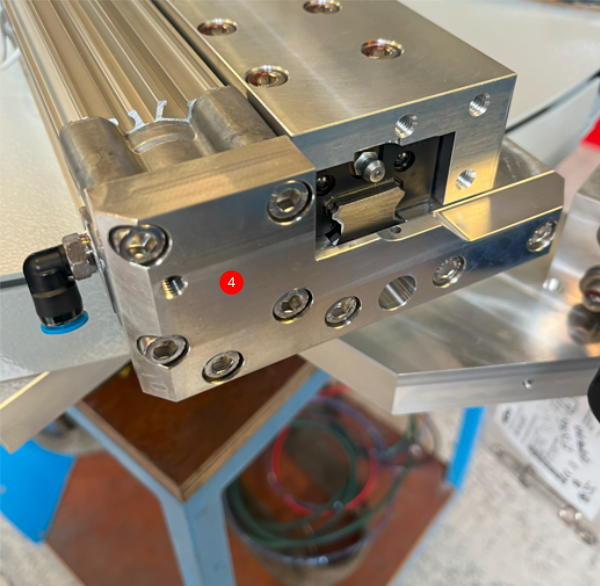

Étape 5 - Fixed P bracket only Mount single plunge spindle cylinder 2,4,6 and 8 Adjustable P bracket

1 Position pre assembled cylinder as shown on spindles 2,4,6 and 8

2 Set P bracket flush on faces indicated and secure with 2 off M5 x 25 socket caps and A form washers . Finalise fasteners

3 Fit D0007790 bracket using 4 off M6x20 socket caps. Set bottom of bracket and bottom of spindle plate flush or parallel . Finalise fasteners

4 Secure base of cylinder as shown using 4 off M6 x 25 socket caps. Finalise fasteners

5 Move assembly by hand to check for smooth running and correct operation

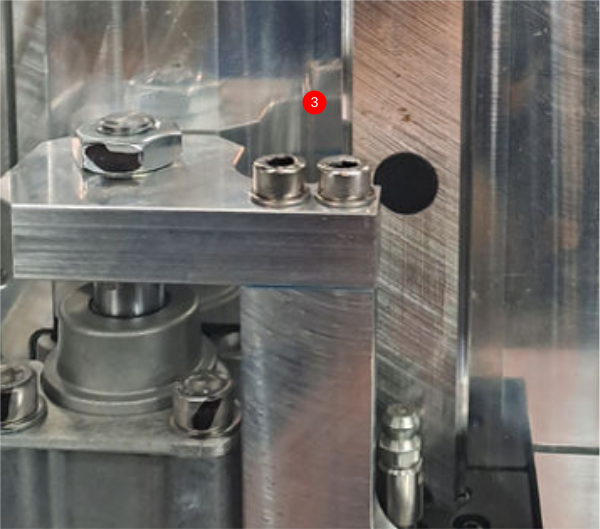

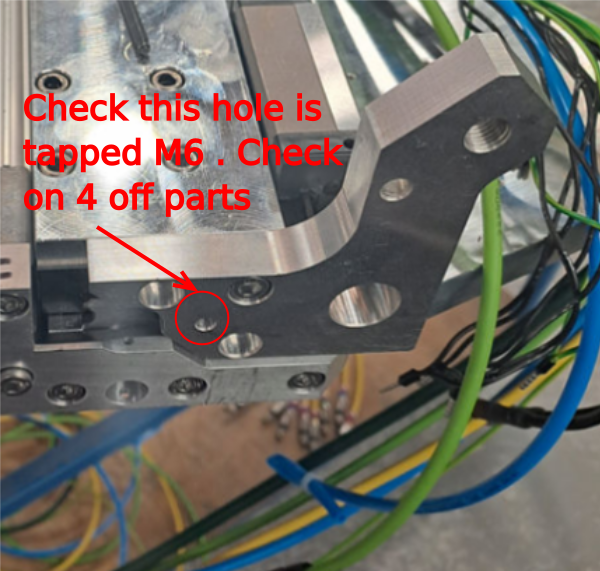

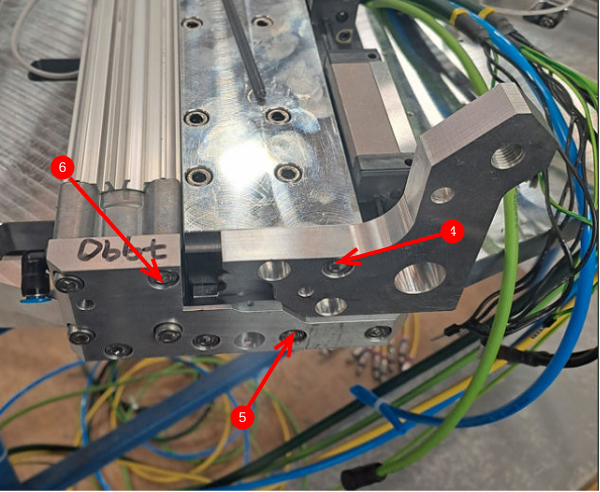

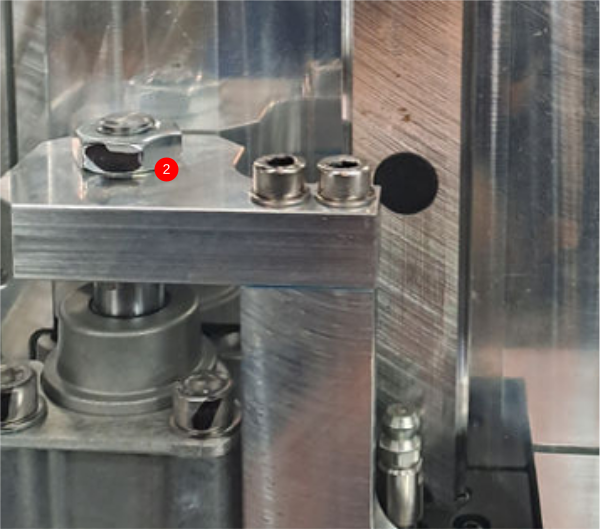

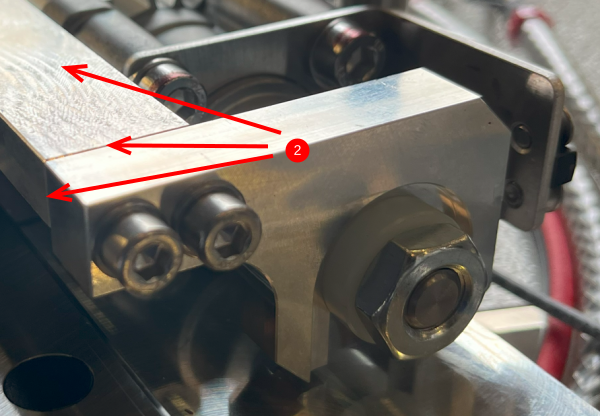

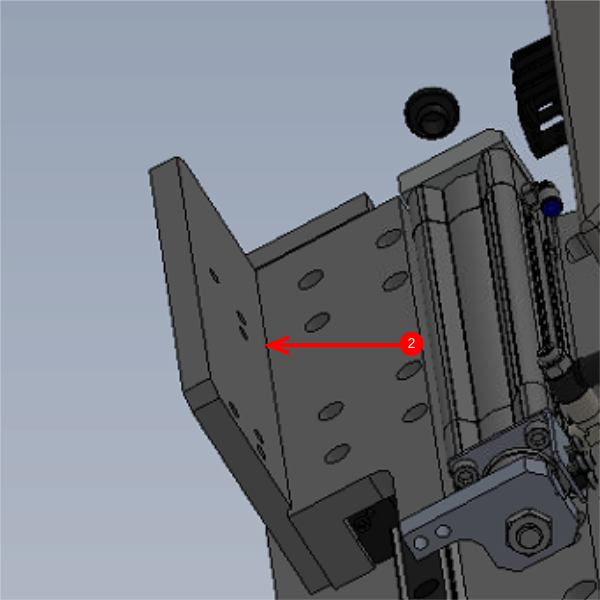

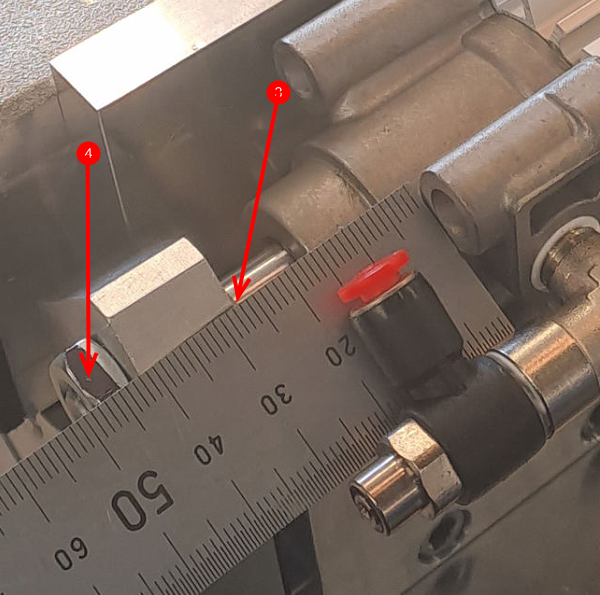

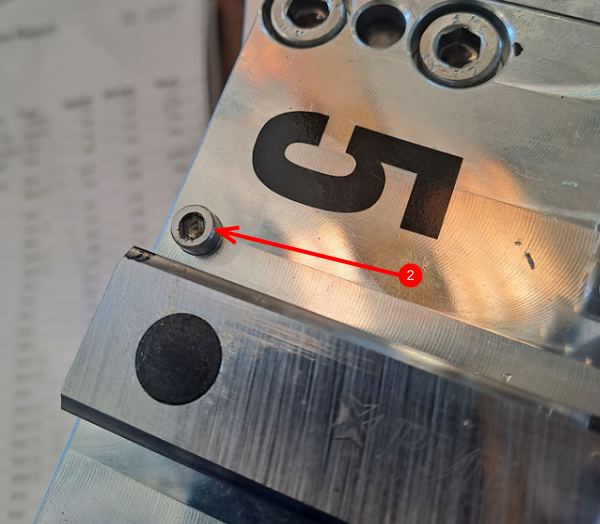

Étape 6 - Check D0007649

Check that component D0007649 has been manufactured correctly

Indicated hole should be tapped M6. Rework and report if not To M6 tapped spec

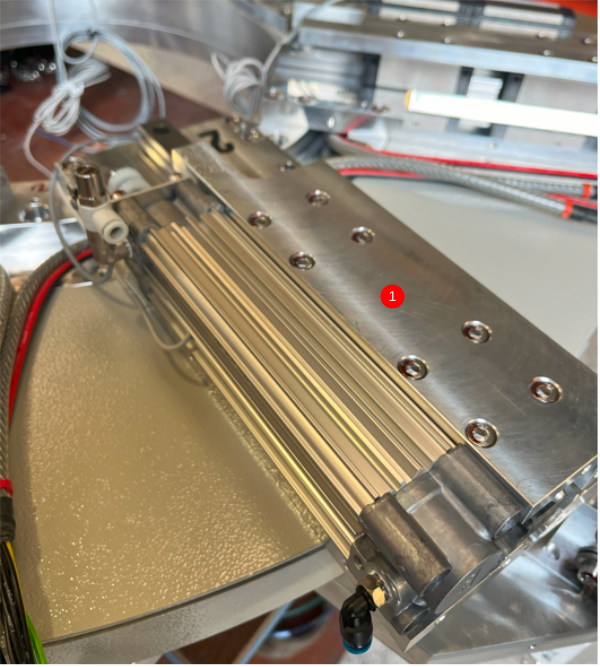

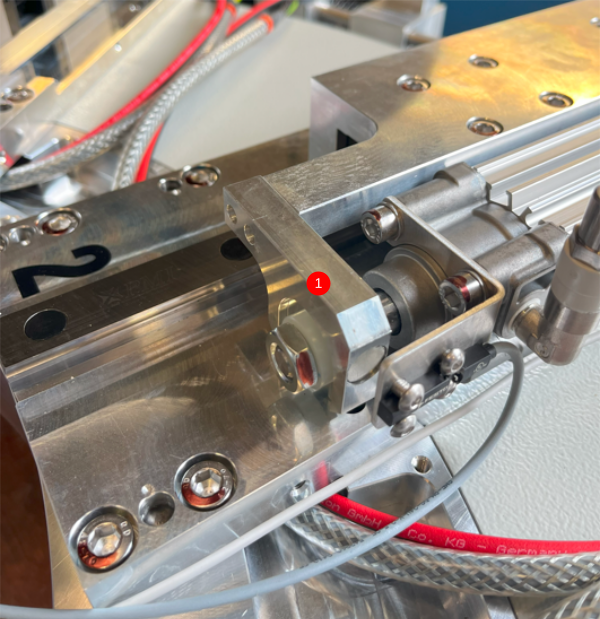

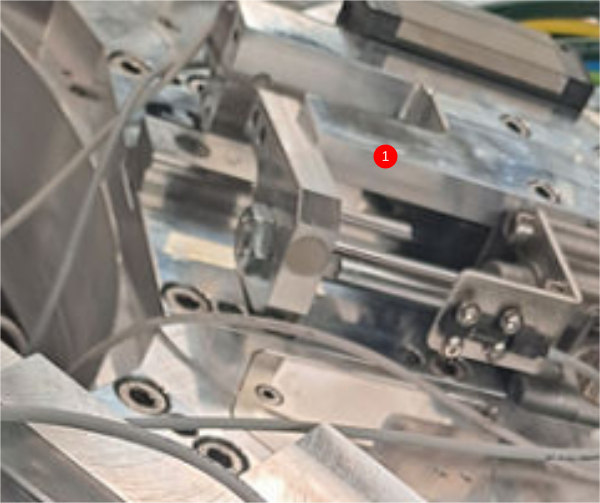

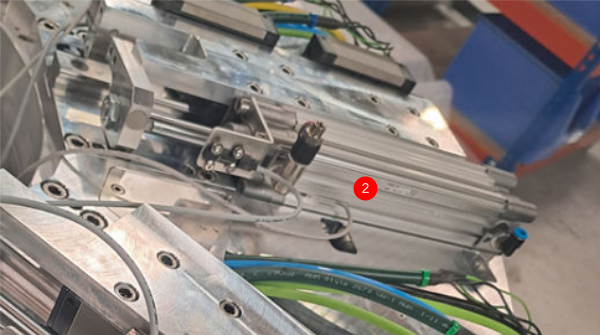

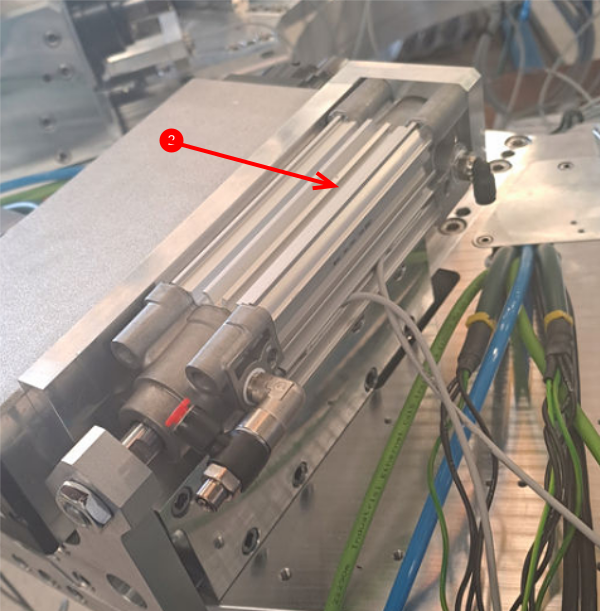

Étape 7 - Adjustable P Bracket only Mount double plunge spindle cylinder 1,3,5 and 7

Adjustable P Bracket only

Do not add final tension to bolts until alignment has been achieved

1 Attach pre built cylinder anchor to end of cylinder

2 Position pre built cylinder on slide base assembly as shown

3 Use 2 off m5 x 25 socket caps with A form washers to attach to slide base

4 Temporarily mount D0007649 with 1 off m6 x 20 socket cap

5 Attach D0007790 cylinder anchor with 4 off M6 x 20 socket caps

6 Attach Cylinder base to anchor with 4 off M6x 20 socket caps

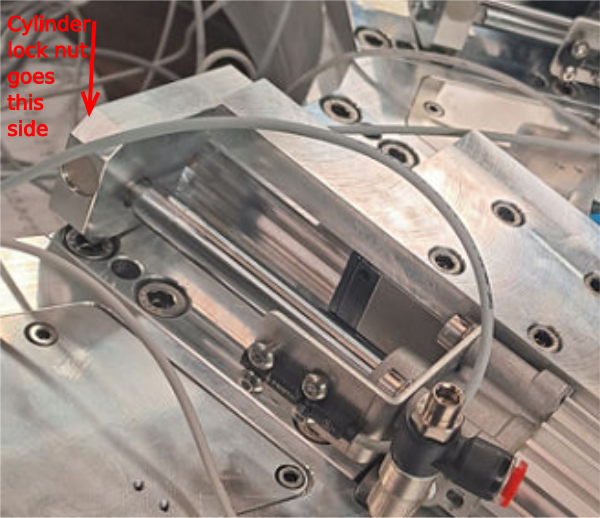

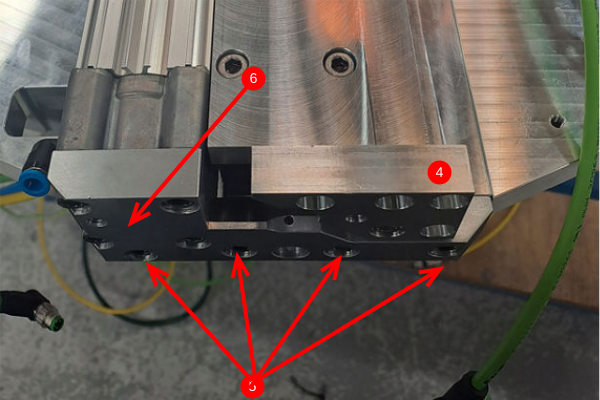

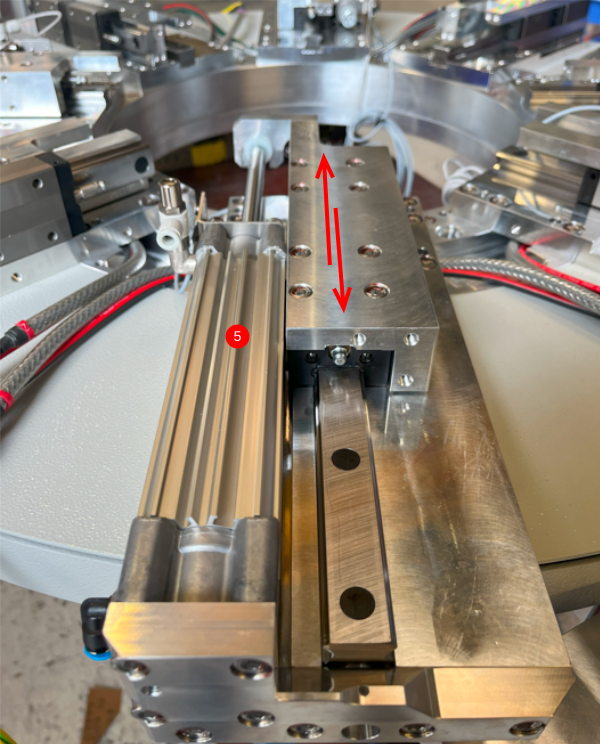

Étape 8 - Adjustable P Bracket only Align components and set position

Adjustable P Bracket only

1 Use cylinder stroke adjustment to align these two faces

2 Apply Loctite 243 to cylinder nut and tighten

3 Use clearance in holes for mounting at points indicated to achieve cylinder alignment. Cylinder stroke should be even and free along entire stroke

4 Finalise bolts

Repeat on all four single spindles (1,3,5 and 7))

Étape 9 - Fixed P Bracket only Mount double plunge spindle cylinder 1,3,5 and 7

Fixed P Bracket only

1 Position pre assembled cylinder as shown on spindles 2,4,6 and 8

2 Set P bracket flush on faces indicated and secure with 2 off M5 x 25 socket caps and A form washers . Finalise fasteners

3 Fit D0007790 bracket using 4 off M6x20 socket caps. Set bottom of bracket and bottom of spindle plate flush or parallel . Finalise fasteners

4 Secure base of cylinder as shown using 4 off M6 x 25 socket caps. Finalise fasteners

5 Move assembly by hand to check for smooth running and correct operation

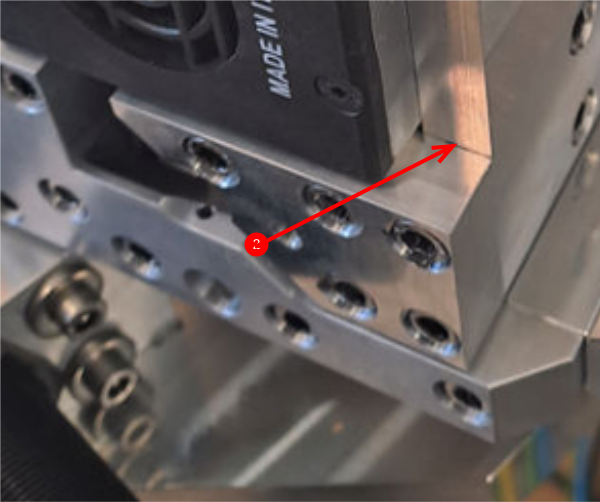

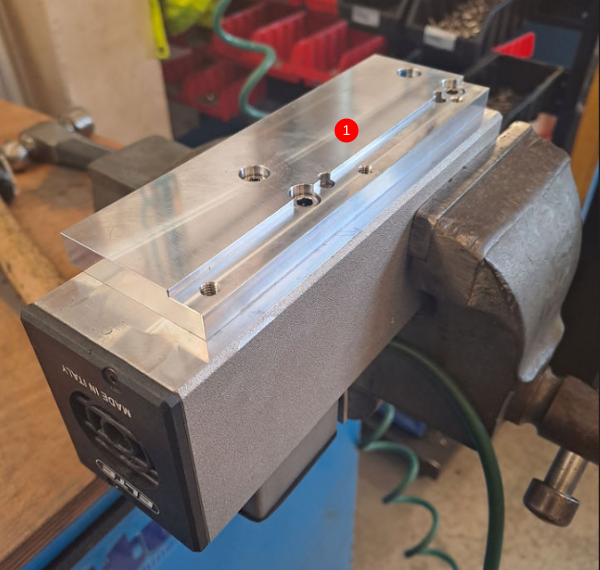

Étape 10 - Adjustable P Bracket only Attach single plunge motor plate

Adjustable P Bracket only

Spindles 2,4,6,8

1 Attach D0007686 motor plate to elte motor using 4 off m6 x 12 socket caps and 2 off 6mmx 20 dowels

2 Attach to single spindle using 4 off m6 x 16 socket caps

Ensure that motor plate butts up to indicated parts and also register is aligned as shown

3 use 5 off m6 x 20 socket caps used to finalise end plate . ensure mounting is even to motor plate

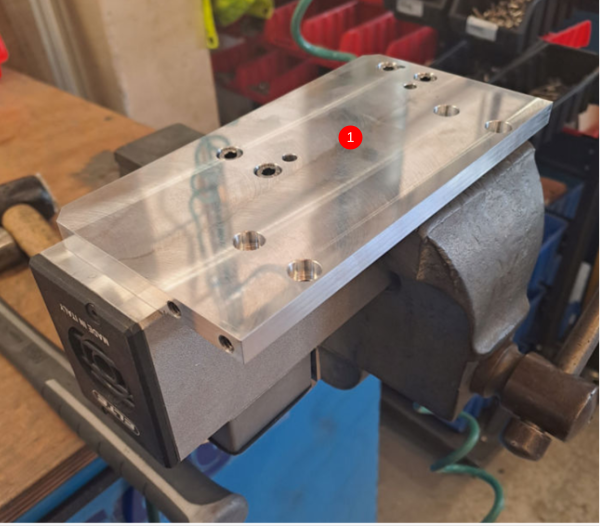

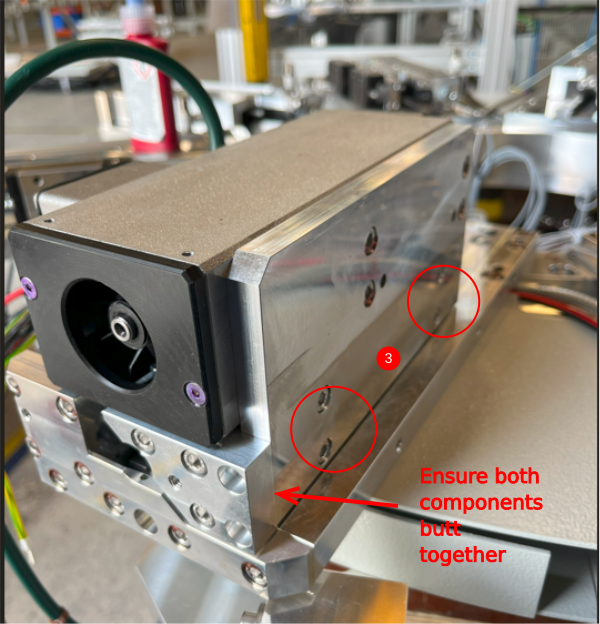

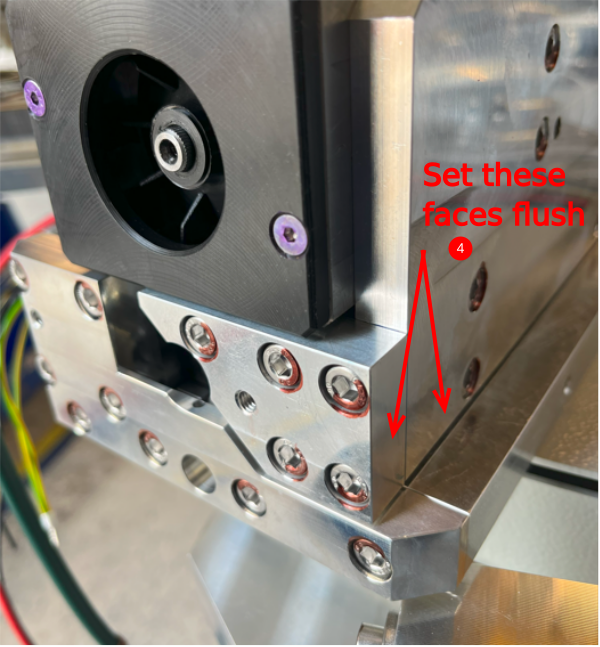

Étape 11 - Fixed P Bracket only Attach single plunge motor plate

4 off

Spindles 2,4,6,8

1 Attach D0007686 motor plate to elte motor using 4 off m6 x 12 socket caps and 2 off 6mmx 20 dowels

2 Fit D0007648 to each spindle using 3 off M6 x 20 socket caps , apply adhesive but only light tension

3 Attach motor to single spindle using 4 off m6 x 16 socket caps

Ensure that motor plate butts up to indicated parts and also register is aligned as shown

4 Finalise D0007648. Glue and fit additional 2 off M6 x 20 socket caps and set faces flush as shown. Finalise fasteners

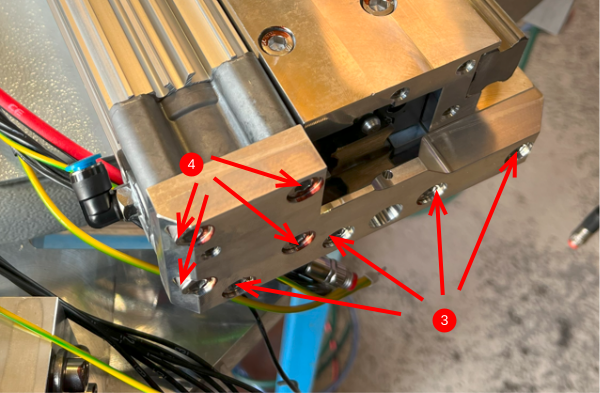

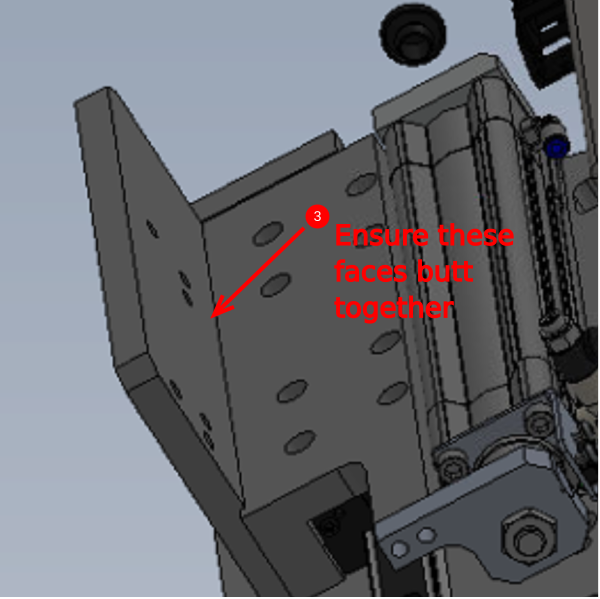

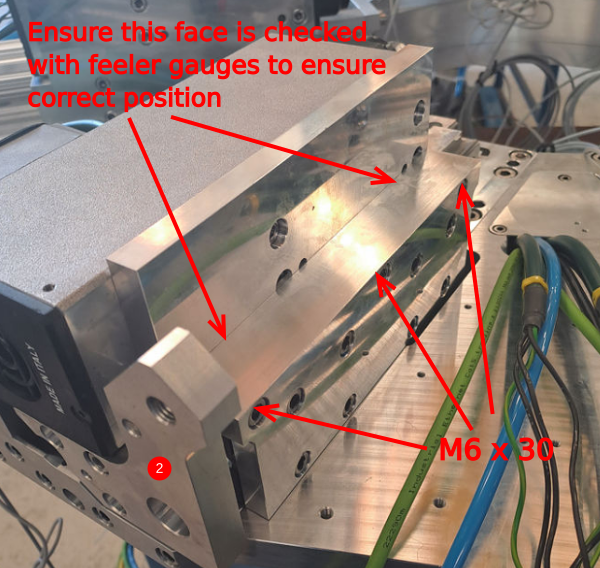

Étape 12 - Double plunge assembly motor mount

4 off

1 Lightly Fix D0007723 motor mount to bearings as shown . Use 8 off M6 x 12 socket caps to fix.

2 Use 0.05mm feeler gauge to check datum faces are in contact, if not remove and inspect parts

3 Finalise bolts

Étape 13 - Mounting double plunge motor

4 off

1 Mount D0007687 motor plate to elte motor with 4 off M6 x 12 socket caps and 2 off 6mm x 20 dowels

2 Use 3 off M6 x 30 socket caps and mount elte motor as shown

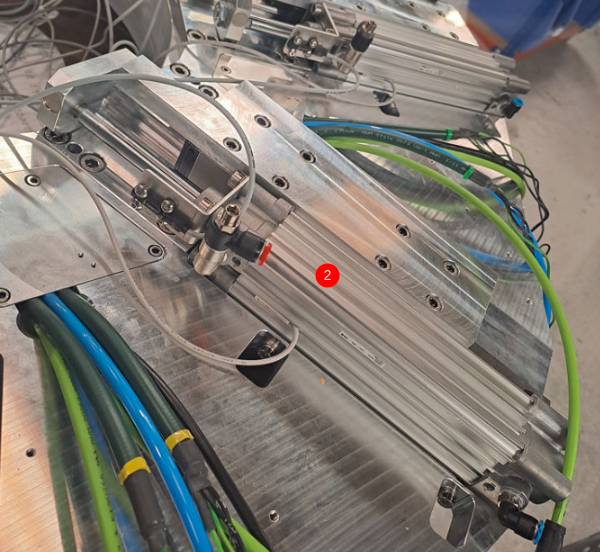

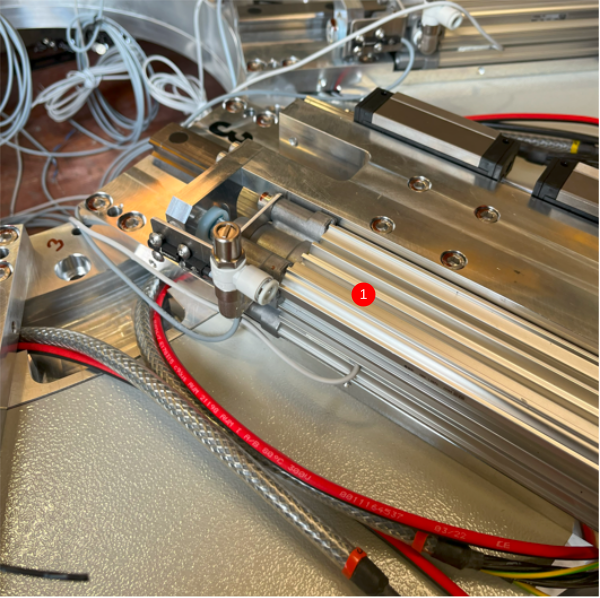

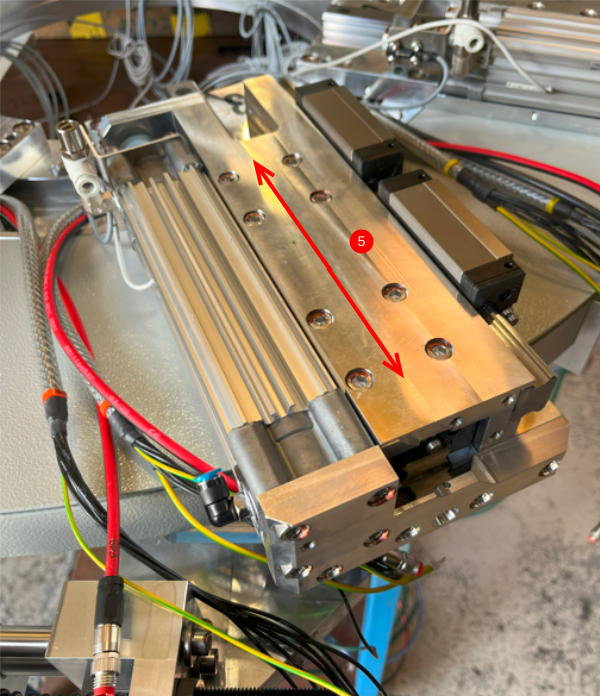

Étape 14 - Mount double plunge cylinder

4 off

1 Attach D0007600 cylinder mount using 2 off M5 x 20 socket caps

2 Attach lighty pre built cylinder assembly using 4 off M6 x 20 socket caps

3 Attach cylinder thread and adjust stroke of cylinder to achieve measurement of 28mm

4 Adhesive and lock off cylinder nut

5 Use clearance in indicated holes to achieve correct cylinder alignment . Stroke of cylinder should be free and consistent

6 Finalise all bolts

Étape 15 - Mount hard stops

1 Use M5 x 16 socket caps to mount 4 off D00015856 hard stops to double plunge assemblies

2 Use 8 off m4x 12 socket caps and fix to all slide bases as a hard stop

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português