How to ensure the optimiser wastes a set amount of profile from the end of every bar

Problem

On some profile types, the last 20mm of the bar is peeling / damaged.

Since the method of optimisation and waste management forces the offcut to be at the start of the bar, it now means the damaged end is now part of the last cut.

Need a method of ensuring there is a fixed amount of waste at the start and end of every bar.

Solution

Changing the standard length would not work, it would just waste more at the other end.

The problem is that leaving an offcut around 100mm in the gripper is EXACTLY what we want to try to avoid with an autoflow. It is the offcut that is very difficult to deal with and gets caught up and trashes the backfence/gripper

A solution is to use the gaps.mul file to always use the trim parameter at the start and end of the bar, then use the profile parameter to dictate the trim amount

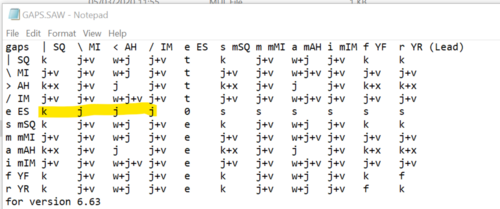

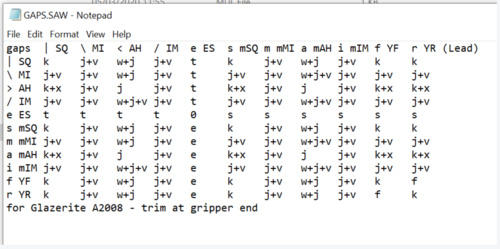

Step 1 - Change the gaps.saw file

to

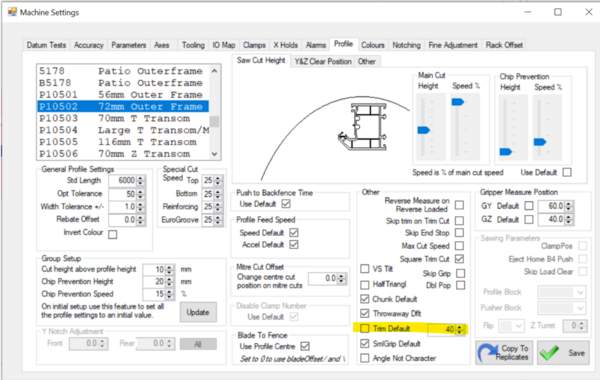

Step 2 - Change the profile parameter for affected profiles

Navigate to the profile that needs this change and untick the "Trim Default", and add in the amount to waste off each end of the bar

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português