How to activate the inbuilt algorithms in winMulti to optimise the spindle switching off and on when doing spot preps

Problem

Problem initially highlighted at Roseview windows

- 100% VS slider sashes and cills.

- Very small selection of operations

- Parts are consistently the same

- Large quantity of 3mm spots

- Mechanically jointed sash can have up to 12 individual holes on one piece and over 5000 individual spots per day

P,10430,ss,01,18,jn51839/017

O,00325,VSLATCHH,0000,0000,0000

O,01095,VSLATCHH,0000,0000,0000

O,01305,VSRP,0000,0000,0000

O,01330,VSLATCHH,0000,0000,0000

O,01580,VSLATCHH,0000,0000,0000

O,01605,VSRP,0000,0000,0000

O,08825,VSRP,0000,0000,0000

O,08850,VSLATCHH,0000,0000,0000

O,09100,VSLATCHH,0000,0000,0000

O,09125,VSRP,0000,0000,0000

O,09335,VSLATCHH,0000,0000,0000

O,10105,VSLATCHH,0000,0000,0000This is a sample 449 code for a single piece. Each operation is a simple spot prep

- Spot prep spindle is regularly cycling on / off as quickly as possible.

- Overall cycle time very dependent on the cycle time of the 3mm spot prep

- Spot prep cycle determined by how fast the inverter can acc / dec

- Inverter Limits pushed

- Inverter faults, which slows the machine down

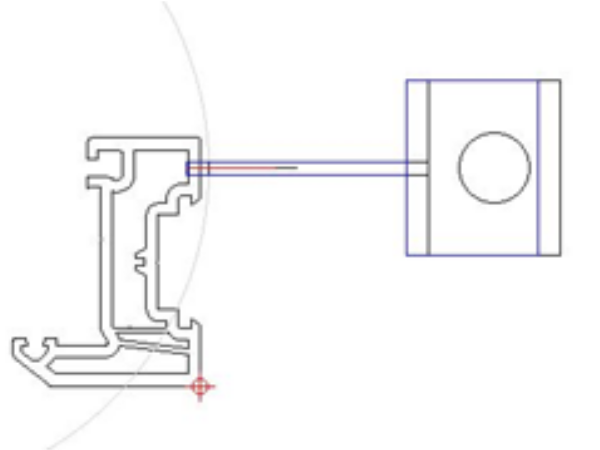

Here is a video of a spot prep before optimisation. Notice the spindle has to switch on, accelerate, plunge, reverse then switch off and decelerate

Solution

Software v5.14.9.0 onwards optimises the spindle operations that use

- The same tool

- At the same angle

The algorithm manipulates the bar recipe to skip spindle deceleration phase and then skip next spindle acceleration phase when it detects the similar operations next to each other. This means the spindle is left running inbetween operations, and only switched off when the angle or tool type is changed

Here is a video of a series of preps after optimisation

Benefits

- Vast improvement in cycle time

- Reduction in spindle off / on stresses which improves reliability – less spindle alarms

Downsides.

- Cannot work with “Speedy” preps.

- Speedy preps rely on the cylinder stroke to pierce profile,

- Tool stays in the profile

- Mk3 ring system has the plunge and relay outputs combined as one

- Plunge cannot be turned off without switching the motor off.

Preparation and Tuning

- Spot Prep must contain plunge commands

- Then tool is retracted clear of profile by Y / Z axes

- Best performance is gained by

- Making the plunge movement as short as possible (but take note of warning below)

- Plunging at traverse speed (use sp=TRAVERSE not sp=PIERCE)

- Increasing Y or Z acceleration to as high as possible

Dangers

Problems occurred at Roseview when moving from one spot prep to another

- Tool was still out and caught on a profile edge

- To ensure this does not happen, make all op starting points the same on Y or Z axis (Y for side preps, Z for top / bottom preps)

- This will mean you need to increase plunge distance for some preps.

Grouping

To maximise optimising, grouping has been added

- On bar download, operations sorted in order

- Now grouped together by tool code

- Machine will complete grouped operations together

- Then reverse for other ops

- Reduces ring rotation

- Maximises the off / on advantage

| Parameter | Description | Default Value | Notes |

|---|---|---|---|

| groupOpNeighbour | Maximum distance from one prep to same prep to group together | 0 | Set to Zero to disable grouping.

If preps are further apart than this, they will not be grouped |

| groupOpFootprint | Maximum footprint of grouped operations | 1000 | This is the distance from the first similar operation when grouping has to stop because it would mean the x axis has to reverse too far. Used as a safety net to prevent the entire bar length from being one big group |

| preemptiveMachining | Switches the system on and off | 0 | Set to 1 to switch on |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português