| [version en relecture] | [version en cours de rédaction] |

| Ligne 37 : | Ligne 37 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate>Check | + | |Step_Title=<translate>Check and set separation</translate> |

|Step_Content=<translate>Using a straight edge placed BETWEEN the teeth of the blade (W/I) you can see we have a gap around 2-3mm. On the opposite blade (W/O) we need to turn the setting bolt anti clockwise until the tips of the teeth just touch the straight edge, as seen in the second picture. If the tips of the teeth were overlapping we would need to increase separation by turning the adjusting bolt clockwise. | |Step_Content=<translate>Using a straight edge placed BETWEEN the teeth of the blade (W/I) you can see we have a gap around 2-3mm. On the opposite blade (W/O) we need to turn the setting bolt anti clockwise until the tips of the teeth just touch the straight edge, as seen in the second picture. If the tips of the teeth were overlapping we would need to increase separation by turning the adjusting bolt clockwise. | ||

Version du 25 septembre 2019 à 18:56

How to mechanically set the V notches on a ZX5.

Sommaire

- 1 Introduction

- 2 Étape 1 - Carry out first V notch test

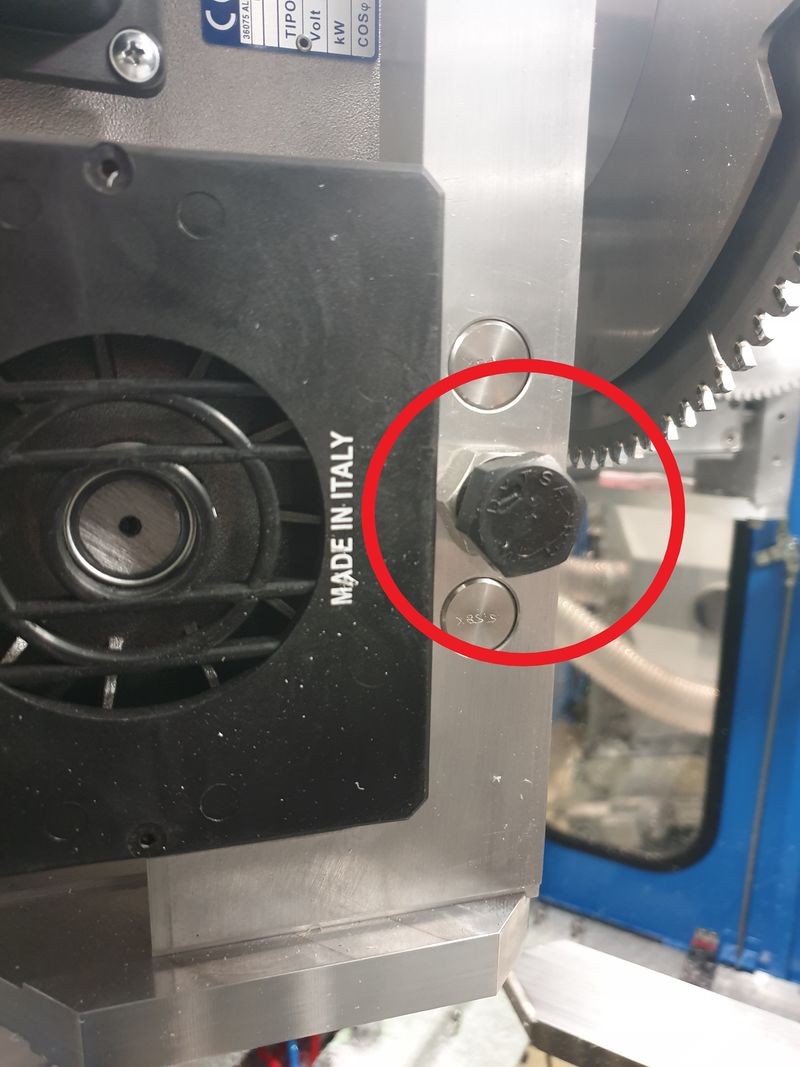

- 3 Étape 2 - Slacken off locking nut on rear of V notch assembly

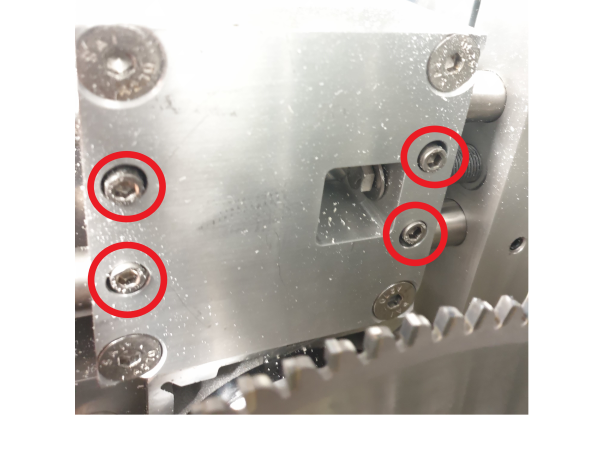

- 4 Étape 3 - Slacken off four bolts on adjusment mechanism.

- 5 Étape 4 - Check and set separation

- 6 Étape 5 - Carry out second test V notch.

- 7 Étape 6 - Another 1/4 to 1/2 turn removes the pip.

- 8 Commentaires

Introduction

On previous models the V notch separation was set via the software. This could be quite time consuming and required a set of tests and measurements to get it right.

On the new ZX5 the separation is set mechanically and once set it should never need changed again, but remember that some customers sharpen their V notch blades instead of replacing them. The following was carried out on the rear V notches using some standard outerframe but the process is exactly the same for the front. Once set you can use the usual software settings to increase/decrease depth and to align back to back.

Étape 1 - Carry out first V notch test

This step isn't really required, I personally like to do it just to see how far out we are to start with, and for the purpose of this tutorial it shows how quick it is to go from this to perfect.

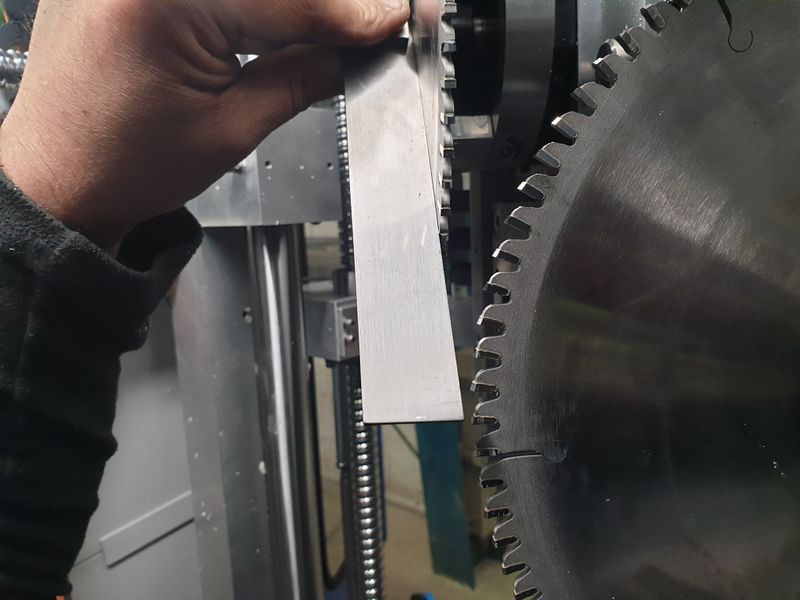

Étape 4 - Check and set separation

Using a straight edge placed BETWEEN the teeth of the blade (W/I) you can see we have a gap around 2-3mm. On the opposite blade (W/O) we need to turn the setting bolt anti clockwise until the tips of the teeth just touch the straight edge, as seen in the second picture. If the tips of the teeth were overlapping we would need to increase separation by turning the adjusting bolt clockwise.

Transfer the straight edge to the opposite blade (W/O) and adjust W/I as above.

Étape 5 - Carry out second test V notch.

This step can be skipped but was left in to show how close you get after following the above.

Lock off the four retaining bolts followed by the locking nut.

We should now be pretty close with only a small pip left in the centre of the notch.

Étape 6 - Another 1/4 to 1/2 turn removes the pip.

We can now repeat the process on the front V notches.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português