| [version en cours de rédaction] | [version en cours de rédaction] |

| (32 révisions intermédiaires par 2 utilisateurs non affichées) | |||

| Ligne 129 : | Ligne 129 : | ||

| | | | ||

|OuA_GripTurn | |OuA_GripTurn | ||

| − | | | + | OuA_Turn90 |

| + | |Sturtz Infeed Grip Turn Cylinder Up to 90 degrees | ||

|- | |- | ||

|22 | |22 | ||

| Ligne 345 : | Ligne 346 : | ||

|OuB_Oiler | |OuB_Oiler | ||

| | | | ||

| + | |- | ||

| + | |79 | ||

| + | | | ||

| + | |OuF_LowerEj | ||

| + | |Lower eject system on Autoflow Mk4 | ||

|- | |- | ||

|80 | |80 | ||

| | | | ||

|OuF_ClampIT | |OuF_ClampIT | ||

| − | | | + | OuF_ITHigh |

| + | |If the clamp on the saw infeed top is a roller clamp, use this output to activate a high pressure 3/2 valve | ||

|- | |- | ||

|81 | |81 | ||

| Ligne 384 : | Ligne 391 : | ||

| | | | ||

|OuF_EjectPush | |OuF_EjectPush | ||

| + | OuF_EjPushA | ||

| + | | | ||

| + | |||

| + | |||

| + | Soenen Eject Push to Conveyor A | ||

| + | |- | ||

| + | |88 | ||

| + | | | ||

| + | |OuF_EjOutfeed | ||

| + | |Autoflow Mk4 Eject Back to Back Cylinder Outfeed Side | ||

| + | |- | ||

| + | |89 | ||

| | | | ||

| + | |OuF_ClampPad | ||

| + | |Static Clamp Pad for Autoflow Mk4 | ||

|- | |- | ||

|90 | |90 | ||

| Ligne 390 : | Ligne 411 : | ||

|OuF_Conveyor | |OuF_Conveyor | ||

| | | | ||

| + | |||

|- | |- | ||

|91 | |91 | ||

| Ligne 453 : | Ligne 475 : | ||

|103 | |103 | ||

| | | | ||

| − | | | + | |OuF_SRBlw |

| − | | | + | |Blower for SR Axis |

|- | |- | ||

|104 | |104 | ||

| | | | ||

| − | | | + | |OuF_ConvYAFwd |

| − | | | + | |Soenen Conveyor Direction Y Position A (next to M/c) FORWARD |

|- | |- | ||

|105 | |105 | ||

| | | | ||

| − | | | + | |OuF_ConvYARev |

| − | | | + | |Soenen Conveyor Direction Y Position A (next to M/c) REVERSE |

|- | |- | ||

|106 | |106 | ||

| | | | ||

| − | | | + | |OuF_EjectInfeed |

| − | | | + | |Autoflow Mk4 Eject Back to Back Cylinder Infeed Side |

|- | |- | ||

|107 | |107 | ||

| Ligne 500 : | Ligne 522 : | ||

|OuA_WheRev | |OuA_WheRev | ||

| | | | ||

| + | |- | ||

| + | |113 | ||

| + | | | ||

| + | |OuA_ConvSlow | ||

| + | |Autoflow Mk4 Output for Infeed Conveyor Slow Speed | ||

| + | |- | ||

| + | |114 | ||

| + | | | ||

| + | |OuG_ConvSlow | ||

| + | |Autoflow Mk4 Output for Outfeed Conveyor Slow Speed | ||

|- | |- | ||

|121 | |121 | ||

| Ligne 610 : | Ligne 642 : | ||

|OuA_DDClamp | |OuA_DDClamp | ||

|Datum Drill Clamp On | |Datum Drill Clamp On | ||

| + | |- | ||

| + | |159 | ||

| + | | | ||

| + | |OuC_GripLock | ||

| + | |Gripper position lock Module C | ||

| + | |- | ||

| + | |160 | ||

| + | | | ||

| + | |OuE_GripLock | ||

| + | |Gripper position lock Module E | ||

|- | |- | ||

|200 | |200 | ||

| Ligne 730 : | Ligne 772 : | ||

|OuF_ZsupportO | |OuF_ZsupportO | ||

|Z Support Cylinder Outfeed Side on ZX5 only | |Z Support Cylinder Outfeed Side on ZX5 only | ||

| + | |- | ||

| + | |226 | ||

| + | | | ||

| + | |OuE_ChanLow | ||

| + | |Low pressure output for channel bar | ||

|- | |- | ||

|227 | |227 | ||

| Ligne 825 : | Ligne 872 : | ||

|OuA_NextBar | |OuA_NextBar | ||

| | | | ||

| + | |- | ||

| + | |251 | ||

| + | | | ||

| + | |OuA_VorBack | ||

| + | |Sturtz Infeed Forward Carriage Back (Vorlaufwagen) | ||

| + | |- | ||

| + | |252 | ||

| + | | | ||

| + | |OuA_VorFwd | ||

| + | |Sturtz Infeed Forward Carriage Fwd | ||

| + | |- | ||

| + | |253 | ||

| + | | | ||

| + | |OuA_VorUp | ||

| + | |Sturtz Infeed Forward Carriage Clamp Up | ||

| + | |- | ||

| + | |254 | ||

| + | | | ||

| + | |OuA_VorDn | ||

| + | |Sturtz Infeed Forward Carriage Clamp Down | ||

| + | |- | ||

| + | |255 | ||

| + | | | ||

| + | |OuA_GSGrip | ||

| + | |Sturtz Infeed Grip Profile Short Grip (Shorter of the two cylinders) | ||

| + | |- | ||

| + | |256 | ||

| + | | | ||

| + | |OuA_GSOff | ||

| + | |Sturtz Infeed Grip Profile Short Open | ||

| + | |- | ||

| + | |257 | ||

| + | | | ||

| + | |OuA_GLOff | ||

| + | |Sturtz Infeed Grip Profile Long Open (longer of the two cylinders) | ||

| + | Output Ref 001 is used for the longer one as this is equivalent to grip output) | ||

| + | |- | ||

| + | |258 | ||

| + | | | ||

| + | |OuA_TurnUp | ||

| + | OuA_Turn0 | ||

| + | |Sturtz Infeed Grip Turn Cylinder Down (0 degrees standard) | ||

| + | |- | ||

| + | |259 | ||

| + | | | ||

| + | |OuA_LiftUp | ||

| + | |Sturtz Infeed Roller Table Up | ||

| + | |- | ||

| + | |260 | ||

| + | | | ||

| + | |OuA_LiftUDn | ||

| + | |Sturtz Infeed Roller Table Down | ||

| + | |- | ||

| + | |261 | ||

| + | | | ||

| + | |OuA_StopUp | ||

| + | |Sturtz Infeed Paddle Stop Up | ||

| + | |- | ||

| + | |262 | ||

| + | | | ||

| + | |OuA_StopDn | ||

| + | |Sturtz Infeed Paddle Stop Down | ||

| + | |- | ||

| + | |263 | ||

| + | | | ||

| + | |OuA_GRTRotate | ||

| + | |Sturtz Infeed Guide Roller Turn Cylinder Rotate | ||

| + | |- | ||

| + | |264 | ||

| + | | | ||

| + | |OuA_GRTOpen | ||

| + | |Sturtz Infeed Guide Roller Turn Cylinder Initial | ||

| + | |- | ||

| + | |265 | ||

| + | | | ||

| + | |OuA_GRHClamped | ||

| + | |Sturtz Infeed Guide Roller Height Cylinder Clamp | ||

| + | |- | ||

| + | |266 | ||

| + | | | ||

| + | |OuA_GRHOpen | ||

| + | |Sturtz Infeed Guide Roller Height Cylinder Open | ||

|- | |- | ||

|267 | |267 | ||

| Ligne 849 : | Ligne 978 : | ||

| | | | ||

|OuB_InvDP | |OuB_InvDP | ||

| − | | | + | |Inverter Double Plunge output |

| + | |||

| + | Signals an inverter that double output power is needed. | ||

| + | {{Info|...This needs to be seperate from a simple plunge signal because the inverter needs the command and a changeover delay before the accelleration command}} | ||

| + | Also referred as 316 on TwinCAT2 machines | ||

|- | |- | ||

|272 | |272 | ||

| Ligne 885 : | Ligne 1 018 : | ||

|OuE_CrankRev | |OuE_CrankRev | ||

|Module E Crank Motor Rev - on reversing motor Z067+ | |Module E Crank Motor Rev - on reversing motor Z067+ | ||

| + | |- | ||

| + | |279 | ||

| + | | | ||

| + | |OuA_OpSiren | ||

| + | |Operator Siren | ||

| + | |- | ||

| + | |280 | ||

| + | |Y280 | ||

| + | |OuF_ConvXA | ||

| + | |Soenen Conveyor Direction X Position A (next to M/c) | ||

| + | |- | ||

| + | |281 | ||

| + | |Y281 | ||

| + | |OuF_ConvXB | ||

| + | |Soenen Conveyor Direction X Position B | ||

| + | |- | ||

| + | |282 | ||

| + | |Y282 | ||

| + | |OuF_ConvYBFwd | ||

| + | |Soenen Conveyor Direction Y Position B FORWARD | ||

| + | |- | ||

| + | |283 | ||

| + | |Y283 | ||

| + | |OuF_ConvYBRev | ||

| + | |Soenen Conveyor Direction Y Position B REVERSE | ||

| + | |- | ||

| + | |284 | ||

| + | |Y284 | ||

| + | |OuB_VibPlate | ||

| + | |Autoflow Mk4 Vibration Plate | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |290 | ||

| + | |Y290 | ||

| + | |OuF_CLHClose | ||

| + | |Sturtz Outfeed Horizontal Clamp Close | ||

| + | |- | ||

| + | |291 | ||

| + | |Y291 | ||

| + | |OuF_CLHOpen | ||

| + | |Sturtz Outfeed Horizontal Clamp Open | ||

| + | |- | ||

| + | |292 | ||

| + | |Y292 | ||

| + | |OuF_LiftUp | ||

| + | |Sturtz Outfeed Lift Station Up | ||

| + | |- | ||

| + | |293 | ||

| + | |Y293 | ||

| + | |OuF_LiftDn | ||

| + | |Sturtz Outfeed Lift Station Down | ||

| + | |- | ||

| + | |294 | ||

| + | |Y294 | ||

| + | |OuF_OBarBlw | ||

| + | |Sturtz Outfeed Bar Blower | ||

| + | |- | ||

| + | |295 | ||

| + | |Y295 | ||

| + | |OuF_ConvFwd | ||

| + | |Sturtz Outfeed Conveyor Forward | ||

| + | |- | ||

| + | |296 | ||

| + | |Y296 | ||

| + | |OuF_ConvRev | ||

| + | |Sturtz Outfeed Conveyor Reverse | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |310 | ||

| + | |Y310 | ||

| + | |OuF_AABlw | ||

| + | |Label Area Blower | ||

| + | |- | ||

| + | |311 | ||

| + | |Y311 | ||

| + | |OuF_AAVac | ||

| + | |Vacuum Pump Valve (Label Applicator) | ||

| + | |- | ||

| + | |312 | ||

| + | |Y312 | ||

| + | |OuF_AATilt | ||

| + | |Applicator Tilt (Label Applicator) | ||

| + | |- | ||

| + | |313 | ||

| + | |Y313 | ||

| + | |OuF_AAPlace | ||

| + | |Applicator Place Up/Down (Label Applicator) | ||

| + | |- | ||

| + | |314 | ||

| + | |Y314 | ||

| + | |OuF_AAPick | ||

| + | |Applicator Pick (Yaxis) (Label Applicator) | ||

| + | |- | ||

| + | |315 | ||

| + | |Y315 | ||

| + | |OuF_AAPulse | ||

| + | |Label Applicator Profile Position Turret Pulse | ||

| + | |- | ||

| + | |316 | ||

| + | |Y316 | ||

| + | |Inv_DP | ||

| + | |Inverter Double plunge output used on TC2 machines | ||

| + | |||

| + | The standard should be Y271, but this refernce has crept in on TwinCAT2 machines only | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

|- | |- | ||

|319 | |319 | ||

| Ligne 897 : | Ligne 1 182 : | ||

|- | |- | ||

|321 | |321 | ||

| − | | | + | |Y321 |

|Ou_EJPSH2 | |Ou_EJPSH2 | ||

| − | |Ecoline outfeed push 2 | + | OuF_EjPushB |

| + | |Ecoline / Microline outfeed push 2 | ||

| + | Soenen Eject Push to Conveyor B | ||

|- | |- | ||

|322 | |322 | ||

| Ligne 949 : | Ligne 1 236 : | ||

| | | | ||

|Ou_BlwInfeed | |Ou_BlwInfeed | ||

| − | |Ecoline Infeed Blower | + | |Ecoline & Sturtz Infeed Blower |

| + | |- | ||

| + | |332 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |333 | ||

| + | | | ||

| + | |OuA_PopUp1Off | ||

| + | |Sturtz Infeed Push To Backfence 1 Open | ||

| + | |- | ||

| + | |334 | ||

| + | | | ||

| + | |OuA_PopUp2Off | ||

| + | |Sturtz Infeed Push To Backfence 2 Open | ||

| + | |- | ||

| + | |335 | ||

| + | | | ||

| + | |OuA_PopUp3Off | ||

| + | |Sturtz Infeed Push To Backfence 3 Open | ||

| + | |- | ||

| + | |336 | ||

| + | | | ||

| + | |OuA_PopUp4Off | ||

| + | |Sturtz Infeed Push To Backfence 4 Open | ||

| + | |- | ||

| + | |337 | ||

| + | | | ||

| + | |OuA_PopUp5Off | ||

| + | |Sturtz Infeed Push To Backfence 5 Open | ||

| + | |- | ||

| + | |338 | ||

| + | | | ||

| + | |OuA_PopUp6Off | ||

| + | |Sturtz Infeed Push To Backfence 6 Open | ||

| + | |- | ||

| + | |339 | ||

| + | | | ||

| + | |OuA_PopUp7Off | ||

| + | |Sturtz Infeed Push To Backfence 7 Open | ||

| + | |- | ||

| + | |340 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |341 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |342 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |343 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |344 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |345 | ||

| + | | | ||

| + | | | ||

| + | | | ||

|- | |- | ||

|350 | |350 | ||

| Ligne 1 065 : | Ligne 1 422 : | ||

Y27 | Y27 | ||

| + | |||

| + | Y373 | ||

|Ou_OBLOW | |Ou_OBLOW | ||

| | | | ||

| + | |||

| + | |||

| + | |||

| + | Sturtz Outfeed Sensor Blower | ||

|- | |- | ||

|374 | |374 | ||

| Ligne 1 100 : | Ligne 1 463 : | ||

|380 | |380 | ||

| | | | ||

| − | | | + | | |

| − | | | + | | |

|- | |- | ||

|381 | |381 | ||

| − | | | + | |Y381 |

| − | | | + | |OuF_ConvBrake |

| − | |Infeed Conveyor Motor | + | |Outfeed Conveyor Motor Brake |

| + | |- | ||

| + | |382 | ||

| + | |Y382 | ||

| + | |OuA_ConvBrake | ||

| + | |Infeed Conveyor Motor Brake | ||

|- | |- | ||

|383 | |383 | ||

| Ligne 1 265 : | Ligne 1 633 : | ||

|Microline | |Microline | ||

|- | |- | ||

| − | |408 | + | |<s>408</s> |

| | | | ||

| − | |Ou_CLSOV | + | |<s>Ou_CLSOV</s> |

|Microline see 418 | |Microline see 418 | ||

|- | |- | ||

| Ligne 1 309 : | Ligne 1 677 : | ||

|Ou_InvDP | |Ou_InvDP | ||

|Inverter Double Plunge Current Boost | |Inverter Double Plunge Current Boost | ||

| + | also 271 | ||

|- | |- | ||

|418 | |418 | ||

| Ligne 1 320 : | Ligne 1 689 : | ||

|Ou_GripPulse | |Ou_GripPulse | ||

|Pulse Output for grip height Somatec unit | |Pulse Output for grip height Somatec unit | ||

| + | |- | ||

| + | |425 | ||

| + | |Reserved | ||

| + | |SPBL1 | ||

| + | | rowspan="8" |Spindle blow outputs reserved due to SPPLn+28 in Spindle On code. See [https://stugaltd.monday.com/boards/297744537/pulses/1091531895 Monday] item | ||

| + | |||

| + | |- | ||

| + | |426 | ||

| + | |Reserved | ||

| + | |SPBL2 | ||

| + | |- | ||

| + | |427 | ||

| + | |Reserved | ||

| + | |SPBL3 | ||

| + | |- | ||

| + | |428 | ||

| + | |Reserved | ||

| + | |SPBL4 | ||

| + | |- | ||

| + | |429 | ||

| + | |Reserved | ||

| + | |SPBL5 | ||

| + | |- | ||

| + | |430 | ||

| + | |Reserved | ||

| + | |SPBL6 | ||

| + | |- | ||

| + | |431 | ||

| + | |Reserved | ||

| + | |SPBL7 | ||

| + | |- | ||

| + | |432 | ||

| + | |Reserved | ||

| + | |SPBL8 | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |440 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

|}</translate> | |}</translate> | ||

{{PageLang | {{PageLang | ||

Version actuelle datée du 6 mars 2024 à 16:54

List of output references used on Stuga Machines

Sommaire

For input references see here

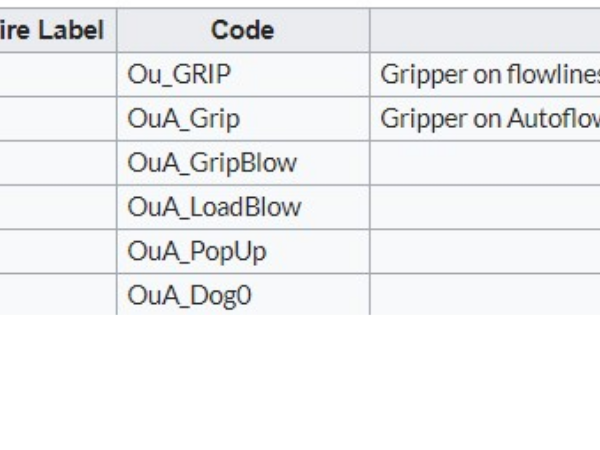

- All Stuga machines share similar outputs to do similar functions (eg the gripper on output is the same on any machine). To keep this modular approach, each function is given a specific reference number from 1 to 500. This reference or IORef is the same on any machine.

- This number is used as the wire labelling number on newer machines (all Autoflows and ZX5s)

- To maintain backwards compatibility with older machines (Saws, Flowlines, Ecolines, etc, there is also a cross-reference to the original cable numbering.

- More information on a particular input can be found by clicking on the code, if external ink is set (blue text)

| IORef | Legacy Wire Label | Code | Description |

|---|---|---|---|

| 1 | Y25

OY2 |

Ou_GRIP

GRIP |

Gripper on flowlines |

| Y001 | OuA_Grip | Gripper on Autoflow | |

| 3 | OuA_GripBlow | ||

| 4 | OuA_LoadBlow | ||

| 5 | OuA_PopUp | ||

| 6 | OuA_Dog0 | ||

| 7 | OuA_Dog1 | ||

| 8 | OuA_Dog2 | ||

| 9 | OuA_Dog3 | ||

| 10 | OuA_Dog4 | ||

| 11 | OuA_Dog5 | ||

| 12 | OuA_PopV9 | ||

| 13 | OuA_PopUpPush | ||

| OuA_PopH1 | |||

| 14 | OuA_PopUp2 | ||

| 15 | OuA_PopUp3 | ||

| 16 | OuA_PopUp4 | ||

| 17 | OuA_PopUp5 | ||

| 18 | OuA_PopUp6 | ||

| 19 | OuA_PopUp7 | ||

| 20 | OuA_PopUp8 | ||

| 21 | OuA_GripTurn

OuA_Turn90 |

Sturtz Infeed Grip Turn Cylinder Up to 90 degrees | |

| 22 | OuA_StopX | ||

| 23 | OuA_InfeedAdv | ||

| 24 | OuA_BrakesOff | ||

| 25 | OuA_CillSupport | ||

| 26 | OuA_EDSpindleOn | ||

| 27 | OuA_EDClamp | ||

| 28 | OuA_EDPlunge | ||

| 29 | OuA_EDGuardOpen | ||

| 30 | OuB_ClampIT | ||

| 31 | OuB_ClampITPos | ||

| 32 | OuB_ClampIS | ||

| 33 | OuB_ClampISPos | ||

| 34 | OuB_ClampOT | ||

| 35 | OuB_ClampOTPos | ||

| 36 | OuB_ClampOS | ||

| 37 | OuB_ClampOSPos | ||

| 38 | OuB_Spin1Pl | ||

| 39 | OuB_Spin2Pl | ||

| 40 | OuB_Spin3Pl | ||

| 41 | OuB_Spin4Pl | ||

| 42 | OuB_Spin5Pl | ||

| 43 | OuB_Spin6Pl | ||

| 44 | OuB_Spin7Pl | ||

| 45 | OuB_Spin8Pl | ||

| 46 | OuB_Spin1On | ||

| 47 | OuB_Spin2On | ||

| 48 | OuB_Spin3On | ||

| 49 | OuB_Spin4On | ||

| 50 | OuB_Spin5On | ||

| 51 | OuB_Spin6On | ||

| 52 | OuB_Spin7On | ||

| 53 | OuB_Spin8On | ||

| 54 | OuB_Spin1DP | ||

| 55 | OuB_Spin2DP | ||

| 56 | OuB_Spin3DP | ||

| 57 | OuB_Spin4DP | ||

| 58 | OuB_Spin5DP | ||

| 59 | OuB_Spin6DP | ||

| 60 | OuB_Spin7DP | ||

| 61 | OuB_Spin8DP | ||

| 62 | OuB_SpinFwd | ||

| 63 | OuB_Spin300 | ||

| 64 | OuB_Oiler | ||

| 79 | OuF_LowerEj | Lower eject system on Autoflow Mk4 | |

| 80 | OuF_ClampIT

OuF_ITHigh |

If the clamp on the saw infeed top is a roller clamp, use this output to activate a high pressure 3/2 valve | |

| 81 | OuF_ClampITPos | ||

| 82 | OuF_ClampOT | ||

| 83 | OuF_ClampOTPos | ||

| 84 | OuF_ClampIS | ||

| 85 | OuF_ClampOS | ||

| 86 | OuF_ClampITRoll | ||

| 87 | OuF_EjectPush

OuF_EjPushA |

| |

| 88 | OuF_EjOutfeed | Autoflow Mk4 Eject Back to Back Cylinder Outfeed Side | |

| 89 | OuF_ClampPad | Static Clamp Pad for Autoflow Mk4 | |

| 90 | OuF_Conveyor | ||

| 91 | OuF_Eject | ||

| 92 | OuF_TiltSaw | ||

| 93 | OuF_OffcutBlow | ||

| 94 | OuF_Siren | ||

| 95 | OuF_Gate | ||

| 96 | OuF_TiltPos | ||

| 97 | OuF_SawOn | ||

| 98 | OuF_ExtractOn | ||

| 99 | OuF_ChuteBlow | ||

| 100 | OuA_Dog6 | ||

| 101 | OuA_Dog7 | ||

| 102 | OuA_Dog8 | ||

| 103 | OuF_SRBlw | Blower for SR Axis | |

| 104 | OuF_ConvYAFwd | Soenen Conveyor Direction Y Position A (next to M/c) FORWARD | |

| 105 | OuF_ConvYARev | Soenen Conveyor Direction Y Position A (next to M/c) REVERSE | |

| 106 | OuF_EjectInfeed | Autoflow Mk4 Eject Back to Back Cylinder Infeed Side | |

| 107 | OuA_Crank | Module A Crank | |

| 108 | OuA_DDrlMot | Datum Drill Motor | |

| 109 | OuA_ConvFwd | ||

| 110 | OuA_ConvRev | ||

| 111 | OuA_WheFwd | ||

| 112 | OuA_WheRev | ||

| 113 | OuA_ConvSlow | Autoflow Mk4 Output for Infeed Conveyor Slow Speed | |

| 114 | OuG_ConvSlow | Autoflow Mk4 Output for Outfeed Conveyor Slow Speed | |

| 121 | OuC_GripH | Module C Grip Height Home | |

| 122 | OuC_BlwRack | Module C Rack Blower | |

| 123 | OuC_BlwGrip | Module C Grip Blower | |

| 124 | OuC_Roller | Module C Roller Lift | |

| 125 | OuC_Chan1 | Module C Channel | |

| 126 | OuC_BeamPosH | GX Axis Beam Position Home | |

| 127 | OuC_BeamPosO | GX Axis Beam Position Out | |

| 128 | OuC_CrankFwd | Module C Crank | |

| 131 | OuE_GripH | Module E Grip Height | |

| 132 | OuE_Grip | Module E Grip | |

| 133 | OuE_BlwRail | Module E Blower for Loader linear rails | |

| 145 | OuE_BlwGrip | Module E Grip Blower | |

| 146 | OuE_Roller | Module E Roller Lift | |

| 150 | OuE_Backfence | Module E Backfence Roller Lift - Not used | |

| 151 | OuE_Crank | Module E Crank | |

| 152 | OuA_Chan1 | Module A Channel 1 | |

| 153 | OuA_Chan2 | Module A Channel 2 (Datum Drill) | |

| 154 | OuA_WheelH | Module A Wheel Height | |

| 155 | OuA_ChanLock | Module A Channel Lock | |

| 156 | OuA_DDrillPl | Datum Drill Plunge | |

| 157 | OuA_Roller | Module A Roller | |

| 158 | OuA_DDClamp | Datum Drill Clamp On | |

| 159 | OuC_GripLock | Gripper position lock Module C | |

| 160 | OuE_GripLock | Gripper position lock Module E | |

| 200 | OuF_GuardOpen | ||

| 201 | OuB_GuardOpen | ||

| 202 | OuF_ClampS | ||

| 203 | OuA_LoadClear | ||

| 204 | OuF_ClampPos | ||

| 206 | OuF_ClampCen | ||

| 207 | OuF_SawCut | ||

| 208 | OuF_Saw90 | ||

| 209 | OuF_Saw135 | ||

| 210 | OuF_ZsupportI | Z Support Cylinder (on ZX5 this is the infeed side) | |

| 211 | OuF_ClampSPos | ||

| 212 | OuF_ClampITHi | ||

| 213 | OuF_SawBlow | ||

| 214 | OuF_ZITurret | Z Turret Turn Infeed | |

| 215 | OuF_ZOTurret | Z Turret Turn Outfeed | |

| 216 | OuB_Red | MH Red Lamp | |

| 217 | OuB_Amber | MH Amber Lamp | |

| 218 | OuB_Green | MH Green Lamp | |

| 219 | OuF_RedSaw | Saw Red Lamp | |

| 220 | OuE_ChannelLock | ||

| 221 | OuE_ChannelPush | ||

| 222 | OuE_FlipZ | ||

| 223 | OuF_GreenSaw | Saw Green Lamp | |

| 224 | OuF_ZsupportO | Z Support Cylinder Outfeed Side on ZX5 only | |

| 226 | OuE_ChanLow | Low pressure output for channel bar | |

| 227 | OuE_SRSTSaw | Added by BB for Flowline with RS Auto/Beckhoff control | |

| 228 | OuE_TrMotor | ||

| 229 | OuE_TrDog1 | ||

| 230 | OuE_TrDog2 | ||

| 231 | OuE_TrDog3 | ||

| 232 | OuE_TrDog4 | ||

| 233 | OuE_TrDog5 | ||

| 234 | OuE_TrDog6 | ||

| 235 | OuE_TranUpDown | ||

| 236 | OuE_TranAcross | ||

| 237 | OuF_OffsetAH | ||

| 238 | OuE_BlwLens | ||

| 239 | OuE_BlwMLoad | Material load blower on Module E on ZX5 | |

| 240 | OuE_BlwHole | ||

| 241 | OuE_BlwRack | ||

| 242 | OuE_PushLift | ||

| 243 | OuB_BlwUR | ||

| 244 | OuC_BlwMLoad | Material Load Blower | |

| 250 | OuA_NextBar | ||

| 251 | OuA_VorBack | Sturtz Infeed Forward Carriage Back (Vorlaufwagen) | |

| 252 | OuA_VorFwd | Sturtz Infeed Forward Carriage Fwd | |

| 253 | OuA_VorUp | Sturtz Infeed Forward Carriage Clamp Up | |

| 254 | OuA_VorDn | Sturtz Infeed Forward Carriage Clamp Down | |

| 255 | OuA_GSGrip | Sturtz Infeed Grip Profile Short Grip (Shorter of the two cylinders) | |

| 256 | OuA_GSOff | Sturtz Infeed Grip Profile Short Open | |

| 257 | OuA_GLOff | Sturtz Infeed Grip Profile Long Open (longer of the two cylinders)

Output Ref 001 is used for the longer one as this is equivalent to grip output) | |

| 258 | OuA_TurnUp

OuA_Turn0 |

Sturtz Infeed Grip Turn Cylinder Down (0 degrees standard) | |

| 259 | OuA_LiftUp | Sturtz Infeed Roller Table Up | |

| 260 | OuA_LiftUDn | Sturtz Infeed Roller Table Down | |

| 261 | OuA_StopUp | Sturtz Infeed Paddle Stop Up | |

| 262 | OuA_StopDn | Sturtz Infeed Paddle Stop Down | |

| 263 | OuA_GRTRotate | Sturtz Infeed Guide Roller Turn Cylinder Rotate | |

| 264 | OuA_GRTOpen | Sturtz Infeed Guide Roller Turn Cylinder Initial | |

| 265 | OuA_GRHClamped | Sturtz Infeed Guide Roller Height Cylinder Clamp | |

| 266 | OuA_GRHOpen | Sturtz Infeed Guide Roller Height Cylinder Open | |

| 267 | OuA_InfeedLift | Profile lift clear of infeed belts | |

| 268 | OuA_SillLift | On Ancil saw, popup cylider to support profile | |

| 269 | OuB_BlwRing | ||

| 270 | OuB_CLIHold | ||

| 271 | OuB_InvDP | Inverter Double Plunge output

Signals an inverter that double output power is needed. Also referred as 316 on TwinCAT2 machines | |

| 272 | OuC_BlwRail | ||

| 273 | OuC_CrankFwd | Module C Crank Motor Fwd - on reversing motor. Z067+ | |

| 274 | OuC_CrankRev | Module C Crank Motor Rev - on reversing motor Z067+ | |

| 275 | OuD_CrankFwd | Module D Crank Motor Fwd - on reversing motor Z067+ | |

| 276 | OuD_CrankRev | Module D Crank Motor Rev - on reversing motor Z067+ | |

| 277 | OuE_CrankFwd | Module E Crank Motor Fwd - on reversing motor Z067+ | |

| 278 | OuE_CrankRev | Module E Crank Motor Rev - on reversing motor Z067+ | |

| 279 | OuA_OpSiren | Operator Siren | |

| 280 | Y280 | OuF_ConvXA | Soenen Conveyor Direction X Position A (next to M/c) |

| 281 | Y281 | OuF_ConvXB | Soenen Conveyor Direction X Position B |

| 282 | Y282 | OuF_ConvYBFwd | Soenen Conveyor Direction Y Position B FORWARD |

| 283 | Y283 | OuF_ConvYBRev | Soenen Conveyor Direction Y Position B REVERSE |

| 284 | Y284 | OuB_VibPlate | Autoflow Mk4 Vibration Plate |

| 290 | Y290 | OuF_CLHClose | Sturtz Outfeed Horizontal Clamp Close |

| 291 | Y291 | OuF_CLHOpen | Sturtz Outfeed Horizontal Clamp Open |

| 292 | Y292 | OuF_LiftUp | Sturtz Outfeed Lift Station Up |

| 293 | Y293 | OuF_LiftDn | Sturtz Outfeed Lift Station Down |

| 294 | Y294 | OuF_OBarBlw | Sturtz Outfeed Bar Blower |

| 295 | Y295 | OuF_ConvFwd | Sturtz Outfeed Conveyor Forward |

| 296 | Y296 | OuF_ConvRev | Sturtz Outfeed Conveyor Reverse |

| 310 | Y310 | OuF_AABlw | Label Area Blower |

| 311 | Y311 | OuF_AAVac | Vacuum Pump Valve (Label Applicator) |

| 312 | Y312 | OuF_AATilt | Applicator Tilt (Label Applicator) |

| 313 | Y313 | OuF_AAPlace | Applicator Place Up/Down (Label Applicator) |

| 314 | Y314 | OuF_AAPick | Applicator Pick (Yaxis) (Label Applicator) |

| 315 | Y315 | OuF_AAPulse | Label Applicator Profile Position Turret Pulse |

| 316 | Y316 | Inv_DP | Inverter Double plunge output used on TC2 machines

The standard should be Y271, but this refernce has crept in on TwinCAT2 machines only |

| 319 | Ou_IPullOff | Ecoline Infeed Pull Off | |

| 320 | Ou_CLVHi | Ecoline V notch top clamp High pressure | |

| 321 | Y321 | Ou_EJPSH2

OuF_EjPushB |

Ecoline / Microline outfeed push 2

Soenen Eject Push to Conveyor B |

| 322 | Ou_VBLOW | Ecoline V Notch Blower | |

| 323 | Ou_IPULLO | Ecoline Infeed Pull Valve off (3 position valve) | |

| 324 | Ou_LENBLOW | Length sensor blower (not Used) | |

| 325 | Ou_VTURN | Ecoline V Front Turn | |

| 326 | Ou_WTURN | Ecoline V Rear Turn | |

| 327 | Ou_CLVO | Ecoline V Notch outfeed Side Clamp | |

| 328 | Ou_CLVI | Ecoline V Notch Infeed Side Clamp | |

| 329 | Ou_BcGrn | Ecoline Barcode Reader Green LED | |

| 330 | Ou_BcRed | Ecoline Barcode Reader Red LED | |

| 331 | Ou_BlwInfeed | Ecoline & Sturtz Infeed Blower | |

| 332 | |||

| 333 | OuA_PopUp1Off | Sturtz Infeed Push To Backfence 1 Open | |

| 334 | OuA_PopUp2Off | Sturtz Infeed Push To Backfence 2 Open | |

| 335 | OuA_PopUp3Off | Sturtz Infeed Push To Backfence 3 Open | |

| 336 | OuA_PopUp4Off | Sturtz Infeed Push To Backfence 4 Open | |

| 337 | OuA_PopUp5Off | Sturtz Infeed Push To Backfence 5 Open | |

| 338 | OuA_PopUp6Off | Sturtz Infeed Push To Backfence 6 Open | |

| 339 | OuA_PopUp7Off | Sturtz Infeed Push To Backfence 7 Open | |

| 340 | |||

| 341 | |||

| 342 | |||

| 343 | |||

| 344 | |||

| 345 | |||

| 350 | Y1 | Ou_CLIT | |

| 351 | Y2 | Ou_CLIS | |

| 352 | Y3 | Ou_CLO | |

| 353 | Y4 | Ou_INDEX | Conveyor Motor |

| 354 | Y5 | Ou_CLUTC | |

| 355 | Y6 | Ou_STRAI | |

| 356 | Y7 | Ou_CLCL | ClampClamp hold - used on

Ecoline Flowline with DOS control |

| 357 | Y8 | Ou_ALIGN | |

| 358 | Y9

Y31 |

Ou_SMOT | |

| 359 | Y10 | Ou_MLOAD | Load Wheel / Roller Motor |

| 360 | Y11 | Ou_WBLOW | |

| 362 | RY1 | SPIN1 | |

| 363 | RY2 | SPIN2 | |

| 364 | RY3 | SPIN3 | |

| 365 | RY4 | SPIN4 | |

| 366 | RY5 | SPIN5 | |

| 367 | RY6 | SPIN6 | |

| 368 | SPIN7 | ||

| 369 | SPIN8 | ||

| 370 | OY1 | Ou_EJPSH | |

| 372 | OY3 | Ou_GRPSH | |

| 373 | OY4

Y27 Y373 |

Ou_OBLOW |

Sturtz Outfeed Sensor Blower |

| 374 | Ou_SRSTM/H | BB added M/H to description because we need to keep M/H and Saw side separate | |

| 375 | Y54 | Ou_OMBLW | Material Load Blower on Module A on Zx5 |

| 376 | SPDP3 | ||

| 377 | SPDP5 | ||

| 378 | Ou_ServoEnMH | Added by BB | |

| 379 | Ou_ServoEnSaw | Added by BB | |

| 380 | |||

| 381 | Y381 | OuF_ConvBrake | Outfeed Conveyor Motor Brake |

| 382 | Y382 | OuA_ConvBrake | Infeed Conveyor Motor Brake |

| 383 | Ou_CLOUO | Under roller on outfeed side of V notch assembly | |

| 384 | Y52 | Ou_IPULL | |

| 385 | Y53 | Ou_IGRIP | OuA_IGrip on ZX5 |

| 386 | OuB_CLOI | ||

| 387 | Ou_VMOT | ||

| 388 | Ou_WMOT | ||

| 389 | Y32 | Ou_VICUT | |

| 390 | Y33 | Ou_VOCUT | |

| 391 | Y36 | Ou_WICUT | |

| 392 | Y37 | Ou_WOCUT | |

| 393 | Y42 | Ou_CLOO | Roller clamps on far outfeed side of Machining centre |

| 394 | Y43 | Ou_CLOUI | Under roller on infeed side of V notch assembly |

| 395 | Y44 | Ou_CLV | Fixed V notch clamp (front). Used for top and side V clamps on ZX5 |

| 396 | Ou_CLW | Fixed V notch clamp (Rear) | |

| 397 | Y16 | SPPL1 | |

| Ou_VOURO | Microline | ||

| 398 | Y17 | SPPL2 | |

| Ou_BLOWC | Microline | ||

| 399 | Y18 | SPPL3 | |

| Ou_BLOWD | Microline | ||

| 400 | Y19 | SPPL4 | |

| Ou_OPEN | Microline | ||

| 401 | Y20 | SPPL5 | |

| Ou_WASTE | Microline | ||

| 402 | Y21 | SPPL6 | |

| Ou_SWMOT | Microline | ||

| 403 | Y22 | SPPL7 | |

| Ou_SAWC | Microline | ||

| 404 | Y23 | SPPL8 | |

| Ou_S90 | Microline | ||

| 405 | Ou_S135 | Microline | |

| 406 | Ou_CLSIV | Microline | |

| 407 | Ou_CLSIP | Microline | |

| Microline see 418 | |||

| 409 | Ou_CLSOP | Microline | |

| 410 | Ou_CLSIH | Microline | |

| 411 | Ou_CLSOH | Microline | |

| 412 | Ou_EJPS2 | Microline | |

| 413 | Ou_RRBLW | Ring Rack Blower | |

| 414 | Ou_RREXT | Ring Rack Extractor | |

| 415 | Ou_IDLE | v3.67 Idle Beacon | |

| 416 | Ou_InvDP | Inverter Double Plunge Current Boost

also 271 | |

| 418 | Ou_CLSOV | Microline - M005 moved to this number because it did not work on 408 (608) | |

| 419 | Y419 | Ou_GripPulse | Pulse Output for grip height Somatec unit |

| 425 | Reserved | SPBL1 | Spindle blow outputs reserved due to SPPLn+28 in Spindle On code. See Monday item |

| 426 | Reserved | SPBL2 | |

| 427 | Reserved | SPBL3 | |

| 428 | Reserved | SPBL4 | |

| 429 | Reserved | SPBL5 | |

| 430 | Reserved | SPBL6 | |

| 431 | Reserved | SPBL7 | |

| 432 | Reserved | SPBL8 | |

| 440 | |||

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português