Process for unloading and locating Autoflow Mk4 machine in Saje upvc

Sommaire

- 1 Introduction

- 2 Pièces et outils

- 3 Tutoriels prérequis

- 4 Étape 1 - Lorry Loading Schedule

- 5 Étape 2 - Machine Arrival

- 6 Étape 3 - Remove the Soenen Machine

- 7 Étape 4 - Prepare the floor

- 8 Étape 5 - Triangulation for Infeed Pads

- 9 Étape 6 - Prepare the Machine Pads / Piles

- 10 Étape 7 - Prepare transport axle

- 11 Étape 8 - Clear the inside area

- 12 Étape 9 - Clear Outside Unloading Area

- 13 Étape 10 - Imporvements to step into building

- 14 Étape 11 - Lorry to reverse along RHS of building

- 15 Étape 12 - Machining Centre

- 16 Étape 13 - Machining Centre Guard

- 17 Étape 14 - Infeed Table

- 18 Étape 15 - Conveyor Table1

- 19 Étape 16 - Conveyor Table2

- 20 Étape 17 - Conveyor Control Cabinets

- 21 Commentaires

Introduction

Access for machinery is limited at the Saje factory.

The machine will be delivered in the following modules, that should be unloaded from the lorry in this order

- Electrical Cabinet

- Machining centre base module (1.8 x 2.2m)

- Infeed module (2.4 x 9.0m)

- Pièces et outils

- Tutoriels prérequis

Étape 1 - Lorry Loading Schedule

The Infeed table in particular needs to be loaded in such a way so it can be unloaded in the correct direction

Étape 2 - Machine Arrival

Thursday PM

Unload machining centre and store in Glass shed

Unload infeed and cover with Tarpaulin

Unload electrical cabinet and store inside

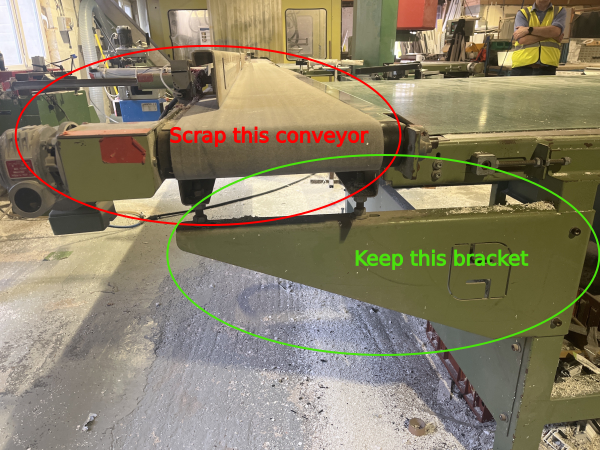

Étape 3 - Remove the Soenen Machine

Friday

remove the Soenen machine, leaving the large outfeed conveyor tables

The Brackets on the outfeed tables will be used for the Stuga conveyors

Étape 4 - Prepare the floor

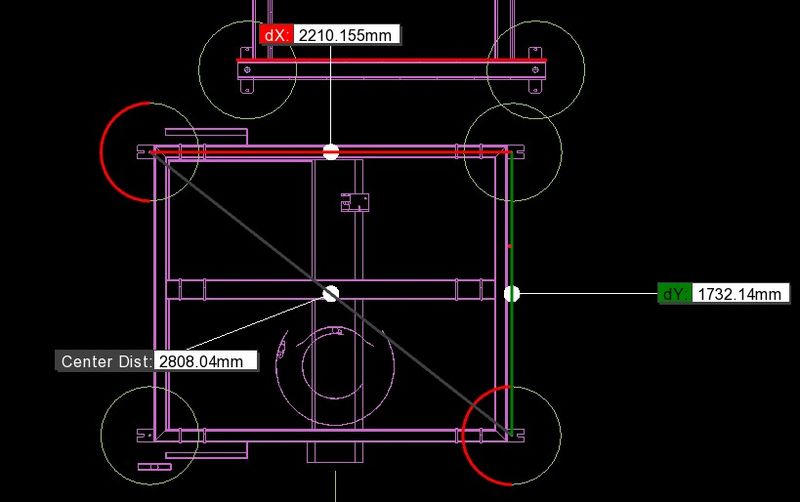

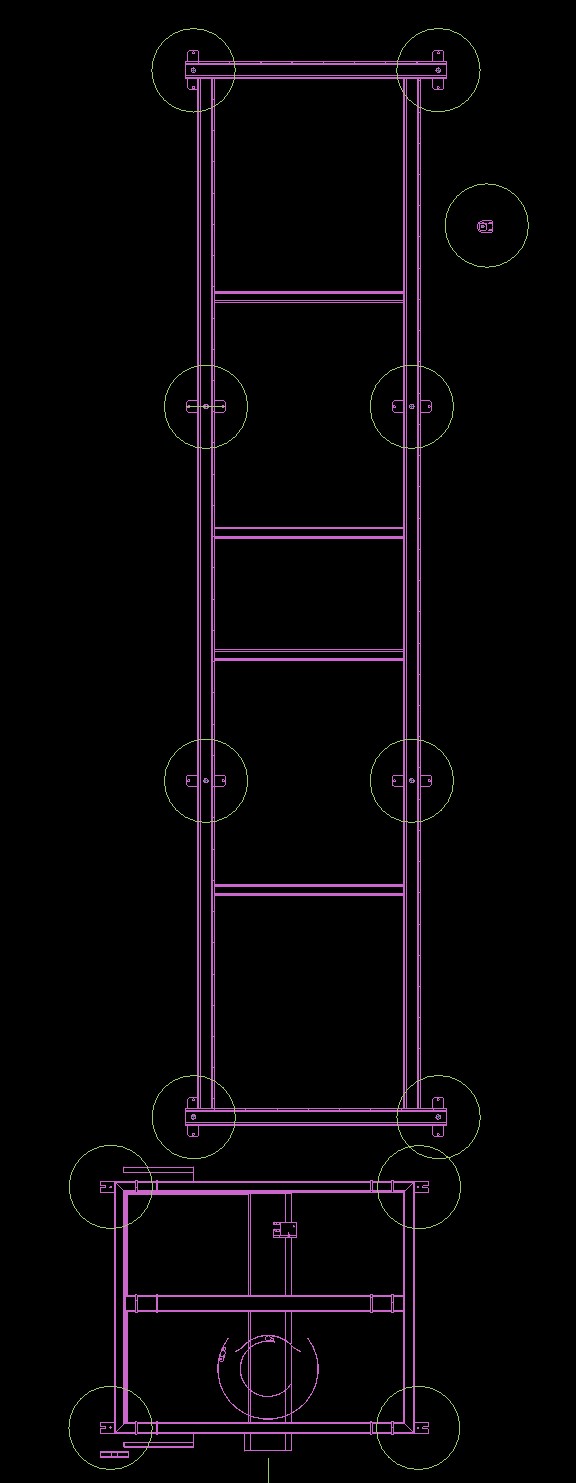

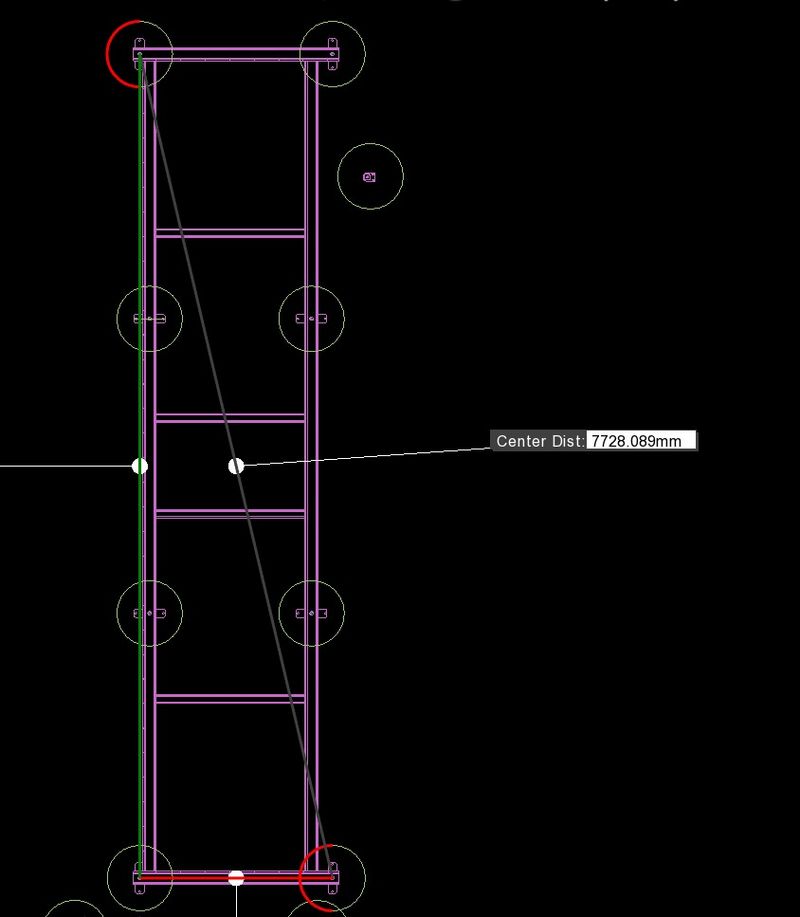

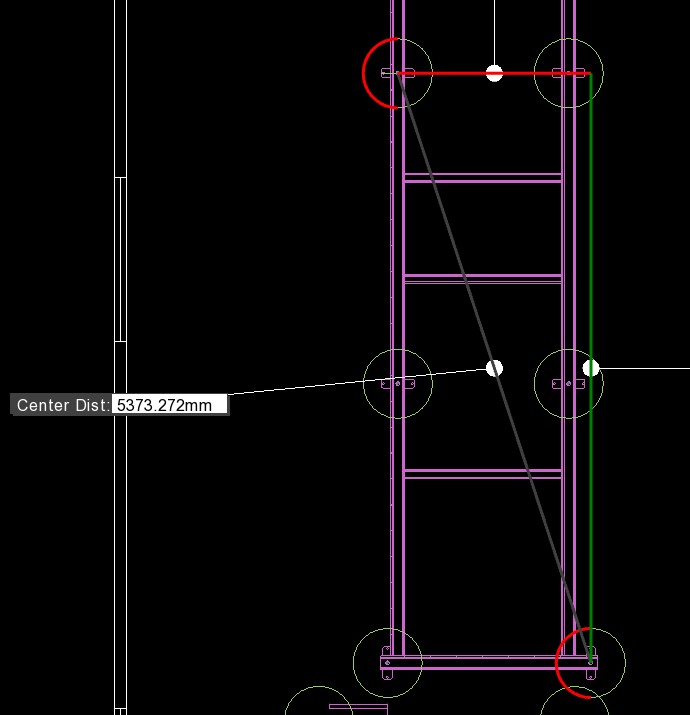

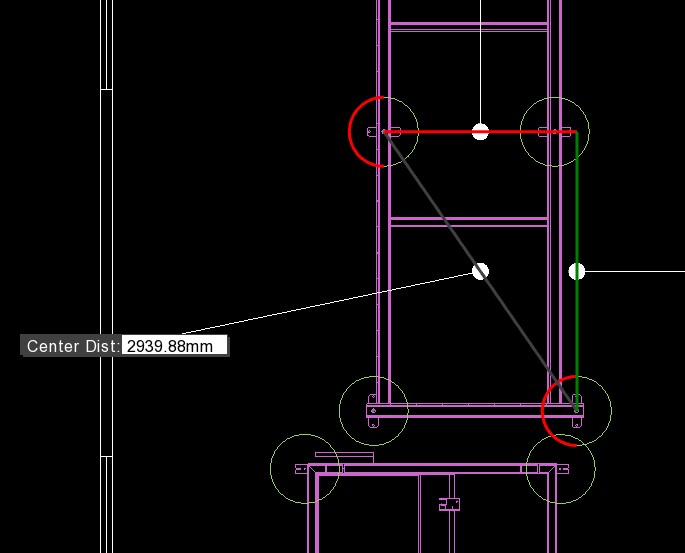

The datum points for loading have already been marked on the floor.

Using these datum points, mark the position of the remainder of the floor pads

Étape 6 - Prepare the Machine Pads / Piles

Friday:- Pad size 300mm x 300mm (or similar)

- Pad Depth 300-500mm

- Use shuttering or large diameter soil pipe

- Find the highest point, string a level agcross to the other pads

- Fill shuttering with quick set cement to +/- 15mm of level

Étape 7 - Prepare transport axle

Stuga will supply a wheeled all-terrain axle

this axle is designed to form a "wheelbarrow" using the forklift as the driver / opposite end. This will enable the heavy machine units to be carefully wheeled over the rough terrain

Étape 8 - Clear the inside area

Including the chop saw table

Leaving a clear route for the 2.4m x 7.5m table to roll in

Étape 10 - Imporvements to step into building

If possible, improve the access pathway.

Potentially find a ramp system for the step into the unit

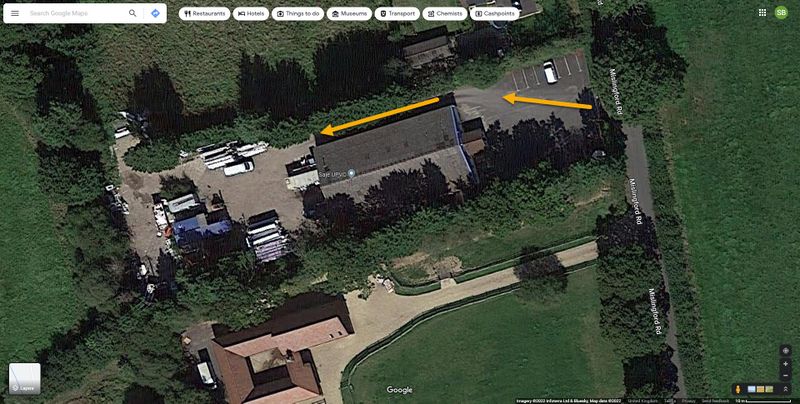

Étape 11 - Lorry to reverse along RHS of building

Monday:

Lorry to reverse along right side of building (when viewed from front)

This allow easy unloading access for forklift to unload to ground, and align components with door

Étape 12 - Machining Centre

The machining centre should be unloaded first

Étape 13 - Machining Centre Guard

The guard is a clam shell design that encases the machine in 2 parts from front and rear

Étape 14 - Infeed Table

- Infeed should lifted to align with rear door

- Bogey on lead end

- Forlift moves to rear end

- Forklift to shunt infeed able into factory

- 2 Off pallet trucks to manouvre into position

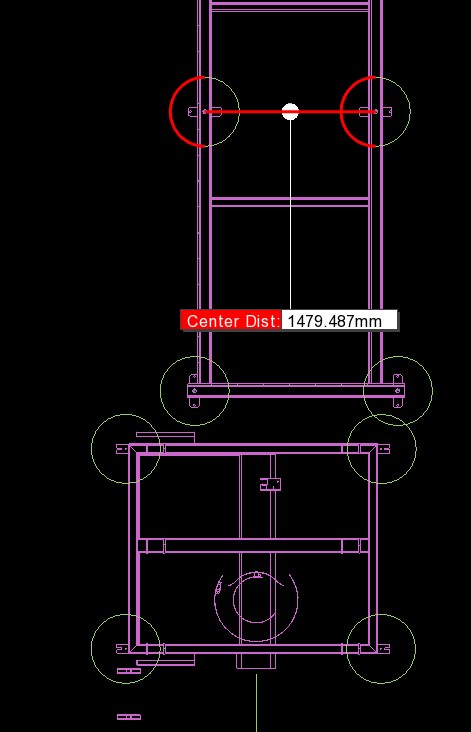

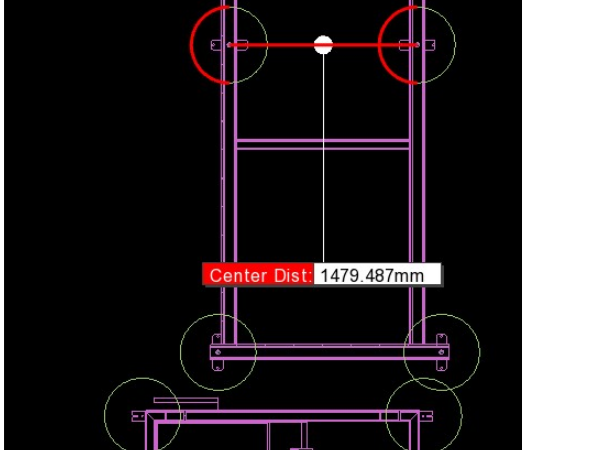

Étape 15 - Conveyor Table1

Conveyor table should attach to existing Soenen Brackets

Position of conveyor 1 adjusted to machining centre, leaving gap of 25mm

Height adjust on Soenen Brackets

Étape 16 - Conveyor Table2

Conveyor table should attach to existing Soenen Brackets

Additional leg for long conveyor to support

Position of conveyor 2 adjusted to Conveyor 1, leaving gap of 10mm

Height adjust on Soenen Brackets

Étape 17 - Conveyor Control Cabinets

Remove old Conveyor control back plate

Premade Backplates fit inside

Rewire as indicated in drawings

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português