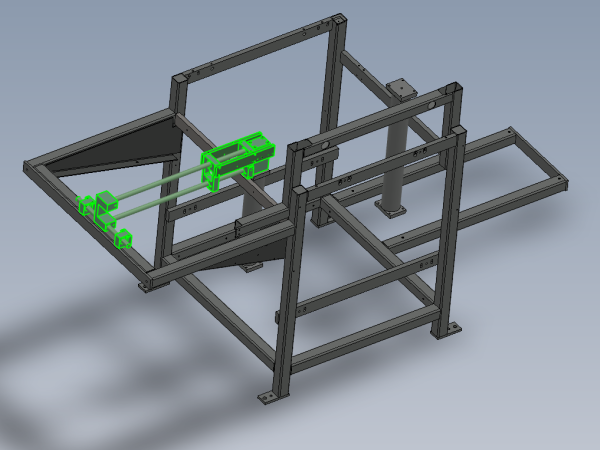

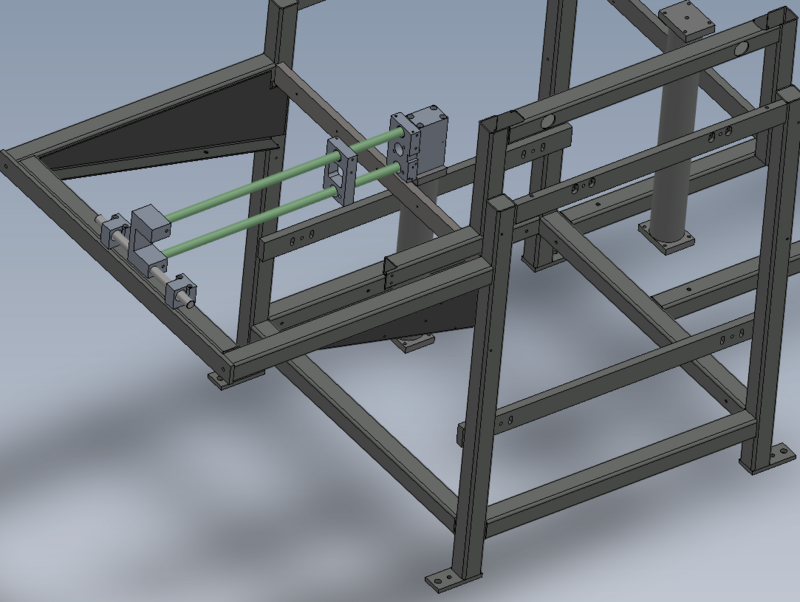

Alignment details for base and 1st stage ejector

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

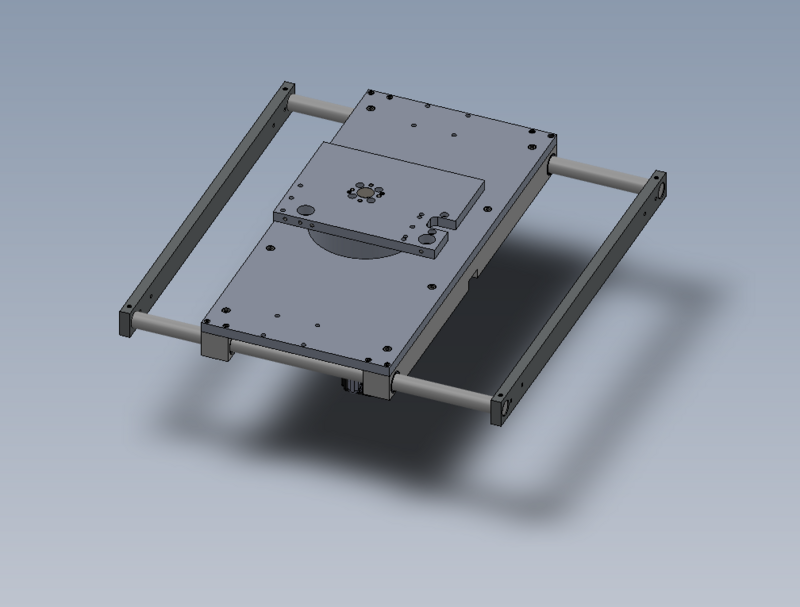

- 3 Étape 2 - Attach eject support

- 4 Étape 3 - Attach Rod base

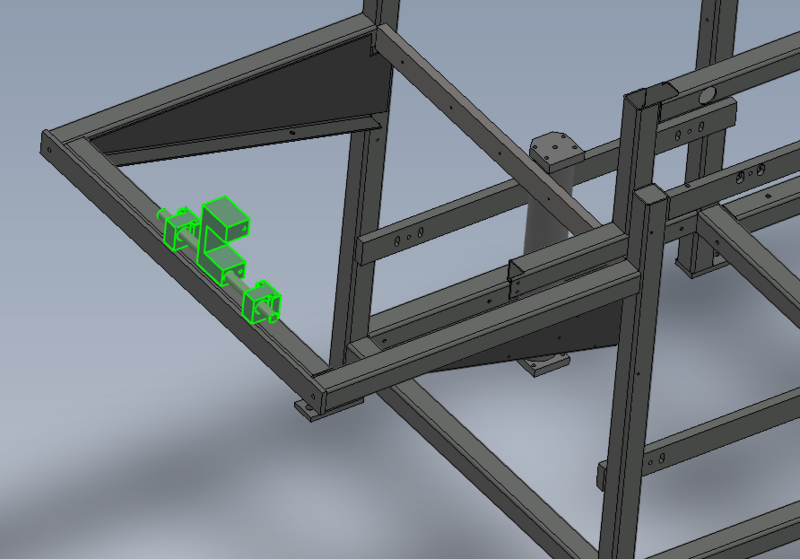

- 5 Étape 4 - Fit eject shafts

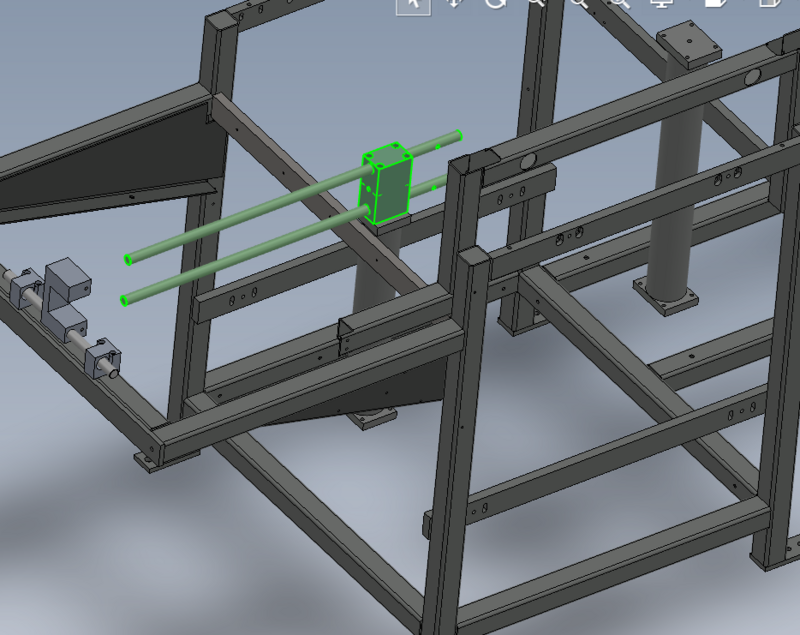

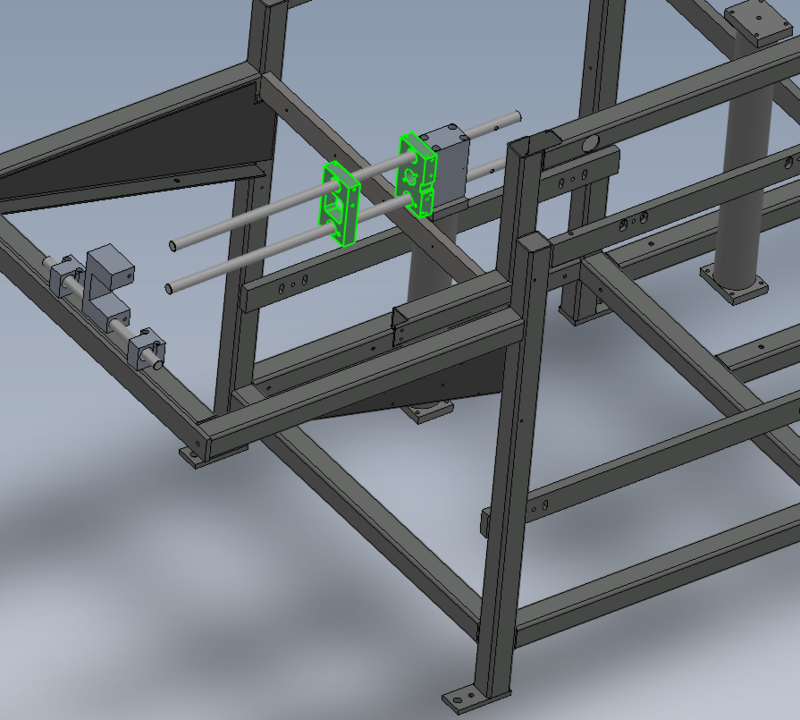

- 6 Étape 5 - Fit eject bearing blocks

- 7 Étape 6 - position eject shafts

- 8 Étape 7 - Level base

- 9 Étape 8 - Level eject shafts

- 10 Étape 9 - Check end plate level

- 11 Étape 10 - Finalise position of base

- 12 Commentaires

Introduction

Tools Required

Standard hex key set

300mm engineers level

Parts Required

D0004014 Ejector Tie Bar x 2

D0004328 Rod Base (5303) x 1

H0004629 Shaft 20mm: 754 Ejector x 2

R0000570B Bench Assemble 1st stage Ejector and Level Base x 1Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

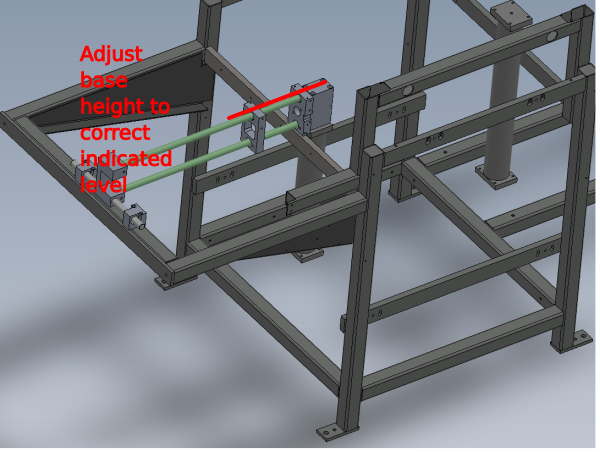

Étape 7 - Level base

Use engineers level at indicated points to set base level

Adjust using jacking screws on support brackets

Étape 8 - Level eject shafts

use engineers level to check level of eject assembly

Adjust base evenly to maintain base level , to adjust eject shafts

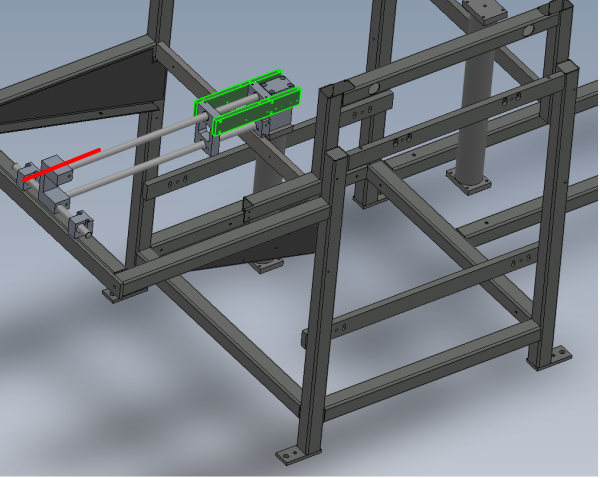

Étape 9 - Check end plate level

End block level should also be checked for level and adjusted to be correct

Étape 10 - Finalise position of base

Adjusting brackets should be removed individually once all settings are complete

remove one bracket and replace with 2nd m8 fixing bolt. Monitor base position with level when removing brackets and adjust to correct if movement occurs

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português