Details for correct setting of roller bed assemblies

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Air Supply

- 4 Étape 3 - Level roller beds

- 5 Étape 4 - Cylinder adjustment

- 6 Étape 5 - Check fasteners

- 7 Étape 6 - Position Engineers level

- 8 Étape 7 - Adjust cylinder stroke

- 9 Étape 8 - Double cylinder roller beds

- 10 Étape 9 - Repeat

- 11 Étape 10 - Quality check on roller beds

- 12 Étape 11 - Height setting

- 13 Étape 12 - Please Note!!

- 14 Étape 13 - Position gripper

- 15 Étape 14 - Gap Setting

- 16 Étape 15 - Double cylinder assemblies

- 17 Étape 16 - Finalise fixings

- 18 Étape 17 - Repeat above steps

- 19 Étape 18 - Check transitions

- 20 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Engineers level

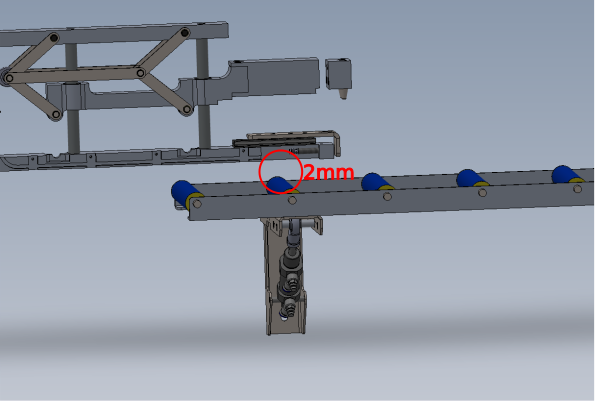

2mm shim spacer

2 meter straight edge

Parts Required

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

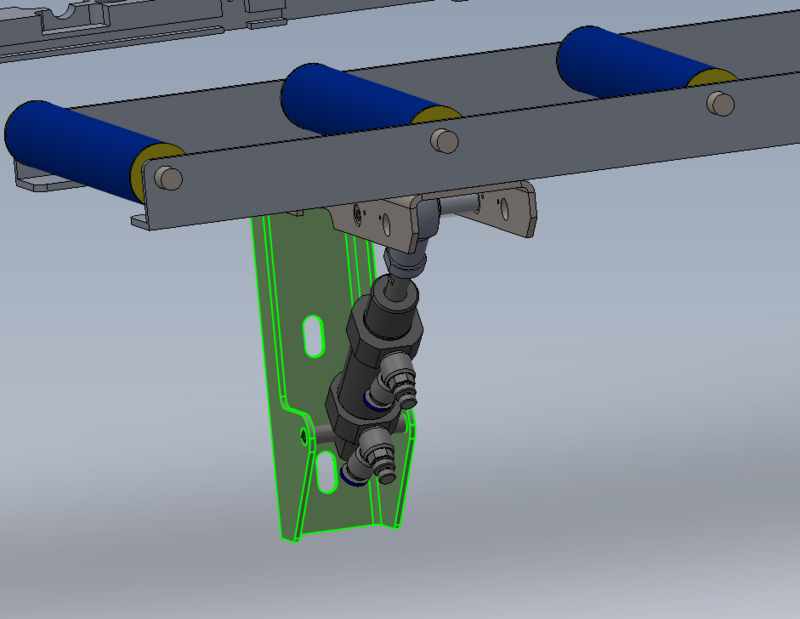

Étape 2 - Air Supply

The following steps require air supply to be active on the home line of the roller beds. Connect air to feed pipe from manifold bank to lift roller assemblies to home position

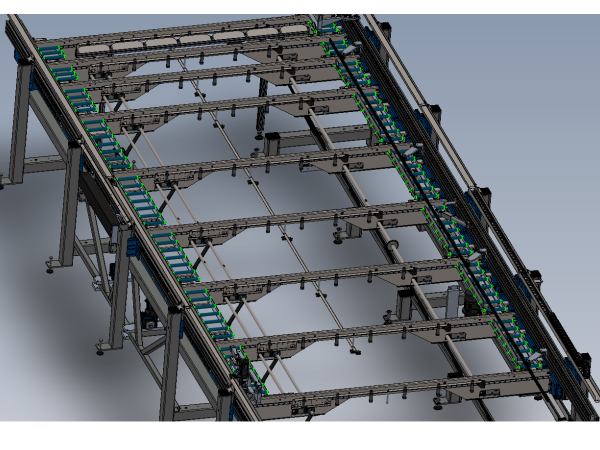

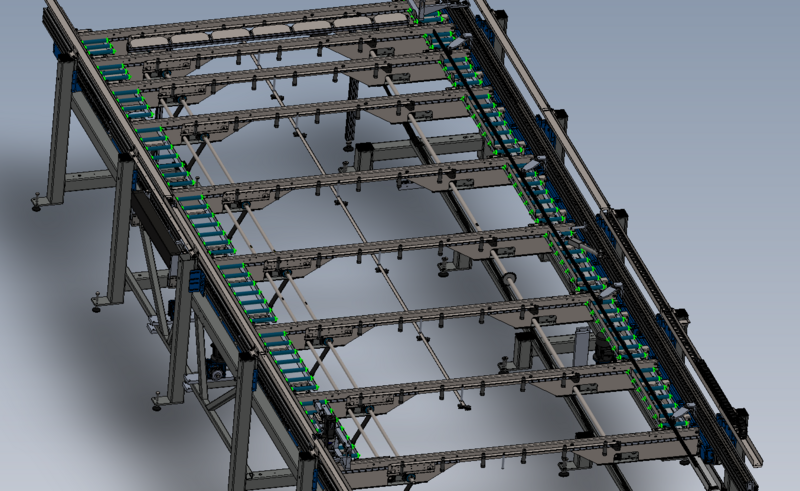

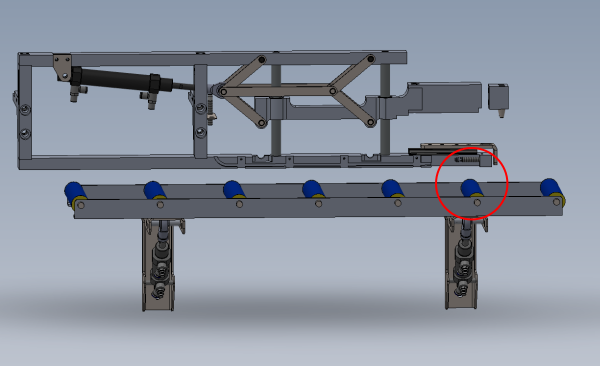

Étape 3 - Level roller beds

It is vital roller beds are levelled and positioned correctly

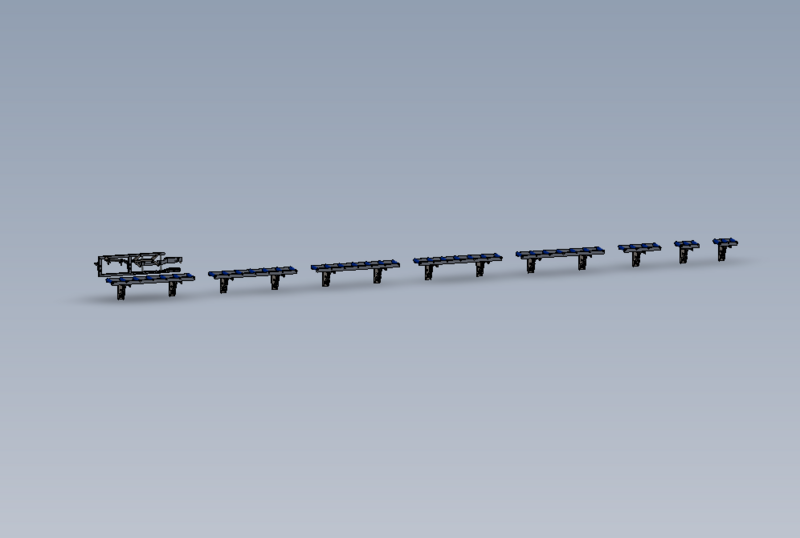

The following steps should be repeated for each and every roller bed assembly

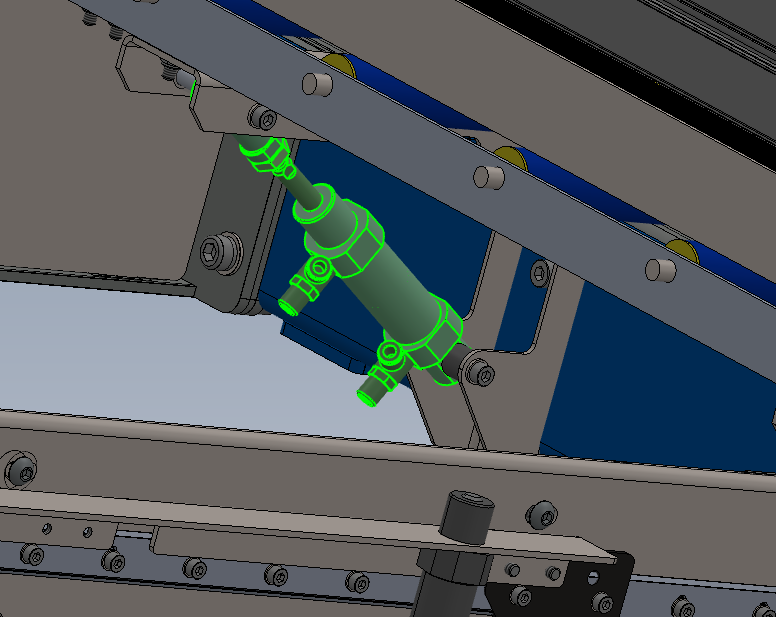

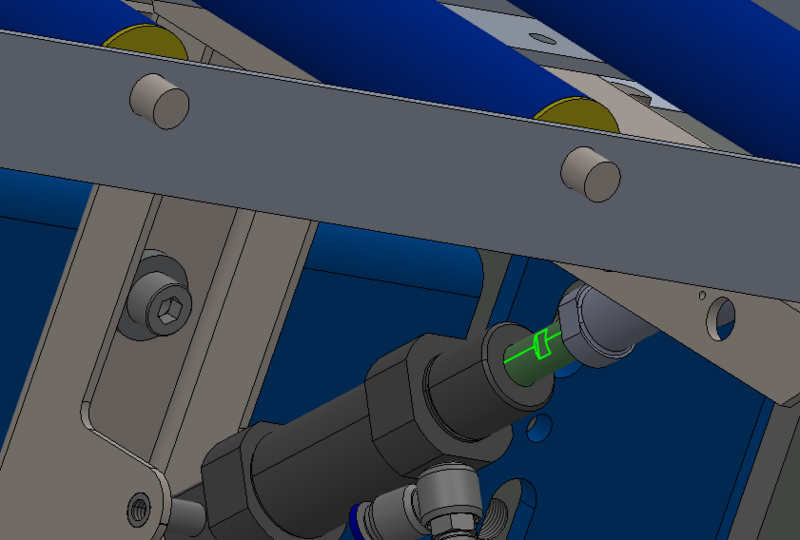

Étape 4 - Cylinder adjustment

Each cylinder assembly will require adjusting to level roller bed correctly

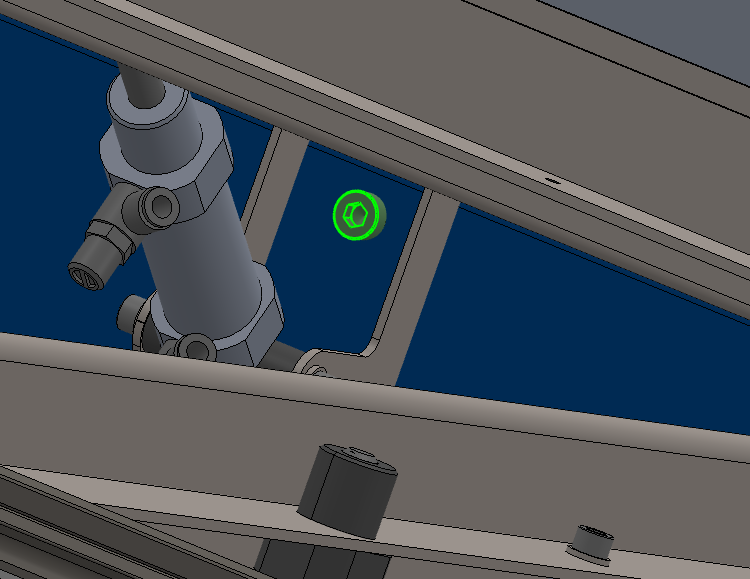

Étape 5 - Check fasteners

Check fasteners holding roller assembly to frame are tensioned correctly. Not adhesive is required at this stage

Étape 6 - Position Engineers level

Engineers level should be positioned directly above cylinder assembly

Étape 7 - Adjust cylinder stroke

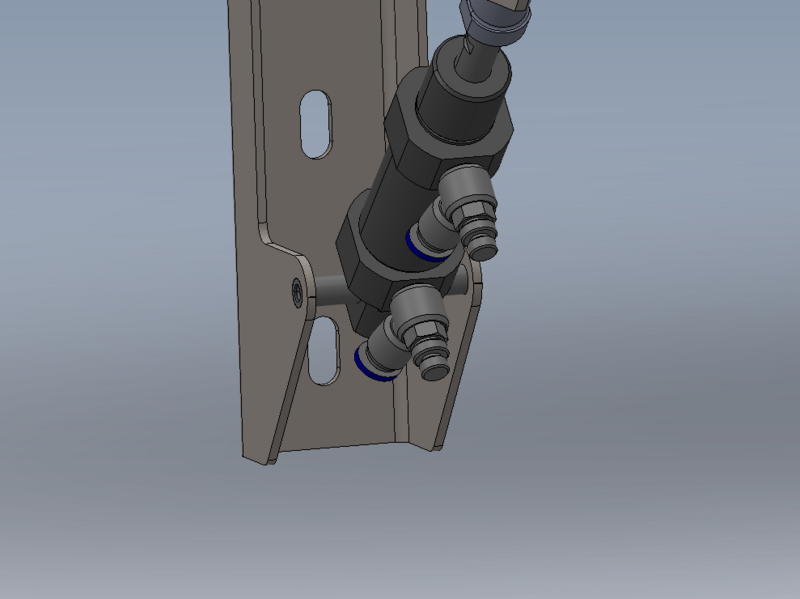

Wind back cylinder lock nut and apply 1 drop of Loctite 243 to exposed cylinder thread

Adjust cylinder stroke to bring engineers level to level position

Lock Locking nut in position ,Ensure that 2 spanners are used to hold spherical bearing and cylinder lock nut when tensioning

Ensure level is not affected on tensioning. If so, re adjust to correct

Apply final tension to cylinder lock nuts and mark as finalised

Étape 8 - Double cylinder roller beds

If a double cylinder roller bed is levelled , it is vital to check the first cylinder again after setting second cylinder level position

Étape 10 - Quality check on roller beds

Use a 2 meter straight edge to roll across the top face of all the roller beds when in the up position.

Transition should be smooth and bump free from each roller bed to the next

Check in both directions of travel

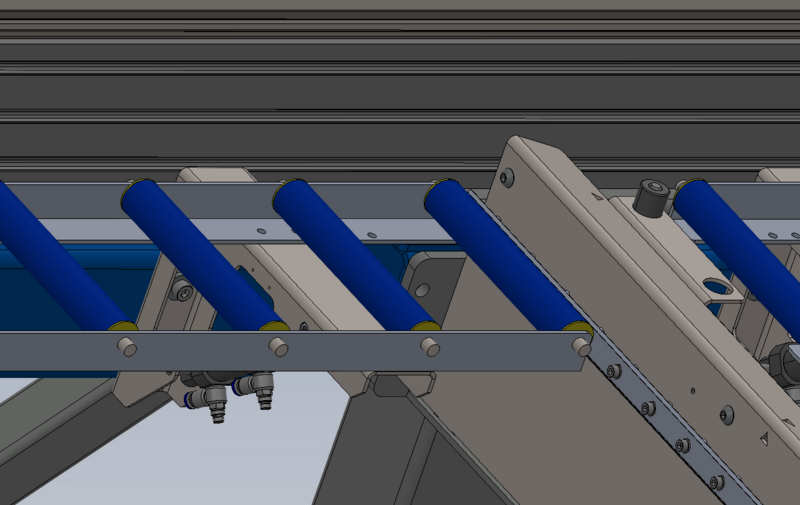

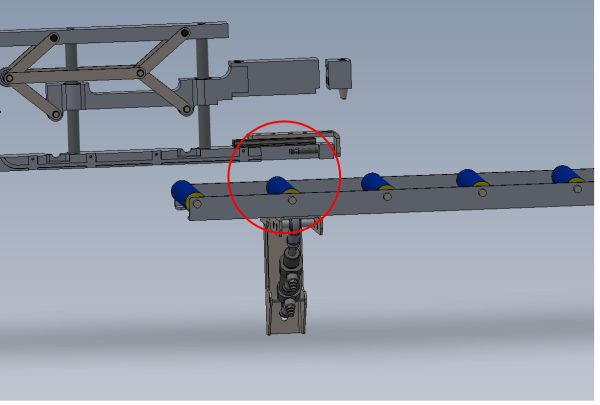

Étape 11 - Height setting

It is vital the roller beds are set at the correct height in relationship to the gripper assembly

The following steps should be used to correctly set roller bed heights

Étape 12 - Please Note!!

When adjusting height of roller bed assemblies, do not use impact from hammer to adjust . This leads to damage of the small top hat bush within the assembly . adjust height position with fasteners slack , so no force is applied to these bushes

Étape 14 - Gap Setting

Gap requires setting to 2mm between bottom of gripper and top of roller

Use a 2mm shim to set this distance

To adjust roller bed height, slacken bracket fixings and move bracket on slot

Étape 15 - Double cylinder assemblies

Double cylinder assemblies will need additional setting.

Adjust first cylinder position height

Move gripper to second cylinder

Adjust second cylinder position

Move gripper back to first cylinder and check position hasn't altered

Étape 16 - Finalise fixings

Once correct height has been set, adhesive will need individually applying to each fastener

2 off M8 per bracket require finalising

Étape 17 - Repeat above steps

Repeat above steps to set all roller beds on module C and E using the gripper as the datum for each roller bed

Étape 18 - Check transitions

Use a 2 meter straight edge to 'Roll ' along the levelled and set roller bed assemblies

Transition from one roller bed assembly to the next should be smooth with with no jump or drop onto neighbouring roller beds

If discrepancies are found, double check height and levelling, and if correct report to supervisor

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português