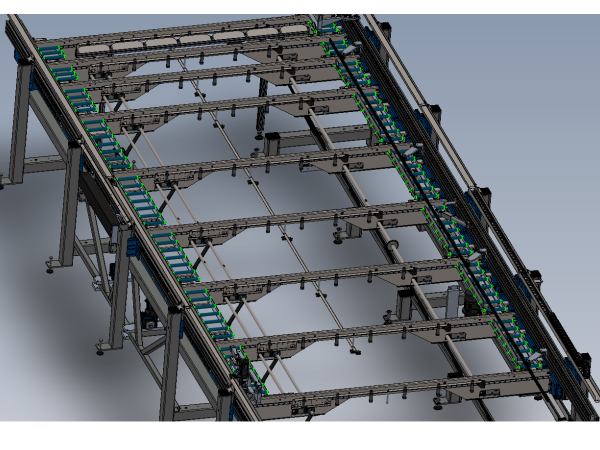

Details for correct setting of roller bed assemblies

Introduction

Tools Required

Standard hex key set

Standard spanner set

Engineers level

2mm shim spacer

2 meter straight edge

Parts Required

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

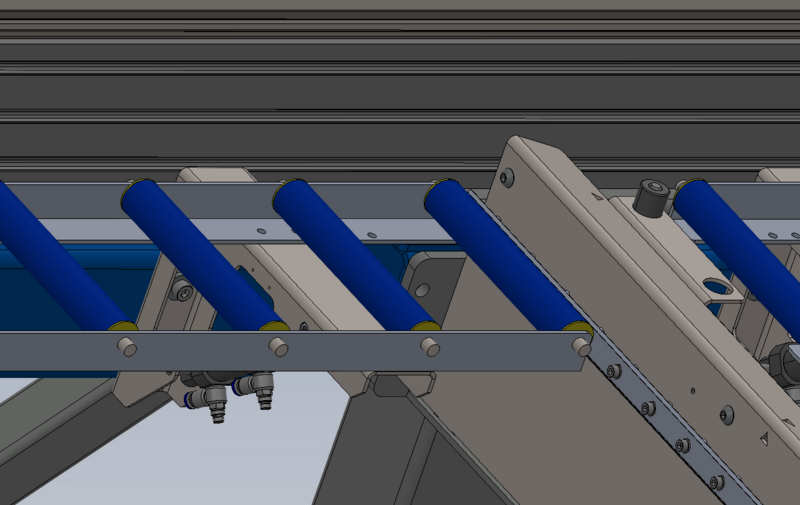

Étape 2 - Level roller beds

It is vital roller beds are levelled and positioned correctly

The following steps should be repeated for each and every roller bed assembly

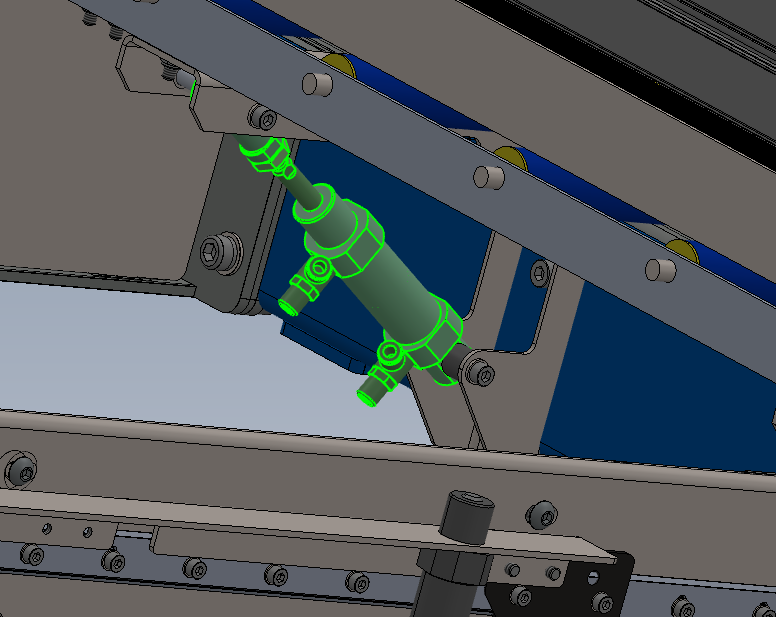

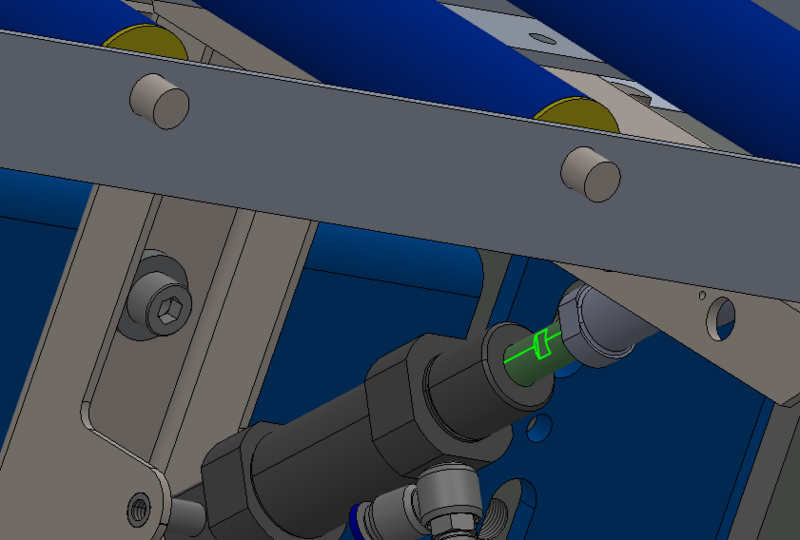

Étape 3 - Cylinder adjustment

Each cylinder assembly will require adjusting to level roller bed correctly

Étape 4 - Check fasteners

Check fasteners holding roller assembly to frame are tensioned correctly. Not adhesive is required at this stage

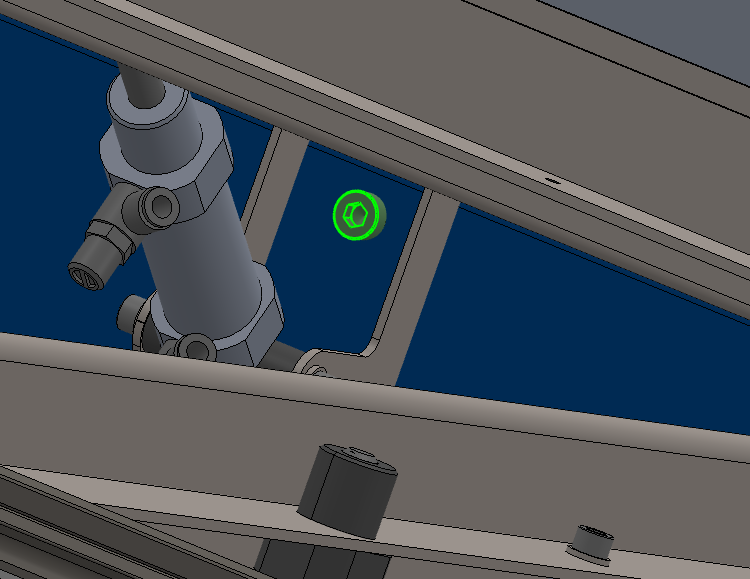

Étape 5 - Position Engineers level

Engineers level should be positioned directly above cylinder assembly

Étape 6 - Adjust cylinder stroke

Wind back cylinder lock nut and apply 1 drop of Loctite 243 to exposed cylinder thread

Adjust cylinder stroke to bring engineers level to level position

Lock Locking nut in position ,Ensure that 2 spanners are used to hold spherical bearing and cylinder lock nut when tensioning

Ensure level is not affected on tensioning. If so, re adjust to correct

Apply final tension to cylinder lock nuts and mark as finalised

Étape 7 - Double cylinder roller beds

If a double cylinder roller bed is levelled , it is vital to check the first cylinder again after setting second cylinder level position

Étape 8 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português