Instructions to install pneumatic connections to main frame

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Y239 Material blower

- 4 Étape 3 - Y231, Y230 and Y299 Pop up feeds

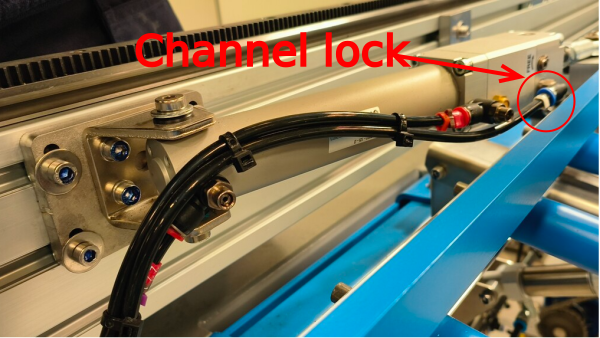

- 5 Étape 4 - Y221 channel

- 6 Étape 5 - Y220 channel lock

- 7 Étape 6 - Y147 pop up E

- 8 Étape 7 - Y146 Roller Bed

- 9 Étape 8 -

- 10 Étape 9 -

- 11 Étape 10 -

- 12 Étape 11 -

- 13 Étape 12 -

- 14 Étape 13 -

- 15 Étape 14 -

- 16 Étape 15 -

- 17 Étape 16 -

- 18 Étape 17 -

- 19 Étape 18 -

- 20 Commentaires

Introduction

Tools require

Pipe cutters

Number identification

Flush cutters

Parts required

P0000010 Elbow Adaptor 6mm - 1/8 BSPT (Taper thread)

P0000160 Fitting: Flow Controller In Line 6mm

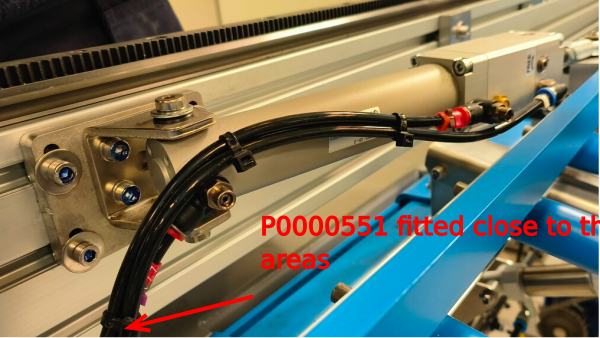

P0000551 6mm inline Quick Exhaust Fitting

P0001008 Regulator: ARG20 0 - 8.5 Bar c/w Gauge

P0001022 Regulator Bracket: to suit P0001008

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

Étape 2 - Y239 Material blower

Material blower should be identified as 2399

P0000160 flow reg required to control flow onto sensors

Connect to active port ln valve bank (4)

Étape 3 - Y231, Y230 and Y299 Pop up feeds

Feed pipes from valve bank should be run to transfer arm location 4

Identifications will be

2319

2309

2299

Connect to active port on valve bank (4)

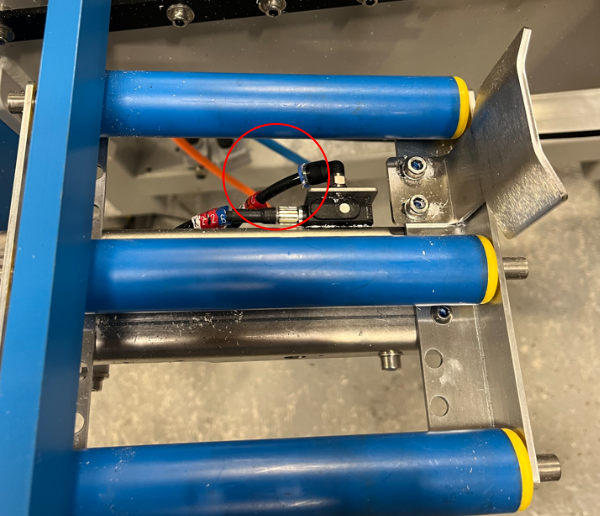

Étape 4 - Y221 channel

Has regulation on active position

Identification

2211 feeds from valve bank (2) to cylinder home port (nose)

2212 feeds from base of cylinder to reg out port

2219 feeds from reg in port to active port on valve bank (4)

P0000551 2 off must be fitted to 2211 and 2212 close to cylinder

Étape 6 - Y147 pop up E

Identification 1479

Connects to active port on valve bank (4)

Ensure enough loom to allow full range of movement

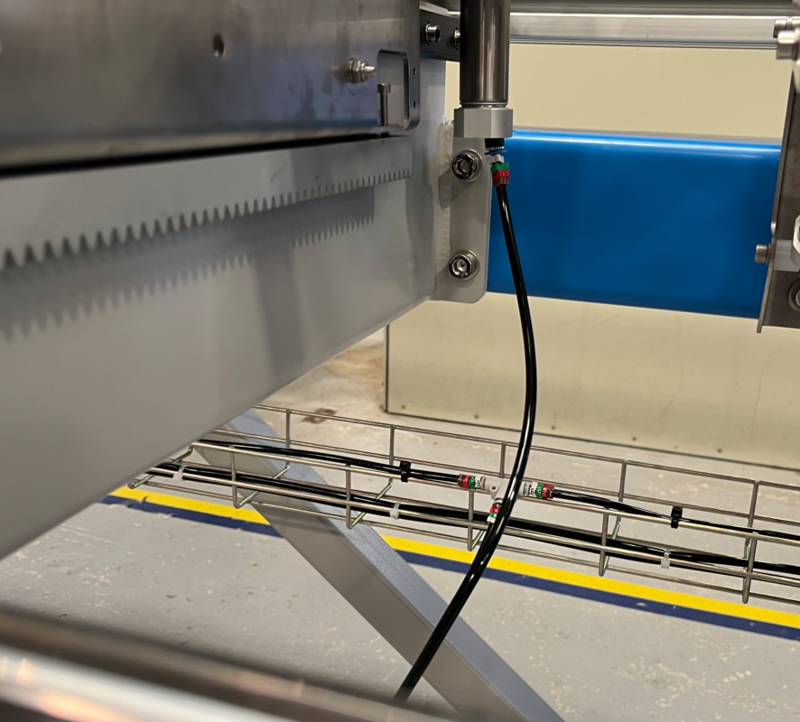

Étape 7 - Y146 Roller Bed

Identification

1461 and 1469

Roller bed is lifted at home position

1461 to home port on valve bank (2)

1469 to active port on valve bank (4)

Étape 8 -

Étape 9 -

Étape 10 -

Étape 11 -

Étape 12 -

Étape 13 -

Étape 14 -

Étape 15 -

Étape 16 -

Étape 17 -

Étape 18 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português