Process for alignment of infeed arms

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Mount 1st section

- 4 Étape 3 - Mount 2nd section

- 5 Étape 4 - Mount 3rd section

- 6 Étape 5 - Quality Check

- 7 Étape 6 - Pin sections in position

- 8 Étape 7 - Finalize fasteners

- 9 Étape 8 - Prepare Support Channels

- 10 Étape 9 - Mount Section

- 11 Étape 10 - Mount Pre assembled load Arm 1

- 12 Étape 11 - Fit Pre assembled support brackets

- 13 Étape 12 - Install remaining arms

- 14 Étape 13 - Arm alignment

- 15 Étape 14 - Check levels

- 16 Étape 15 - Quality check

- 17 Étape 16 - Drill and Pin 1st stage

- 18 Étape 17 - Finalize fasteners

- 19 Étape 18 - Drill and Pin 2nd stage

- 20 Commentaires

Introduction

Tools Required

Standard spanner set

Standard Hex key set

Pedestal stand

Adjustable jack

1 meter straight edge

300mm engineers level

Lever bar

Standard tap set

Standard hss drill set

Hammer

Tape measure

Wire line

Clamps

Parts Required

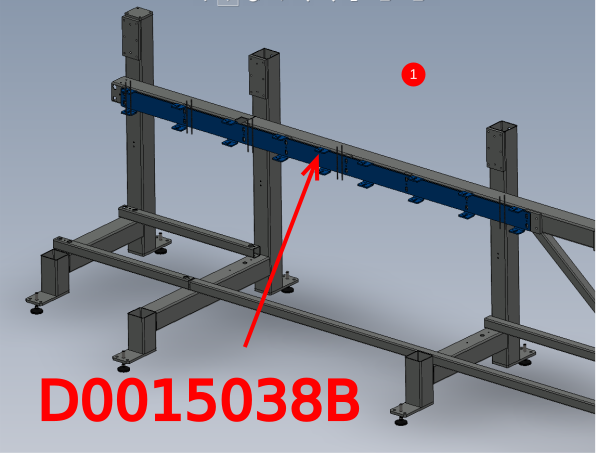

D0015038B x 1

D0015039B x 1

D0015257 x 1

D0015035B x 1

D0015036B x 1

D0015037B x 1Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

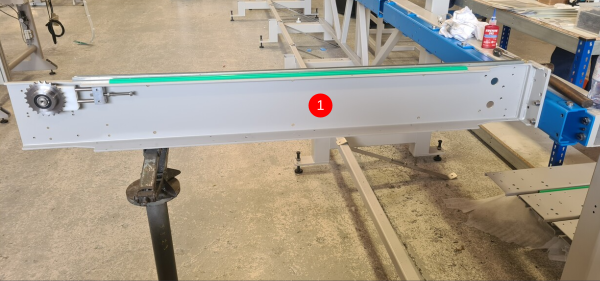

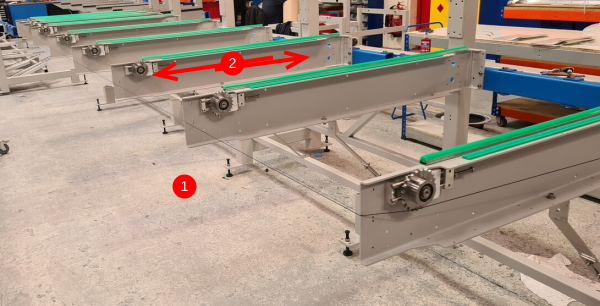

Étape 2 - Mount 1st section

1 Mount D0015038B in position shown .

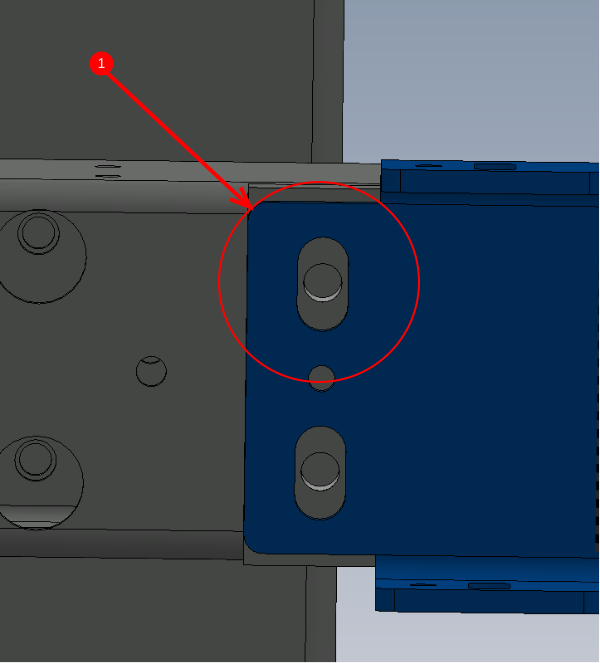

Use M12 x 25 set bolts and M12 A form washers. Do not add loctite 243 at this stage. Ensure Section is mounted mid slot as shown

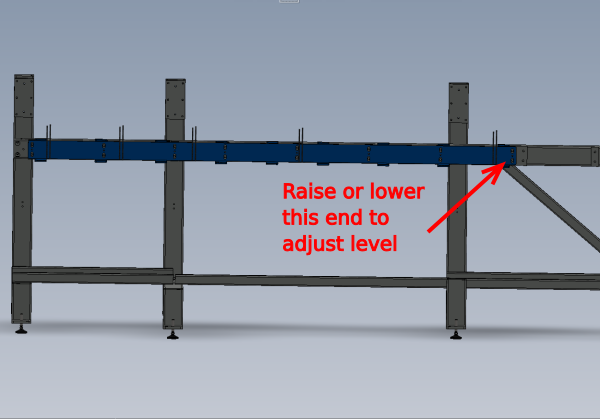

2 Use a 2 meter straight edge and position on top of mounted section as shown

Use 300mm engineers level and adjust indicated point to bring section level

3 Tension fasteners to hold support section position

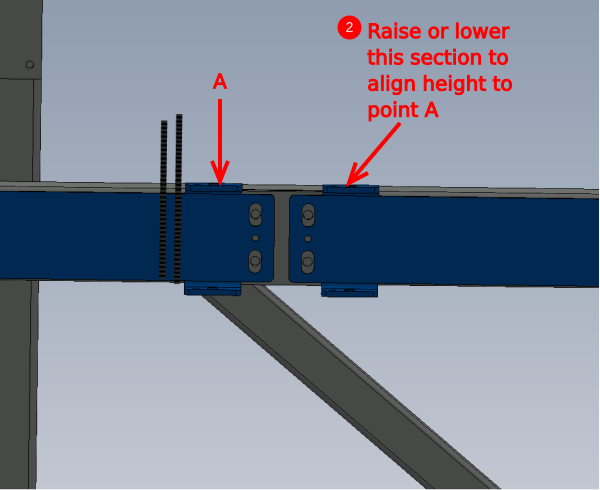

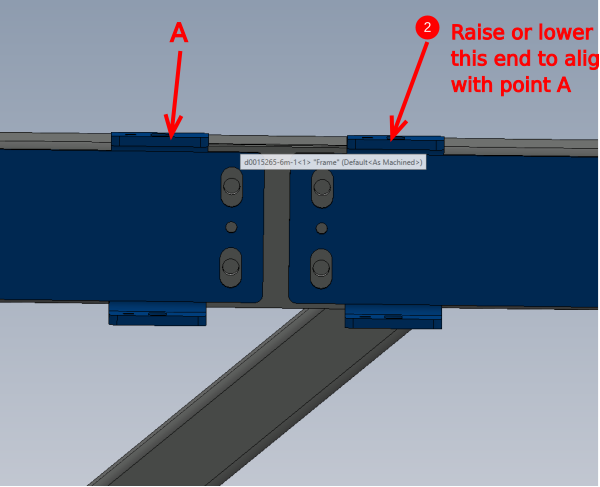

Étape 3 - Mount 2nd section

1 Mount D0015039B at position shown using same fixings as previous step

2 By extending 2 meter straight edge slightly from previous fitted section, set height at point shown to be flush with 1st section

3 Move straight edge to sit only on 2nd section and move indicated point to adjust level

4 Tension fasteners to hold support section position

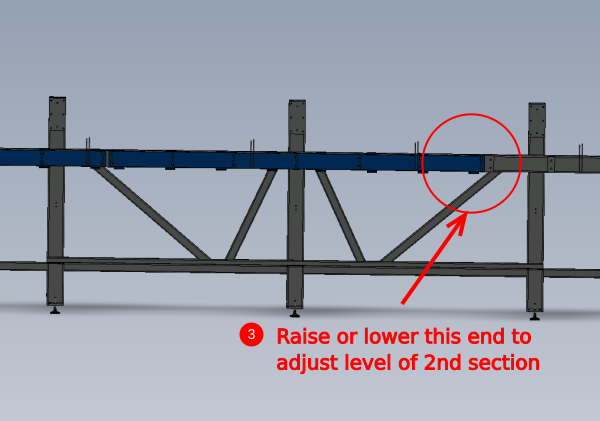

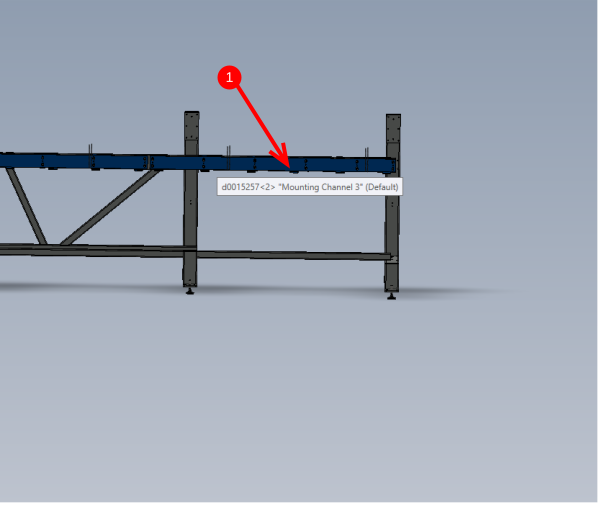

Étape 4 - Mount 3rd section

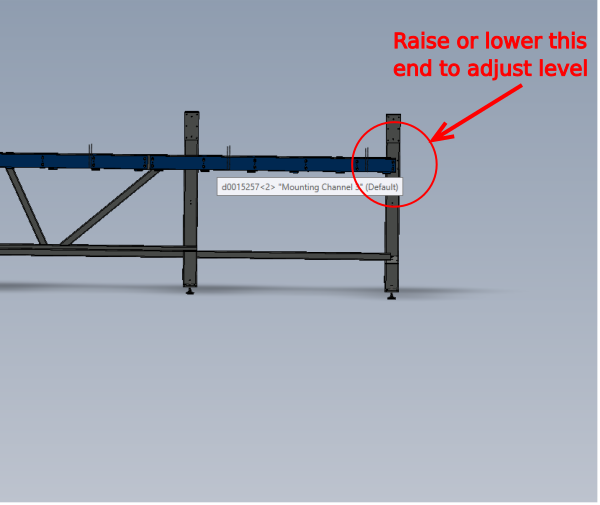

1 Mount D0015257 at position shown using same fixings as previous

2 By extending 2 meter straight edge slightly from previous fitted section, set height at point shown to be flush with 1st section

3 Move straight edge to sit only on 2nd section and move indicated point to adjust level

4 Tension fasteners to hold support section position

Étape 5 - Quality Check

If the frame has been leveled accurately, the last section mounted should still be approximately mid slot when leveled

If there is not enough adjustment available in the slot at this point to level section, it indicates an error on frame leveling.

Supervisor check required at this point to confirm adjustments

Étape 6 - Pin sections in position

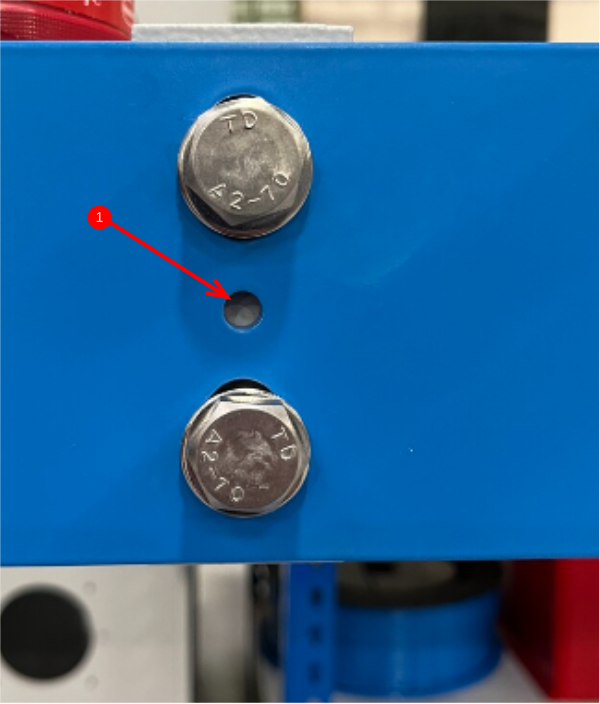

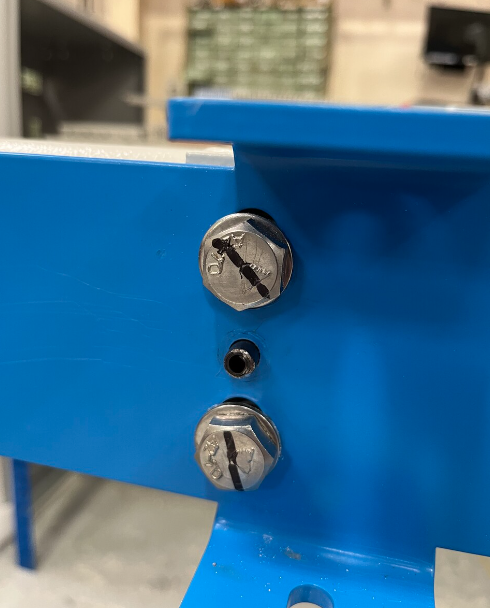

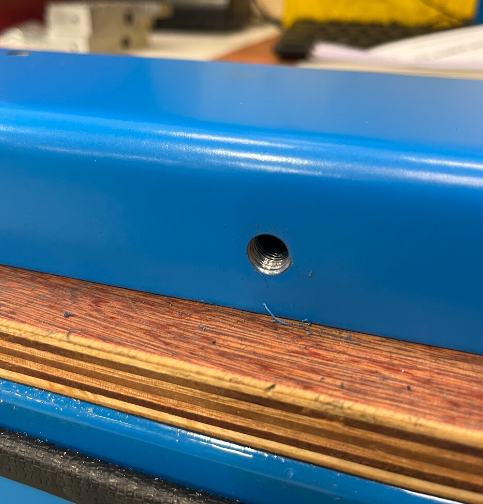

1 3 off mounted sections now require drilling for spirol pins

2 Drill hole 7mm , then increase to 8mm and then fit 8mm x 24mm spirol pin

3 Repeat this on all dowel positions on all 3 mounted sections

Étape 7 - Finalize fasteners

1 Remove M12 x 25 set bolt

2 Add Loctite 243 to thread

3 Refit and add final tension

4 Mark bolt as complete

5 Repeat for all M12 fasteners

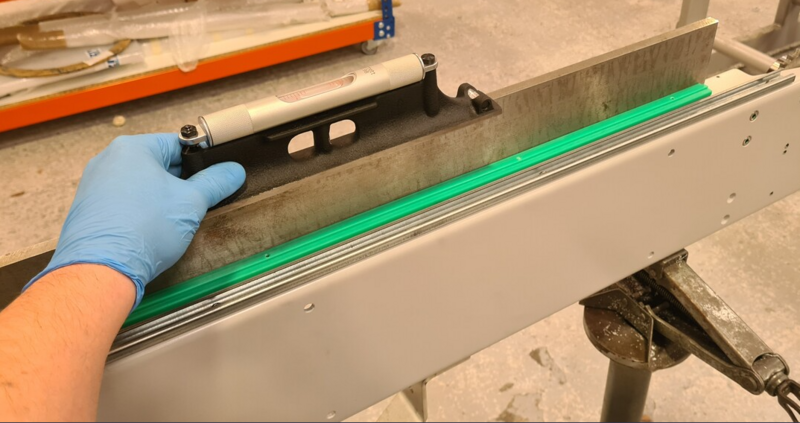

Étape 8 - Prepare Support Channels

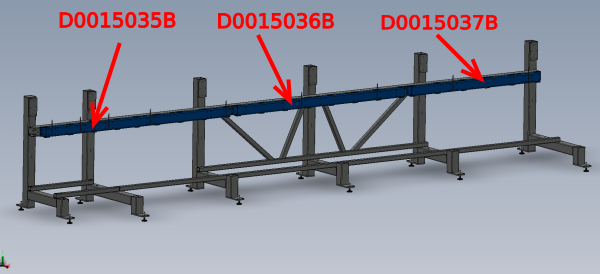

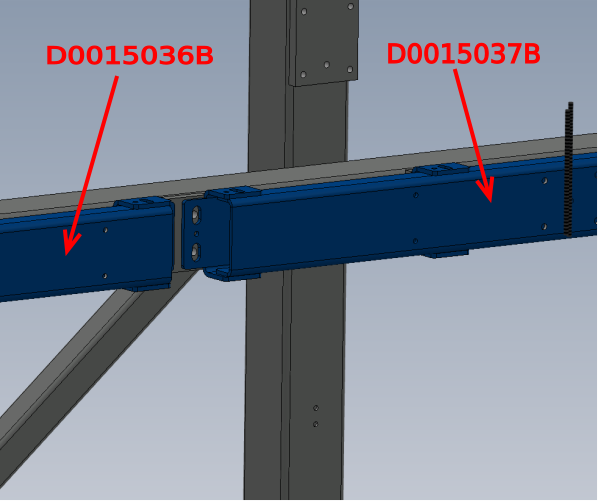

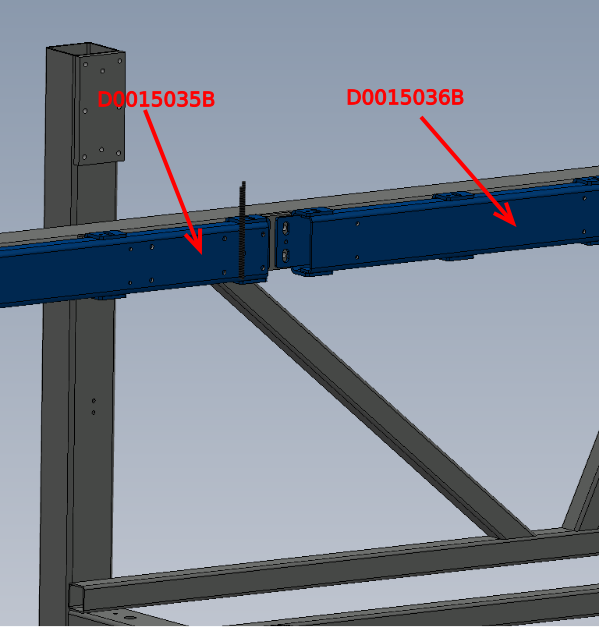

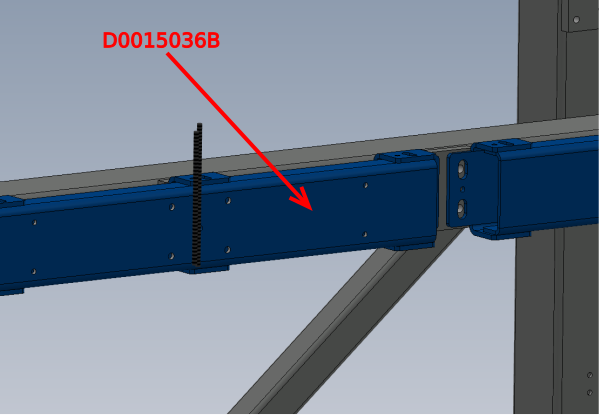

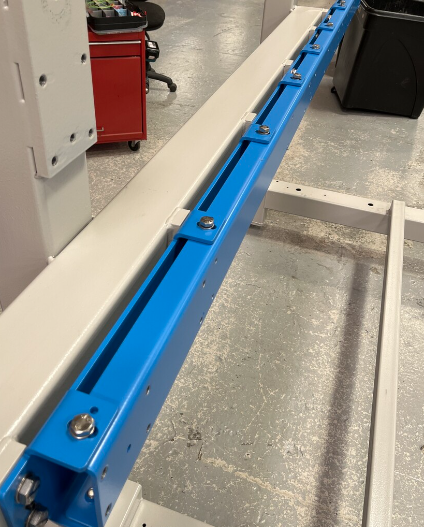

Prepare D0015035B,D0015036B and D0015037B ready for fitting.

All tapped holes require cleaning to remove any debris from coating process

Étape 9 - Mount Section

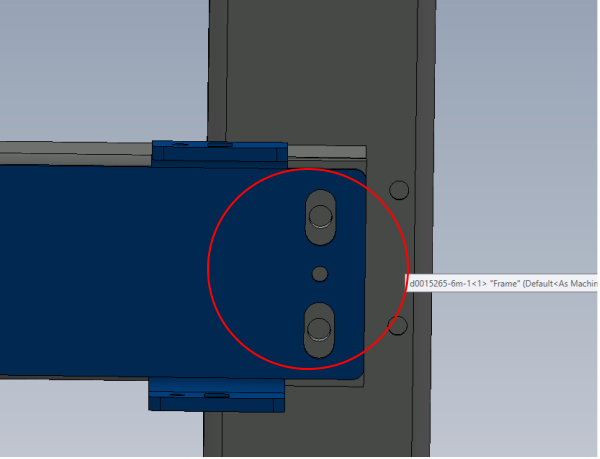

1 Mount D0015035B as shown using M10 x 20 set bolts and A form washers

2 Mount D0015036B as shown M10 x 20 set bolts and A form washers

3 Mount D0015037B as shown M10 x 20 set bolts and A form washers

4 Ensure when mounted, Middle slot position is obtained

5 Do not use Loctite 243 at this point

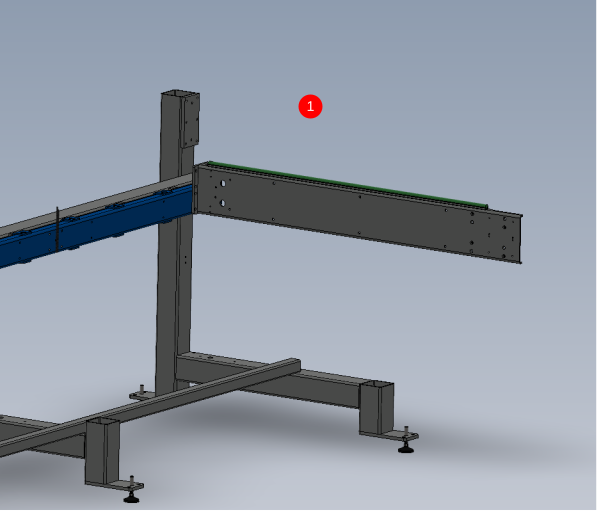

Étape 10 - Mount Pre assembled load Arm 1

1 Mount 1st Arm as shown , using pedestal stand and jack to support arm Fix with M10 x 30 socket caps and A form washers.

2 Use engineers level to adjust arm level at the indicated point

3 Use 1 meter straight edge and engineers level and adjust to level using jack

Étape 11 - Fit Pre assembled support brackets

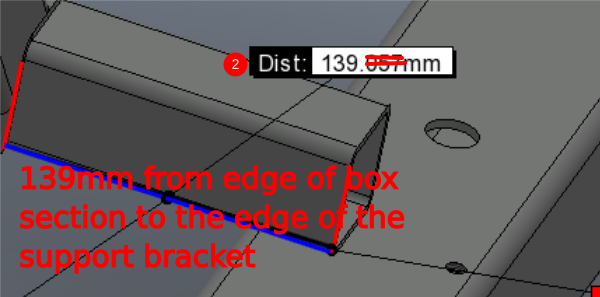

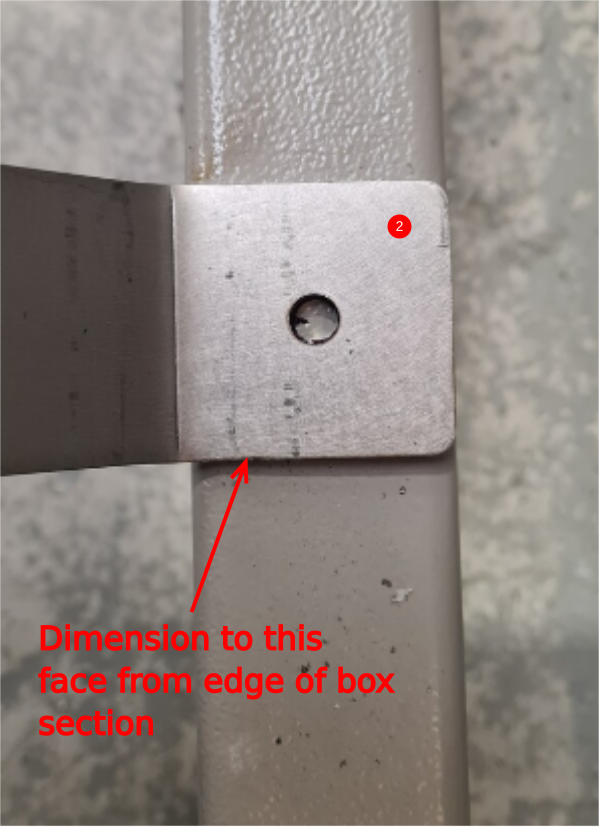

1 Mount support arm to loader arm using M8 x 30 socket cap , heavy M8 washers and M8 nyloc nut

2 Position Bottom of support bracket to dimension shown, and mark hole onto box section

3 Drill and tap hole to M6 and secure bracket with M6 x 20 socket cap and heavy M6 washer

4 Tighten 2 off M8 socket caps and nylocs on support bracket and remove jack and pedestal

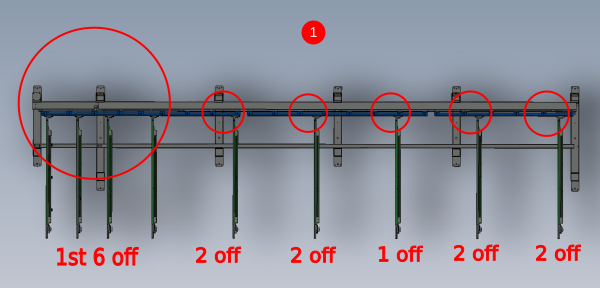

Étape 12 - Install remaining arms

1 Mount remaining 8 arms using to the same procedure .

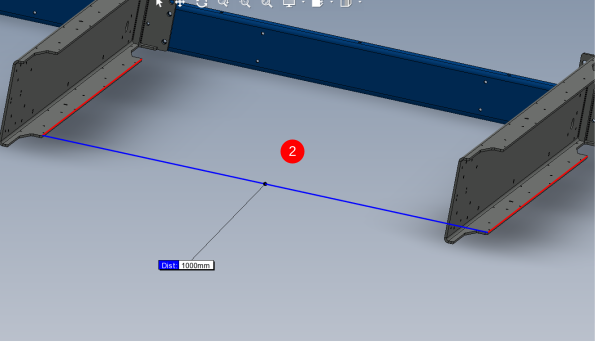

2 To determine bottom bracket drilling position, measure between each arm when fitting to calculate the pitch, and set bottom support bracket to position to replicate the top . Picture shows points to measure

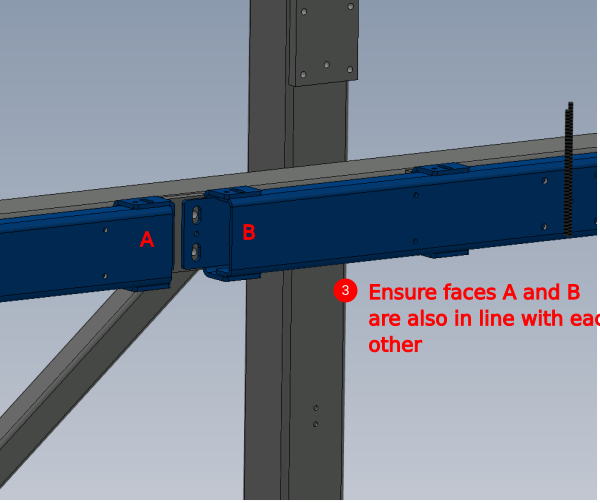

Étape 13 - Arm alignment

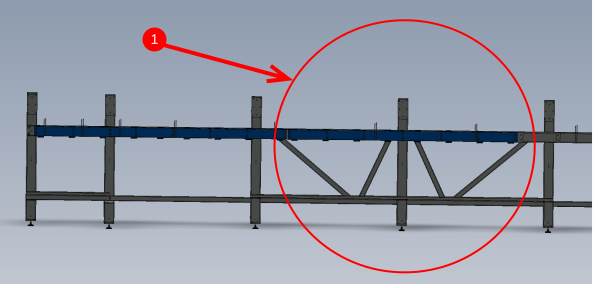

1 Set a wire line along front face of all arms

Use dokit ALIGNMENT USING WIRE LINE to ensure correct use

2 Leave arms 1 and 9 as datum positions. Do not adjust these

Move arms 2 to 8 in or out to achieve alignment on wire line

3 Ensure mounting channel joining points are also aligned to each other

4 Apply light tension to fasteners next to arms on support channel

Étape 14 - Check levels

1 Check levels as shown and adjust if required as this may have moved slightly when adjusting arm position

2 If any level adjustments are done, recheck wire line for straightness

Étape 16 - Drill and Pin 1st stage

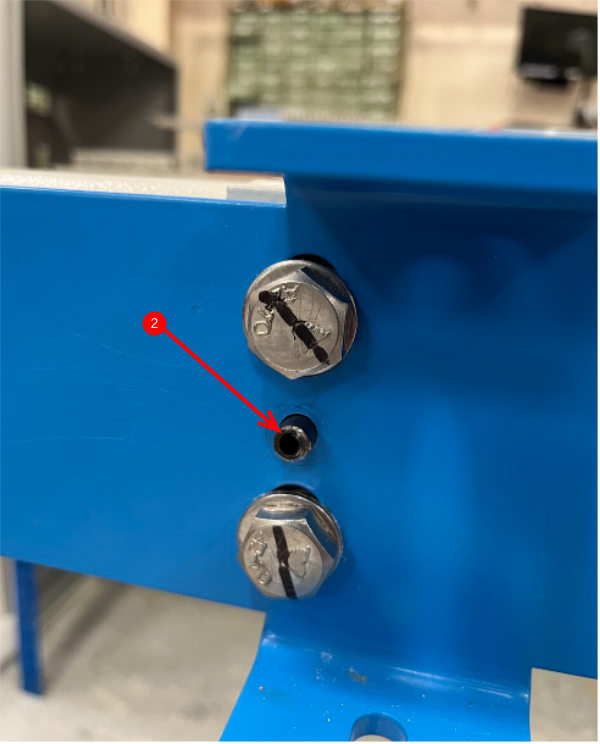

1 Drill first stage dowels above and below at points indicated to stop movement when finalising fasteners. Drill 7mm, Then increase to 8mm and then add 8mm x 24mm spirol pin . Repeat these steps at all indicated dowel points.

Étape 17 - Finalize fasteners

Remove M10 x 20 set bolts one at a time, add Loctite 243, refit, add final tension and mark . Repeat this for all M10 fasteners along aligned channels.

Étape 18 - Drill and Pin 2nd stage

Remaining dowel points can now be drilled as above, and final spiral pins added

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português