Instructions for upgrade to material loaded assembly on Ecoline load rollers

Sommaire

- 1 Introduction

- 2 Étape 1 - Remove original Assembly

- 3 Étape 2 - Remove original Assembly

- 4 Étape 3 - Remove original Assembly

- 5 Étape 4 - Disconnect Sensor Cable.

- 6 Étape 5 - Fit new Sensor

- 7 Étape 6 - Route new connection cable

- 8 Étape 7 - Connect new sensor cable

- 9 Étape 8 - Fit blower pipe

- 10 Étape 9 - Connect blower feed pipe

- 11 Étape 10 - Complete set up

- 12 Commentaires

Introduction

Upgrade of load sensor For infeed table on Ecoline machines

Component list

A0001046 P Clip 6mm Steel / Rubber Liner x 2

D0010973 Material Loaded Sensor Plate x 1

E0001104 PreMade Cable: M8 Socket 4 Way Cable 5m x 1

E0001120 Sensor: Ultrasonic M8 20-150mm x 1

M0001053 Copper Tube 6mm x 4.4mm 10m Coil x 0.3

P0000046 Fitting: 'Y' Adaptor 6mm x 1

P0000069 Tube to tube fitting 6mm x 1

P0000160 Fitting: Flow Controller In Line 6mm x 1

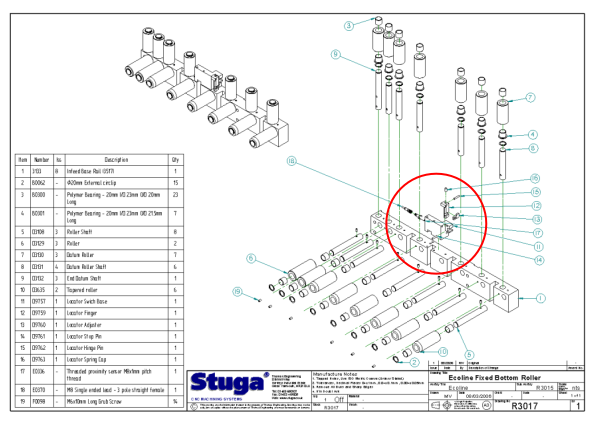

Étape 1 - Remove original Assembly

Remove old material load assembly from machine. Held on by 2 off M6 socket caps indicated

2 Disconnect switch/sensor. Depending on variant fitted

either

Unscrew M8 plug connection to disconnect for sensor style

Or

Disconnect 2 off fork connections onto rear on switch

3 Disconnect blower

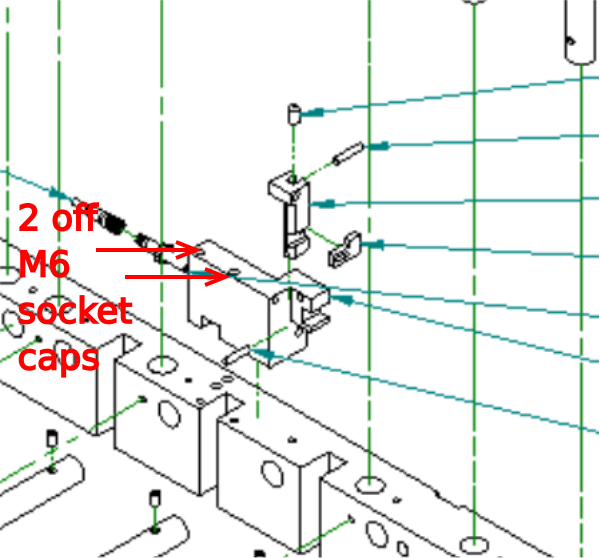

Étape 2 - Remove original Assembly

Disconnect switch/sensor.

Depending on variant fitted

either

Unscrew M8 plug connection to disconnect for sensor style

Or

Disconnect 2 off fork connections onto rear on switch

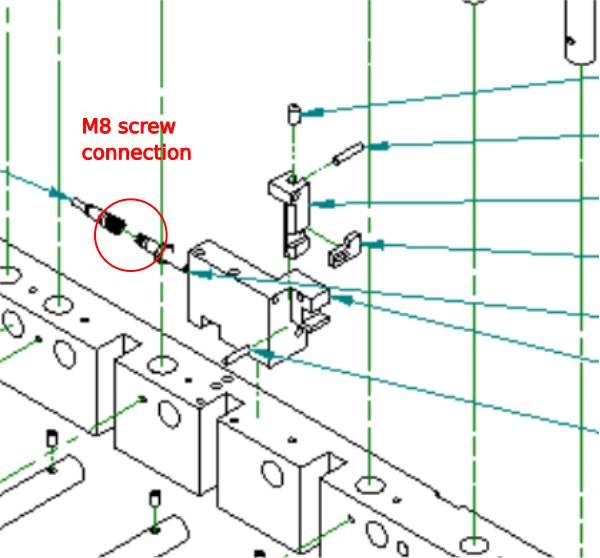

Étape 3 - Remove original Assembly

Disconnect blower feed to assembly

6mm pipe will be connected to remove assembly via push fit connections.

Remove pipe from connections

(may not be present on some machine variants )

Assembly can now be removed fully and disregarded

Étape 4 - Disconnect Sensor Cable.

Trace back cable fitted to old sensor and disconnect at connection box.

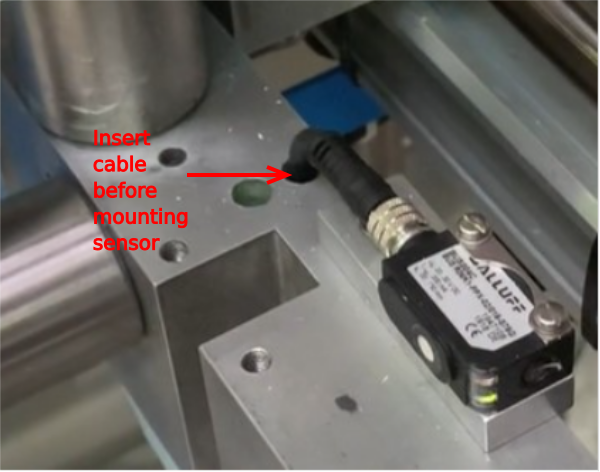

Étape 5 - Fit new Sensor

Fit new ultrasonic sensor E0001120 as shown using mounting block D0010973

Ensure cable E0001104 is fitted to sensor before mounting, and cable is fed through access point before finalising position of sensor

Étape 6 - Route new connection cable

Route new cable to connection point previously used to disconnect old sensor cable.

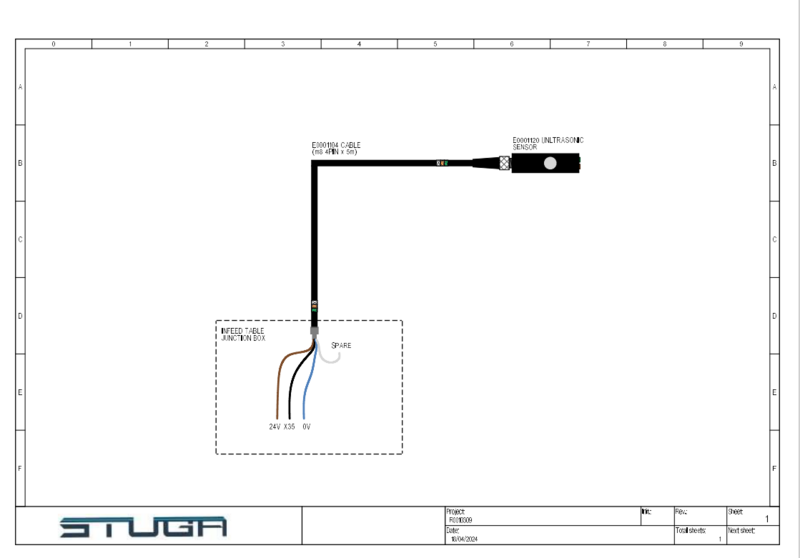

Étape 7 - Connect new sensor cable

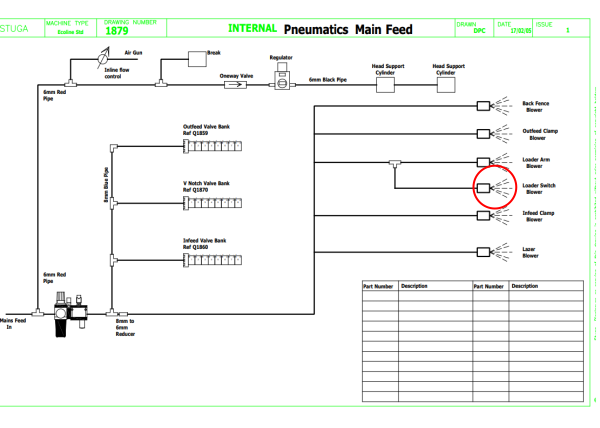

Use attached drawing to connect new sensor to terminal rail in connection box

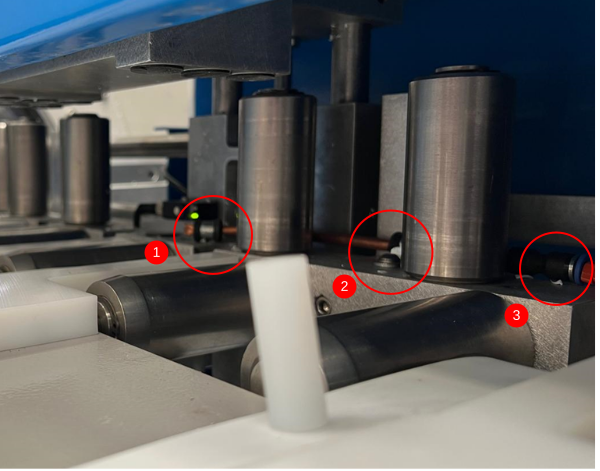

Étape 8 - Fit blower pipe

1 End of copper blower should be flattened to allow a vertical blow pattern across the front of newly fitted ultrasonic sensor

2 Use A0001046 P clips to secure blower pipe in place

3 Use P0000069 tube connection on end of copper pipe

Ensure when fitting copper pipe that no contact is made onto rotating rollers

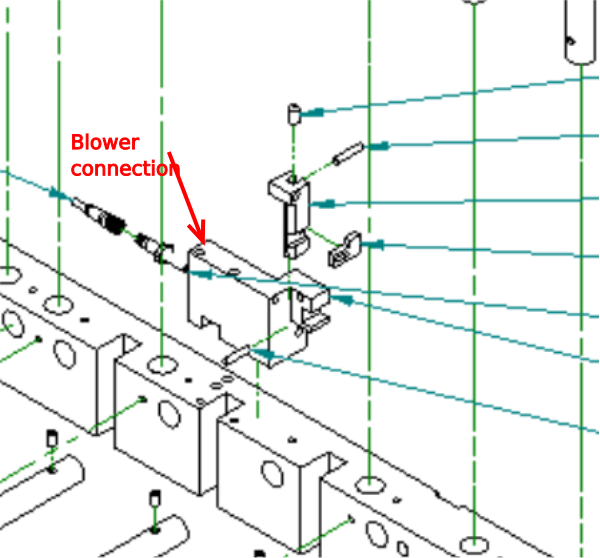

Étape 9 - Connect blower feed pipe

Use original switch assembly blower line to feed new copper blower

Add P0000160 inline flow regulator to allow correct adjustment of air flow to blower

Note, if no blower line is present for the old assembly, a blue pipe line can be used to provide a permanent feed to the blower.

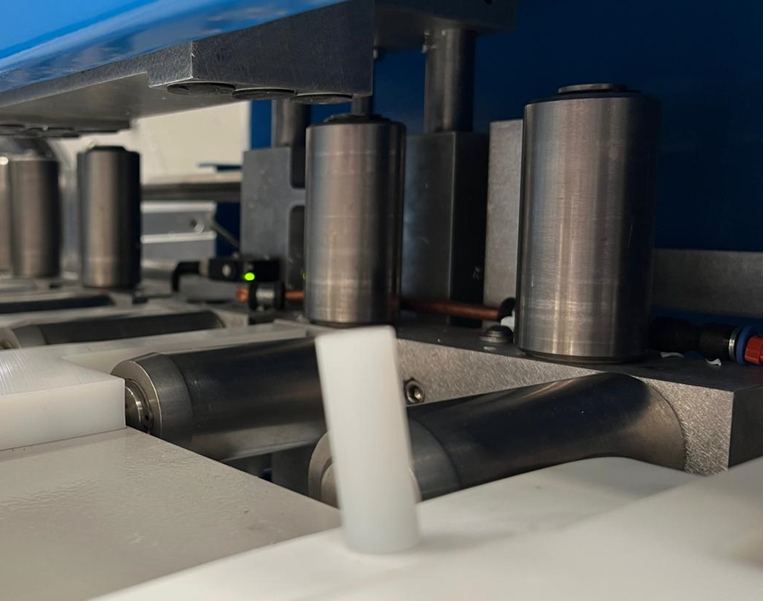

Étape 10 - Complete set up

Completed set up by following guide

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português