| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=Stage_2_spindle_assembly_Screenshot_47.png |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":... ») |

|||

| Ligne 13 : | Ligne 13 : | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Unless otherwise stated</translate> | ||

| + | |Step_Content=<translate>Use Loctite 243 on all fasteners | ||

| + | |||

| + | Pen mark bolts when finalised</translate> | ||

| + | |Step_Picture_00=R0000712E_Rotary_Trunking_Screenshot_2023-05-31_084239.png | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Mount single plunge spindle cylinder 2,4,6 and 8</translate> | |Step_Title=<translate>Mount single plunge spindle cylinder 2,4,6 and 8</translate> | ||

| Ligne 103 : | Ligne 110 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Attach single plunge motor plate</translate> | |Step_Title=<translate>Attach single plunge motor plate</translate> | ||

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>4 off |

| + | |||

| + | |||

| + | 1 Attach D0007686 motor plate to elte motor using 4 off m6 x 12 socket caps and 2 off 6mmx 20 dowels | ||

| + | |||

| + | |||

| + | 2 Attach to single spindle using 4 off m6 x 20 socket caps | ||

| + | |||

| + | Ensure that motor plate butts up to indicated part and also register is aligned as shown | ||

| + | |||

| + | <br /></translate> | ||

|Step_Picture_00=Stage_2_spindle_assembly_Screenshot_59.png | |Step_Picture_00=Stage_2_spindle_assembly_Screenshot_59.png | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":657,"height":581,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.91,"scaleY":0.91,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/7/79/Stage_2_spindle_assembly_Screenshot_59.png","filters":[]},{"type":"wfnumberedbullet","version":"2.4.6","originX":"left","originY":"top","left":283,"top":89,"width":25,"height":25,"fill":"rgb(0,0,0)","stroke":"#FF0000","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"objects":[{"type":"circle","version":"2.4.6","originX":"center","originY":"center","left":0,"top":0,"width":24,"height":24,"fill":"#FF0000","stroke":null,"strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":12,"startAngle":0,"endAngle":6.283185307179586},{"type":"text","version":"2.4.6","originX":"center","originY":"center","left":0,"top":0,"width":7.79,"height":15.82,"fill":"rgba(255,255,255,255)","stroke":null,"strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"1","fontSize":14,"fontWeight":"normal","fontFamily":"arial","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"styles":{} }],"number":1}],"height":531,"width":600} | ||

| + | |Step_Picture_01=Stage_2_spindle_assembly_Screenshot_60.png | ||

| + | |Step_Picture_02=Stage_2_spindle_assembly_Screenshot_61.png | ||

| + | |Step_Picture_03=Stage_2_spindle_assembly_Screenshot_62.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 1 juin 2023 à 14:01

2nd stage of assembly of spindle assemblies

Sommaire

- 1 Étape 1 - Unless otherwise stated

- 2 Étape 2 - Mount single plunge spindle cylinder 2,4,6 and 8

- 3 Étape 3 - Align components and set position

- 4 Étape 4 - Mount double plunge spindle cylinder 1,3,5 and 7

- 5 Étape 5 - Align components and set position

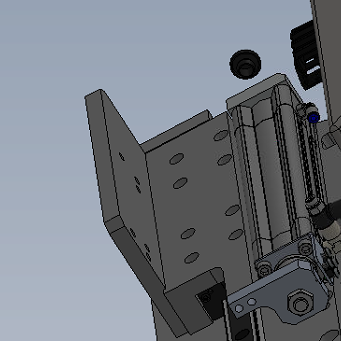

- 6 Étape 6 - Attach single plunge motor plate

- 7 Commentaires

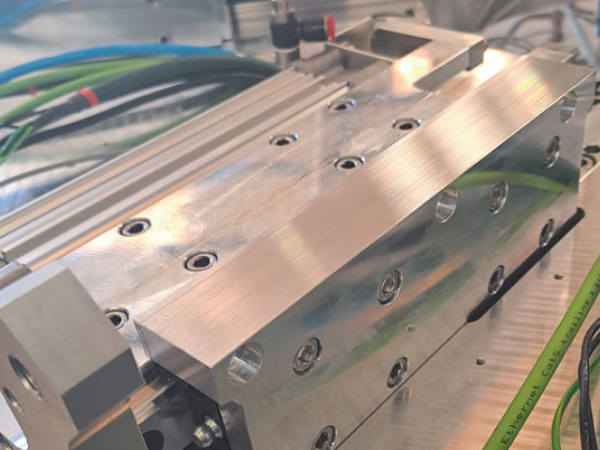

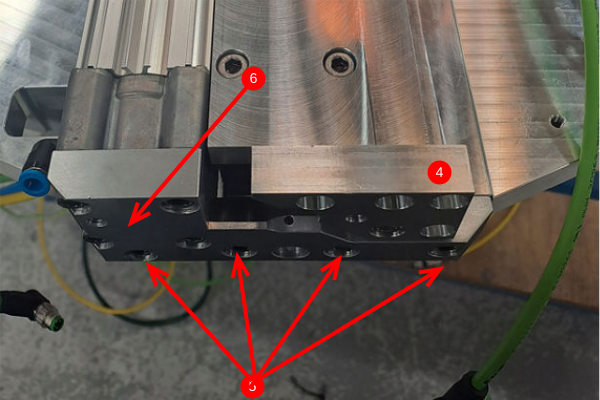

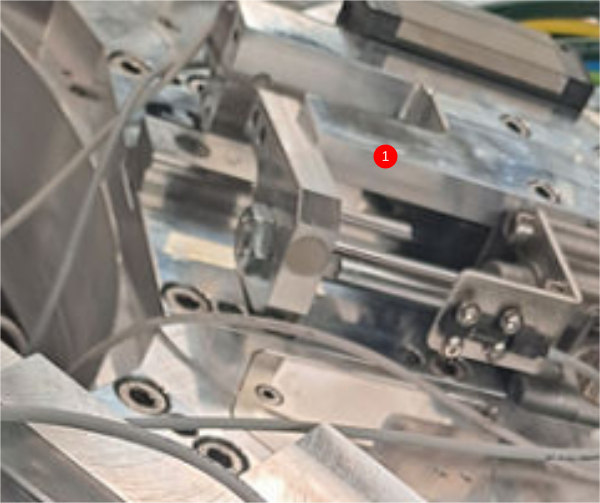

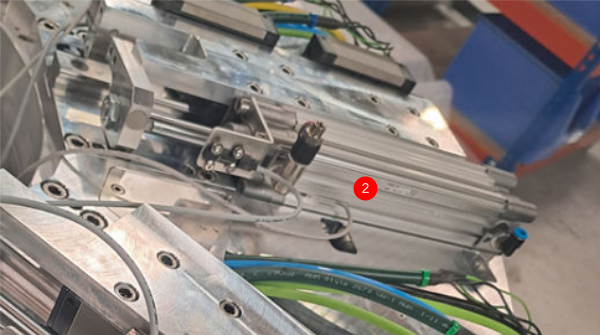

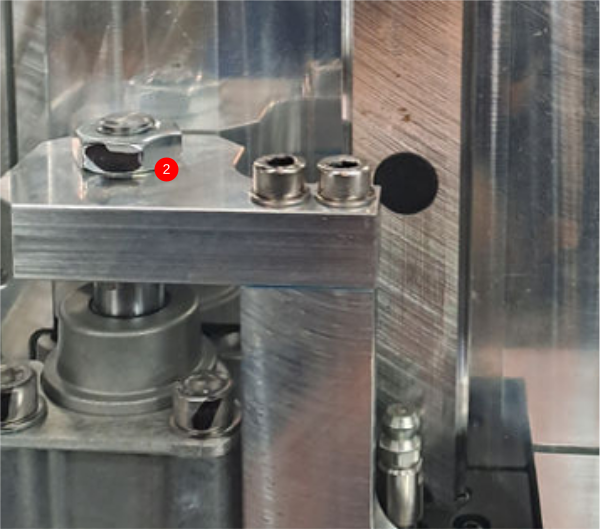

Étape 2 - Mount single plunge spindle cylinder 2,4,6 and 8

Do not add final tension to bolts until alignment has been achieved

1 Attach pre built cylinder anchor to end of cylinder

2 Position pre built cylinder on slide base assembly as shown

3 Use 2 off m5 x 25 socket caps with A form washers to attach to slide base

4 Temporarily mount D0007648 with 1 off m6 x 20 socket cap

5 Attach D0007790 cylinder anchor with 4 off M6 x 20 socket caps

6 Attach Cylinder base to anchor with 4 off M6x 20 socket caps

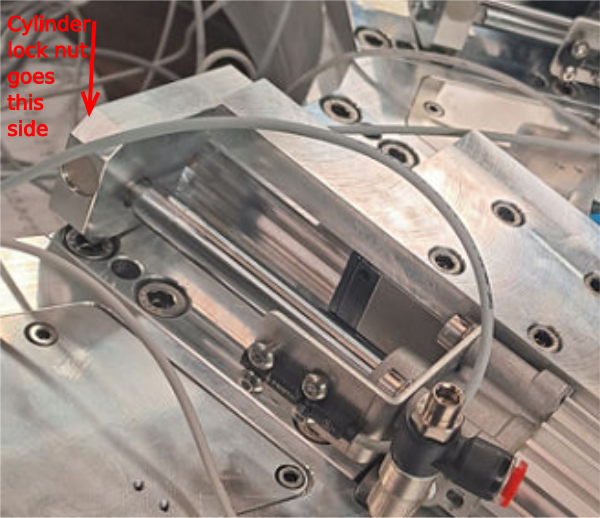

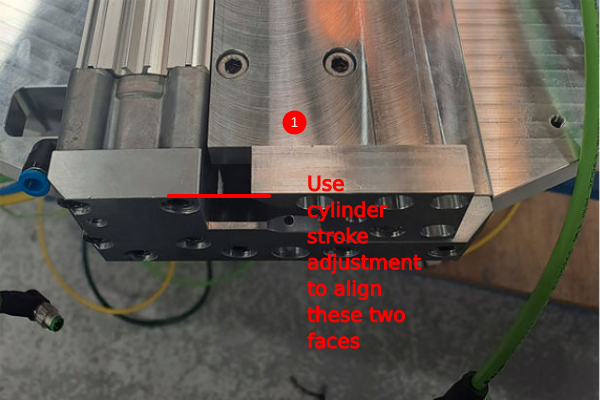

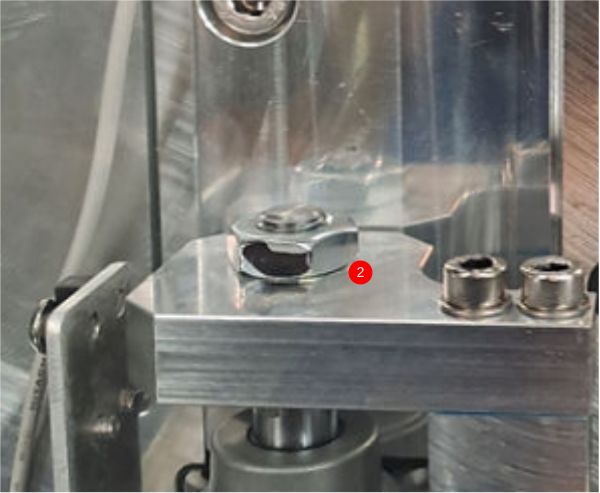

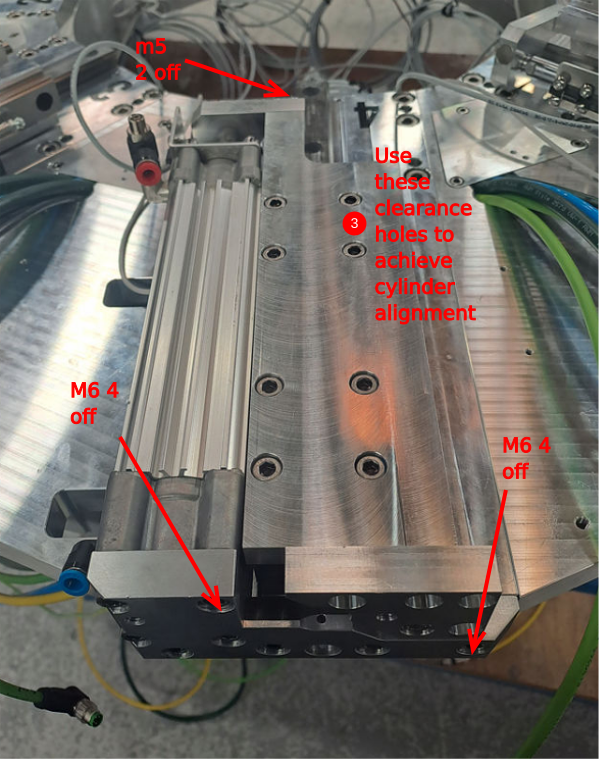

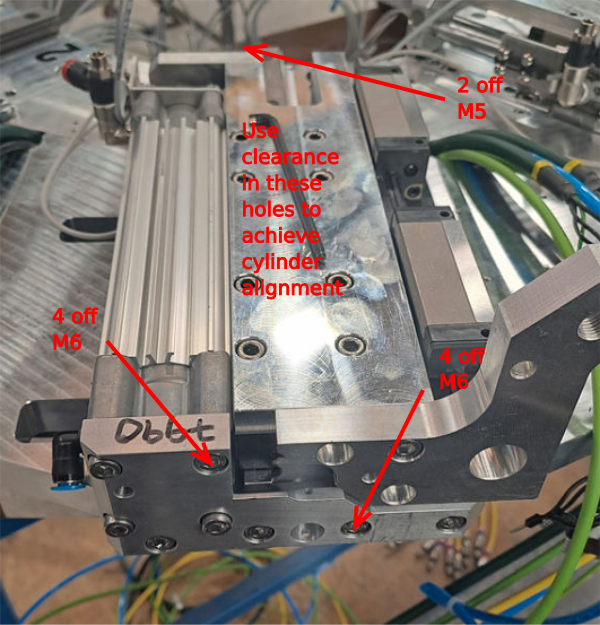

Étape 3 - Align components and set position

1 Use cylinder stroke adjustment to align these two faces

2 Apply Loctite 243 to cylinder nut and tighten

3 Use clearance in holes for mounting at points indicated to achieve cylinder alignment. Cylinder stroke should be even and free along entire stroke

4 Finalise bolts

Repeat on all four single spindles (2,4,6 and 8)

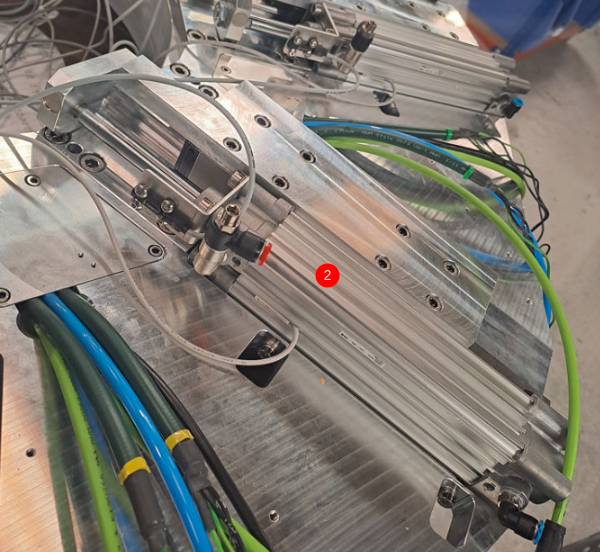

Étape 4 - Mount double plunge spindle cylinder 1,3,5 and 7

Do not add final tension to bolts until alignment has been achieved

1 Attach pre built cylinder anchor to end of cylinder

2 Position pre built cylinder on slide base assembly as shown

3 Use 2 off m5 x 25 socket caps with A form washers to attach to slide base

4 Temporarily mount D0007649 with 1 off m6 x 20 socket cap

5 Attach D0007790 cylinder anchor with 4 off M6 x 20 socket caps

6 Attach Cylinder base to anchor with 4 off M6x 20 socket caps

Étape 5 - Align components and set position

1 Use cylinder stroke adjustment to align these two faces

2 Apply Loctite 243 to cylinder nut and tighten

3 Use clearance in holes for mounting at points indicated to achieve cylinder alignment. Cylinder stroke should be even and free along entire stroke

4 Finalise bolts

Repeat on all four single spindles (1,3,5 and 7))

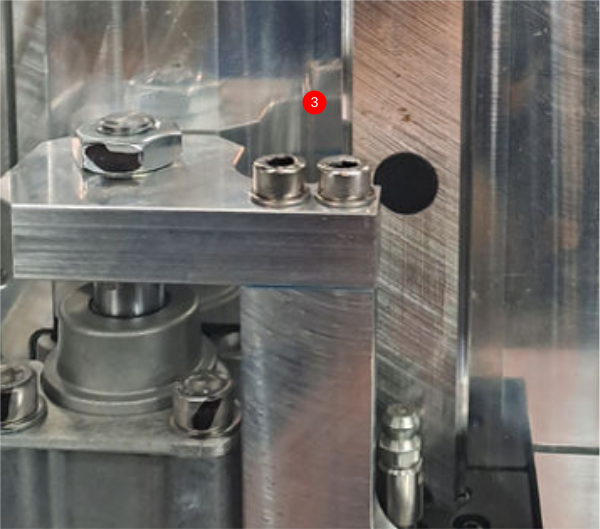

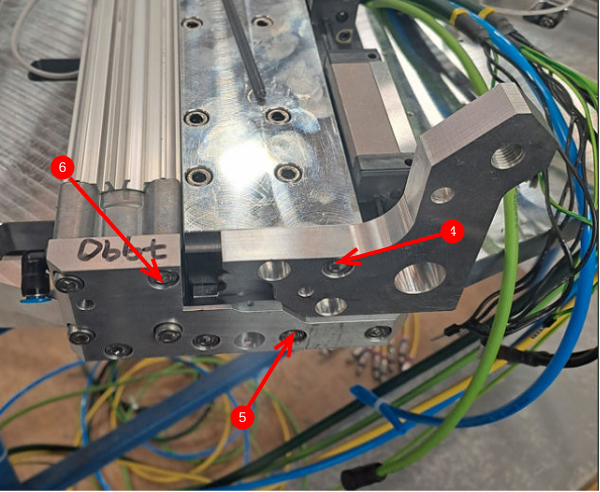

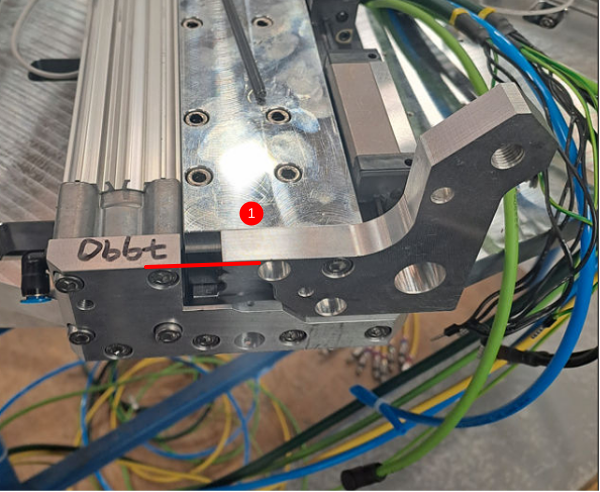

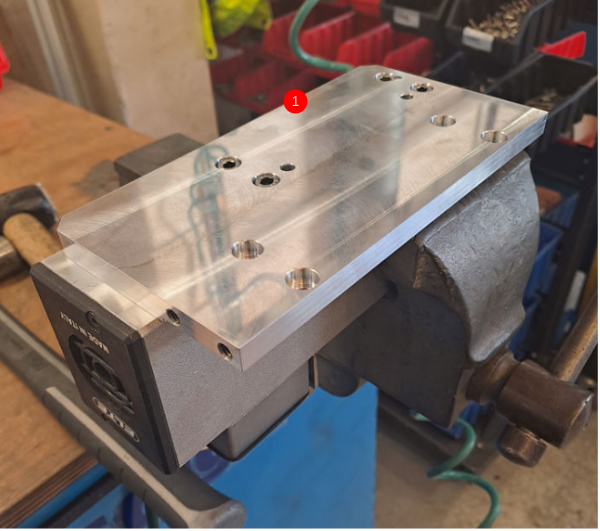

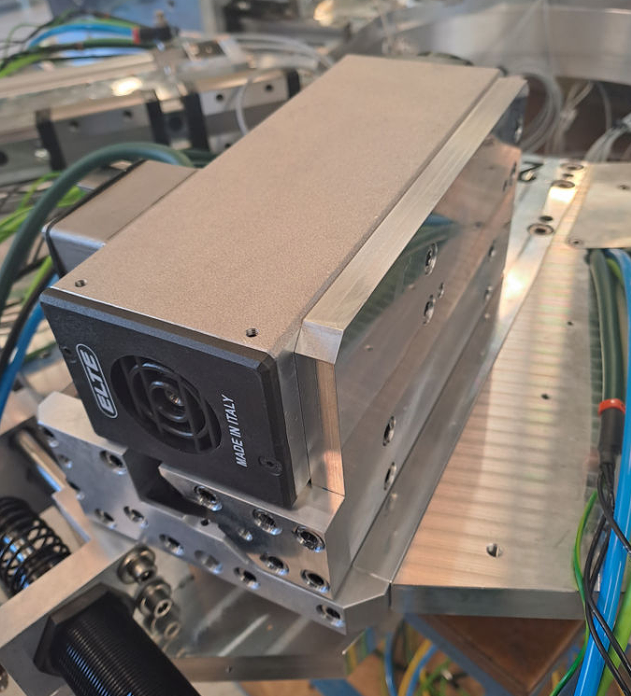

Étape 6 - Attach single plunge motor plate

4 off

1 Attach D0007686 motor plate to elte motor using 4 off m6 x 12 socket caps and 2 off 6mmx 20 dowels

2 Attach to single spindle using 4 off m6 x 20 socket caps

Ensure that motor plate butts up to indicated part and also register is aligned as shown

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português