| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 32 : | Ligne 32 : | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Test</translate> | |Step_Title=<translate>Test</translate> | ||

| − | |Step_Content=<translate> | + | |Step_Content=<translate>Adjust and slow down - Get someone to operate the Grip push output whilst you slow it down so you can see the change, an ideal speed is 1.5 seconds for it to move to full stroke when activated.</translate> |

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version actuelle datée du 7 octobre 2019 à 12:41

How to adjust the Grip Push speed on a flowline and the consequences if it is too fast

Difficulté

Facile

Durée

15 minute(s)

Introduction

There is a cylinder called Grip push, when bar is moved to its unload position the Gripper Comes OFF then Grip push is activated to push the profile of the gripper to clear ready for the Eject push onto transfer Table.

The video shows what happens if the grip push is set too fast. The speed of the cylinder is Far too Fast and is Throwing/punching back down machine. -- This needs to be slowed Down.Vimeo

Étape 1 - Adjust flow control

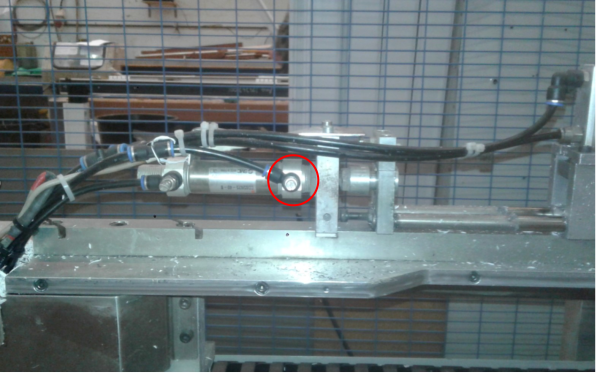

You can adjust the Flow control and Slow down the cylinder speed.

The one you need to wind IN (clockwise) to slow down is the one nearest to the MH side - Not the Extractor side.

Étape 2 - Test

Adjust and slow down - Get someone to operate the Grip push output whilst you slow it down so you can see the change, an ideal speed is 1.5 seconds for it to move to full stroke when activated.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português