Assembly instructions

Introduction

Tools Required

Standard Hex Key set

Standard spanner set

Standard screwdriver set

Bearing press

Test box for cylinder switch function

Parts Required

B0000034 Linear Bearing: Ø16 x 30 Compact (Metal Case Only) x 8

B0000236 90 Deg Grease Nipple M6 ST/ST x 4

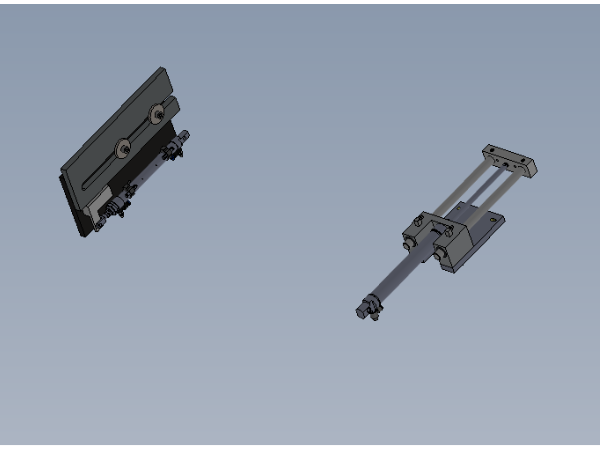

D0004311 Side Eject Block x 2

D0004591 Side Eject Housing x 2

D0004592 Eject Housing Plate x 2

D0005200 Safety Dead Stop Block x 1

D0005201 Safety Dead Stop Backer (5357) x 1

D0005202 Safety Dead stop Yoke (5358) x 1

D0005203 Safety Slider Cap x 2

H0004626 Shaft 16mm: 275 Eject Push x 4

M0000101 Compression Spring 11 D 15 D 25 Long x 1

P0000035 Cylinder 25x160 x 2

P0000174 Fitting: Plug 1/4'' BSP (Grubscrew Type x 2

P0000201 Flow Controller 6mm x M5 Elbow x 2

P0000367 16mm bore X 125 stroke with rod end clevis x 1

P0000369 Clamp to suit P0000367 x 2

P0000444 Reed Switch: Pneumax 1580U (5.0m Lead) x 2

P0001068 Valve Base: Type 41 2 Position Ø6 x 1

P0001085 Fitting: SMC 1/4" to Ø8 Swivel Elbow x 1

P0001163 1/4 bsp male silencer x 2

P0001186 Valve/ 5/2 smc x 2

P0001198 1/8 bsp 6mm speed controller x 4Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 570 on all threaded pneumatic connections

Pen mark all bolts when finalised

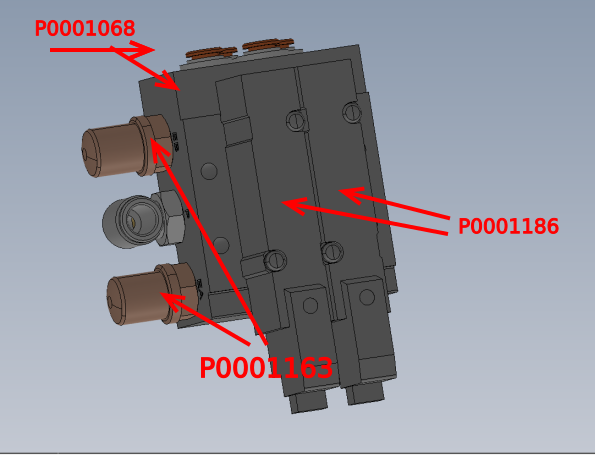

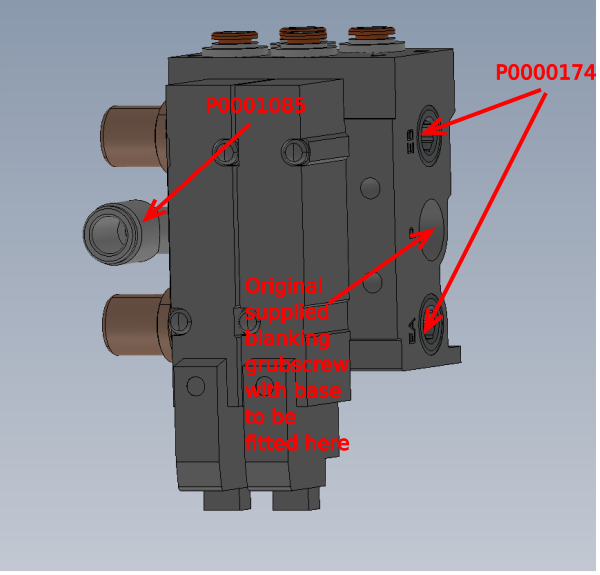

Étape 2 - Assemble Valve Bank

Assemble valve bank orientated as shown

Use parts

P0001068 Valve Base: Type 41 2 Position Ø6 x 1

P0000174 Fitting: Plug 1/4'' BSP (Grubscrew Type x 2

P0001085 Fitting: SMC 1/4" to Ø8 Swivel Elbow x 1

P0001186 Valve/ 5/2 smc x 2

P0001163 1/4 bsp male silencer x 2

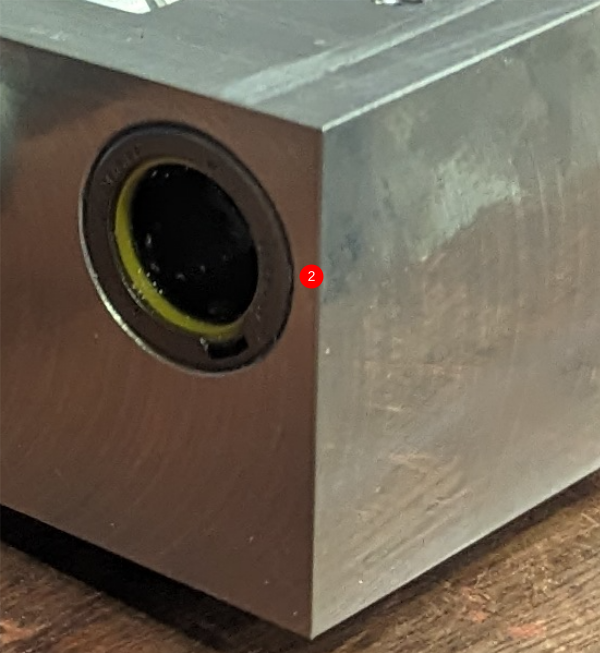

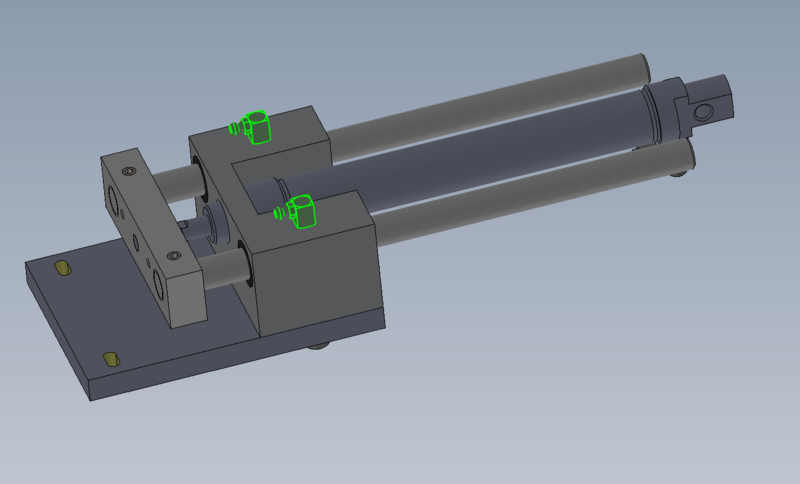

Étape 3 - Fit bearings

1 Photo required of this step please!

2 Fit B0000034 Linear Bearing 8 off into D0004591 Side Eject Housing. Ensure yellow seal of bearing faces outwards as shown

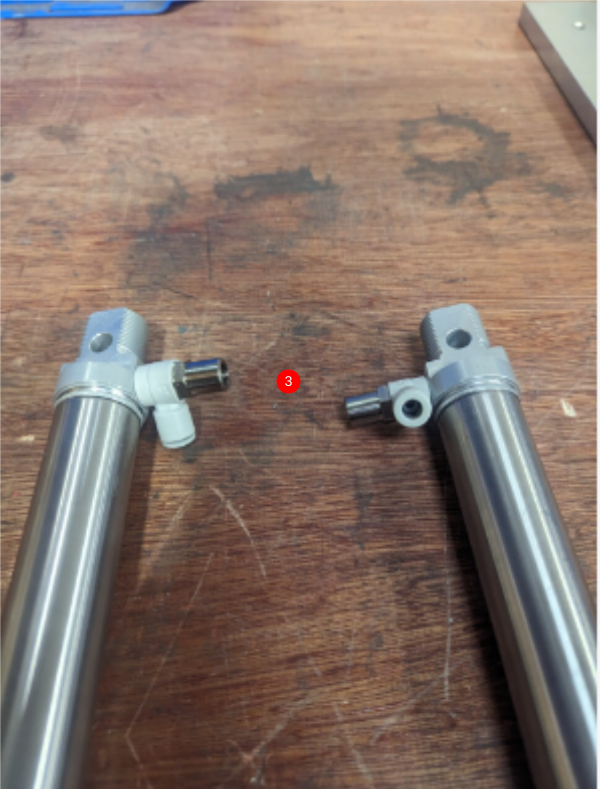

3 Attach 4 off P0001198 1/8 bsp 6mm speed controller to P0000035 Cylinder 25x160 2 off as shown

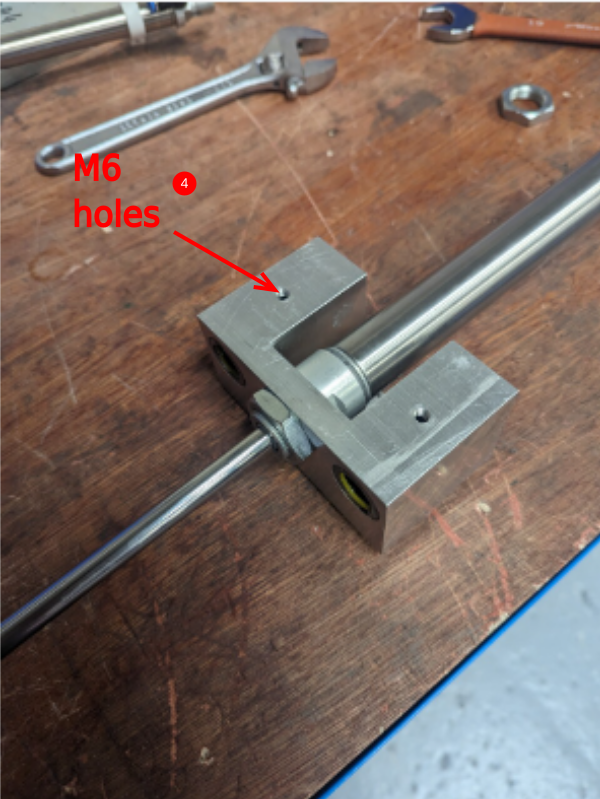

4 Fit assembled cylinder to bearing block orientated as indicated , and apply adhesive to large locking nut but do not tension

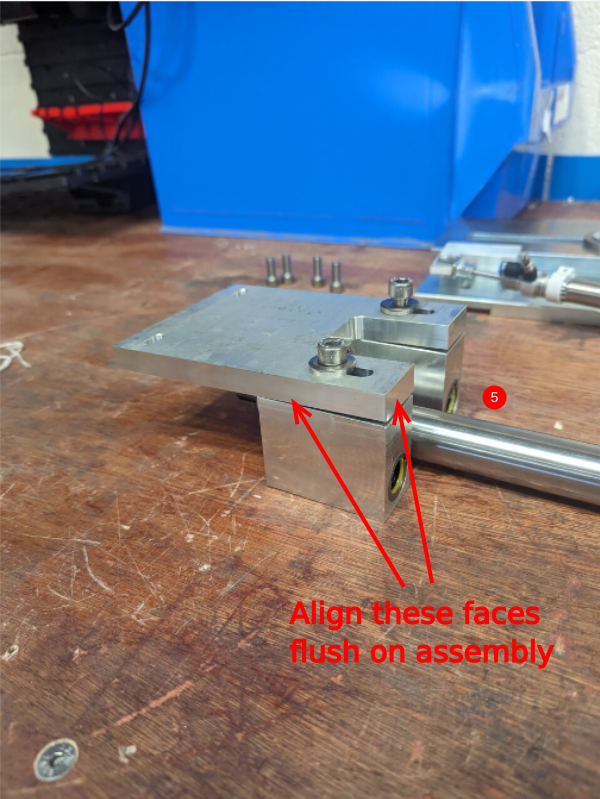

5 Fit D0004592 Eject Housing Plate and secure with M8 socket caps (size required) and Heavy M8 washers . Ensure these bolts are glued and tensioned correctly.

6 Insert 4 off H0004626 Shaft 16mm: 275 and fit 2 off D0004311 Side Eject Block orientated as shown. Wind in cylinder piston into eject block ,then Secure shafts by aligning dimples and securing with m8 x 12 kcp grubscrews

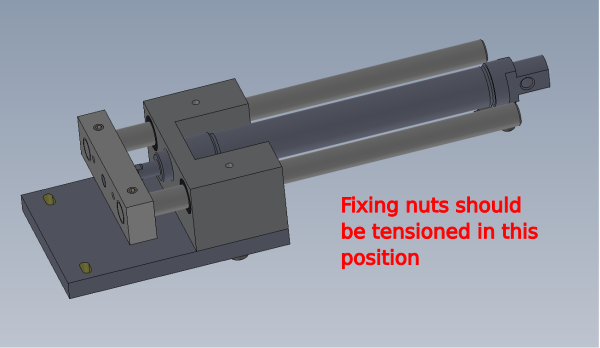

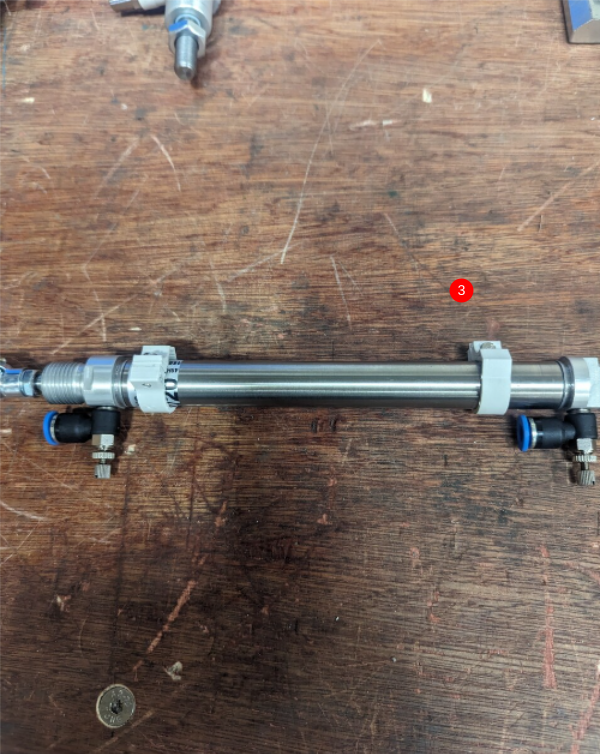

Étape 4 - Finalise cylinders

Finalise 32mm nut and 17mm nut on cylinders.

Ensure both nuts are tightened when the cylinder is the closed position, to aid alignment

To apply final tension to 32mm nut, it may be required to remove 1 off hardened shaft to allow correct access for tensioning nut

Once all fixings are tensioned correctly, cylinder stroke travel should be smooth and consistent at all points of travel. No tight spots should be present at any area.

Étape 5 - Fit grease points

Fit 4 off B0000236 90 Deg Grease Nipple M6 as indicated ( 2 per assembly)

Use grease gun to apply grease to assemblies

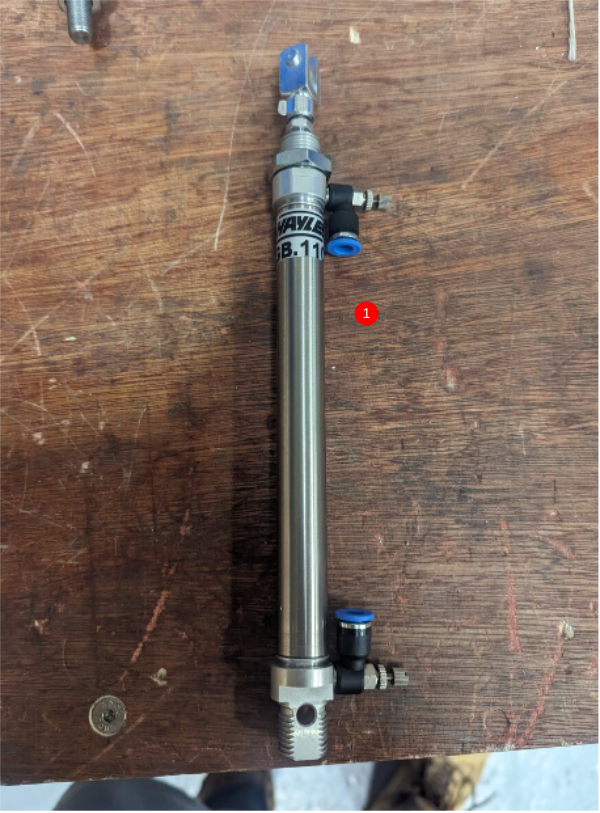

Étape 6 - Assemble Safety gate cylinder

1 Fit 2 off P0000201 Flow Controller 6mm x M5 Elbow as shown

2 Remove fixing nut shown as not required

3 Fit 2 off P0000369 reed switch clamp as shown

4 Identify using markers 2 off P0000444 reed switches as X189 and X190

5 Fit P0000444 switches as shown . X190 goes to base, X189 goes to nose of cylinder

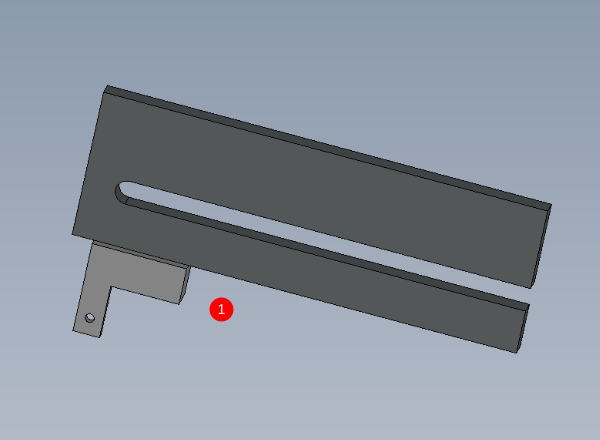

Étape 7 - Assemble safety gate

1 Attach D0005202 Safety Dead stop Yoke to D0005200 Safety Dead Stop Block as shown using M6 cap heads and A form washers (size required)

2 Attach dead stop block to D0005201 Safety Dead Stop Backer using D0005203 Safety Slider Cap 2 off. Fix as shown using M8 socket caps (size required) M8 penny washers and backed off with a M8 nyloc nut as shown

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português