As the development of uPVC systems has advanced, there is greater and greater use of pre-reinforced profile on Stuga machinery. The profile is often made of a recycled plastic and is inserted into full lengths of profile. It is fixed using a series of staples along the length. The machines were not originally designed with this in mind. We have experienced four serious issues from testing this system in the field.

Issue 1 – Steel Staples

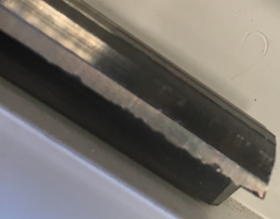

Steel staples are often used to attach the reinforcing to the profile. This creates a very big problem for the router bits and the saw blades on the machine. They are designed for uPVC profile, so when any kind of steel is encountered, no matter how small, it will damage the tooling.

This results in chipped teeth on the saw blade that cannot be repaired or re-sharpened,

and if undetected will lead to chipped profiles, accuracy problems and will permanently

destroy the saw blade.

Steel also very quickly destroys the cutting edges of expensive carbide router bits,

leading to a reduction in their performance, thereby overloading the spindle motors

and leading to premature spindle motor failure.

Aluminium staples can be used, as the cutters and blades will not be damaged.

Issue 2- Routing Speed

When routing, for example, a trickle vent, the amount of plastic that needs to be machined away is massively increased, compared to cutting the uPVC frame alone. Depending on the shape and design of the reinforcing, this can be up to 10x the material. To remove this much material, the cutting needs to be processed in more passes, meaning these operations will inevitably be much slower. This will degrade the performance of the machine, which is always specified by Stuga WITHOUT reinforcing added.

Issue 3 – Reinforcing offcuts

This issue is particularly a problem when machining a top head of a window with a trickle vent in. The trickle vent operation removes a very large section of the reinforcing, leaving a very short leftover at each end of the piece. This leftover will inevitably not be in line with a staple, so will often fall out of the end of the piece when it is sawn. This creates blockages and jams.

Issue 4 – What is it made of?

The machine is designed and specified around cutting uPVC. Often it is not clear what the reinforcing material is made from. Stuga have been told that the recycling process often includes “sweepings”, therefore the profile can often contain:

- Rubber

- Steel reinforcing swarf from old windows

- Reinforcing screw fragments

- Glass fragments

- Any other rubbish

Obviously, these materials will have a further damaging effect on the tooling. Stuga has also witnessed premature wear to many of the important bearing components. It is impossible to define and specify the effect of this when the material used in the reinforcing profile is unspecified by the profile company.

Issue 5 - Staple Position and Short Lengths

If the staple position and frequency does not fall in the correct place, shorter pieces may not have any staples in them. This could lead to the reinforcing falling out or moving during cutting

Advice

In general, the Stuga machines are capable of cutting pre-inserted plastic reinforcing, but the end user must be aware of the above issues that are not covered by the warranty.

- Aluminium staples should ALWAYS be used instead of steel

- Check with your profile supplier what material is used in the reinforcing profile and how “clean” is it?

- It is inevitable that some machining operations (e.g trickle vents and espags) will be slower than “unreinforced” profile, hence the actual output cycle time will be slower than the quoted Stuga figure.

- Be prepared that cutters, saw blades and bearing surfaces will wear out more quickly and need to be checked regularly. Worn tooling causes:

- Profile chipping

- Accuracy issues

- Premature spindle motor overload / failure

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português