Instructions for mounting and aligning hepco x axis beam

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Additional spacer

- 4 Étape 3 - Attach Setting jigs

- 5 Étape 4 - Level Setting Jigs

- 6 Étape 5 - Level x axis between jigs

- 7 Étape 6 - Wire line for setting straightness

- 8 Étape 7 - Quality Check

- 9 Étape 8 - Position Hepco double edge slide

- 10 Étape 9 - Mechanically join Hepco beam

- 11 Étape 10 - Set beam position

- 12 Étape 11 -

- 13 Étape 12 -

- 14 Commentaires

Introduction

Tools Required

Engineers level

Hepco flat spanner

Hepco Box spanner

Standard hex key set

Incremental shim pack

Parts Required

B0000046 Slide Base Bearing Block (Straight Grease Nipple) x 6

B0000184 Journal Cap Seal 34 x 4

B0000185 Double Row Long Stud Journal Eccentric x 2

B0000186 Double Row Long Stud Journal Concentric x 2

B0000234 Straight Grease Nipple M6 ST/ST x 6

B0001006 Linear rail 25mm x 820mm x 6

B0001102 Double edge spacer slide and beam 7600mm x 1

D0015072 Carriage Plate x 1

D0015492 Vertical Beam Adjustment Plate x 5

D0015493 Lateral Beam Adjustment Plate x 5

P0000200 Elbow Adaptor 6mm - M5 x 1Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 570 on all threaded pneumatic connections

Pen mark all bolts once finalised

Étape 2 - Additional spacer

Ensure additional spacer is removed from jigs when using for alignment on module C

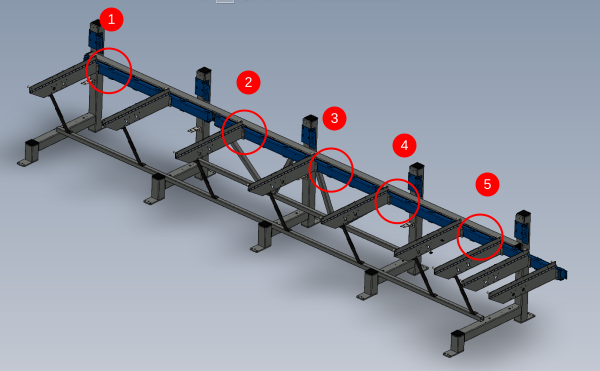

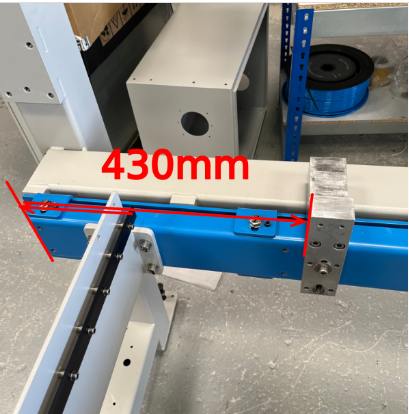

Étape 3 - Attach Setting jigs

Mount setting jigs to channel section in positions shown using M8 cap head bolts and heavy washers

Position one shown will require fixing points drilling to channel section . Drill M8 and position to measurement shown of 430mm

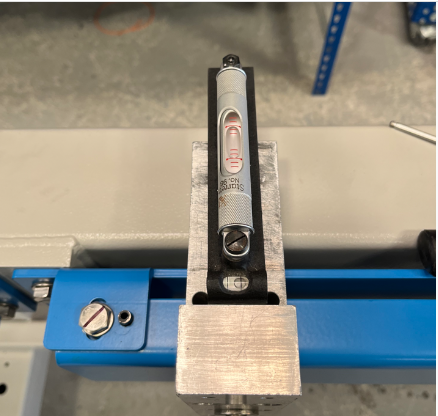

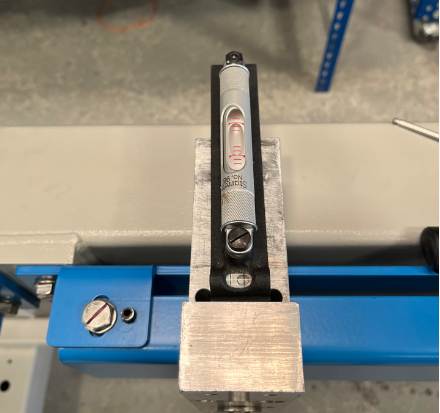

Étape 4 - Level Setting Jigs

Use an engineers level to individually adjust each jig to be level on both axis

Étape 5 - Level x axis between jigs

Using a 2 meter straight edge , the jigs should be levelled to each other as shown.

Identify which Jig is the lowest point by using the straight edge and level . Adjust the lower height jigs to match the highest point one. This is to ensure that the height is maintained as much as possible between blue mounting bar and jig top face

When a jig is adjusted for height, i will need rechecking to see if the other previous levelled plains have moved. If so, re adjust to bring jig level in all axis

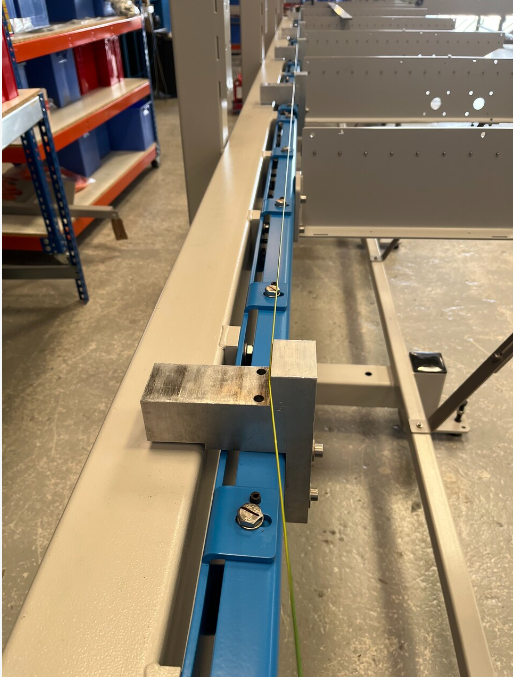

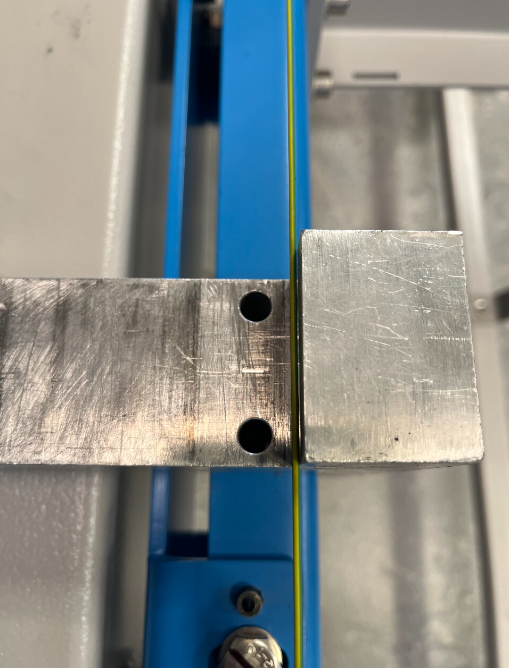

Étape 6 - Wire line for setting straightness

A wire line should be used for setting the straightness of the jigs along the x axis

Use dokit Alignment guide using wire line for correct process to set up

Étape 7 - Quality Check

Qc Double check required at this point from Supervisor that all alignment is correct.

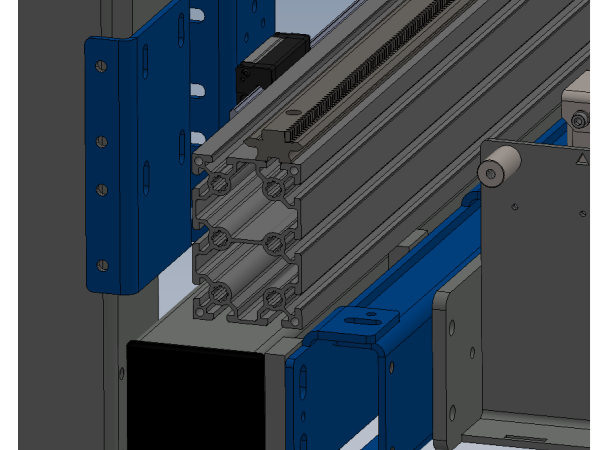

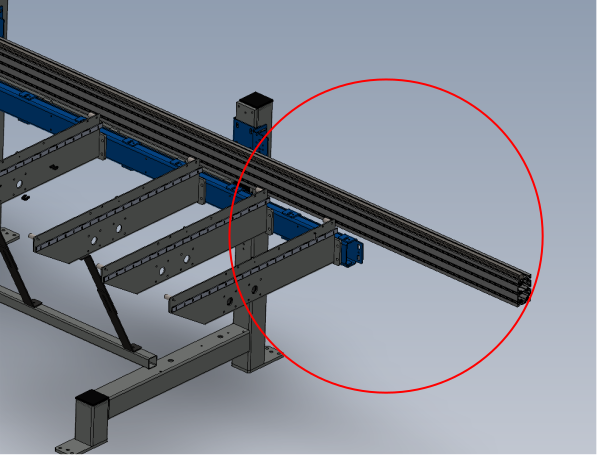

Étape 8 - Position Hepco double edge slide

B0001102 can now be assembled on jigs .

These beams are paired so check you have been issued a set correctly

Pairs can be identified as follows

1 and 1

2 and 2

A and A

B and B

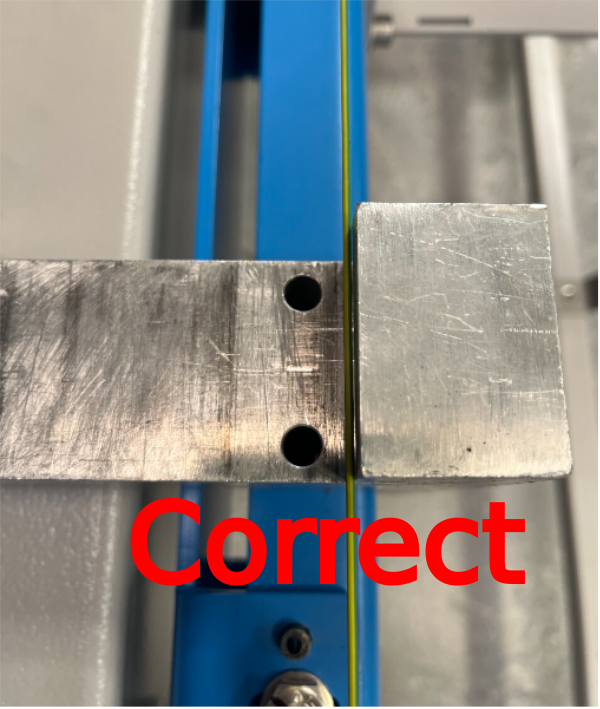

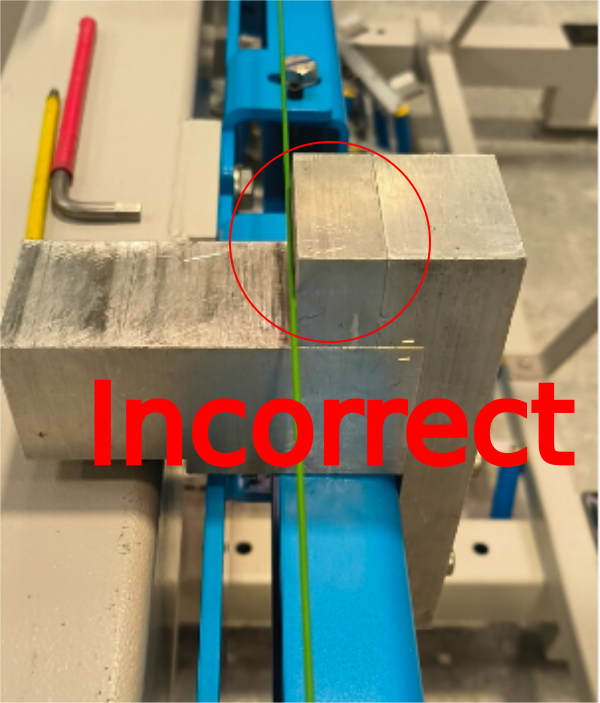

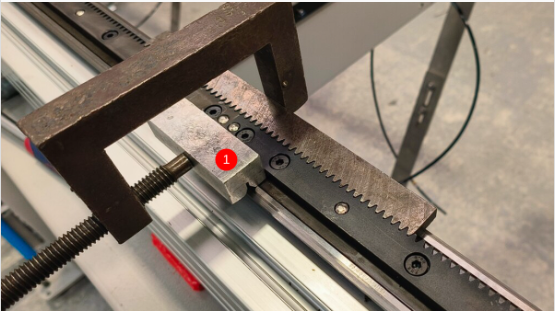

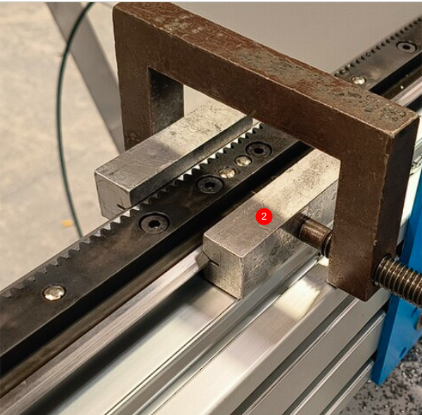

Étape 9 - Mechanically join Hepco beam

1 Use jig shown to ensure correct pitching of 2 sections of drive rail when coupled together

2 Use v blocks to ensure alignment of V's on hepco rail are correct when mating the two parts

3 Position and tighten the joining bars between the two sections (picture required)

Étape 11 -

Étape 12 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português