Build instructions for stage one assembly of spindle heads

Sommaire

- 1 Étape 1 - Fit Linear rails

- 2 Étape 2 - Position and finalise rails

- 3 Étape 3 - Fit Blanking caps B0000173

- 4 Étape 4 - Prepare bearing blocks

- 5 Étape 5 - Position bearing blocks onto rails

- 6 Étape 6 - Fit greasing points

- 7 Étape 7 - Fit 2nd linear rails

- 8 Étape 8 - Adjust bearings and add grease points

- 9 Étape 9 -

- 10 Commentaires

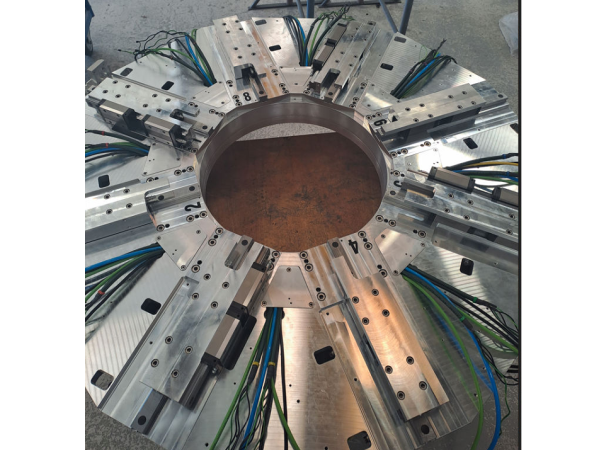

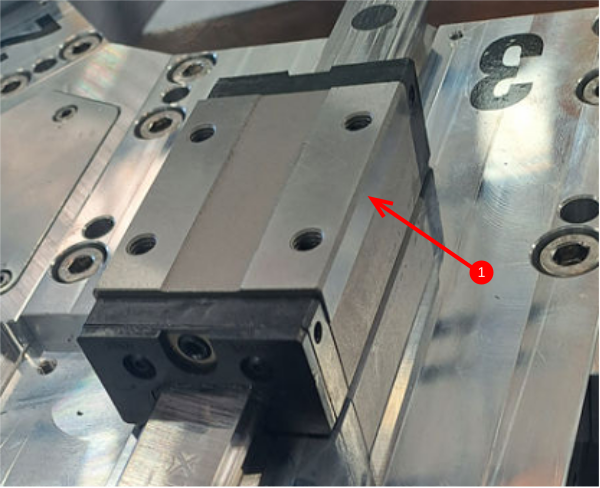

Étape 1 - Fit Linear rails

Linear rail B0000045 needs fitting to each spindle base

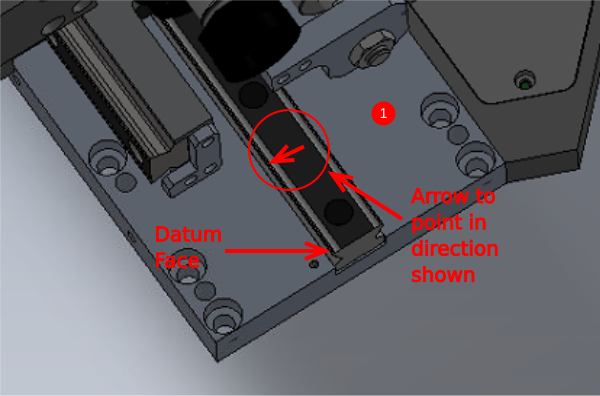

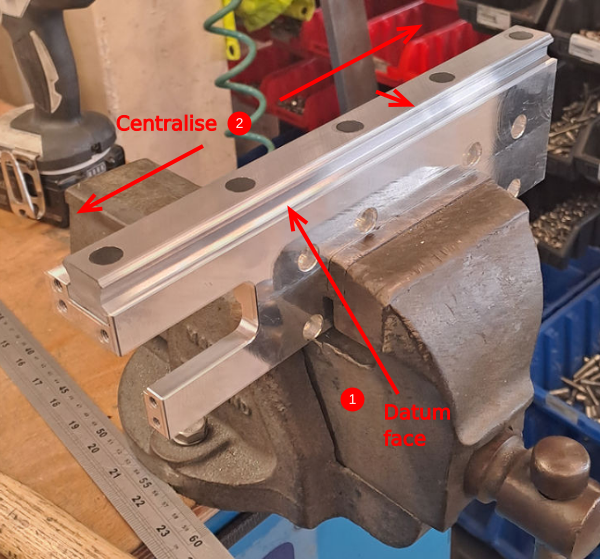

1 Orientation of Datum face is as shown

Ensure all linear rails and machined grooves in spindle plates are free from debris. Use compressed air.

2 Insert linear rail into each spindle base and drop in m6 x 20 socket caps with adhesive applied into all rail counterbores, do not screw in

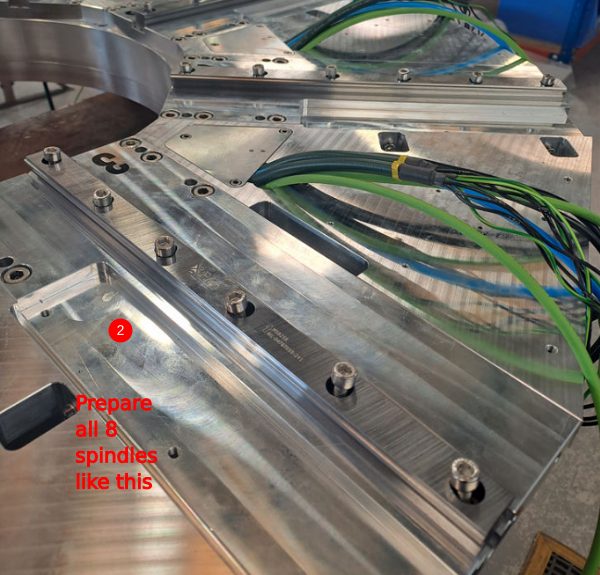

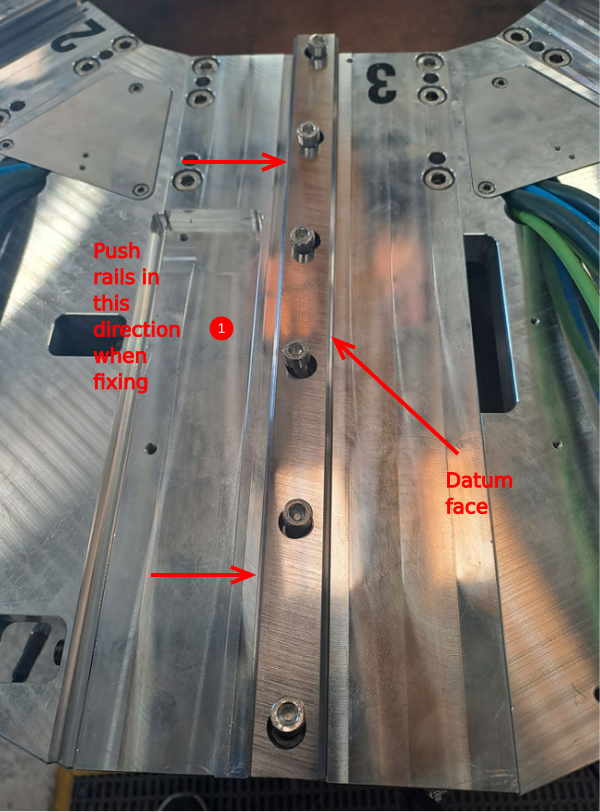

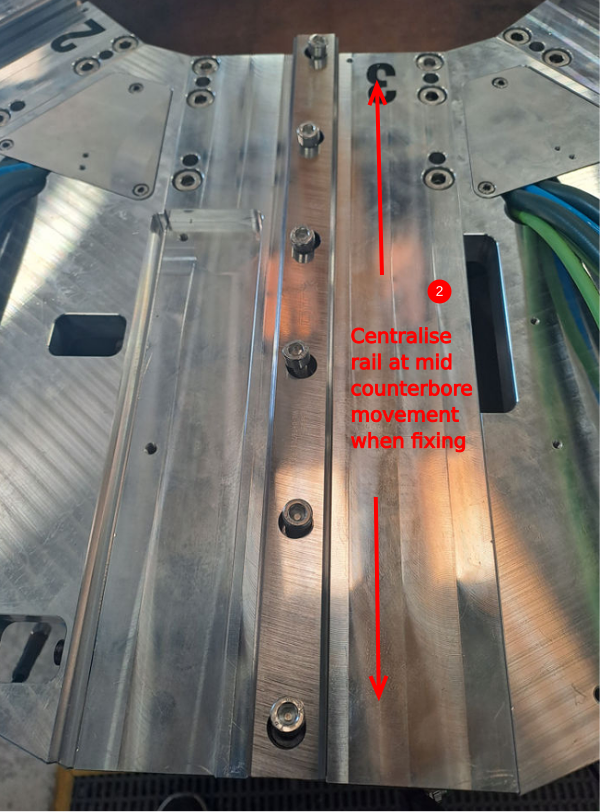

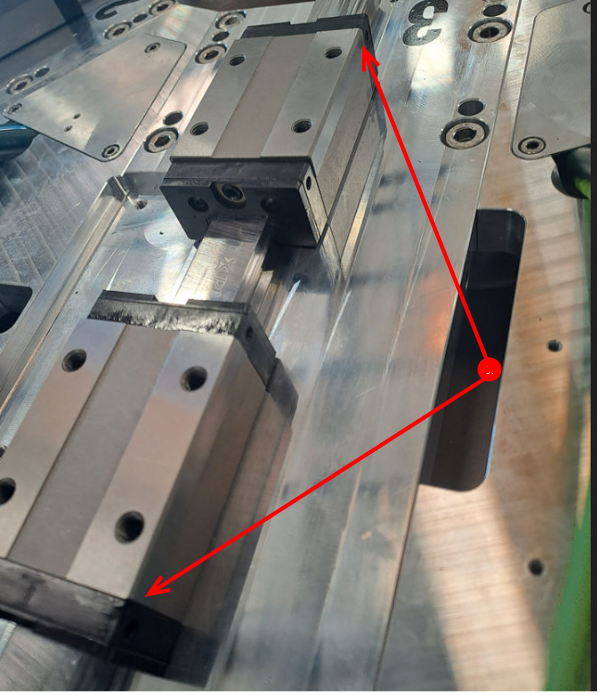

Étape 2 - Position and finalise rails

When finalising rails , the following should be observed

1 Rails should be pushed against this face when fixing, to ensure consistent positioning between spindles

2 Rails should be centralised in this direction , due to the clearance in the counterbores

3 Use a drill driver @ 15 torque and 5mm hex bit to drive in m6 cap heads on all spindles

4 Use hex key to apply final tension to m6 bolts on all spindles

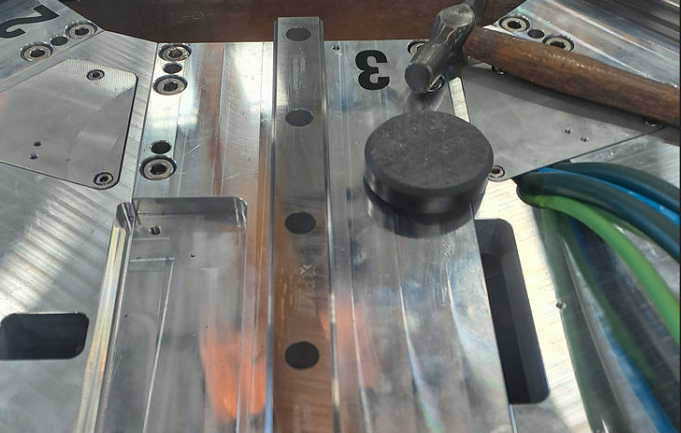

Étape 3 - Fit Blanking caps B0000173

Fit blanking caps to all rails fitted . It is vital rail caps are fitted flush to allow bearing seals to work correctly.

Use a nylon block as a dolly to ensure caps are driven in flush but no damage is possible to linear rail.

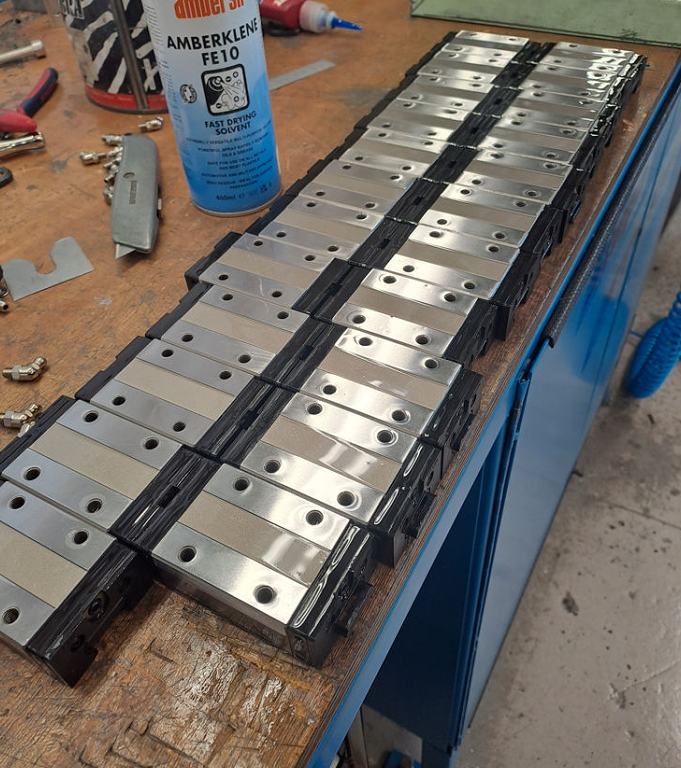

Étape 4 - Prepare bearing blocks

Bearing blocks B0000046 must be prepared for installation . They must be de greased to ensure loctite 243 activates correctly

1 Lay out all 24 bearing blocks as shown and use Fe10 solvent and spray entire top face of lined up bearings, ensuring solvent floods into top facing m6 holes.

2 use compressed air to remove solvent from bearing blocks and tapped holes. 3 Wipe remaining solvent from bearing with clean rag

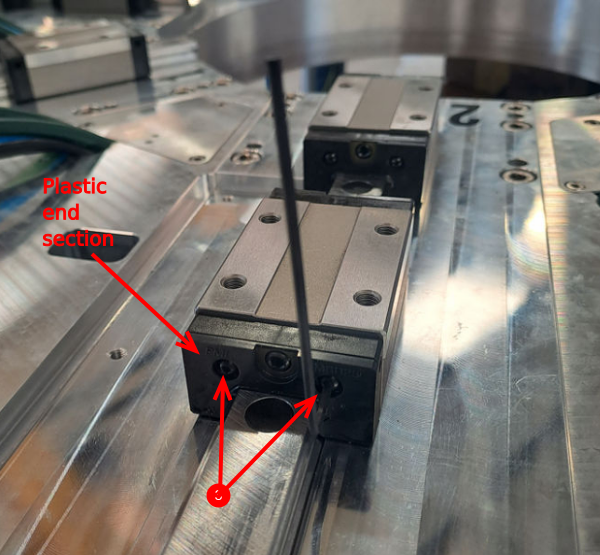

Étape 5 - Position bearing blocks onto rails

1 Datum faces of bearings must be observed and installed correctly

Bearing will only have one side that has a machined datum face. It is vital this is orientated correctly when adding bearings to the linear rails

2 Fit 16 bearing to rails as shown

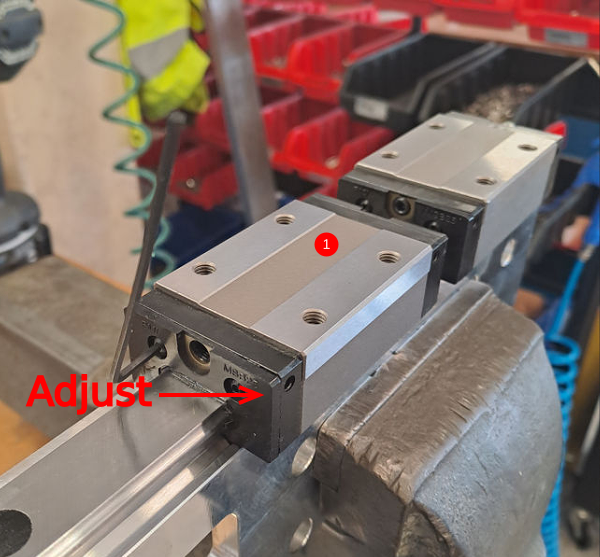

3 Adjust bearing seals to suit rail. release tension on indicated 2 bolts until end plastic section can move

4 Move bearing up and down on rail

5 Re tension 2 bolts

6 Repeat on other end of bearing

This should be done to all bearings fitted

Étape 6 - Fit greasing points

1 Fit 12 off B0000223 m6 x 0.75 grease nipples to D0007816 as shown

2 Remove grubscrew from greasing point at indicated points

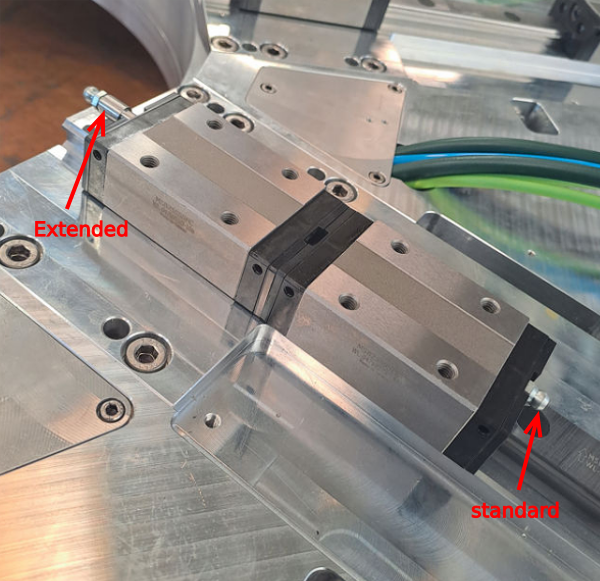

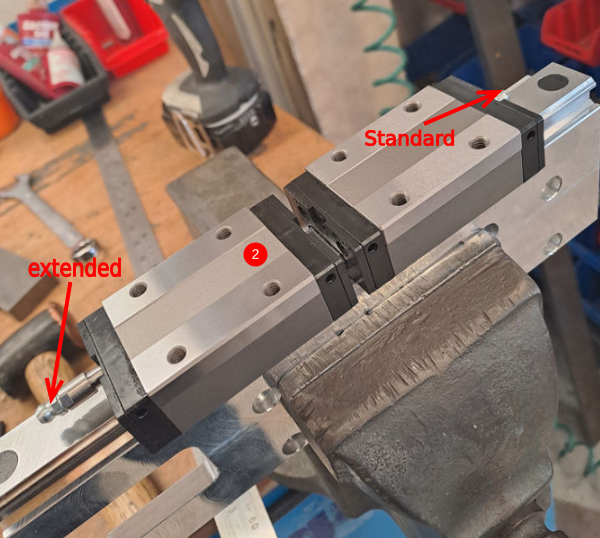

3 Fit one extended grease nipple and one standard nipple as shown to all 8 spindles

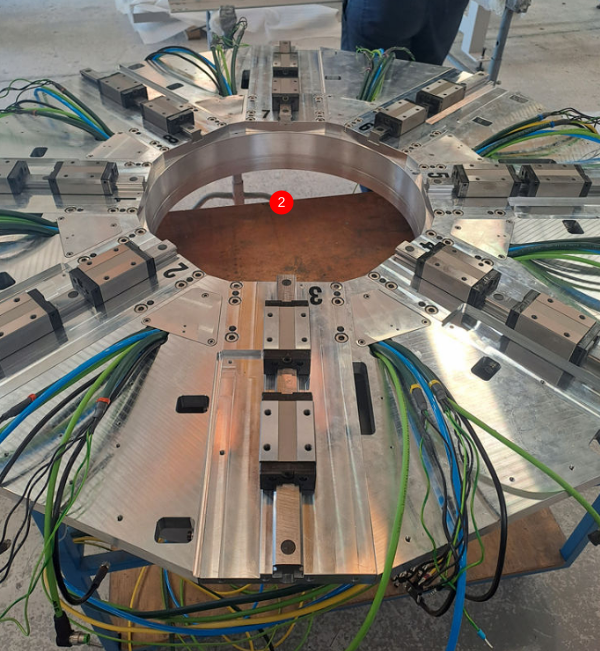

Étape 7 - Fit 2nd linear rails

4 off

Fit linear rail B0000044 to double slide base D0007724 with m6 x 20 socket caps

1 ensure rail datum is orientated correctly

2 ensure linear rail is centralised

3 Add b0000173 caps once finalised

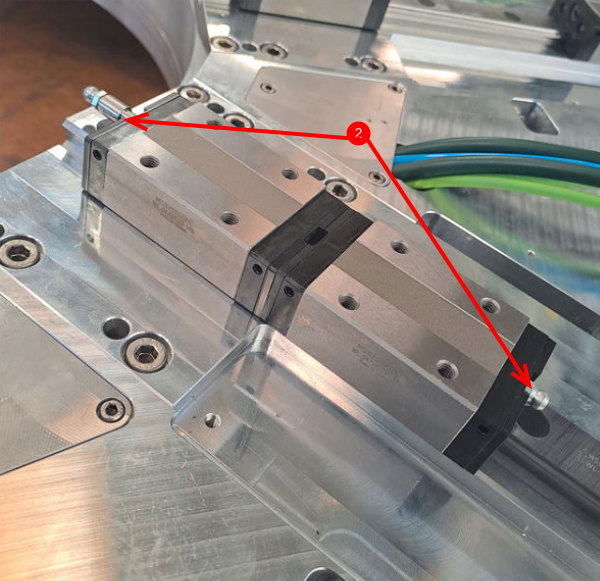

Étape 8 - Adjust bearings and add grease points

4 off

1 Follow 5.3 for adjustment details

2 Fit grease nipples to bearing blocks as shown

Étape 9 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português