Instructions for correct assembly of Notching gearboxes

Introduction

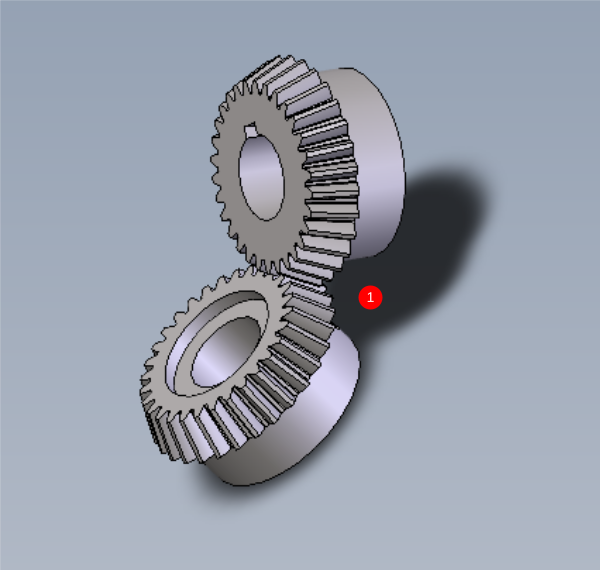

Étape 1 - Q/C Bevel Gears

1 Supplied drive gears should be inspected for the following

- Evidence of damage to drive gear teeth, such as burrs or impact points.

- Cleanliness check. There should be no contaminants on the gears

Report any damage to gears through NCR system to log and retrieve replacement gears

Any rust/ surface contaminate should be removed with a wire brush

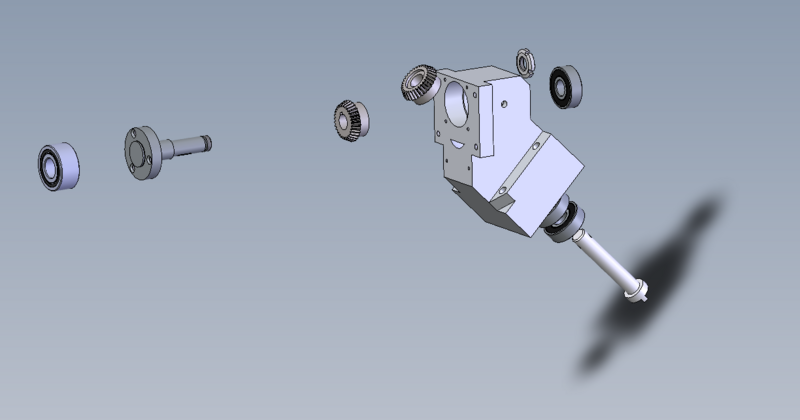

Étape 2 - Q/C Hardened parts for contaminates

Drive shafts should be inspected for the following

1 Damage to indicated thread

2 Presence of burrs on roll pin hole

3 Contaminates from hardening

Damage to thread should be reported by NCR system and replacement sourced

Burrs should be removed by file

Contaminates should be removed with Scotch brite pad

Étape 3 - Degreasing of components

It is vital for correct function that all the shown components are thoroughly degreased before assembly .

To do this, wash all parts with FE10 solvent spray and dry with airline.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português