How to create a new TwinCAT3 Project from scratch

Sommaire

- 1 Introduction

- 2 Étape 1 - Install Visual Studio / TwinCAT XAE Shell (if required)

- 3 Étape 2 - Add the latest Device Description Table

- 4 Étape 3 - Add Drive Manager 2 for AX8000 drives (if not installed already)

- 5 Étape 4 - Start a new project

- 6 Étape 5 - Clone the Repository

- 7 Étape 6 - Enter Git Credentials (if required)

- 8 Étape 7 - Add The tc3Multi then PLC_Reset Project

- 9 Étape 8 - Check PLC Ports 851 and 852 correct

- 10 Étape 9 - Ensure Correct Machine Commented in tcMulti project

- 11 Étape 10 - Add TwinSAFE project

- 12 Étape 11 - Add the route to the Target System

- 13 Étape 12 - Scan for Devices

- 14 Étape 13 - Check EtherCAT validity

- 15 Étape 14 - Name all EtherCAT devices according to network

- 16 Étape 15 - Map all IO References

- 17 Étape 16 - Map Analogue Input references

- 18 Étape 17 - Double check all IO references with someone else

- 19 Étape 18 - Install Drive Manager 2 Project

- 20 Étape 19 - Add Axis Task

- 21 Étape 20 - Add Axes

- 22 Étape 21 - Map Axes

- 23 Étape 22 - Add PLC_Reset to tc3Multi Link

- 24 Étape 23 - Activate configuration

- 25 Étape 24 - Set up Drives

- 26 Étape 25 - Add The PC types to Monday Log

- 27 Commentaires

Introduction

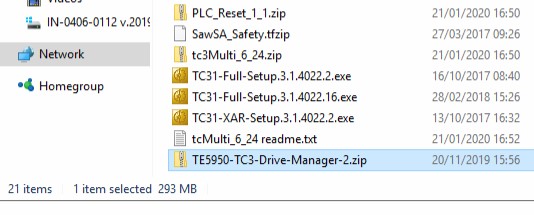

Étape 1 - Install Visual Studio / TwinCAT XAE Shell (if required)

- Uninstall all references to Visual Studio 2013 and Beckhoff Twincat3. If this is needed, restart the PC

- Copy the install file from g:\Design\TwinCAT3\TC31-Full-Setup.3.1.4024.7.exe to the desktop of the Beckhoff PC

- Run the install as Administrator

- Delete the setup zip file and unzipped directory to save hard drive space

Étape 2 - Add the latest Device Description Table

Copy the contents of g:\design\twincat3\Beckhoff_EtherCAT_XML.zip

to

C:\TwinCAT\3.1\config\Io\EtherCAT and overwrite all the .xml files in this folder

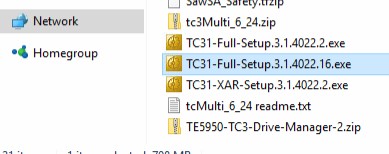

Étape 3 - Add Drive Manager 2 for AX8000 drives (if not installed already)

- Copy the Drive Manager 2 setup g:\design\TwinCAT3\TE5950-TC3-Drive-Manager-2.zip to Install Files or the desktop on the PC running Visual Studio

- Close Visual Studio if it is open

- Extract the Zip File

- Run the Setup File

- Delete the setup zip file and unzipped directory to save hard drive space

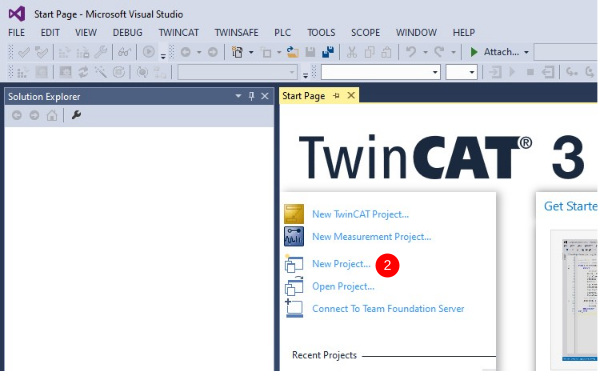

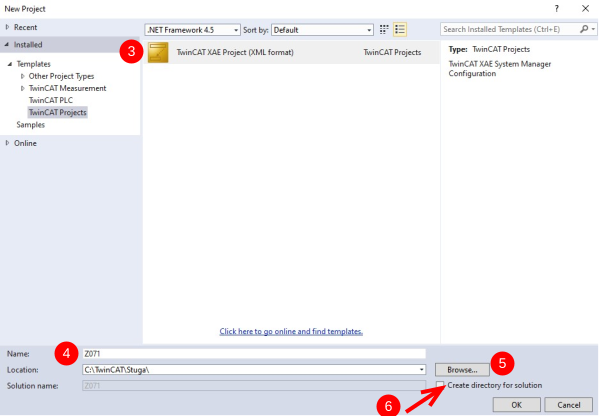

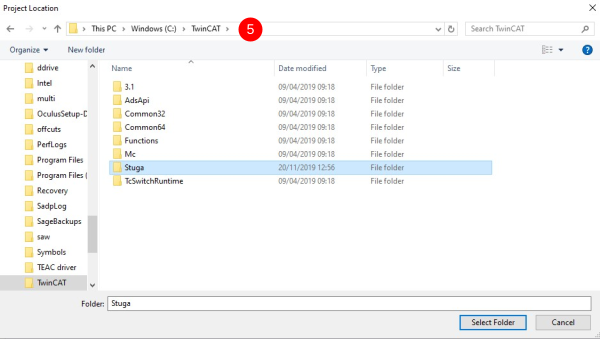

Étape 4 - Start a new project

- Open Visual Studio

- Click on New project

- Choose TwinCAT projects->TwinCAT XAE Project (xml format)

- Name is build number (no Suffix)

- Location is c:\TwinCAT\Stuga\

- Untick "Create Directory for solution"

- This may take some time - a long delay sometimes "Rebuilding Device Description Cache"

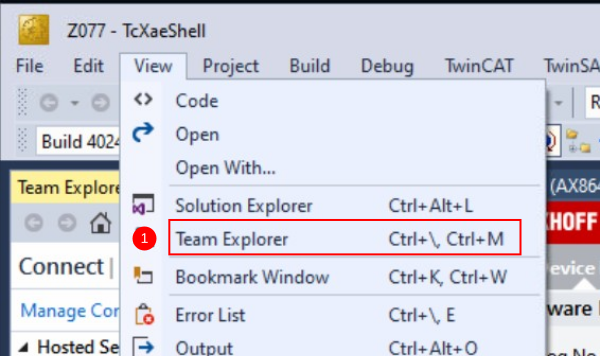

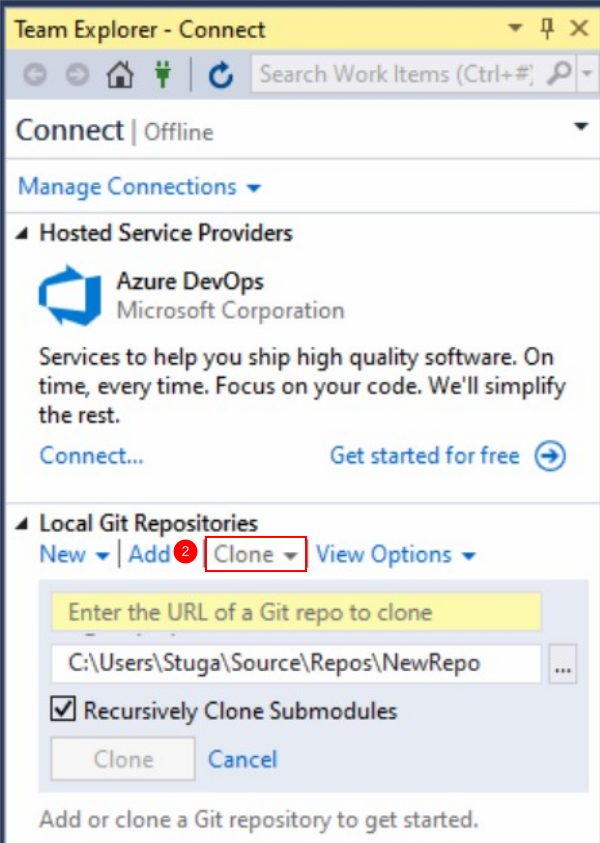

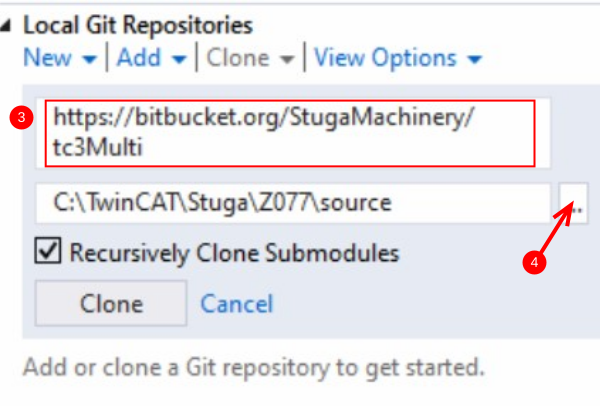

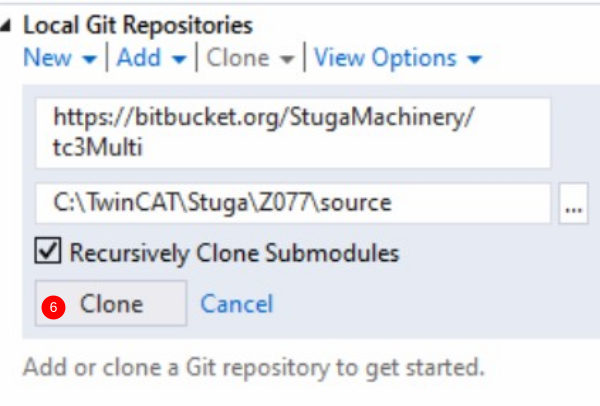

Étape 5 - Clone the Repository

- Open Team Explorer

- Clone a new Git Repository

- URL to clone: https://bitbucket.org/StugaMachinery/tc3Multi

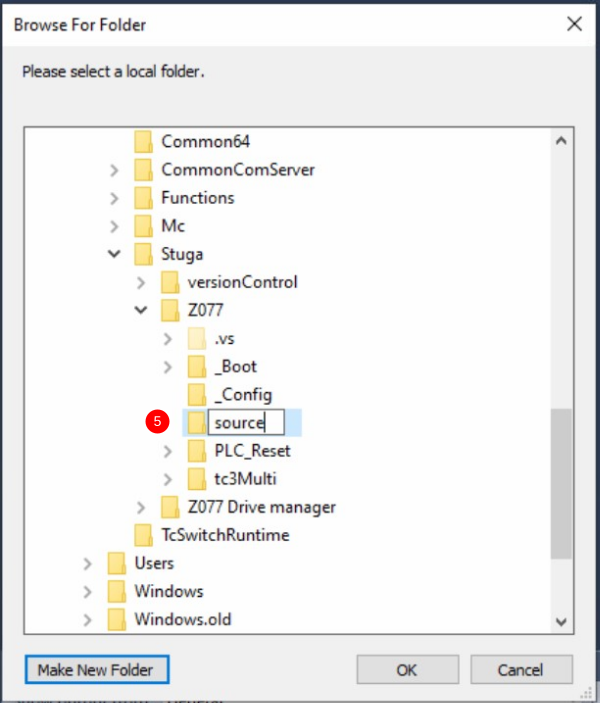

- Click on the destination setup

- Create a new folder under the machine build folder called "source"

- Click 'Clone'

Étape 6 - Enter Git Credentials (if required)

Atlassian Username is StugaMachinery

Password is stored in the file

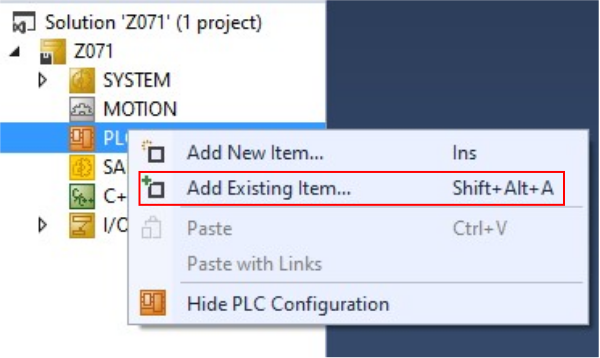

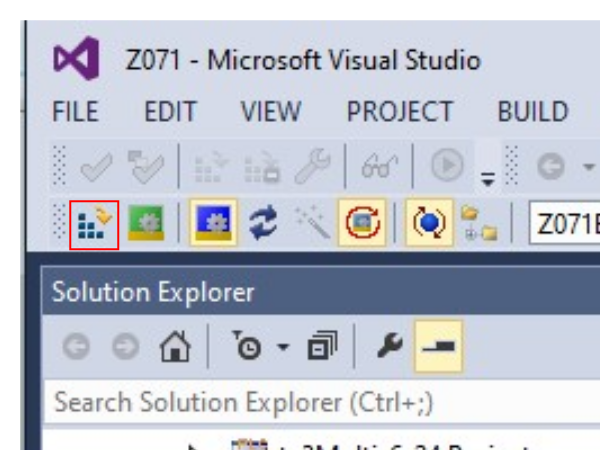

Étape 7 - Add The tc3Multi then PLC_Reset Project

- Right click PLC

- Select Add Existing Item

- Navigate to the repository you have created in Step 6 c:\TwinCAT\Stuga\BuildNo\source\tc3Multi\tc3Multi.plcproj

- Repeat for the PLC_Reset project

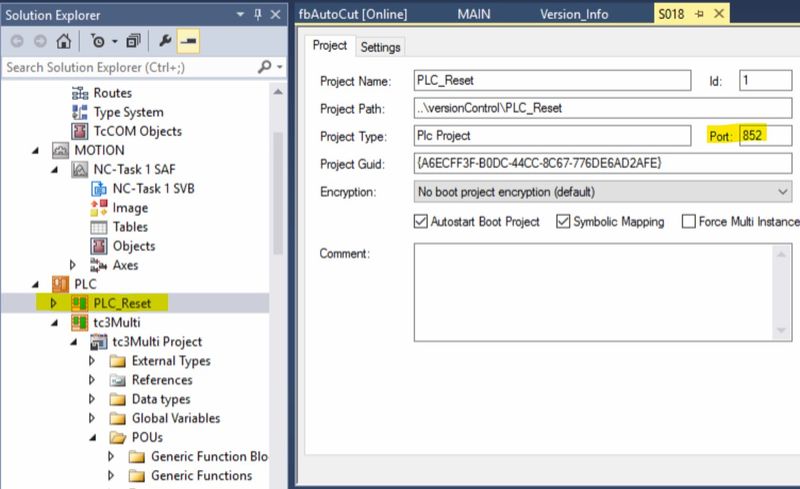

Étape 8 - Check PLC Ports 851 and 852 correct

Check that

tcMulti - Port 851

PLC_Reset - Port 852

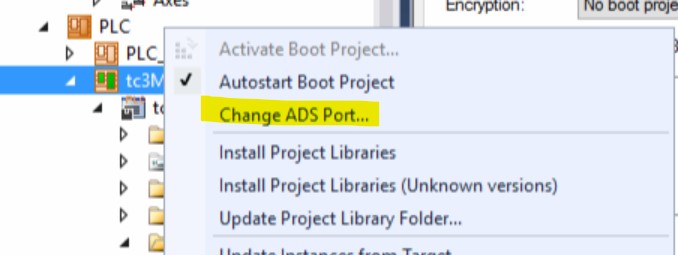

If not you can change the port assignment by right clicking the PLC project - you will need to change one to a "spare" port 853 first

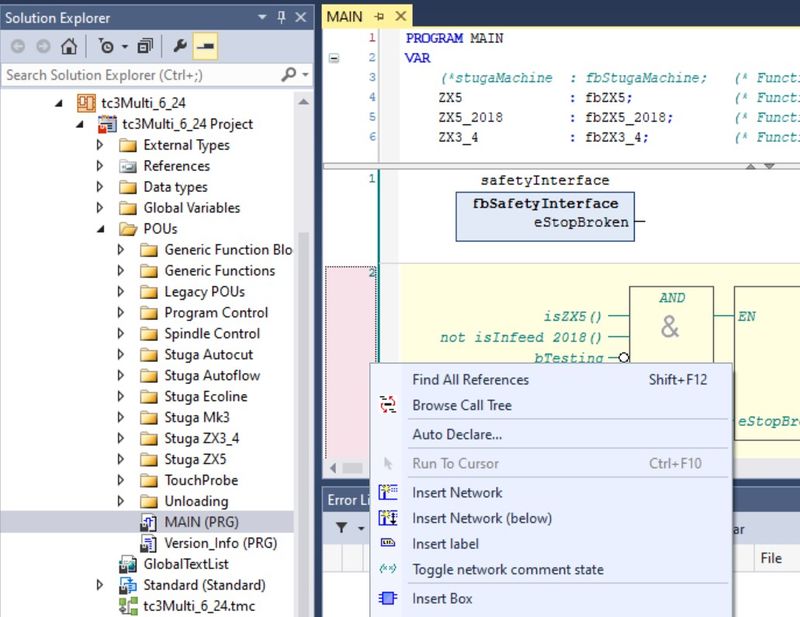

Étape 9 - Ensure Correct Machine Commented in tcMulti project

- Navigate to tcMulti project->POUs->MAIN

- Scroll down to the machine types. The "comment State" can be toggled on and off by right clicking next to the step number on the left

- Your goal is to ensure the correct machine is highlighted and the incorrect ones are commented out (in green)

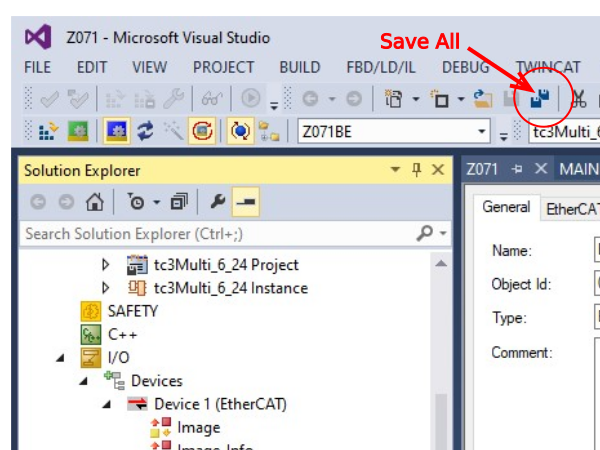

- Click Save All

Étape 10 - Add TwinSAFE project

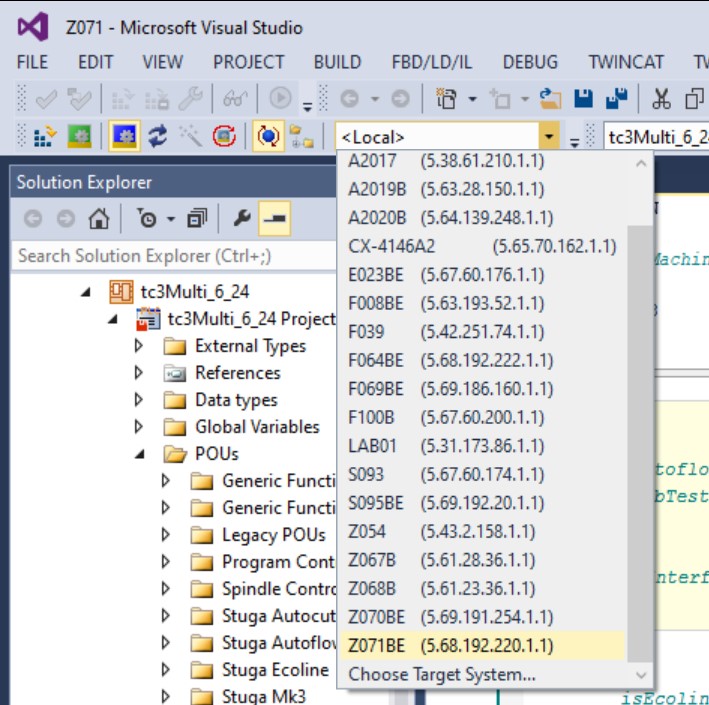

Étape 11 - Add the route to the Target System

If the front and back end PLCs are the same, the Target System is <Local>

If this is a separate Front End PC

- From Dropdown box select the Build number (If it does not exist we will need to add a new route)

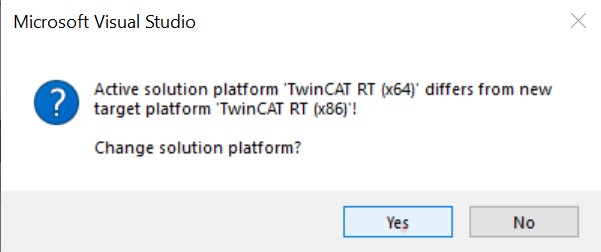

- If there is a request for a platform change, click Yes

- On success, the Route dropdown will not read Error

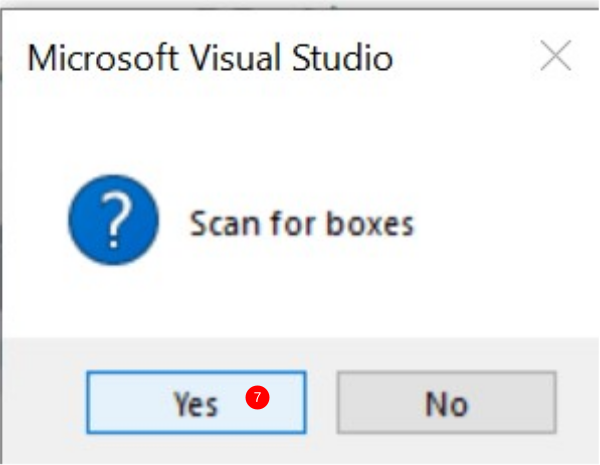

Étape 12 - Scan for Devices

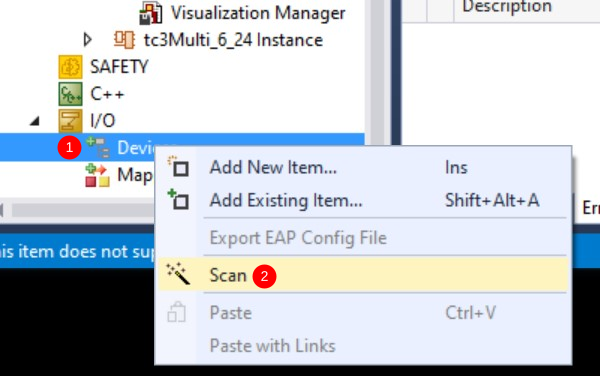

- Expand IO

- Right click on devices, Scan

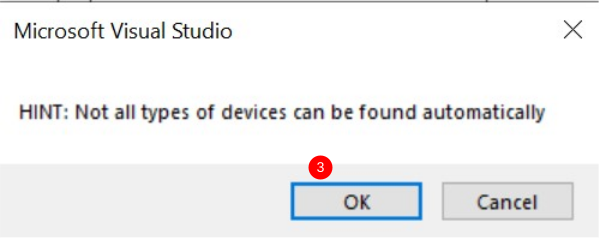

- Click OK on the Hint:

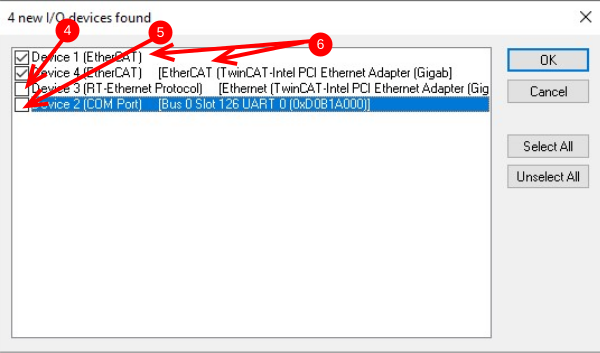

- Untick RT-Ethernet

- Untick COM-Port

- Just have the EtherCAT ports

- Scan for boxes - Yes

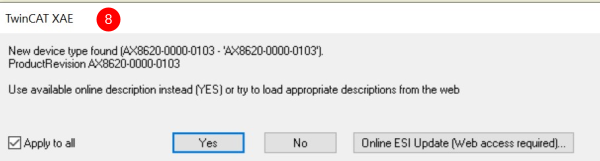

- If there is a request for New Device Type, Click Apply to All, Click Yes

If the scan does not work, a potential root casue could be missing EtherCAT drivers for the network adapter. See Updating Realtime Drivers for EtherCAT

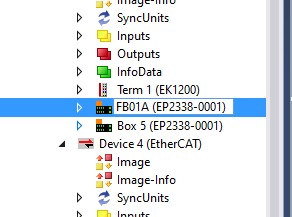

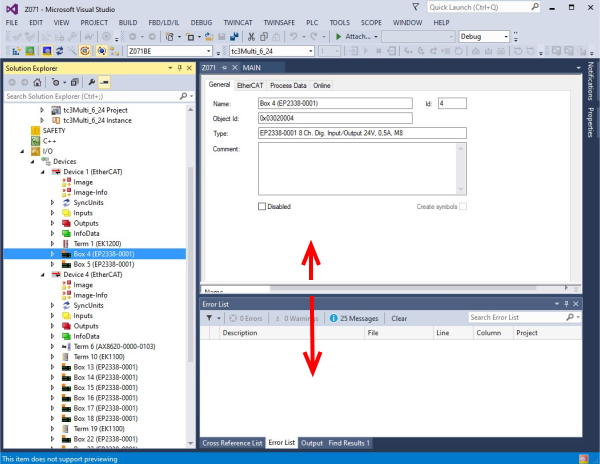

Étape 13 - Check EtherCAT validity

Check the Devices and boxes match the expected EtherCAT setupRepeat steps 7 and 8 until the physical network matches the scanned networkYou may need to Right Click->scan Boxes on the second device if the EtherCAT boxes do not appear

Étape 14 - Name all EtherCAT devices according to network

Click twice on each device (not double click) to enable the device to be renamed

rename to convention

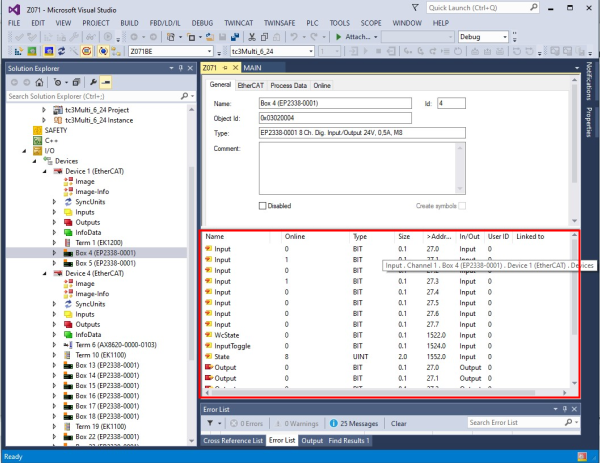

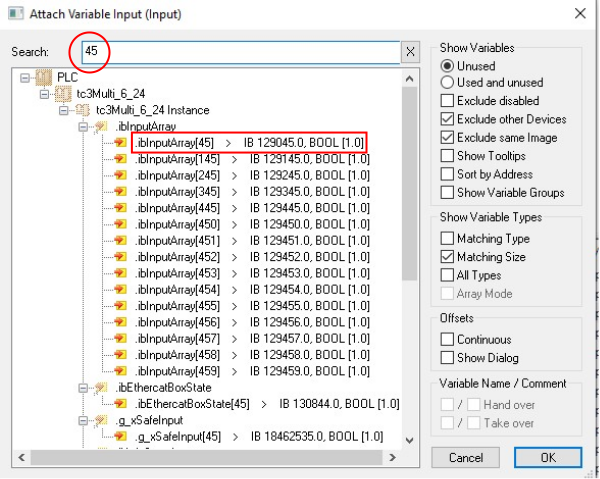

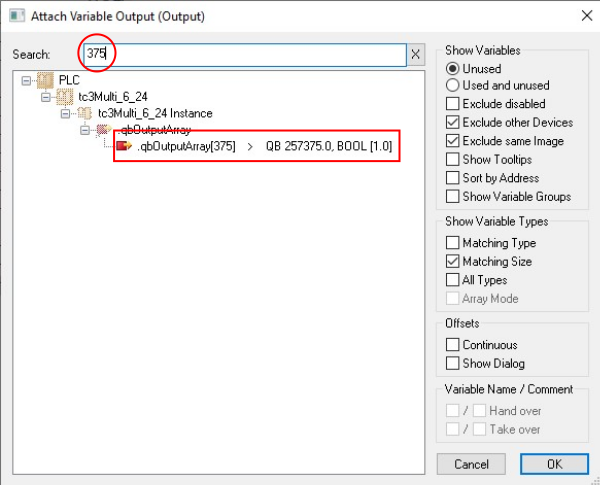

Étape 15 - Map all IO References

Using the circuit diagrams, map all the IO ref numbers to the associated IO channels

- Double click a field-bus box or slice

- Ensure you can see the input / Output list (may need some screen resizing

- Double click an IO channel

- Enter the number in the search box

- Double click the associated IO Ref number from ibInputArray(inputs) or qbOutputArray(outputs)

Repeat for all IO

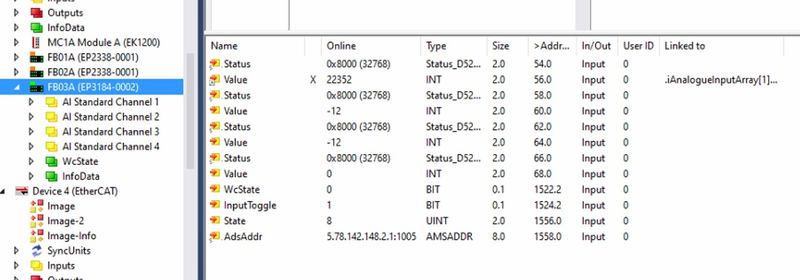

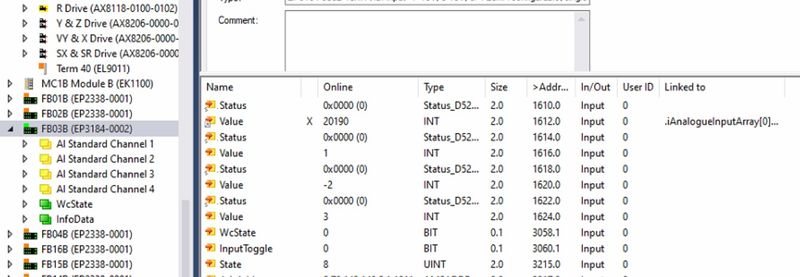

Étape 16 - Map Analogue Input references

Length and width sensors need to be mapped to their relevant EtherCAT boxes

- Width Sensor on Machining centre is iAnalogueInputArray[0]

- Length Sensor on Infeed table is iAnalogueInputArray[1]

Étape 17 - Double check all IO references with someone else

Any mistakes made will save hours if spotted here

Étape 18 - Install Drive Manager 2 Project

- Note which Device number has the drive in it

- Left-click on FILE. A new context menu open

- Move the mouse to Add.

- Left-click on New Project.

- Select TwinCAT Drive manager 2 on left

- Click on TwinCAT Drive manager 2 Project on right

- Save with filename "[BuildNo] Drive Manager" in the folder for the project (c:\TwinCAT\Stuga\[BuildNo])

- EtherCAT master will be the device that has the drive in from Step 1

- Leave the basic settings, click OK

- This should link up the drives set in previous steps to a Drive Manager project

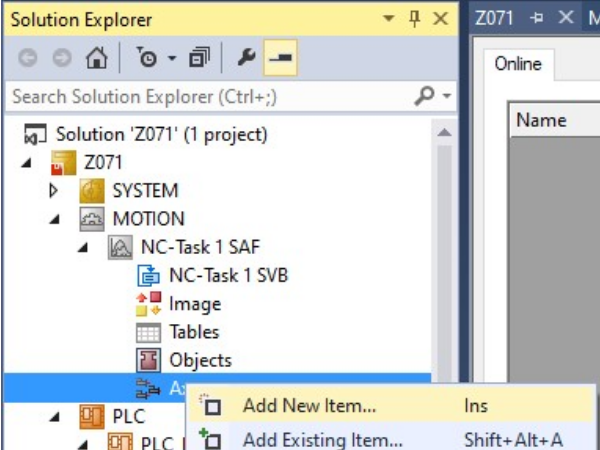

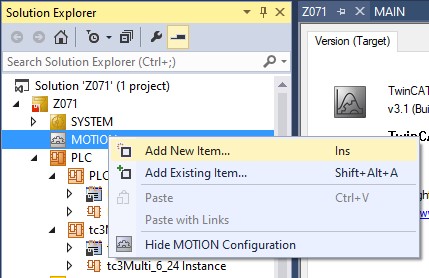

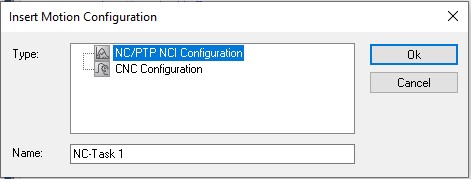

Étape 19 - Add Axis Task

A smooth setup will have detected the axes and added them under the MOTION tab already.

if not, an axis task may need to be added under the MOTION tree:

- Add New Item

- NC/PTP Configuration

- Leave the Name as default

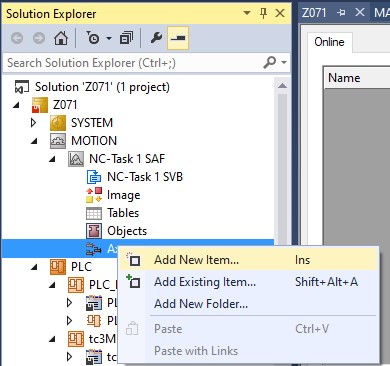

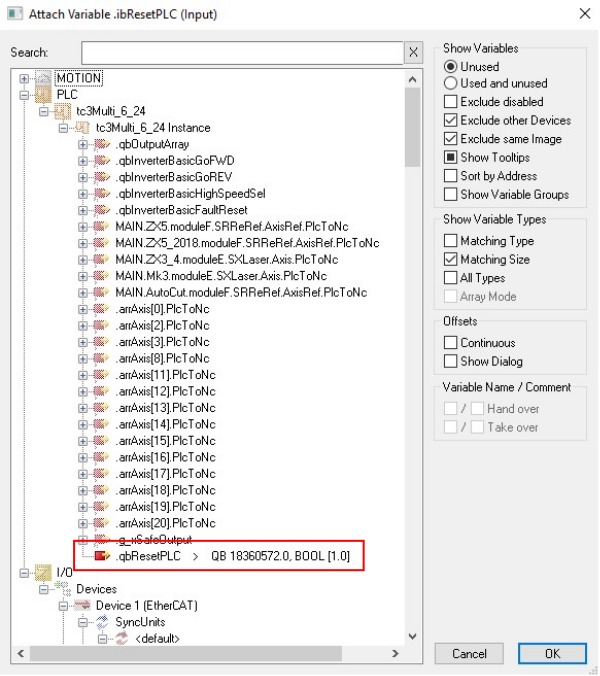

Étape 20 - Add Axes

If the axes do not exist under MOTION->NC Task->Axes, add them

- Right Click Add axis

- Name to convention nn Axis

Repeat for each axis on machine

Axis naming and configuration for different machines can be found here

Étape 21 - Map Axes

- Double click an axis

- Settings tab

- Click Link To IO

- Connect to associated Drive

- Click Link to PLC

- Use the reference here to get the Axis Numbers

Repeat for each axis

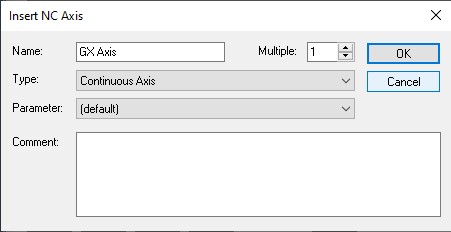

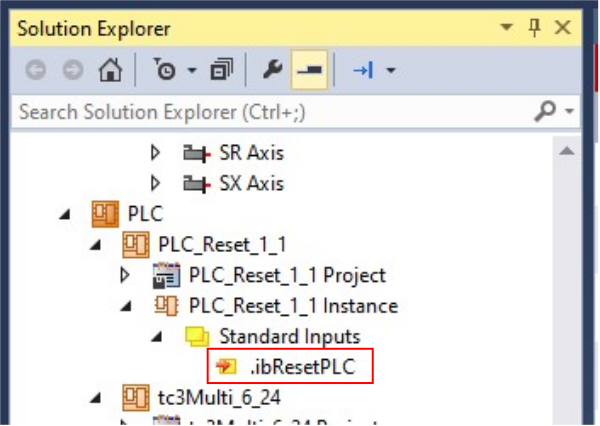

Étape 22 - Add PLC_Reset to tc3Multi Link

- Expand PLC_Reset Instance to get to ibResetPLC

- Double Click ibResetPLC to open the properties

- Link to qbResetPLC (this is very far down the list)

- Activate configuration

Étape 24 - Set up Drives

https://stuga.dokit.app/wiki/Specialised_Settings_for_Beckhoff_Drives

Étape 25 - Add The PC types to Monday Log

The board "Control Systems Log" is setup to log all machine setups

https://stugaltd.monday.com/boards/304269981

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português