How to temporarily prevent the saw blade nut from clashing with the chute

Problem: Saw Blade Nut Clashing with Chute

The chute mounting system becomes dislodged causing the chute to move sideways into the blade nut. As well as the obvious damage to the machine, this can lead to the nut coming undone.

The consensus is that the root cause is the top half moon plate is getting pushed over when an offcut gets trapped. This happens on ZX5s because we have a servo motor, through 100:1 gearbox, driving the rotation rather than the tandem cylinder. The top half moon plate is only held with a couple of M6 countersinks. Its been the same since 1992 but this design is now not fit to handle the servo / gearbox combo.

Temporary Solution

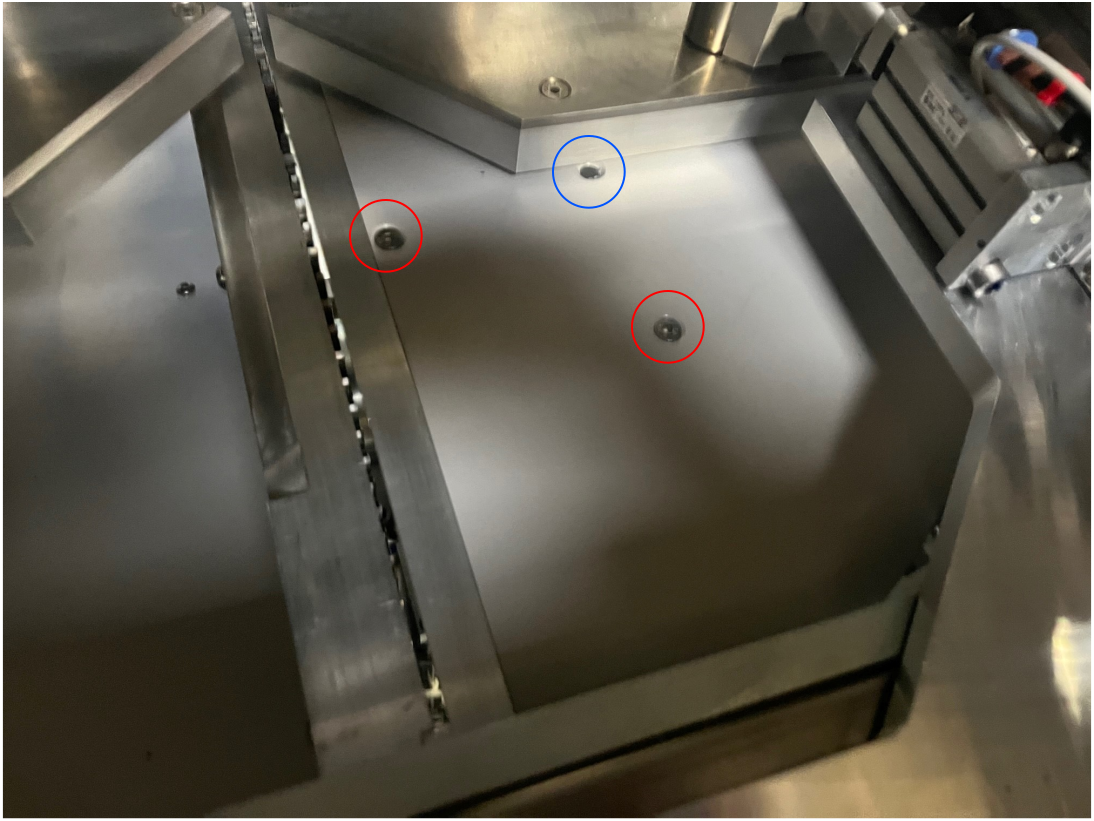

To improve the situation, the chute can be angled away by fitting spacers to the bracket mounting

And strengthen the top half moon plate mounting by drilling extra countersunk holes and using M8 instead of M6 bolts

It is also possible to utilise the handing hole for an additional screw

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português