This page is a mod in depth explanation of the Bar Data Tab

Sommaire

This tab is split into 3 sections

1. The Bar Queue

2. Bar Drawing

3. Machine Variables

The machine variables should not be adjusted as they are set to describe the type of machine this relates to.

The Bar Drawing shows a rough graphical representation of the operations and cuts on the bar.

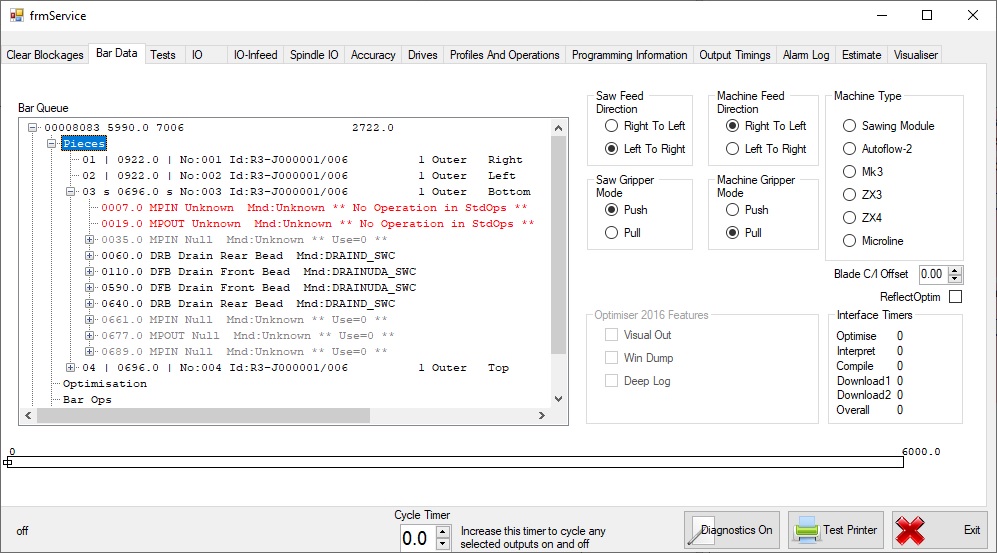

Bar Queue

The Bar Queue displays a list of the bars in the batch. This can be expanded by clicking on the + next to the bar to show 4 further options

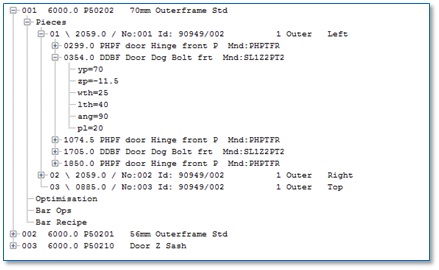

a. Pieces

Expanding this area shows the individual pieces on the bar, this can then be further expanded to show the routing operations on that piece along with the position from the left hand side of the piece, and then further expanded to show the variables relevant to that routing operation (e.g. Slot Length)

b. Optimisation

This area shows the optimisation detail including gaps between the pieces etc.

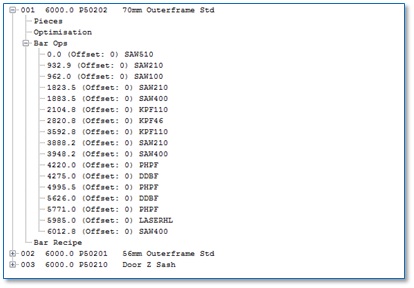

c. Bar Ops

This area shows the operations and cuts as positions on the bar rather than positions on the piece as shown below.

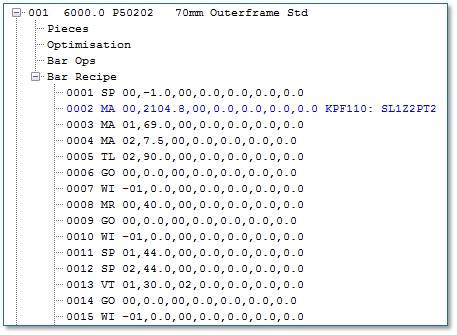

d. Bar Recipe

The bar recipe shows each action that will be taken on the bar, along with the action number which is shown on error reports. A list of recipe actions is shown below

Please note, at the end of each of these lines may be 2 codes separated by a colon

e.g. KPF110: SL1Z2PT2

this denotes the start of an operation, the code before the colon is the code sent by the office to denote the routing operation, the code after the colon is the program or macro used to determine the tool/axis movements needed to produce the machining operation.

SP Speed Setting

This command sets the speed for an axis or group of axes.

- Format

- SP Axis,Speed,00,0.0,0.0,0.0,0.0

- Speeds

- -1.0 Traverse (fast) speed for all axes

- Axes

- 00 X Axis

- 01 Y Axis

- 02 Z Axis

- e.g

- SP 00,-1.0,00,0.0,0.0,0.0,0.0 Set Traverse Speed for all axes

- SP 01,44,0,00,0.0,0.0,0.0,0.0 Set Y axis Speed to 44

MA Move Absolute

This command moves to an absolute position for the specified axis.

- Format

- MA Axis,Position,00,0.0,0.0,0.0,0.0

- Axes

- 00 X Axis

- 01 Y Axis

- 02 Z Axis

- e.g.

- MA 01,69.0,00,0.0,0.0,0.0,0.0 Move Y Axis to an absolute pos of 69m

MR Move Relative

This command moves to relative distance from the current position.

Format MR Axis,Position,00,0.0,0.0,0.0,0.0

Axes 00 X Axis

01 Y Axis

02 Z Axis

e.g. MA 01,69.0,00,0.0,0.0,0.0,0.0 Move Y Axis a further 69mm

TL Tool activation

This command sends the closest of a selected tool type to a chosen angle around the bar and activates it.

Format TL Tool,Angle,00,0.0,0.0,0.0,0.0

Tool The tool Ids are determined in the settings area described previously, a sample setting is shown below.

e.g. TL 03,90.0,00,0.0,0.0,0.0,0.0 Send the closest 5mm tool to 90 degrees.

GO Go Command

This command activates the previous commands, which in effect wait in a queue until the go command is activated. This command has no sub variables.

e.g. GO 00,0.0,00,0.0,0.0,0.0,0.0

WI Wait for Idle

This command instructs the machine to wait until the axes are idle i.e. the positions previously specified are reached.

e.g. WI -01,0.0,00,0.0,0.0,0.0,0.0

WA Wait for a specified time

This command tells the machine to wait for an allotted amount of time before the next command is executed.

SC Saw Cut

This command activates a saw cut.

ToolOff Turn Tool Off

Turns the specified tool off.

HL Hole

Performs a Hole operation.

VT Vector Move

Moves 2 axis in conjunction with each other.

OP Output

Checks a specified output signal is made.

LB Label

Prints a Label

WaitOnLoad Wait for load operation

Waits for the bar to load

ToolH Tool H?

?

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português