How to successfully change the control of the transfer table on an all-in-one machine from the saw side to MH side

Why Change

JF noted during training that when the saw paused, the MH could only finish the bar it was on but not eject its bar onto the transfer table. If the soft pause then led to a hard reset, the bar was stuck on MH outfeed. This is difficult for the operator to retrieve.

If the MH controls the transfer, the saw can pause, but MH can carry on. This is more efficient and faster

How

Software updates are needed which give a new parameter

transferMHControlSwitching to 1 will change control from the saw side to MH side

| winMulti | 6.4.32.0 |

| tc3Multi PLC | 6.3007 |

Stoppable Outputs

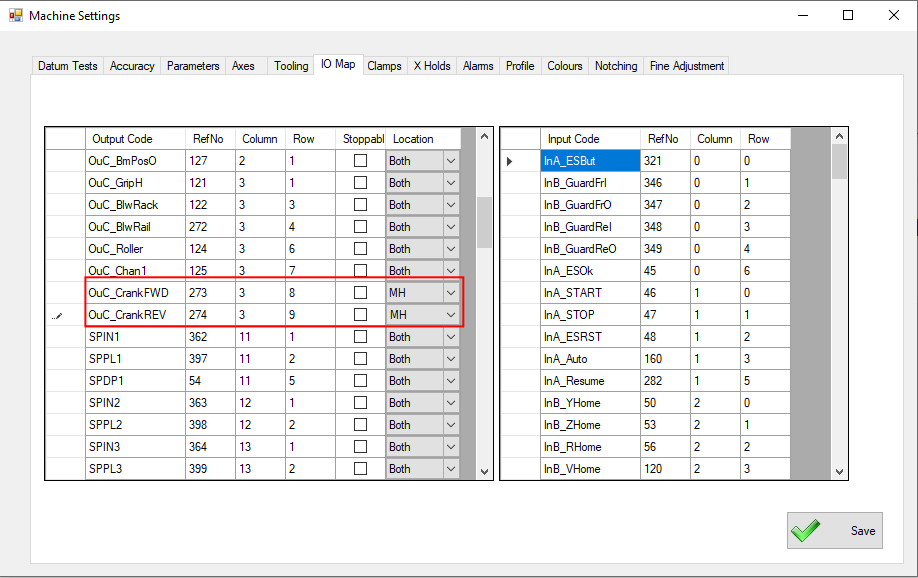

StoppableOutputs are outputs that need to switch off when the machine is paused - these are generally conveyor motors or blowers. When the machine is restarted from the pause, the outputs are automatically restarted.

Care must be taken to change the "Location" of any relevant stoppableOutputs. This is important because these outputs will deactivate during a pause on the controlling side - if this is wrongly set, the output will switch off when the wrong side is paused.

The location is set via Machine settings, IO screen.

The critical outputs would be the transfer table motors

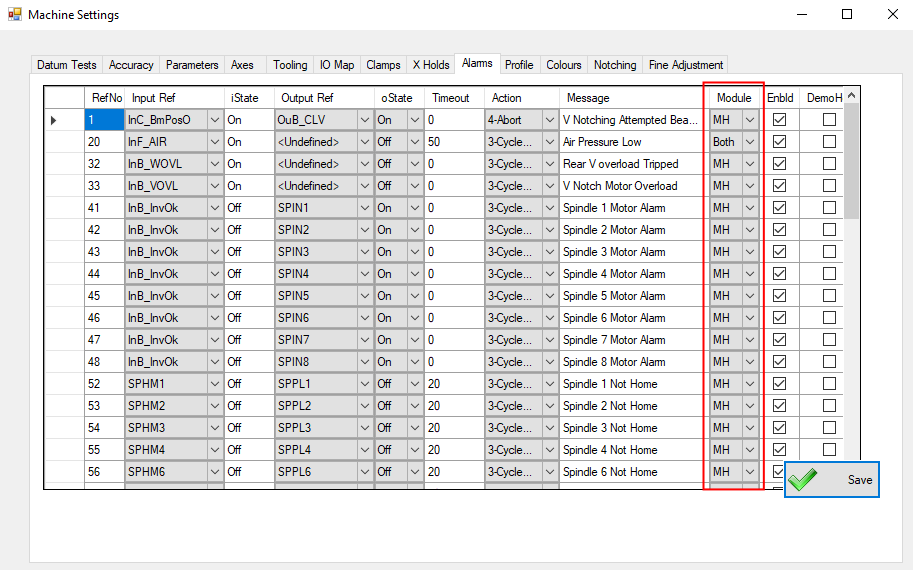

Alarm Outputs

The alarm "module" column will also need to be updated for any specific alarms that need moving across for saw control to MH control. On recent ZX5 software, there are no alarms in this category, all alarms are done internally.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português