PC network configuration of the Flowline following a Nextmove PC upgrade to overcome obsolescence

Summary

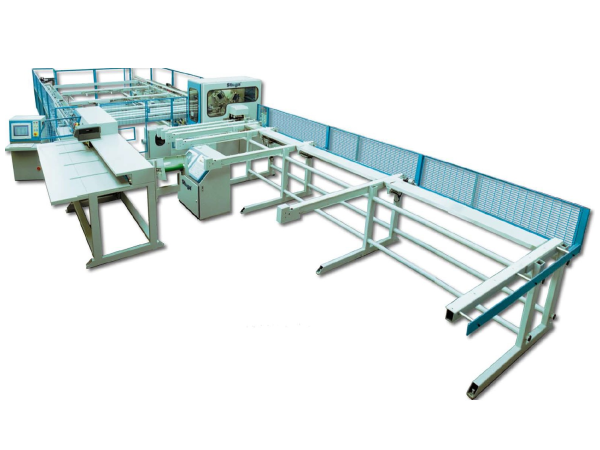

Setup follows the format of FlowlineA with two independent machines with independent control systems. In FlowlineB, the MH (Multi-Head) side Industrial PC is replaced with a small footprint Windows XP machine.. The Saw side PC is a much smaller DOS based system, containing DOS boot and network software to map a drive and run its control software from a shared directory on the MH side computer.

Both PCs have a network port and are connected through a 5 port switch located in the MH cabinet

| MH Setup Files | Saw Setup Files | MH Front End Software | Saw Front End Software |

|---|---|---|---|

*.mul initialisation filesc:\

|

*.saw initialisation filesd:\ |

written in vb.net c:\multi\winmulti.exe |

d:\saw.exe |

Location of folder structure of MH side can be changed in masterdir.saw. See https://stuga.dokit.app/wiki/Masterdir_File

Saw Side PC

- Arcom ACEpc running DOS

- 8Mb Flash Drive containing ROM-DOS to boot up

- Uses NetBEUI or TCP-IP to share all setup data from MH side PC

- Maps d:\ to MH SAW shared directory for all control software

- Old units available for loan

- Instructions in dokit for re-flashing drive and programming TCP-IP https://stuga.dokit.app/wiki/Manual:ACE_PC

- Serial port COM1 used to send instructions to Smartmove/1 or Nextmove ESB Motion control card

- Serial Port COM2 used for printer

- Located in Saw console

MH Side PC

- ACER revo

- Windows XP,

- Uses TCP-IP to share all setup data from MH side PC and share a folder for batch writing

- Connects via USB to Nextmove E100 motion control card to control Machining centre axes and IO

- Located in a box next to machining centre door

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português