How to safely decommission and load a Stuga Autoflow Mk4.1 machine

Difficulté

Difficile

Durée

1 jour(s)

Sommaire

- 1 Introduction

- 2 Étape 1 - Move axes to park positions

- 3 Étape 2 - Power off

- 4 Étape 3 - Infeed Conveyor Module - Disconnect

- 5 Étape 4 - Infeed Conveyor Module - Move

- 6 Étape 5 - Infeed Gripper Module - Disconnect

- 7 Étape 6 - Infeed Gripper Module - Stowing

- 8 Étape 7 - Infeed Gripper Module - Attach lifting Equipment

- 9 Étape 8 - Outfeed table disconnect

- 10 Étape 9 - Machining Head and Saw - Disconnects

- 11 Étape 10 - Unlink Upper Guards

- 12 Étape 11 - Split Machining Head and Saw

- 13 Étape 12 -

- 14 Commentaires

Introduction

The Autoflow Mk4.1 machine has been designed to separate into modules for safe transport

The infeed table gripper carriage and conveyor split into two sections

The machining head and saw split apart like a cam shell

The outfeed splits in to a rear bed and front tray

Étape 1 - Move axes to park positions

- X axis to machining side of lifting points

- GZ axis to minimum

Étape 2 - Power off

Étape 3 - Infeed Conveyor Module - Disconnect

Ensure the plugs are labelled

Étape 4 - Infeed Conveyor Module - Move

Pull away from backfence towards front of machine

Étape 5 - Infeed Gripper Module - Disconnect

Ensure the plugs are labelled

Étape 6 - Infeed Gripper Module - Stowing

Move Gripper system

Étape 7 - Infeed Gripper Module - Attach lifting Equipment

Attach safe moving equipment - see R0019264 Autoflow Mk 4,1 Infeed Safe moving equipment

Étape 8 - Outfeed table disconnect

Ensure the plugs are labelled

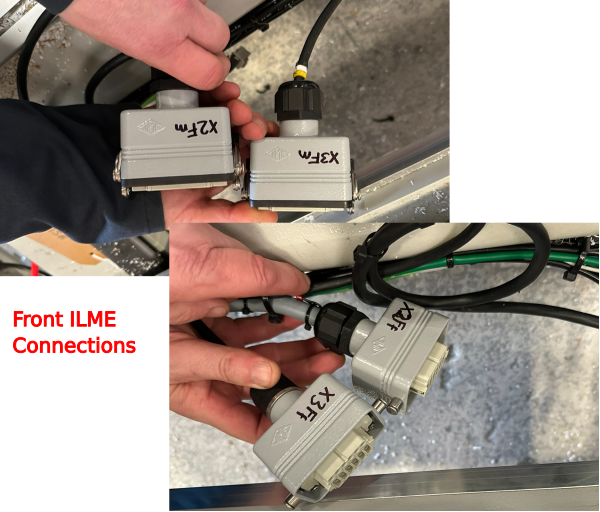

Étape 9 - Machining Head and Saw - Disconnects

Locate and unplug the electrical and pneumatic interconnections.

Front Side

- X2F and X3F ILME Connectors. Pull one through one way, one through other way

- Grease Lines - 2 off

- Air Lines Red and Blue

Rear

- ILME Connection

- Network Connection - 2 Off

Rear side

Étape 10 - Unlink Upper Guards

Étape 11 - Split Machining Head and Saw

Using a crowbar, spit the main modules apart

Étape 12 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português