instructions to assemble motor assembly

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Cut chute Flap

- 4 Étape 3 - Assemble chute flap

- 5 Étape 4 - Prepare conduit

- 6 Étape 5 - Attach fixed end brackets

- 7 Étape 6 - Tap Holes in Motor R-L and L-R Machine positions

- 8 Étape 7 - Mount connection box R-L

- 9 Étape 8 - Mount connection box L-R

- 10 Étape 9 - Secure lid

- 11 Étape 10 - Orientate Motor box

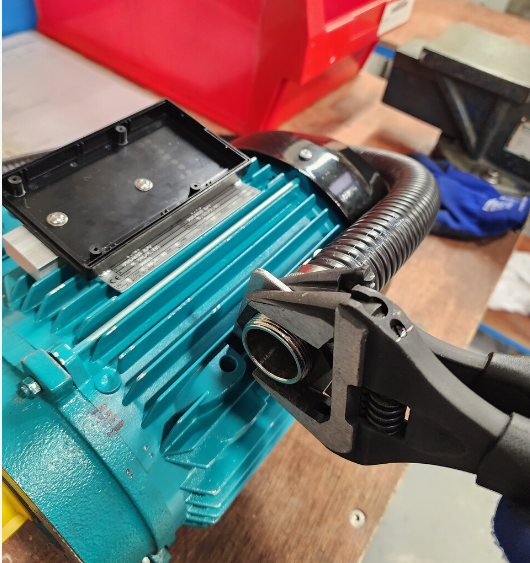

- 12 Étape 11 - Attach conduit mount

- 13 Étape 12 - Attach conduit to motor

- 14 Commentaires

Introduction

Tool Required

Standard hex key set

Standard spanner set

Cutting disc

Standard hand taps

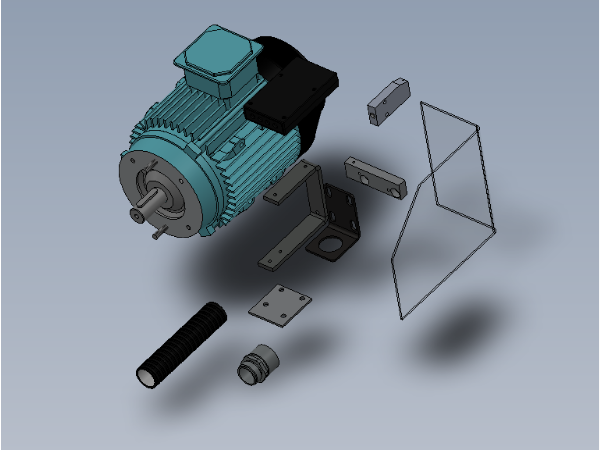

Parts Required

A0000013 32mm Conduit Adaptorx 1

A0000027 Flexible Conduit Ø32mm x 1

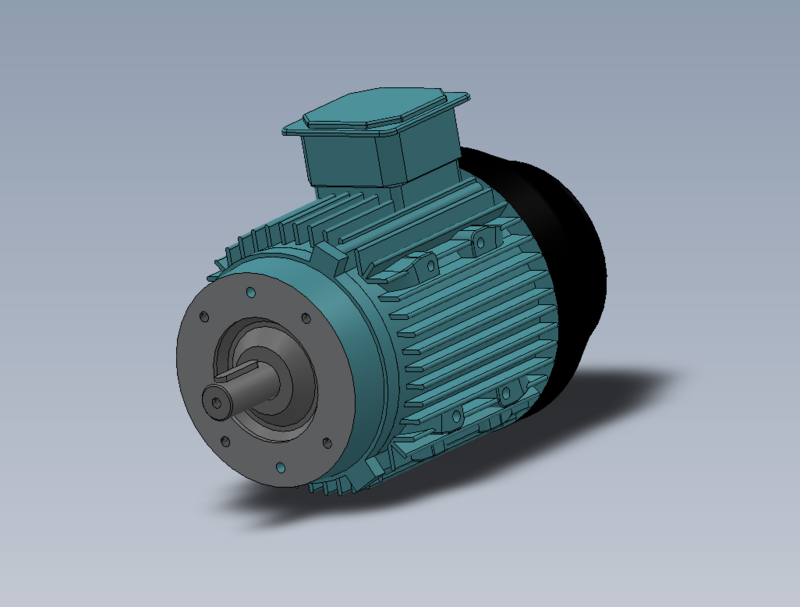

D0004079 Saw Motor (Modified Front Flange) x 1

D0004437 Motor Conduit Bracket x 2

D0004835 Flex conduit plate x 1

D0004997 Connector Support Block (5360) x 1

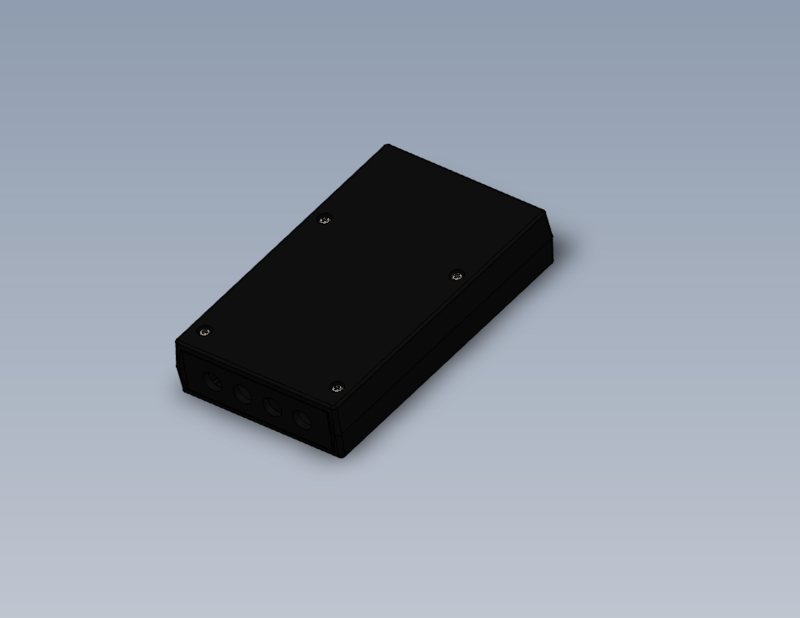

D0004999 Reed Switch Terminal Box x 1

D0005219 Turntable Nozzle x 1

D0008198 Chute Flap x 1

H0008200 Chute Flap Bracket x 1

P0000295 Elbow Adaptor 6mm - 1/8 BSPT (Metal type) x 1

Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

Étape 2 - Cut chute Flap

Use jig to cut safety flap

Remove additional 8mm from bottom of cut piece as shown once cut

(Jig requires amending to new correct size -8mm)

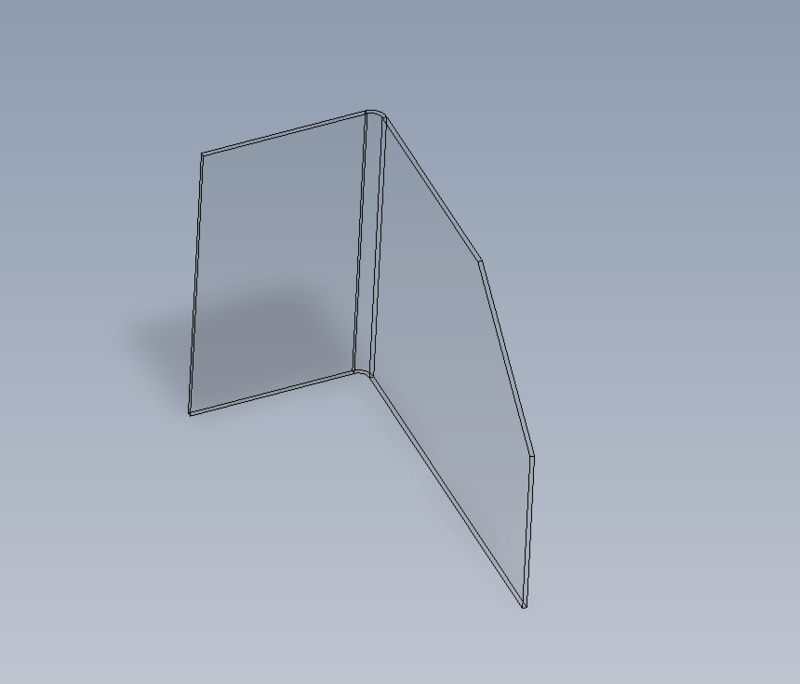

Étape 3 - Assemble chute flap

1 tap holes in chute bracket

2 Orientated pre cut flap onto bracket orientated as shown. Mark 4 off holes and drill to 6.8mm . Mount to bracket using M5 x 10 socket caps 2 off and M5 penny washer 2 off

Insert 2 off M5 x 20 socket caps and 2 off M5 a form washers into bracket ready for main frame fixing

3 Assemble blower . fit p0000295 fitting to D0005219 Turntable Nozzle

4 Mount blower to bracket using M5 x 20 socket cap 2 off and 2 off M5 A form washer 2 off

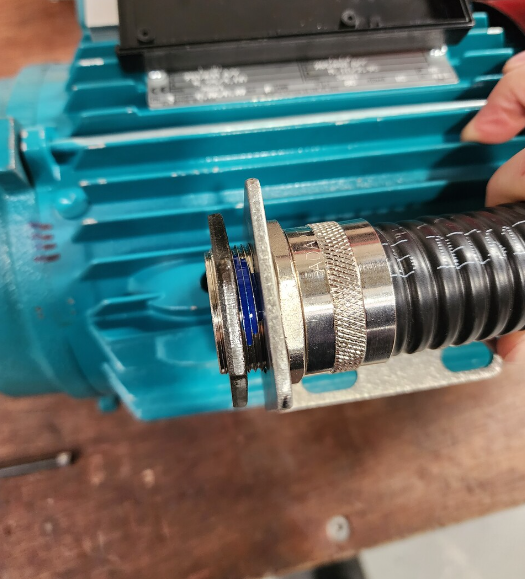

Étape 4 - Prepare conduit

1 Cut length of 32mm conduit for saw motor at 850mm Long using disc grinder

2 Fit collar as shown . Ensure static variant has been issued, not rotating

3 Fit insert as shown

4 Tighten in vice

5 Repeat for other end

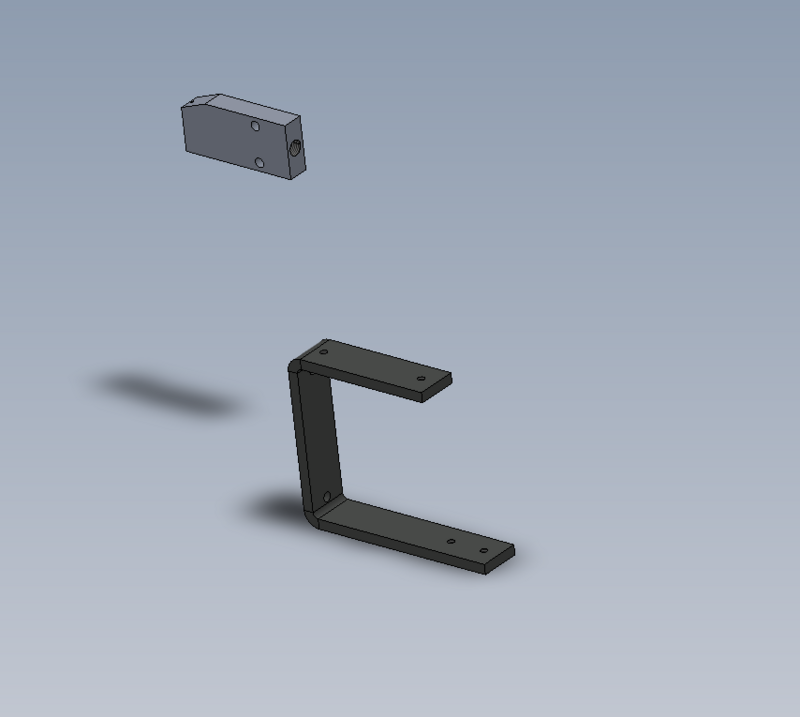

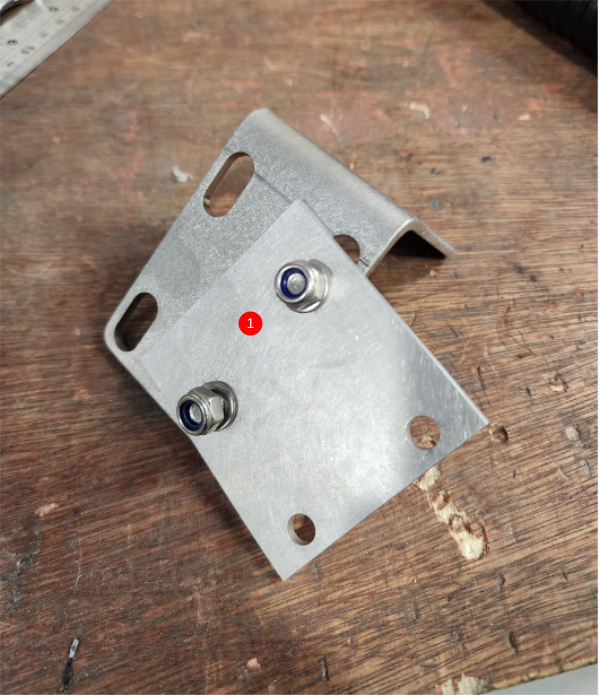

Étape 5 - Attach fixed end brackets

1 Assemble D0004437 Motor Conduit Bracket and D0004835 Flex conduit plate as shown using M6 x 16 socket cap 2 off, M6 A form washers 2 off , M6 Penny washer 2 off and M6 nyloc nut 2 off

2 Attach pre built anaconda as shown , using loctite 243 on fixing nut

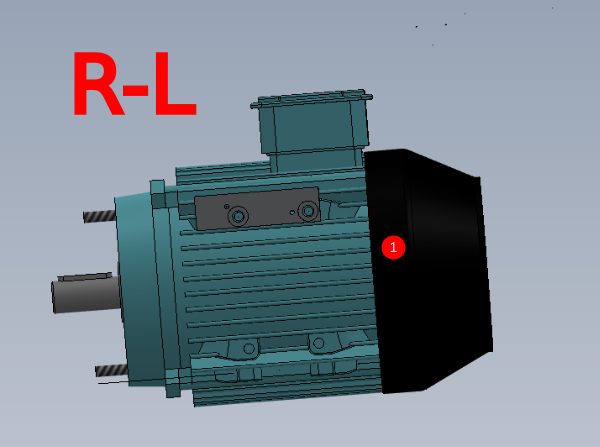

Étape 6 - Tap Holes in Motor R-L and L-R Machine positions

Ensure correct holes are tapped for correct hand of machine being assembled

Tap indicated holes in main motor to M8

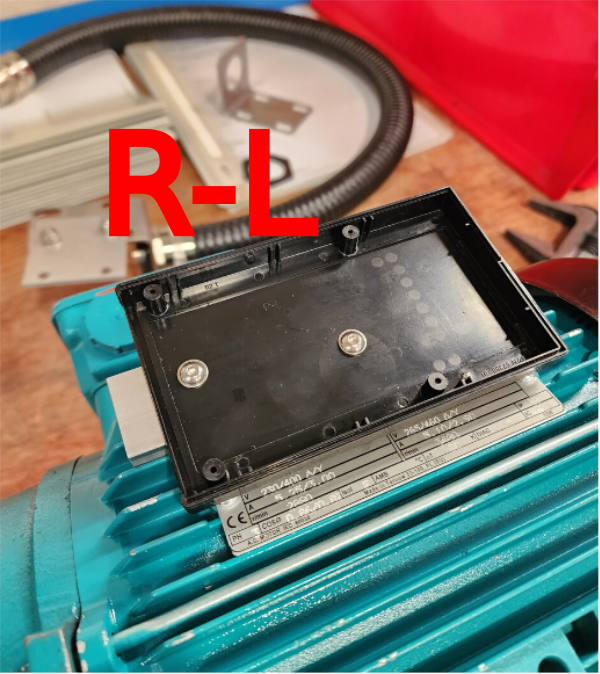

Étape 7 - Mount connection box R-L

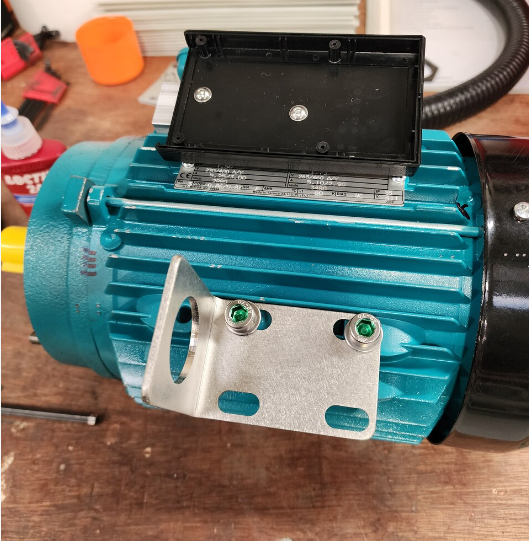

1 Attach terminal mounting block to saw motor as shown using 2 off M8 x 16 socket caps

2 attach connection box using 2 of M4 x 12 button hex and 2 off M4 A form washers

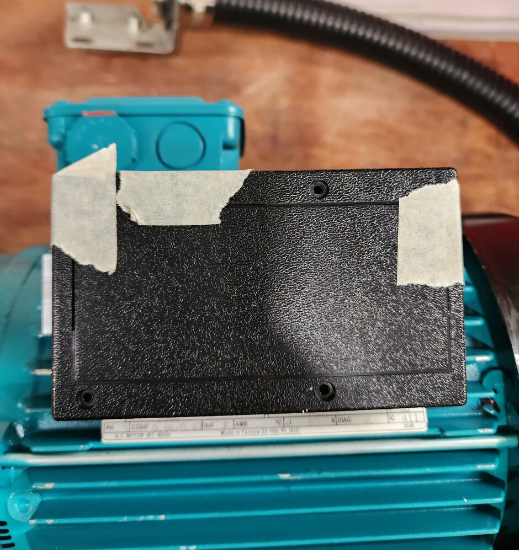

Étape 9 - Secure lid

Use making tape to secure lid, cable entry plate and screws safely together .

Do not use provided screws to fix lid

Étape 10 - Orientate Motor box

Check orientation of motor connection box shown

Glands should face black connection box

Étape 11 - Attach conduit mount

Attach conduit mount to main motor orientated as shown

Use 2 off M8 x 16 socket caps and A form washers to fix

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português