Details for fitting motor and swarf chute

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Fit Saw cut sensors

- 4 Étape 3 - Fit motor

- 5 Étape 4 - Fit pulley and belts

- 6 Étape 5 - Fit Infill panel to chute

- 7 Étape 6 - Fit Infill panel to chute

- 8 Étape 7 - Fit chute support

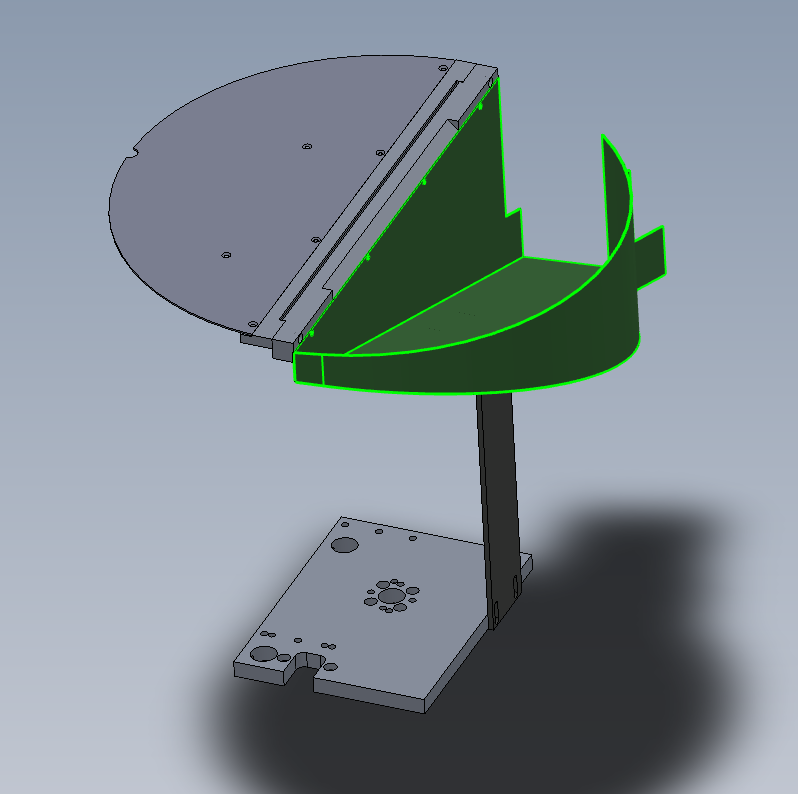

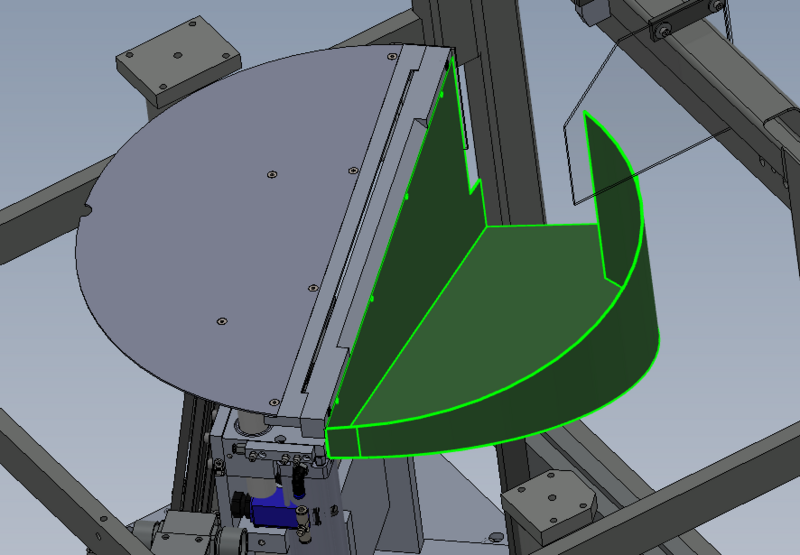

- 9 Étape 8 - Fit chute

- 10 Étape 9 - Quality

- 11 Étape 10 - Align swarf chute and finalise

- 12 Étape 11 - Check spindle clearance and eject clearance

- 13 Étape 12 - Attach anaconda assembly

- 14 Étape 13 - Attach chute flap

- 15 Commentaires

Introduction

Tools Required

standard hex keys

Standard spanner set

1 meter steel rule

Copper slip

Chute flap template jig

Standard Hss drills

Standard taps

Ratchet 3/8 drive and 13mm socket

Copper/hide hammer

Parts Required

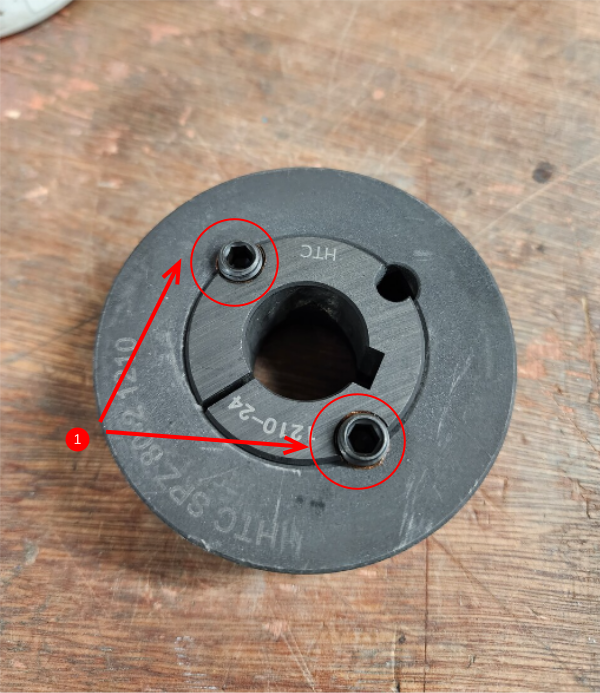

B0000048 Taperlock Set SPZ 80-2 1210-24 x 1

B0001175 Saw V-belt (special size 987mm) for 500mm blade x 2

D0005628 Saw chute infill panel x 1

H0004637 Offcut Chute (H0005333) x 1

H0004660 Chute Bracket x 1

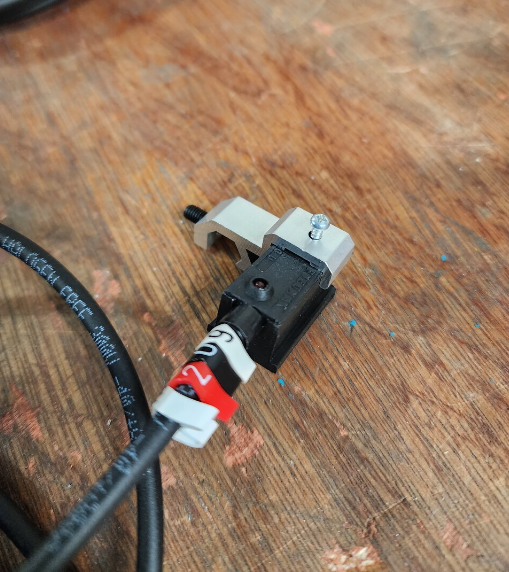

P0000609 Reed Switch Mount (Tie Bar) x 3Étape 1 - Unless otherwise stated

All bolts to have Loctite 243 adhesive applied unless otherwise stated

All Threaded Pneumatic connections to have Loctite 570 applied

All bolts to be pen marked once adhesive applied and correct tension added

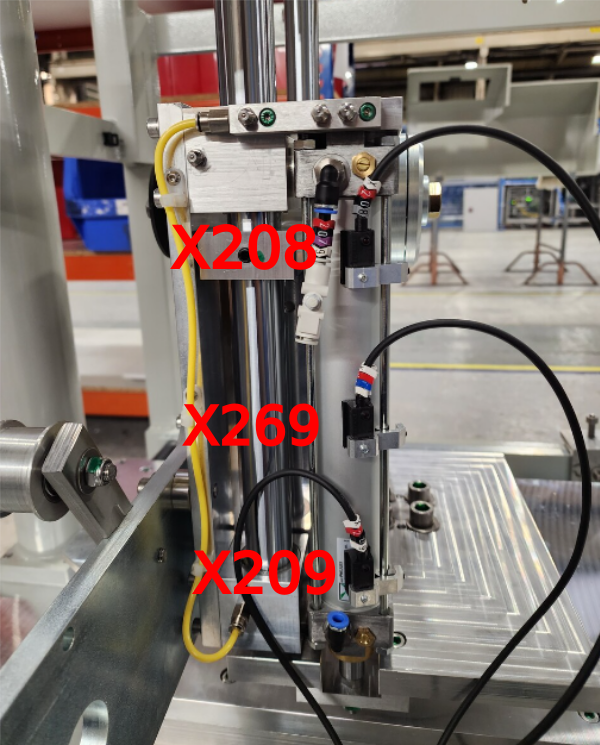

Étape 2 - Fit Saw cut sensors

Fit 3 off saw cut sensors from electrical dept.

Ensure orientated as shown

Labelled as

X208

X209

X269

Use test box to set

X208 at home position. Cylinder contracted

X209 Saw cut out position. Cylinder extended, use air to lift head

X269 Saw mid switch . Set this in the middle of the 2 previous fitted sensors

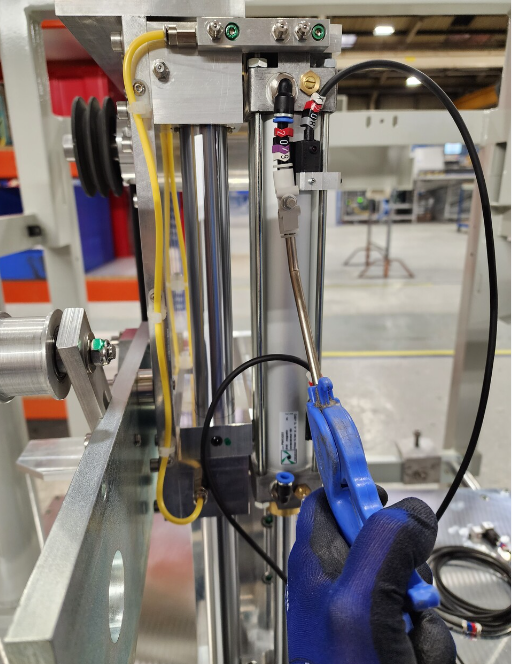

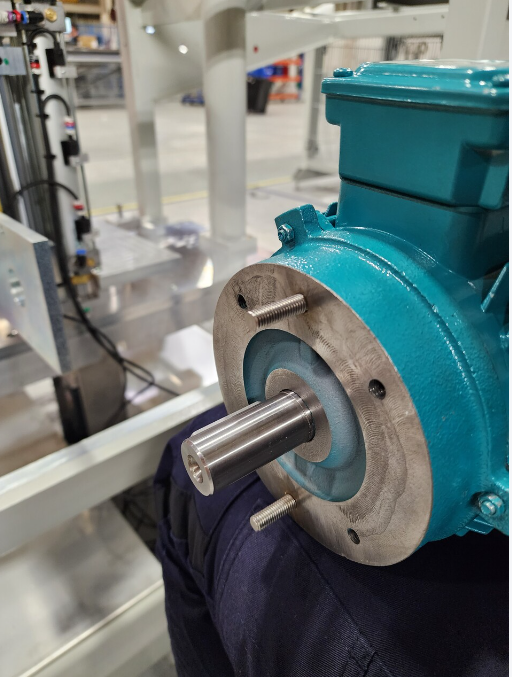

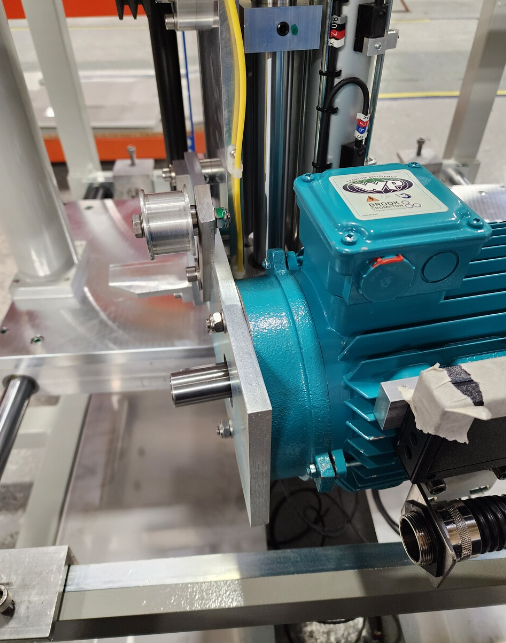

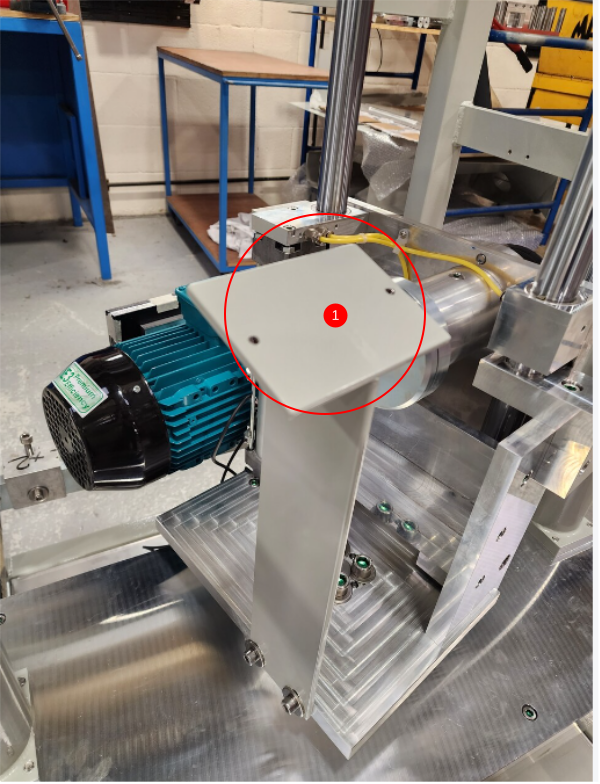

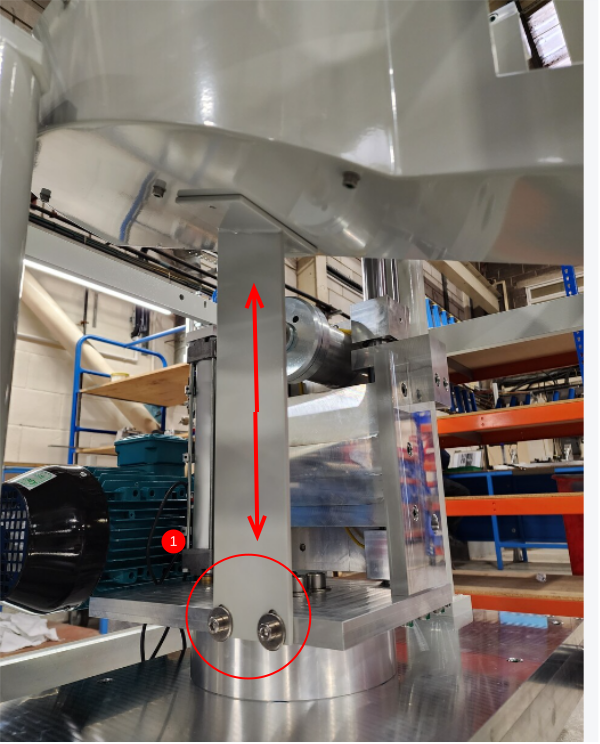

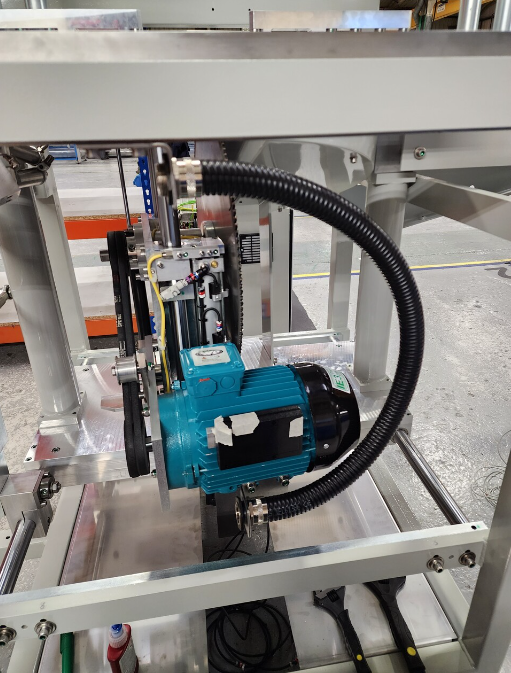

Étape 3 - Fit motor

Fit pre assembled motor to head assembly. Use 2 off M8 Nyloc nuts and A form washers.

Ensure correct orientation

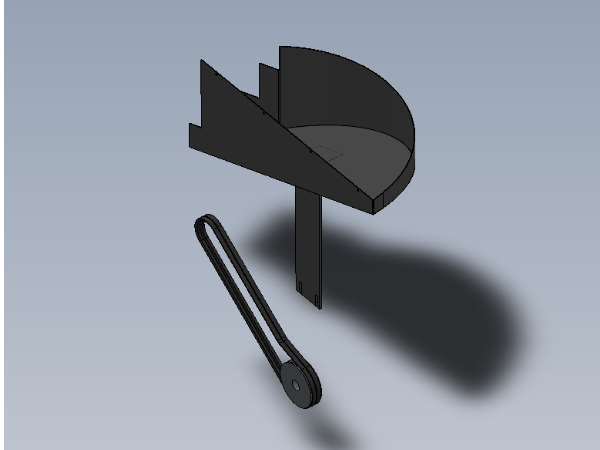

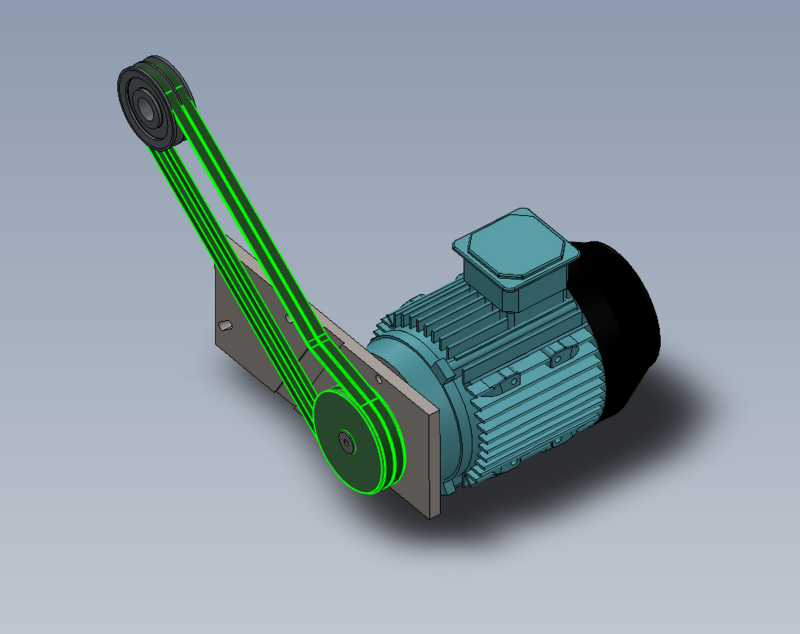

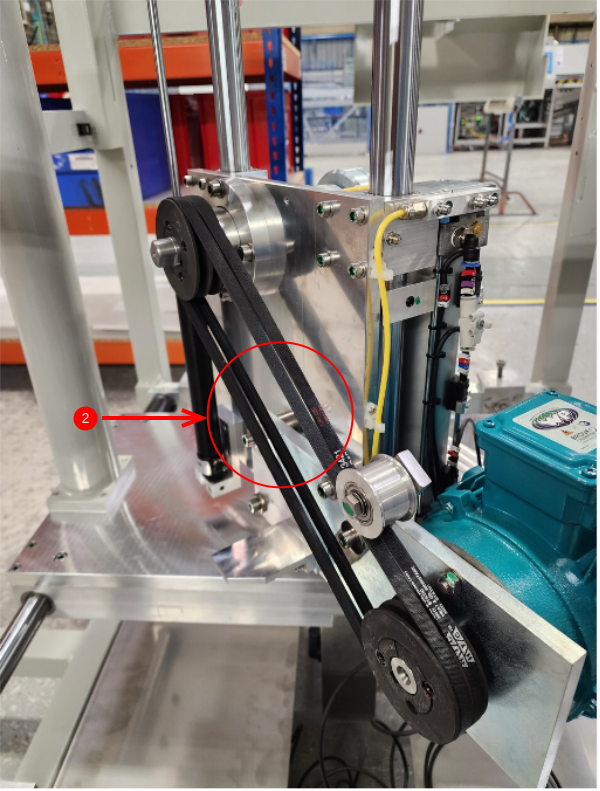

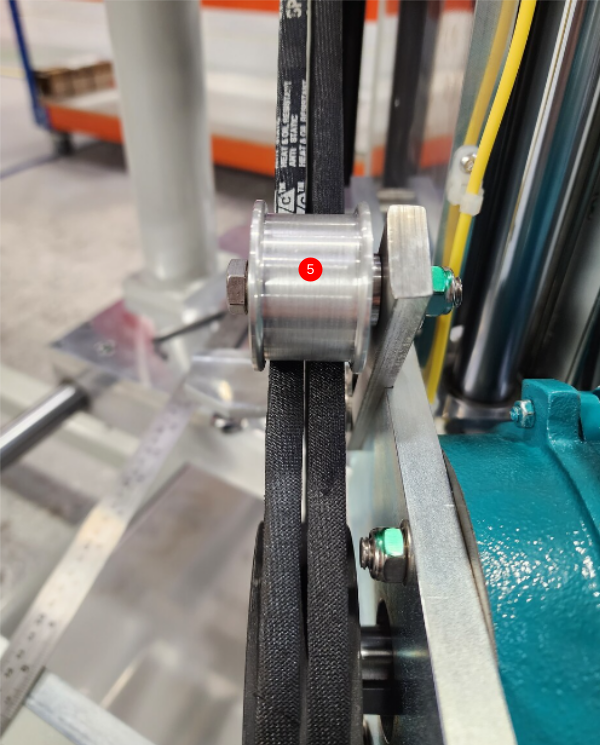

Étape 4 - Fit pulley and belts

1 Fit pulley to saw motor ensure copper slip is used on taper lock grubscrews

2 Fit 2 off belts

4 Apply tension to belts with belt tensioner

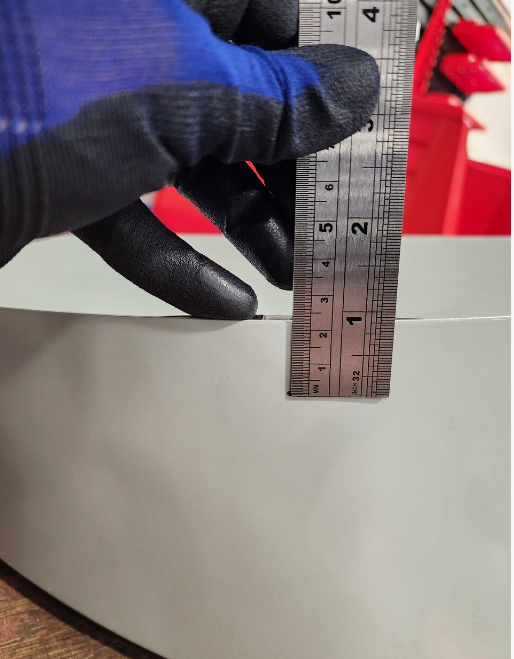

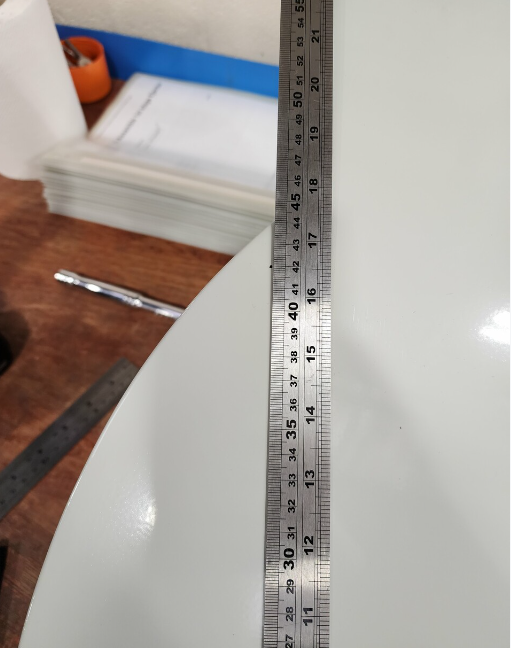

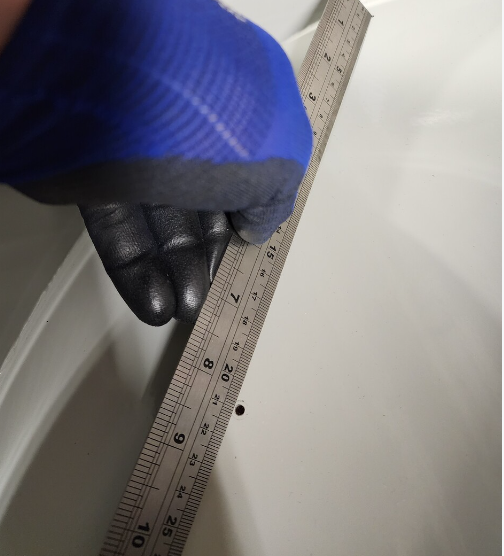

5 Align both pulleys with steel rule, whilst aligning belts to be central on idler puller.

6 Tension all securing grubscrews on both pullers . Pulley will move when tensioned, so take this into account when aligning

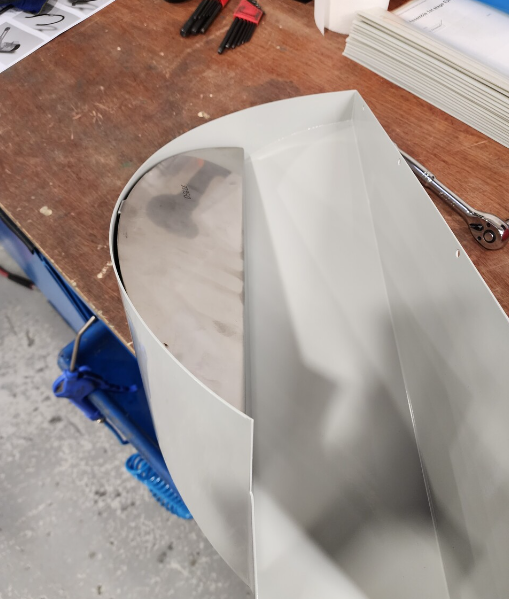

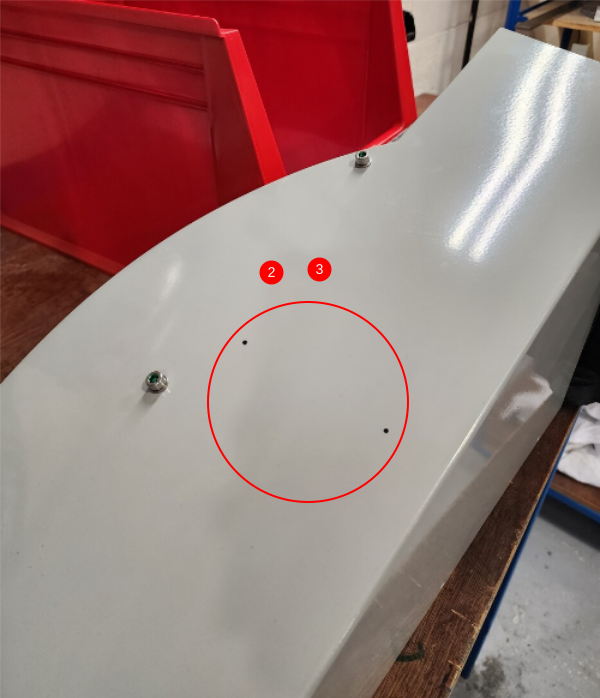

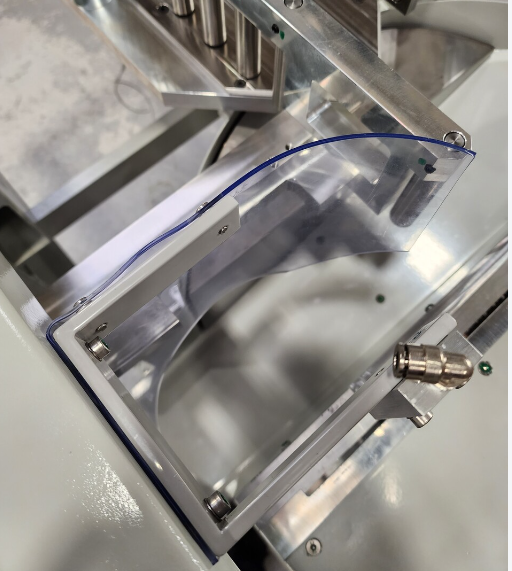

Étape 5 - Fit Infill panel to chute

Fit D0005628 Saw chute infill panel to H0004637 Offcut Chute

Use M6 x 10 pointed grubscrews in infill section to use as markers

Position as shown

Use M6 x 12 socket caps with M6 A form washers to fix

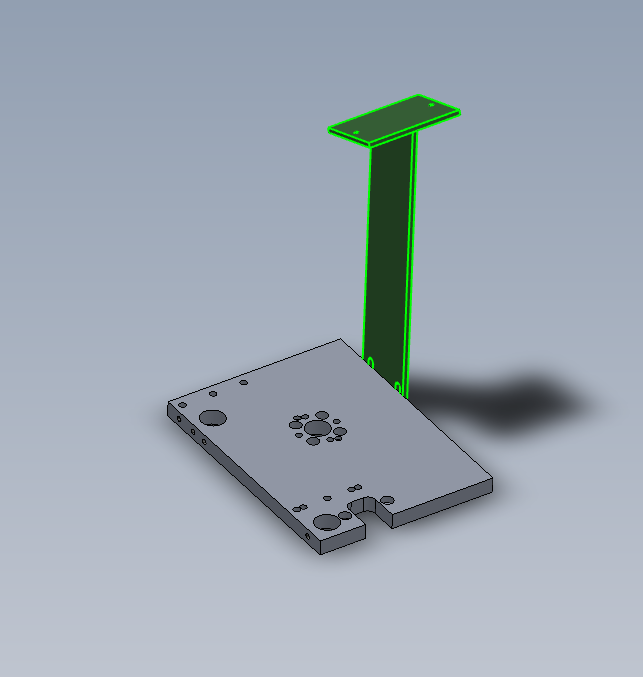

Étape 7 - Fit chute support

1 Tap 2 off M6 tapped holes on top face of bracket

2 Fit chute support to head assembly using 2 off M8 =x25 socket caps and 2 off M8 motor plate washers , do not apply final tension

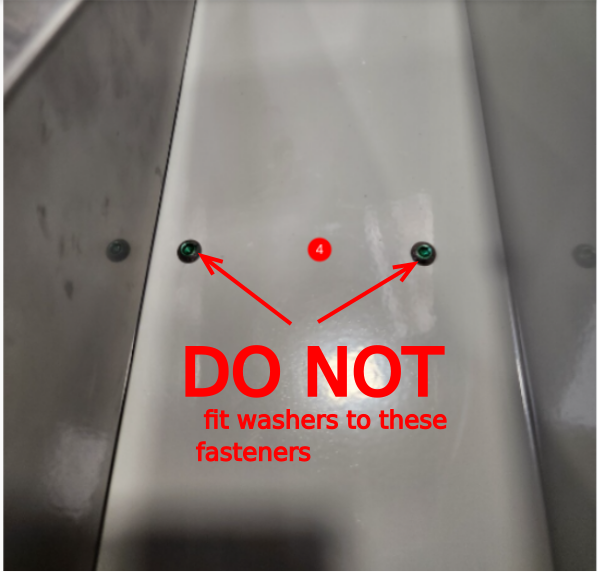

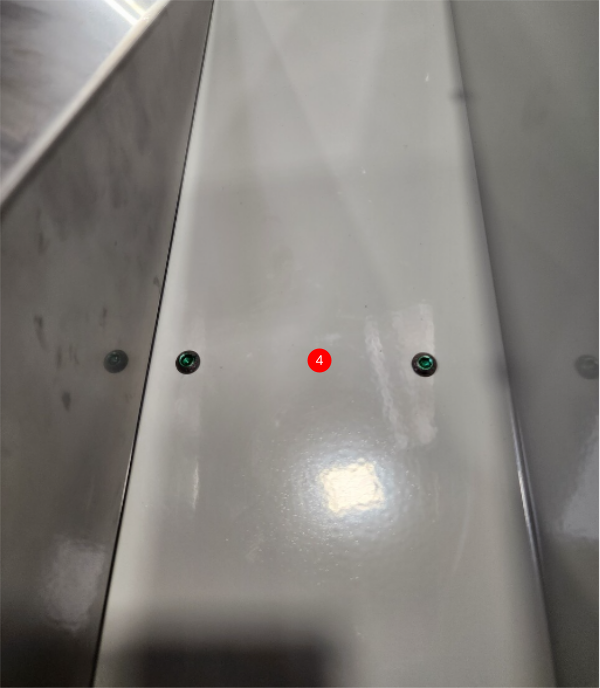

Étape 9 - Quality

When the next step is done, it is vital that only M6 button heads are used to secure swarf chute to support bracket.

Use of washers creates a snag point for profile, so must not be used

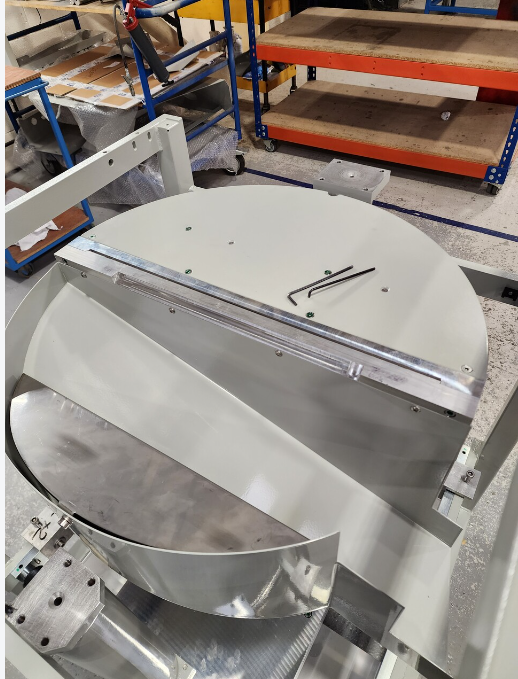

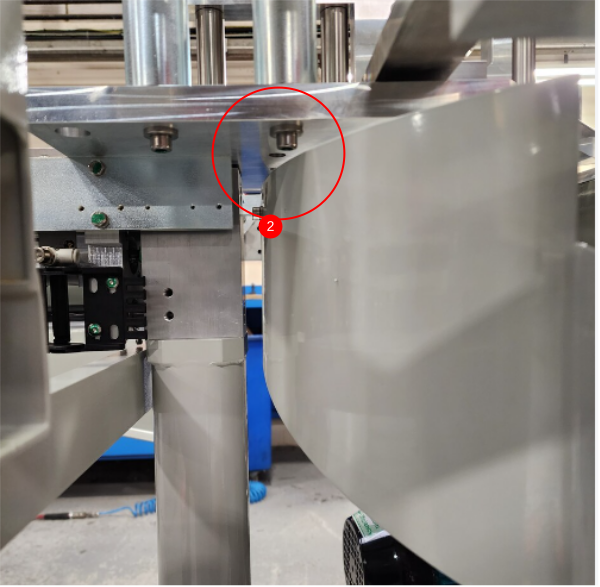

Étape 10 - Align swarf chute and finalise

1 Adjust chute support so chute sits parallel to blade, Use slots on Bracket with M8 fasteners to adjust

2 Mark through 2 off M6 tapped holes on chute support bracket onto swarf chute

3 Remove swarf chute , drill 6.5mm diameter clearance holes

4 Refit swarf chute and secure with M6 x 10 button sockets

Étape 11 - Check spindle clearance and eject clearance

1 Check spindle clearance once chute is fixed.

Hex head on spindle should clear swarf chute on all points of travel

2 Check that when eject table moves in and out towards saw blade, clearance is present between M8 cap heads and top of chute

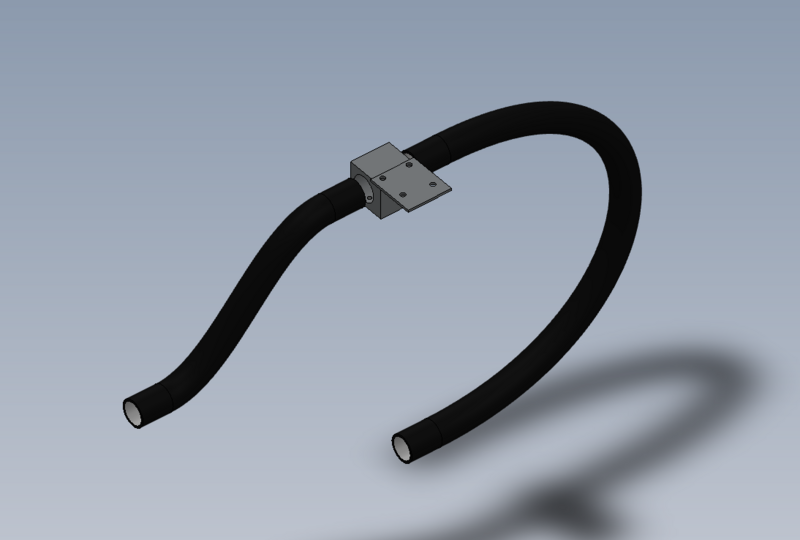

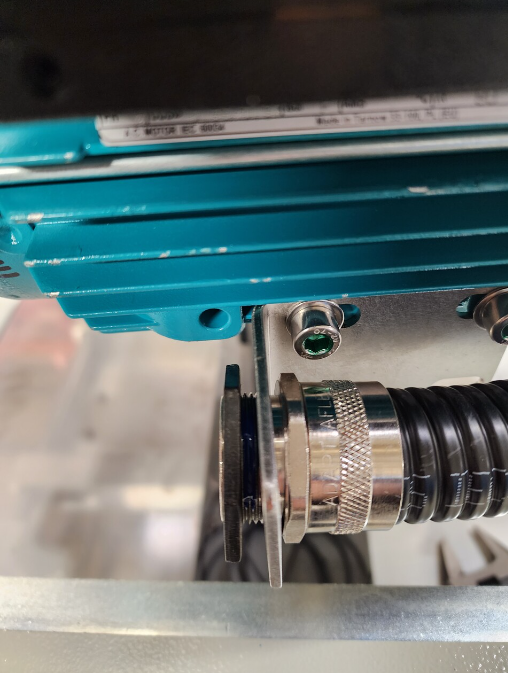

Étape 12 - Attach anaconda assembly

Attach saw motor anaconda to frame, using 2 off M6 x 16 socket caps and M6 A Form washers

Ensure dokit Correct Adjustment of Saw Anaconda Rotation is used, to correctly set anaconda

Étape 13 - Attach chute flap

Attach pre built chute flap using M5 x 20 socket caps and M5 A Form washers

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português