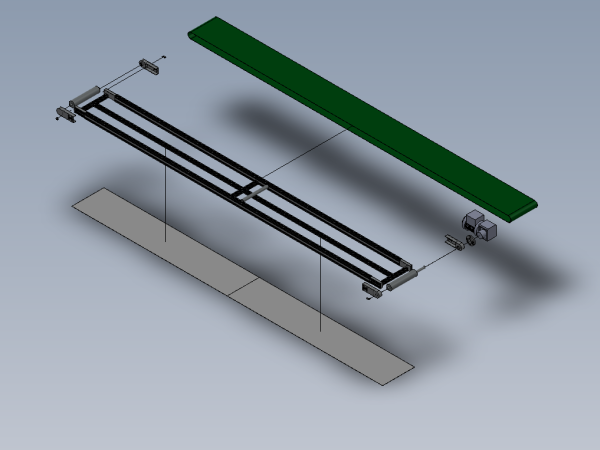

Assembly details for conveyor frame

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Drill blower points on rollers

- 4 Étape 3 - Assemble mounts

- 5 Étape 4 - insert M4 plate nuts

- 6 Étape 5 - Assemble main frame

- 7 Étape 6 - Finalise all fasteners

- 8 Étape 7 - Fit Slave roller (non driven)

- 9 Étape 8 - Fit drive roller

- 10 Étape 9 - Attach adhesive tape

- 11 Étape 10 - Quality Check

- 12 Étape 11 - Fit stainless top plates

- 13 Étape 12 - Fit belt

- 14 Étape 13 - Fit mid rollers

- 15 Étape 14 - Tension drive roller

- 16 Étape 15 - Tension slave roller

- 17 Étape 16 - Check all fasteners

- 18 Étape 17 - Fit drive motor and flange

- 19 Étape 18 - Fit blower fittings

- 20 Commentaires

Introduction

Tools Required

standard hex key set

Standard spanner set

Standard HSS drill set

Standard tap set

Utility knife

Parts Required

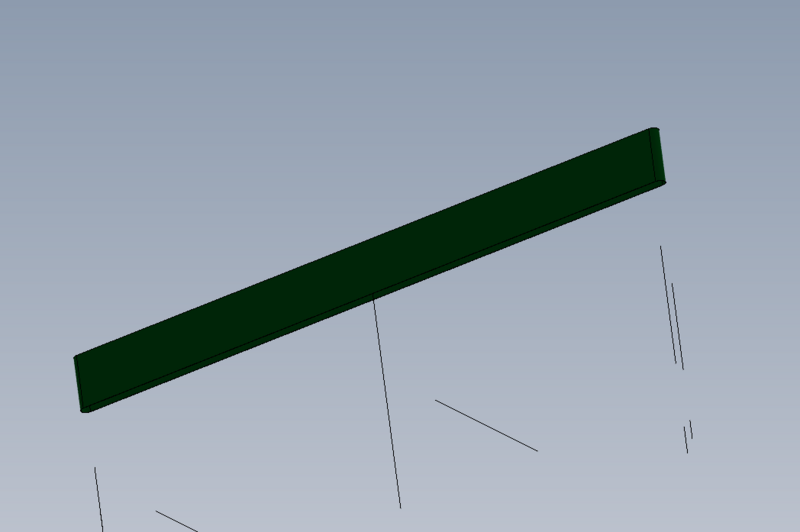

B0000441 Conveyor 3580mm x 300mm x 1

B0001013 Conveyor Motor SEW - WA 10 x 1

B0001177 Pair conveyor side cheeks and bearings slave x 2

M0000133 Conveyor Belt XL-AS 7350 x 300 B x 1

P0000200 Elbow Adaptor 6mm - M5 x 3

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Drill blower points on rollers

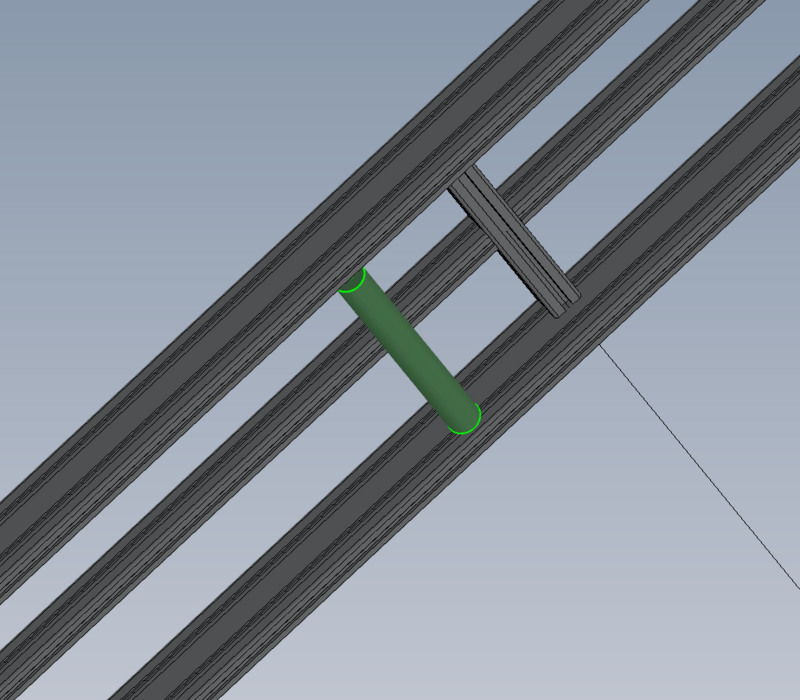

indicated 3 roller housings will require blower holes adding

Mark Blowers as shown . Please provide dimensions for these holes

Drill through with 2.5mm drill

Then drill half way from outside face with 4.2mm drill

Then tap outside face shown M5

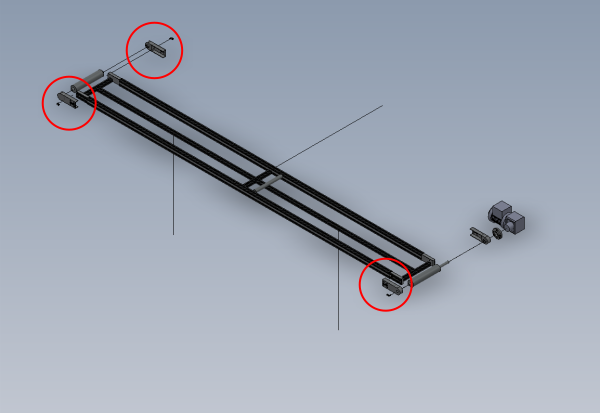

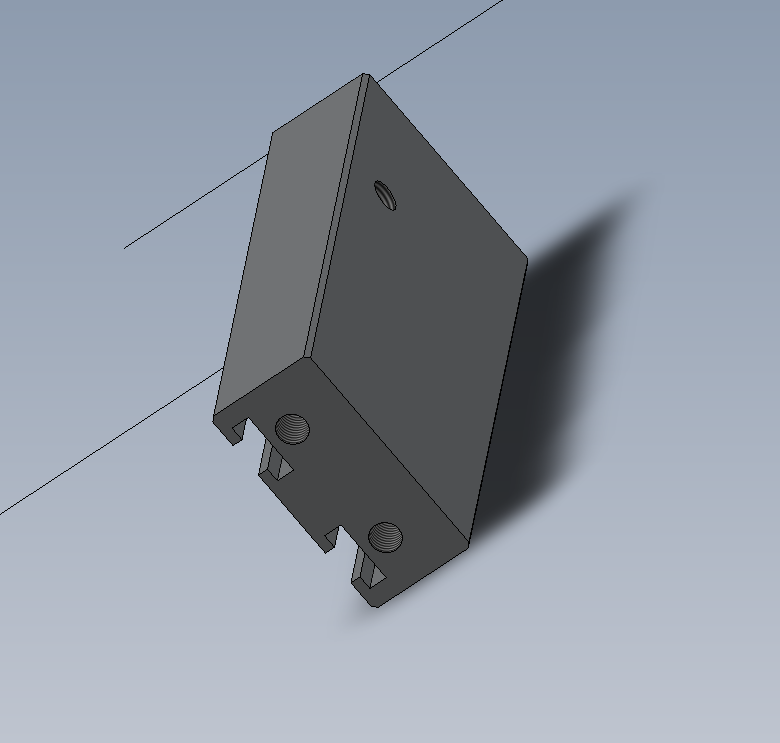

Étape 3 - Assemble mounts

Assemble 4 off mounts

Ensure maytec fittings are orientated correctly

Ensure spring clip is fitted to D nut

Please capture picture of maytec fittings added to this block and correct orientation

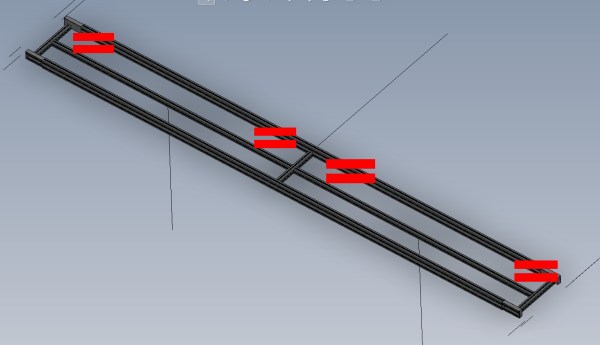

Étape 4 - insert M4 plate nuts

insert 8 off supplied m4 plate nuts into correct face of long frame sections

4 off per side

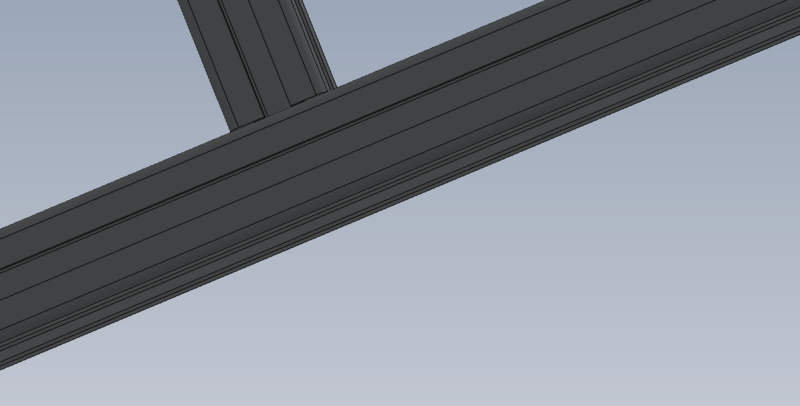

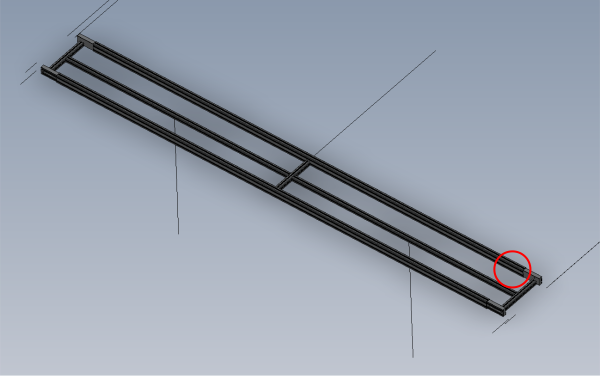

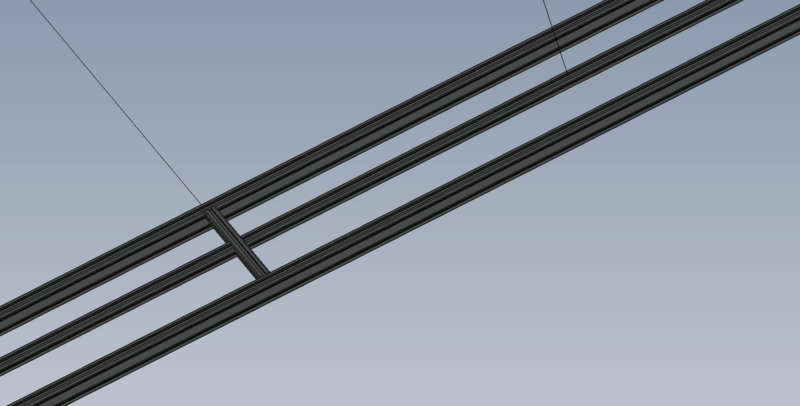

Étape 5 - Assemble main frame

Assemble main maytec frame

Ensure all sections are set in a parallel position

Please capture pictures for this please

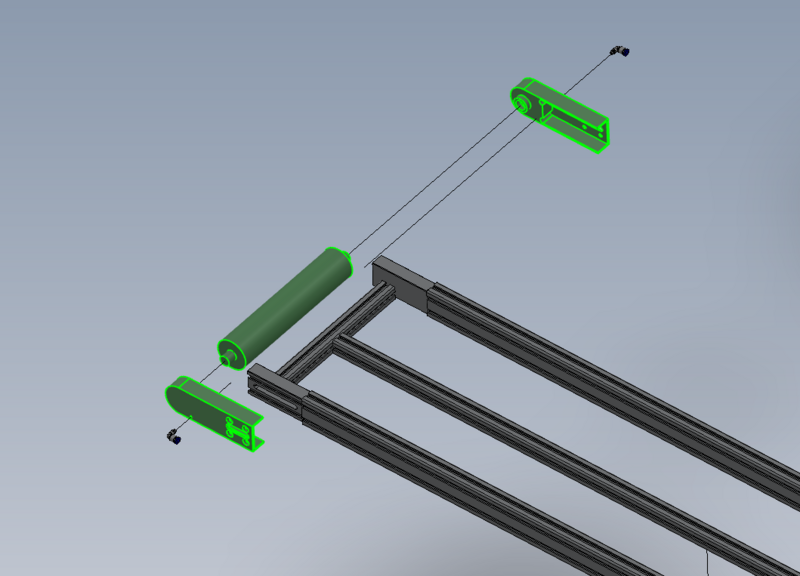

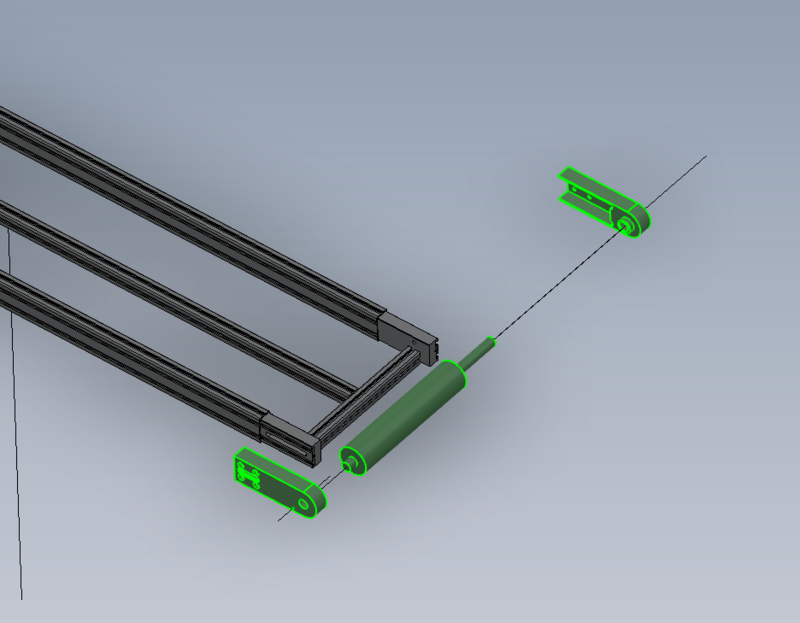

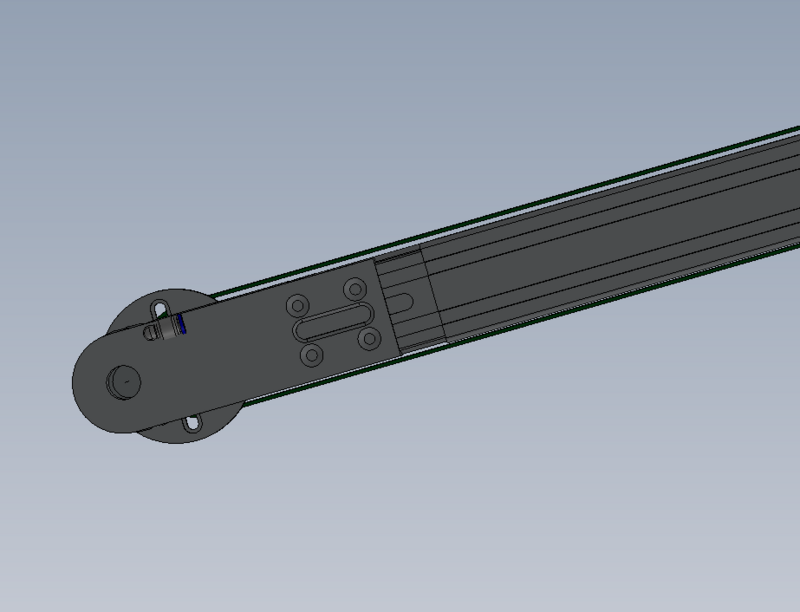

Étape 7 - Fit Slave roller (non driven)

Fit slave roller assembly as shown

Ensure spacer washers are fitted

Ensure blower points are orientated correctly to suit belt rotation direction

Better photos required please

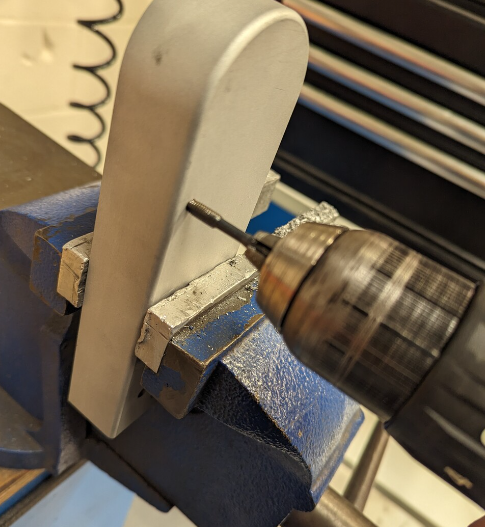

Étape 8 - Fit drive roller

Fit drive roller assembly as shown

Ensure spacer washers are fitted

Ensure blower point is orientated correctly to suit belt rotation direction

Photos in correct sequence required please

Étape 9 - Attach adhesive tape

Fit supplied adhesive tape to top face of frame at shown points

Photos required in correct sequence please

Étape 10 - Quality Check

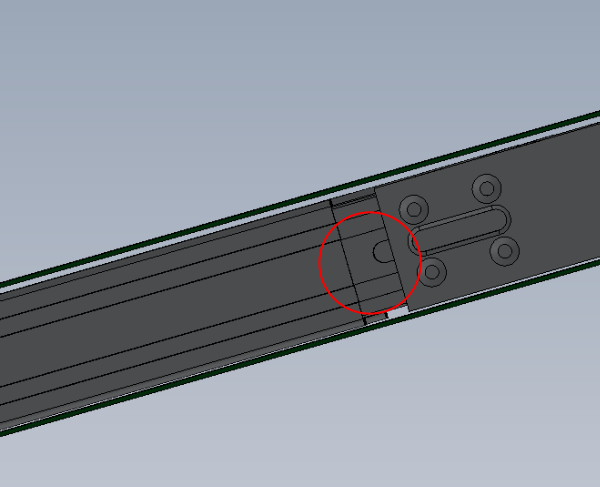

Check issued stainless plates 2 off have been countersunk correctly

M4 countersunk should sit flush, not above top of stainless sheet

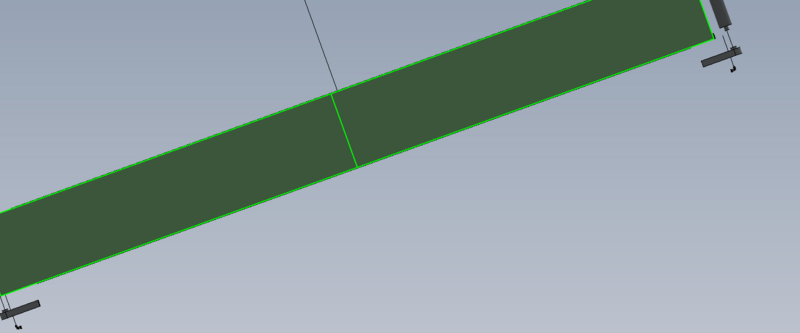

Étape 11 - Fit stainless top plates

Use stainless plates as a guide to align M4 plate nuts before removing adhesive tape backing

Once aligned , remove adhesive tape backing and secure stainless plates into position

Fit 8 off supplied m4 countersunk hex sockets to finalise stainless plate fitting

Photos required in correct sequence please

Étape 14 - Tension drive roller

Set lower roller tension (motor end)

Measure and set gap to 15mm either side

Photos required in correct sequence please

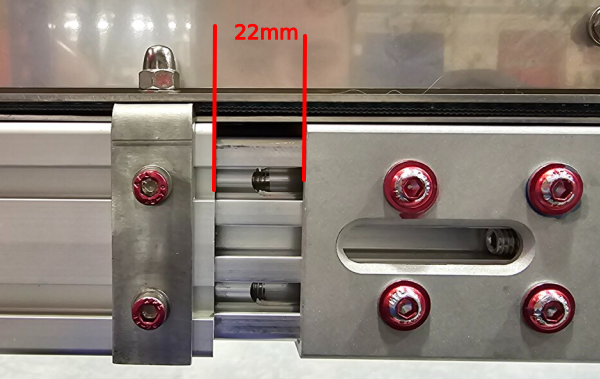

Étape 15 - Tension slave roller

Tension drive roller to 22mm gap at both sides of roller

Ensure both sides are set tot he same measurement

Photos required in correct sequence please

Étape 16 - Check all fasteners

Quality check all fasteners

ensure all fasteners have adhesive applied, are correctly tensioned and are pen marked to indicate finalised

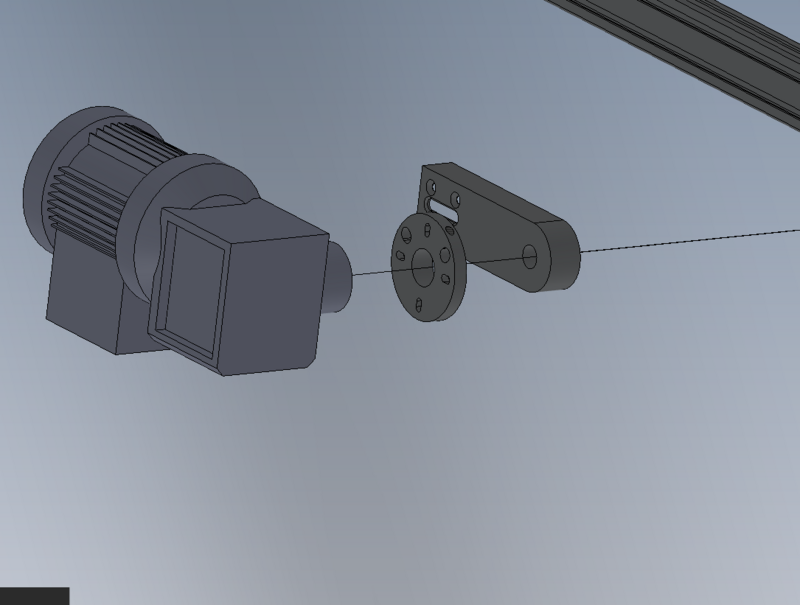

Étape 17 - Fit drive motor and flange

Fit drive flange to bearing cheek ensuring correct orientation to allow correct fitment of motor

Fit motor to bearing flange, do not apply final tension or adhesive to locating grubscrew as motor will need to be removed later on

It is important to test fit at this stage to identify correct fitment

Photos required in correct sequence please

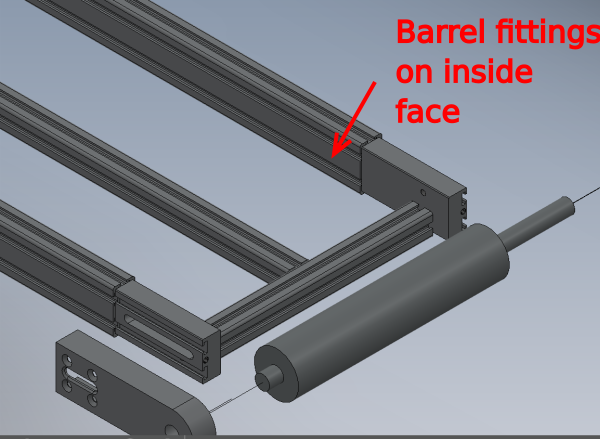

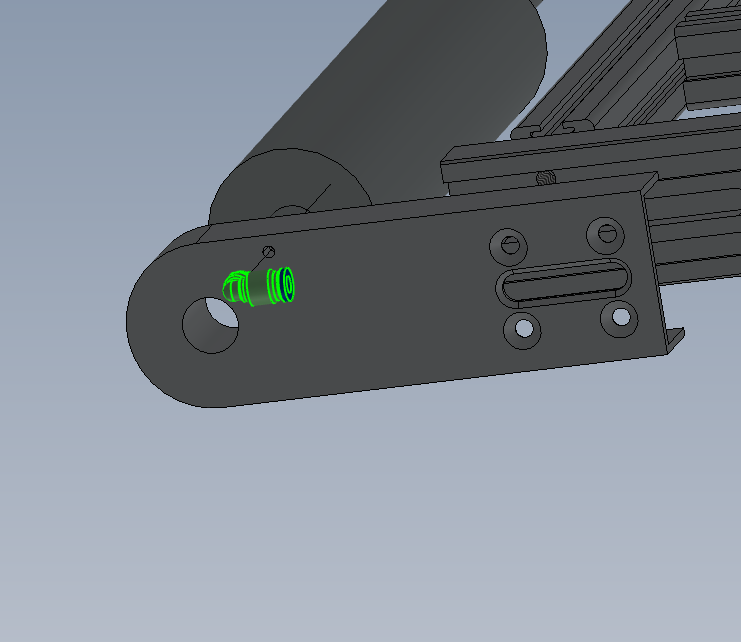

Étape 18 - Fit blower fittings

Fit 3 off blower fittings to mounting points on bearing cheeks

Photos required in correct sequence please

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português