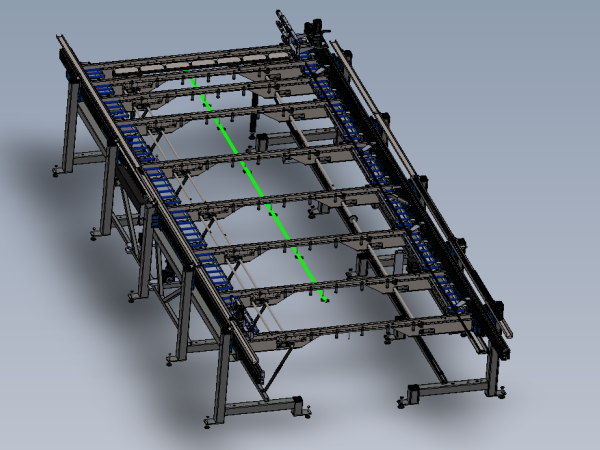

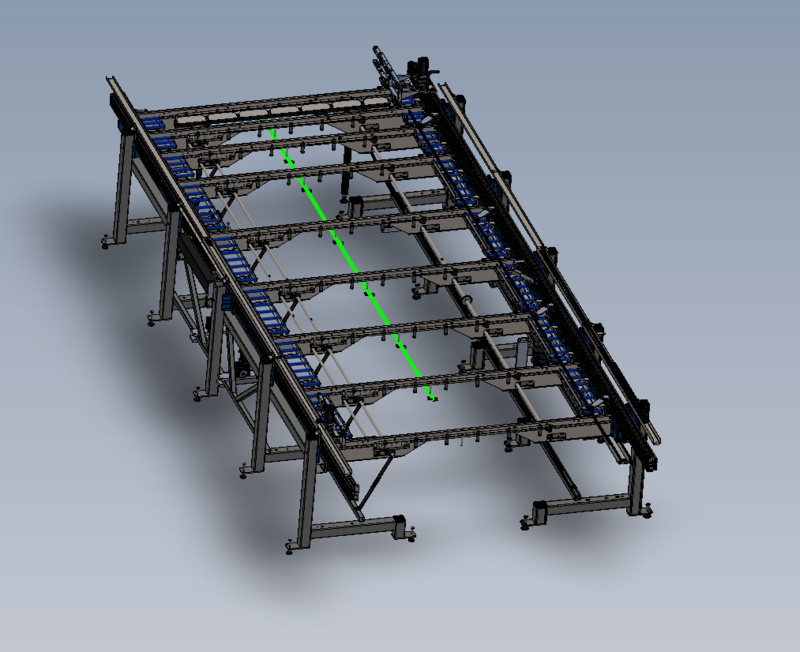

Assembly and connection details for transfer pneumatic rail

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

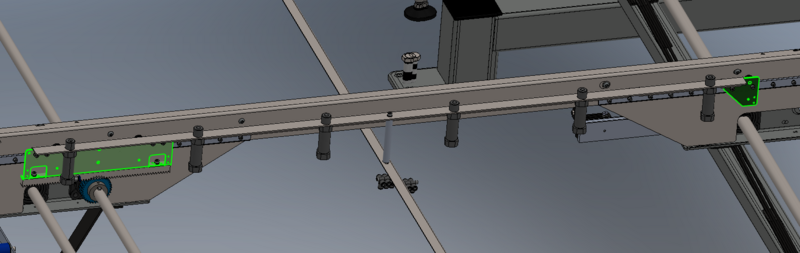

- 3 Étape 2 - Fit connection rail

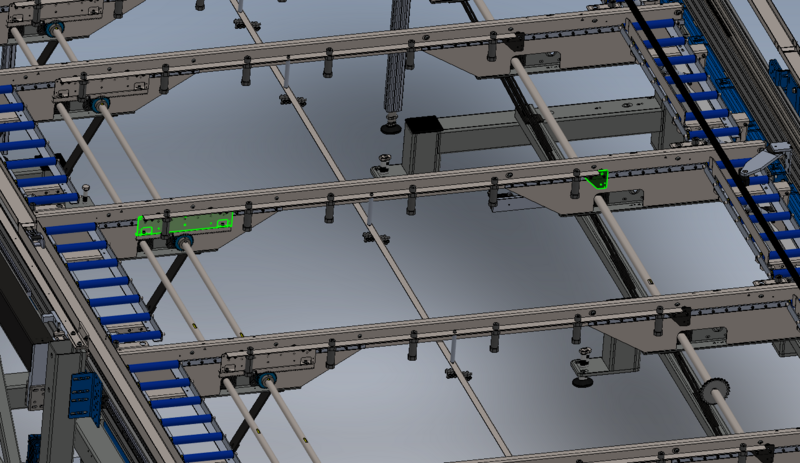

- 4 Étape 3 - Add energy chain mounting brackets

- 5 Étape 4 - Connect energy chains from modules

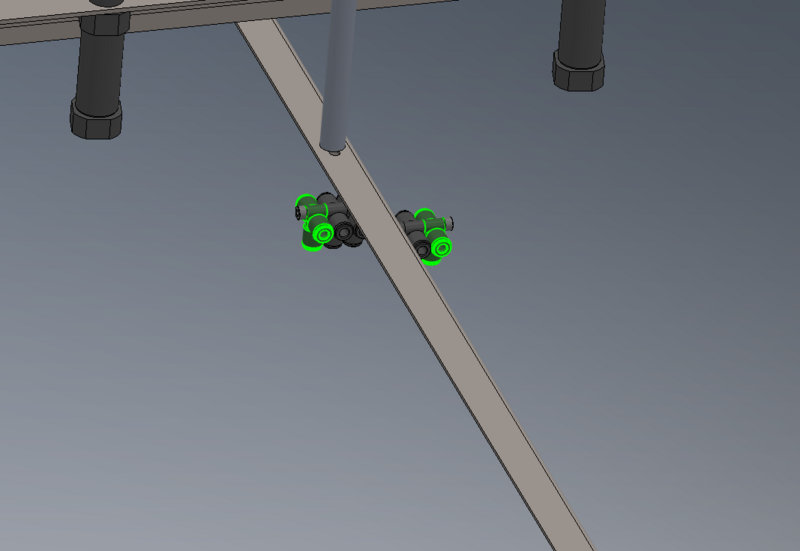

- 6 Étape 5 - Add Y connections

- 7 Étape 6 - Connect Feed pipes

- 8 Étape 7 - Add P0000551 Quick exhaust valves

- 9 Étape 8 - Connect cylinder rail 1 pipe loom

- 10 Étape 9 - Connect cylinder rail 2 pipe loom

- 11 Étape 10 - Connect cylinder rail 3 pipe loom

- 12 Étape 11 - Connect cylinder rail 4 pipe loom

- 13 Étape 12 - Connect cylinder rail 5 pipe loom

- 14 Étape 13 - Connect cylinder rail 6 pipe loom

- 15 Étape 14 - Connect cylinder rail 7 pipe loom

- 16 Étape 15 - Connect cylinder rail 8 pipe loom

- 17 Étape 16 - Connection test

- 18 Commentaires

Introduction

Tools Required

Standard hex key set

Pipe cutters

Standard spanner set

Parts Required

D0015578 Energy Chain Bracket - Moving x 2

P0000551 6mm inline Quick Exhaust Fitting x 6

P0000046 6mm y fitting x 6

R0015289 Bench assemble pipe connection rail

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 4 - Connect energy chains from modules

Connect fitted energy chains from modules C and E to brackets

Étape 16 - Connection test

Once all pneumatic connections have been made, an air test is required to identify any connection leaks

2349 Disconnect from module C multi head outfeed valve bank and connect to air supply. Check no audible leaks are present and all cylinders identified as 2349 fire and pistons extend. Check that pistons retract when air is removed

2339 Disconnect from module C multi head outfeed valve bank and connect to air supply. Check no audible leaks are present and all cylinders identified as 2339 fire and pistons extend. Check that pistons retract when air is removed

2329 Disconnect from module C multi head outfeed valve bank and connect to air supply. Check no audible leaks are present and all cylinders identified as 2339 fire and pistons extend. Check that pistons retract when air is removed

2319 Disconnect from module E Saw infeed valve bank and connect to air supply. Check no audible leaks are present and all cylinders identified as 2319 fire and pistons extend. Check that pistons retract when air is removed

2309 Disconnect from module E Saw infeed valve bank and connect to air supply. Check no audible leaks are present and all cylinders identified as 2309 fire and pistons extend. Check that pistons retract when air is removed

2299 Disconnect from module E Saw infeed valve bank and connect to air supply. Check no audible leaks are present and all cylinders identified as 2299 fire and pistons extend. Check that pistons retract when air is removed

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português