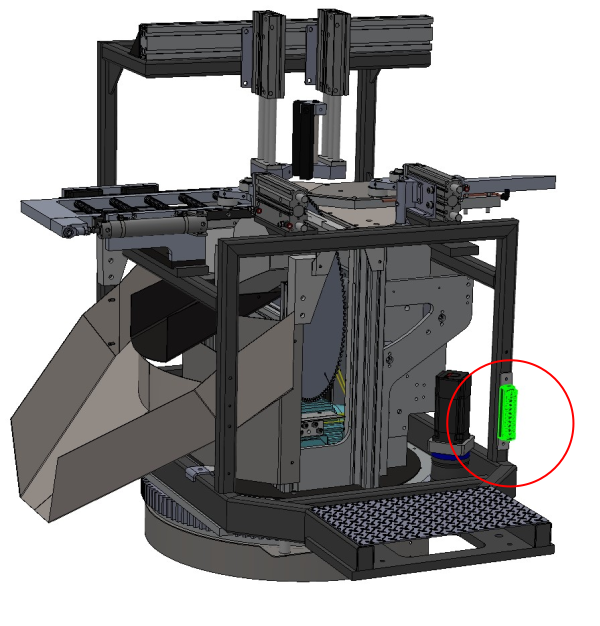

Moving the SR axis datum sensor to a higher level to prevent damage and improve reliability Autoflow Mk4 only

Introduction

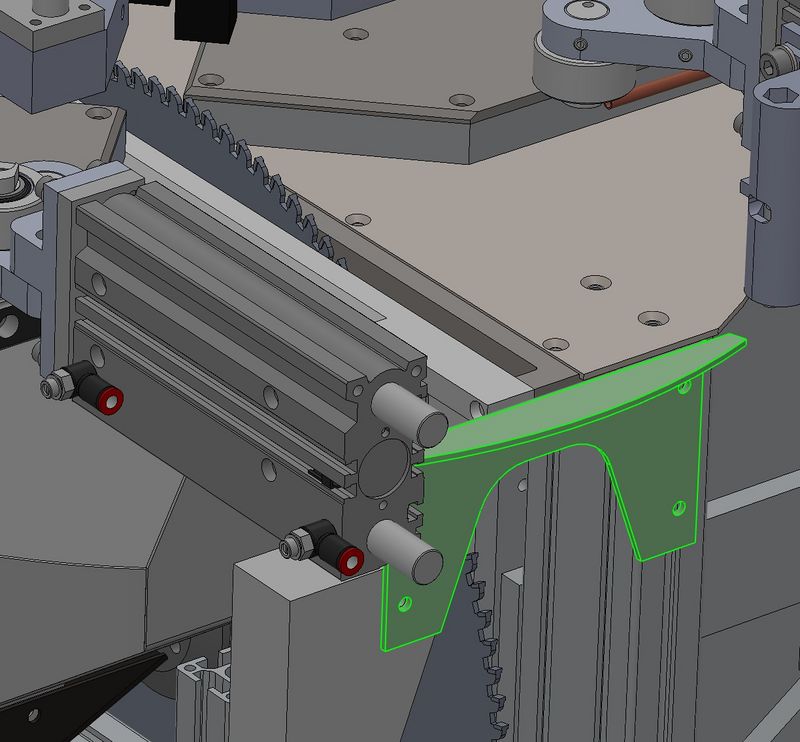

On a Mk4 Autoflow, The SR axis daum sensor is originally located at the rear and to the base of the SR axis. This area is prone to offcuts, so a new location has been designed at the top, with the following design parameters

- Easy to retrofit

- Sensor is protected in a case

- Short distance to connection box

- Uses existing mounting holes

- Easy to adjust and maintain

- Sensing end location should be vertical onto a plate, not horizontal on to a radiused surface

- Can use E0000336 2mm range sensor reliably

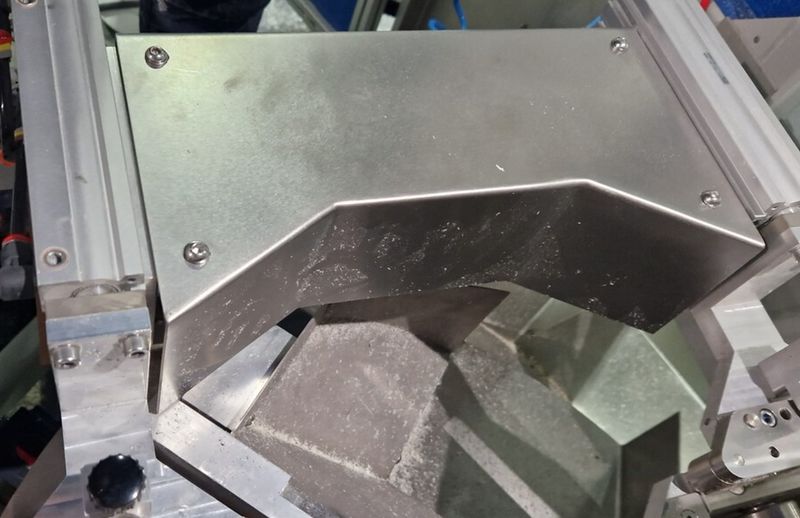

- Incorporate a front fence to help deflect offcuts down the chute and to protect the sensor

The parts are supplied in Kit R0019217B

Étape 1 - Fit Replacement SR Detection bracket

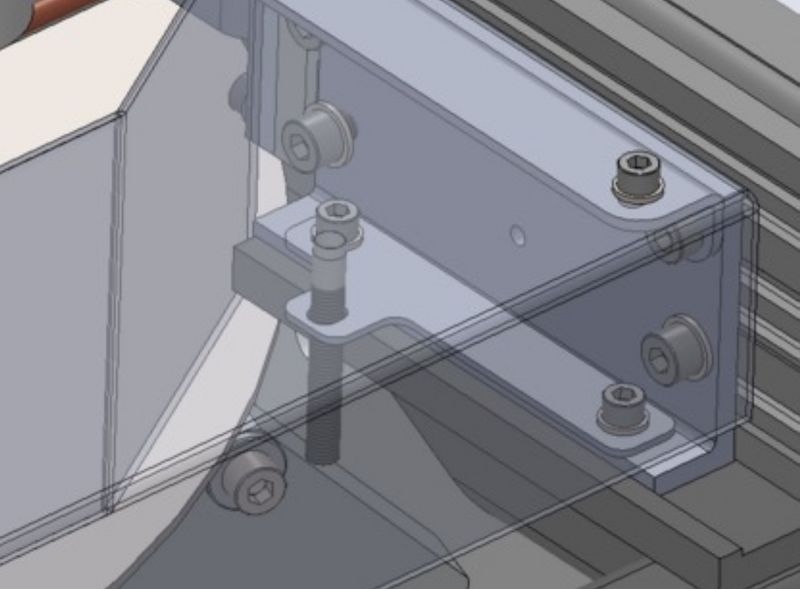

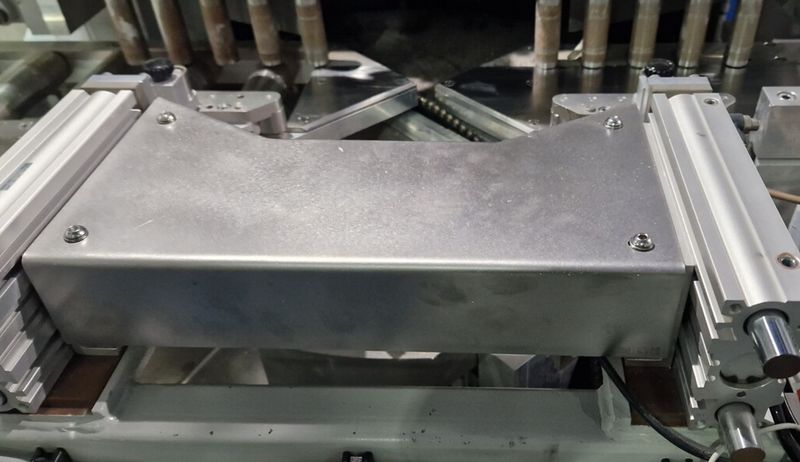

Replace the upper brace plate with D0016338. This has the detection plate for the SR axis added on the top

Étape 2 - Assemble Sensor Cable and Holder

- Assemble the cable using E0001046 cable plus E0001069

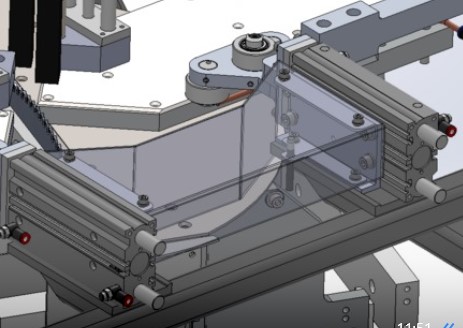

- Add E0000336, and assemble in to D0016348 Autoflow SR Sensor holder

- The sensor (with fastening nut) should protrude 5mm from base of holder

Étape 3 - Fit wire

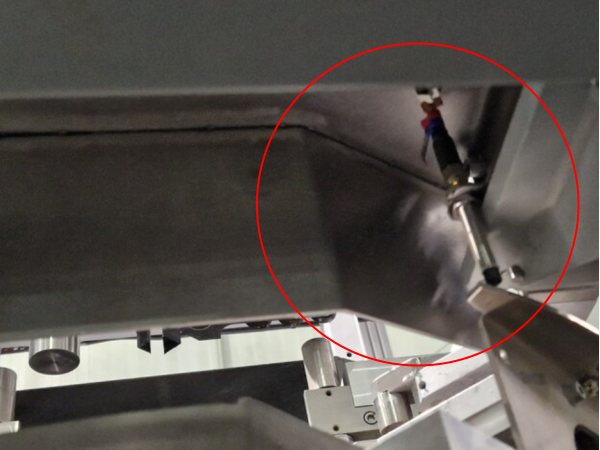

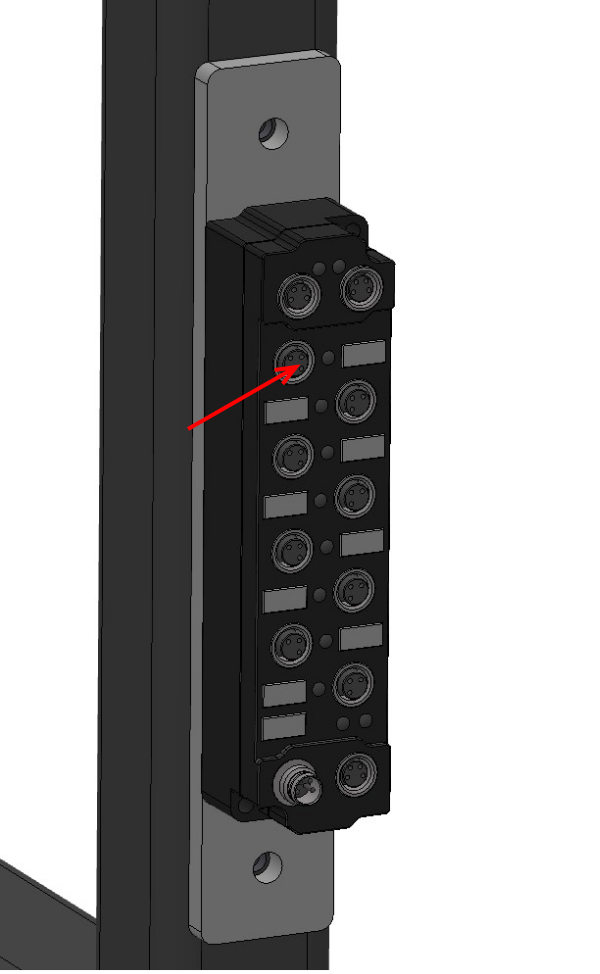

Sensor Cable X126 replaces the original cable in top channel

(see pic)

Tidy the cable into a loop and cable tie along length to saw frame upright strut

Étape 4 - Adjust Datum sensor height

Adjust the height of the sensor so it is 0.5-1mm clear of SR Detection Bracket

Check the sensor switches on and off with rotation of SR axis

Check the input flashes on and off the EtherCAT box

Étape 6 - Reset Datum

Changing the datum sensor location will mean that the SR datum position will need to be reset

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português