Instructions to mount completed assemblies to main frame

Sommaire

- 1 Introduction

- 2 Étape 1 - This Dokit has two parts

- 3 Étape 2 - Unless otherwise stated

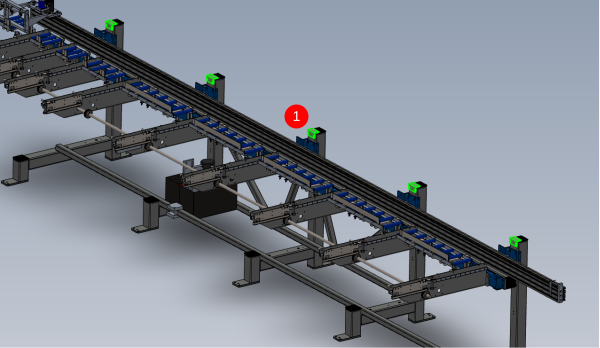

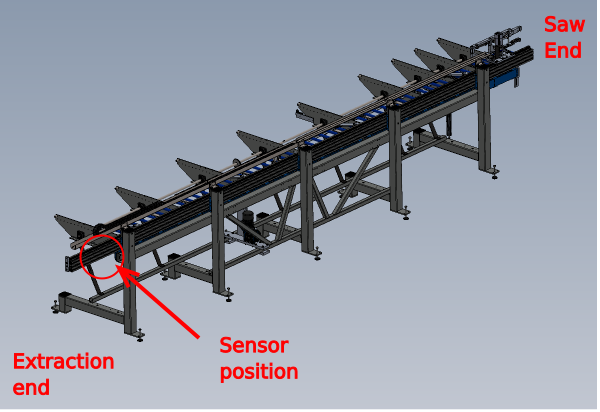

- 4 Étape 3 - Mount pre built R0015063 Bench Assemble Roller Tables

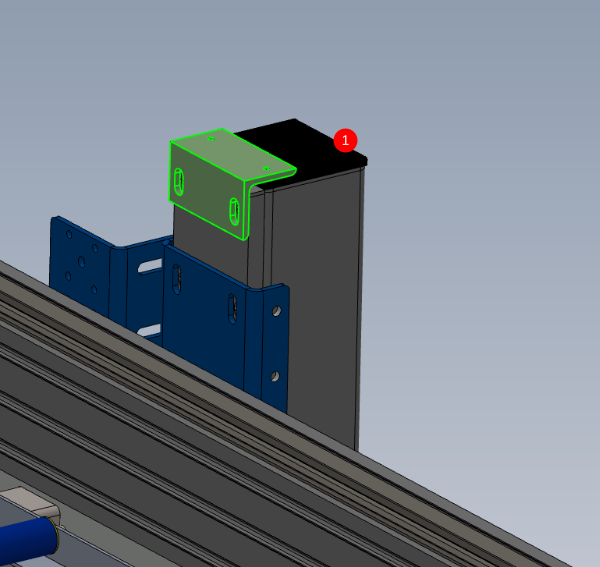

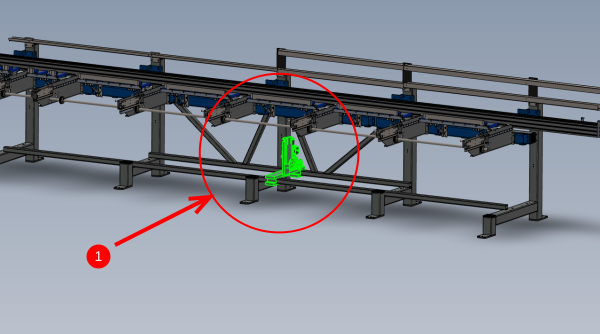

- 5 Étape 4 - Mount pre built R0015011 Bench Assemble Gripper

- 6 Étape 5 - Mount Energy chain angle brackets Lower

- 7 Étape 6 - Mount short upper chain angle brackets

- 8 Étape 7 - Fit lower chain trays

- 9 Étape 8 - Fit Carriage bracket

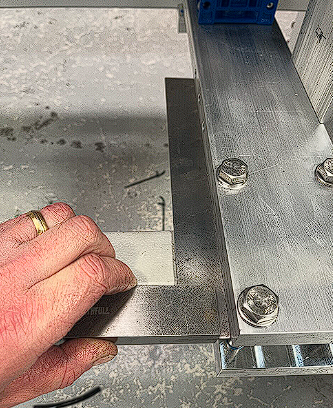

- 10 Étape 9 - Fixed end fixing position

- 11 Étape 10 - Attach pre built R0015286 energy chain

- 12 Étape 11 - Adjust lower trays to suit energy chain

- 13 Étape 12 - Adjust lower tray height

- 14 Étape 13 - Quality check

- 15 Étape 14 - Finalise fixings

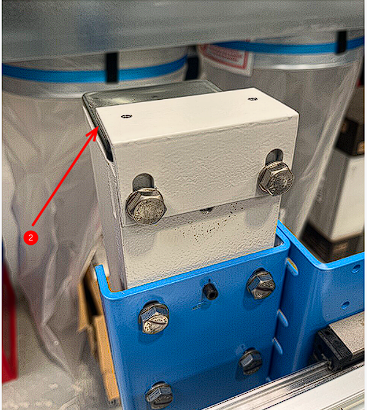

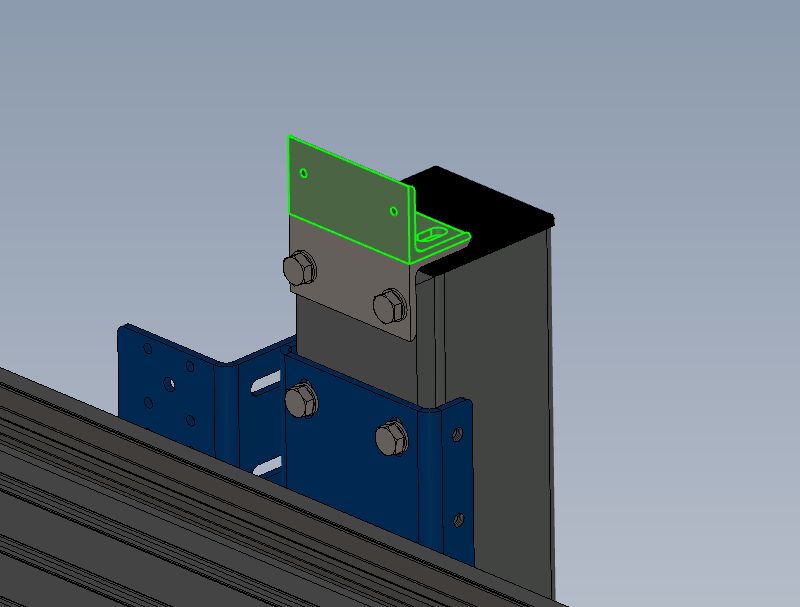

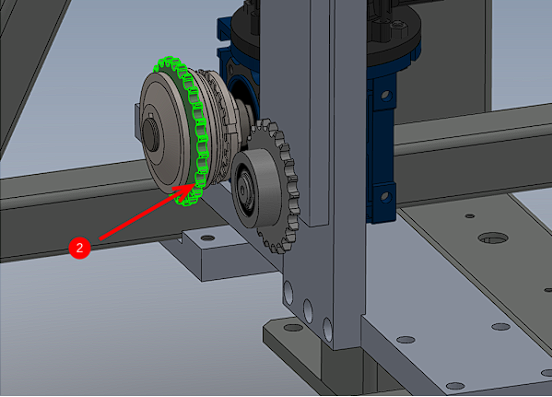

- 16 Étape 15 - Mount Datum Sensor and bracket

- 17 Étape 16 - Mount R0015096 Bench Assemble Transfer Drive Assembly

- 18 Étape 17 - Add drive chain

- 19 Étape 18 - Now move to section two

- 20 Commentaires

Introduction

Tools Required

Standard Hex key set

Standard spanner set

300 mm rule

1000mm rule

Parts Required

D0008288 Takeup Pad Left (D7339) (Wet/P F Matt) x 1

D0015583 Take Up Beam Joiner x 1

D0015598 Datum Flag: Saw Infeed x 1

D0015717 Energy Chain Angle Bracket Lower x 5

D0015718 Energy Chain Angle Bracket Upper x 5

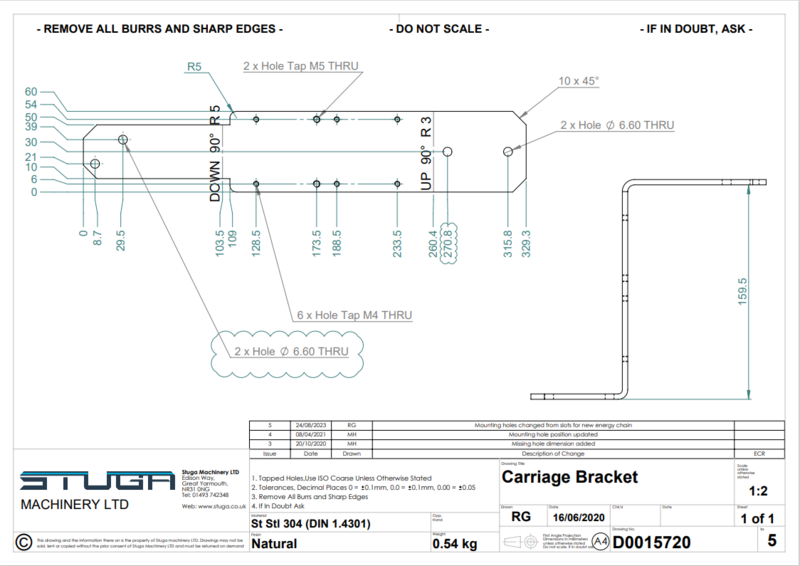

D0015720 Carriage Bracket x 1

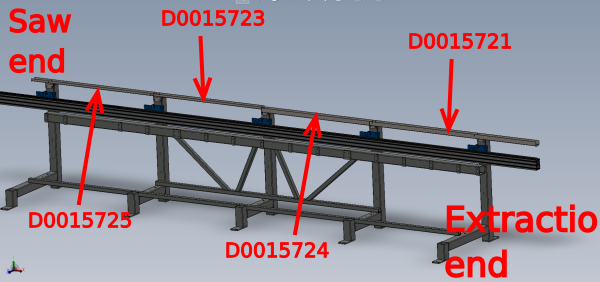

D0015721 Energy Chain Tray Deep Long x 1

D0015723 Energy Chain Tray Shallow x 1

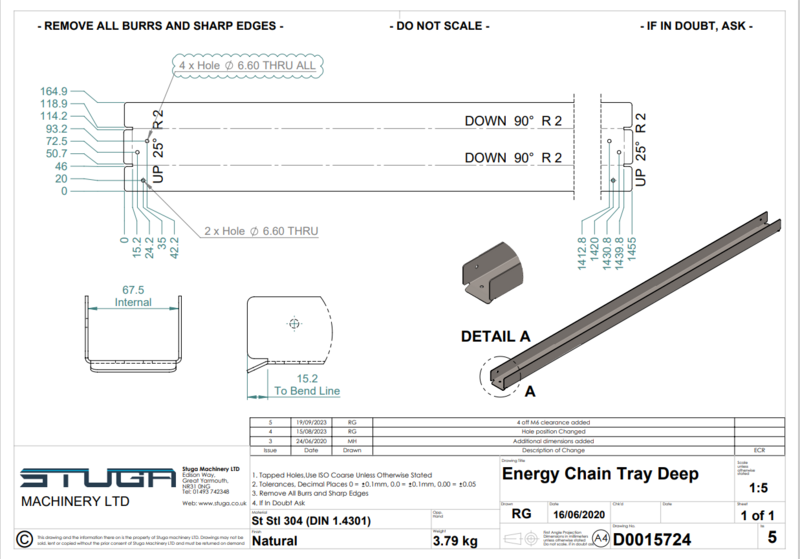

D0015724 Energy Chain Tray Deep x 1

D0015725 Energy Chain Tray Shallow Medium x 1

D0015742 Takeup Pad Right ZX5 x 1

E0000336 Sensor: M8; 2mm, PNP N/O, M8 conn x 1

R0015011 Bench Assemble Gripper

R0015063 Bench Assemble Roller Tables

R0015096 Bench Assemble Transfer Drive Assembly

R0015101 Bench assembly take up assembly

R0015286 Bench Assemble X axis components and energy chain

Étape 1 - This Dokit has two parts

This dokit is split into 2 parts , please ensure part 2 is used

Étape 2 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all fasteners to show finalised

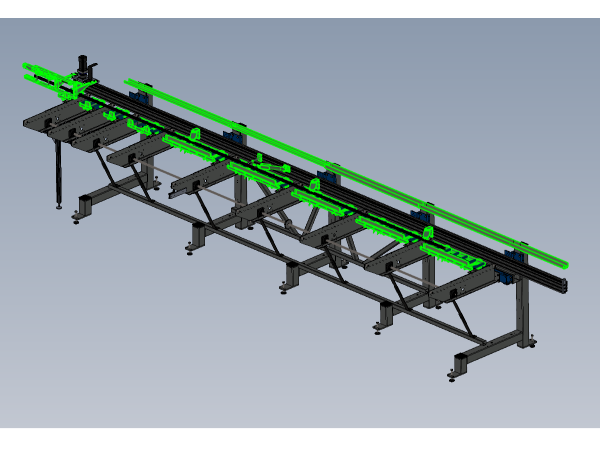

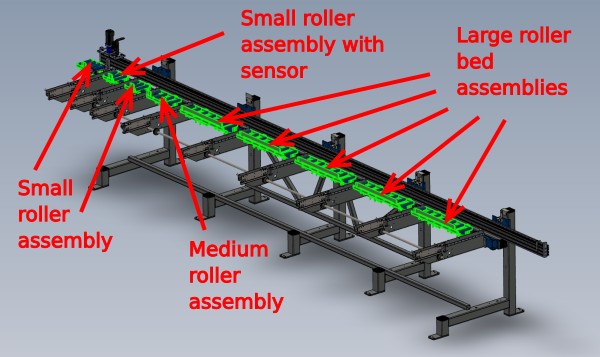

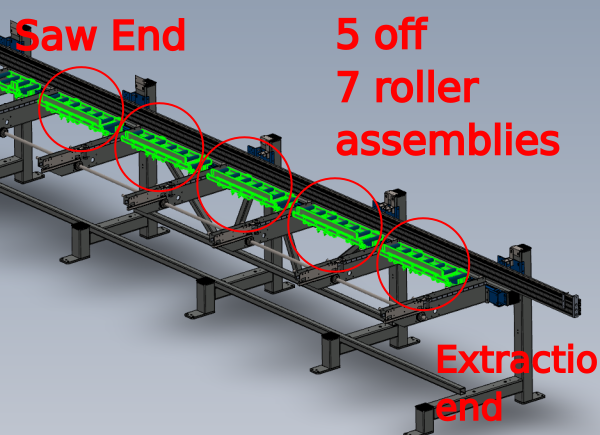

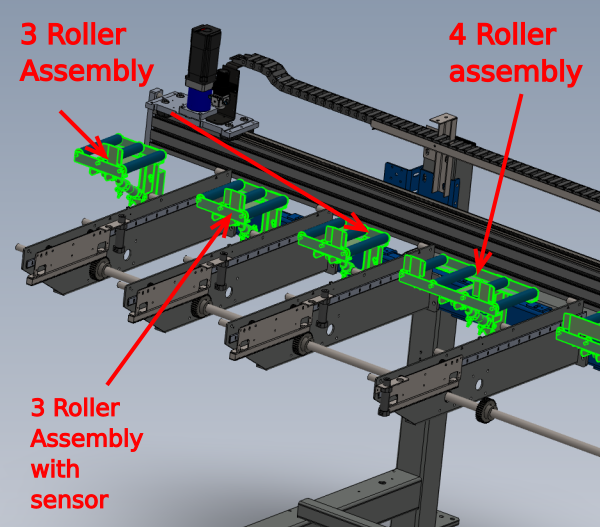

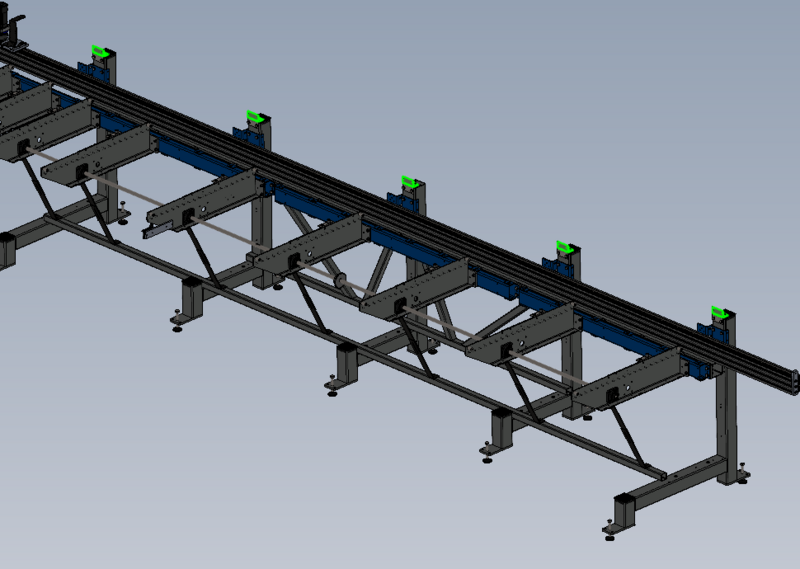

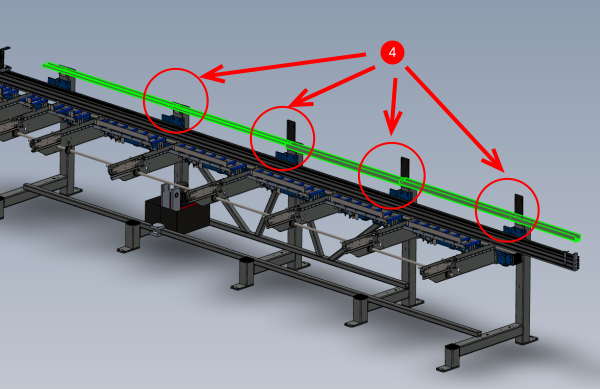

Étape 3 - Mount pre built R0015063 Bench Assemble Roller Tables

Mount roller beds as indicated , using M8 x 30 socket caps and heavy M8 washers.

Do not apply adhesive to fasteners and only apply holding tension to fasteners

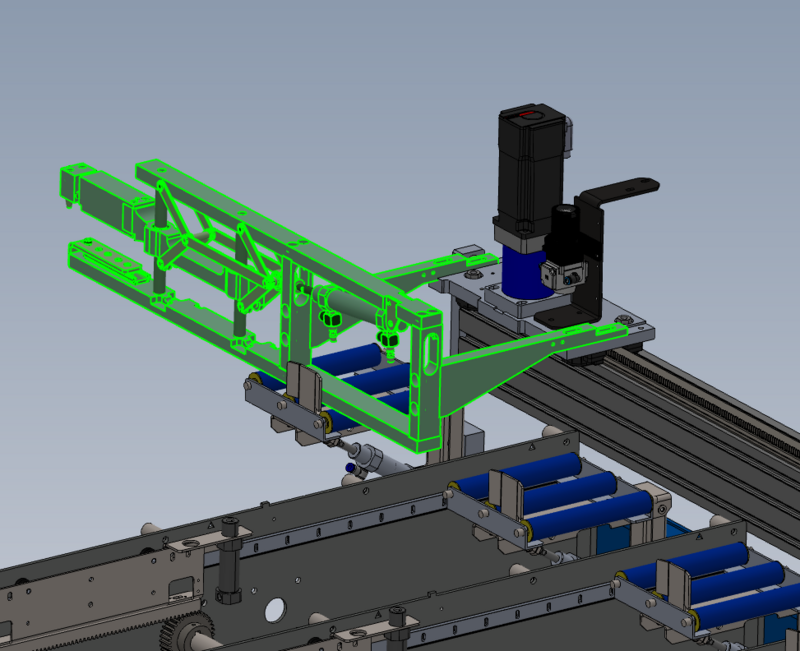

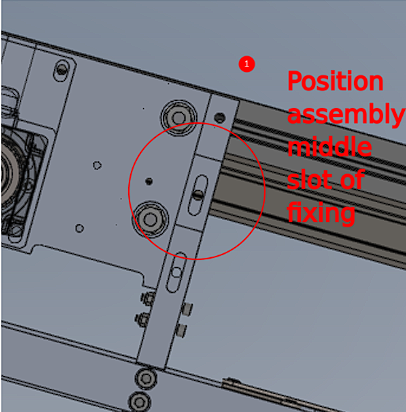

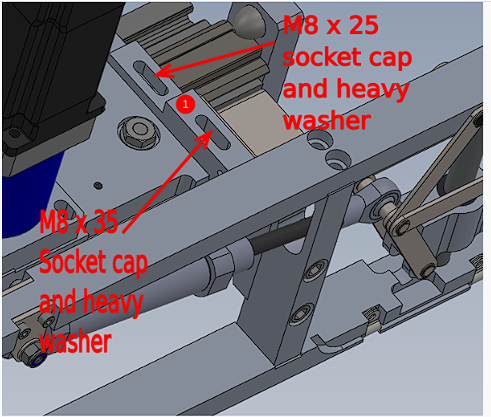

Étape 4 - Mount pre built R0015011 Bench Assemble Gripper

1 Mount Gripper assembly to carriage using 2 off M8 x 35 socket caps 2 off Mi8 x 2 5 socket caps and heavy M8 washers

2 Check and adjust parallel to ensure gripper is true to hepco beam both indicated measurements should be identical

Étape 5 - Mount Energy chain angle brackets Lower

1 Mount 5 off D0015717 Lower mounting angle with 2 off M10 x 30 set bolts and A form washers per bracket . Do not apply adhesive at this point

2 Set height to just clear plastic frame cap and set bracket level

Étape 6 - Mount short upper chain angle brackets

Mount 5 off D0015718 to indicated points using M6 x 16 socket caps and heavy M6 washers . Set faces flush as with previous step

Do not apply adhesive at this point

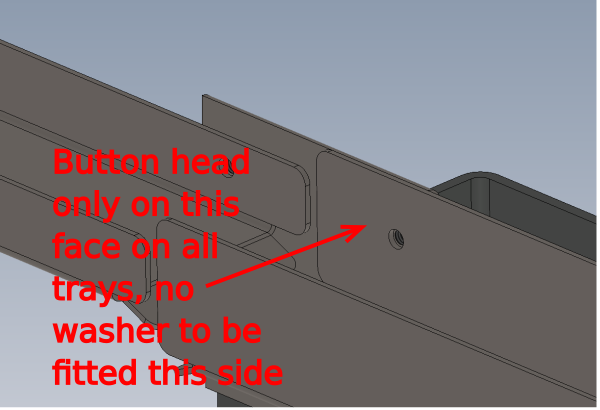

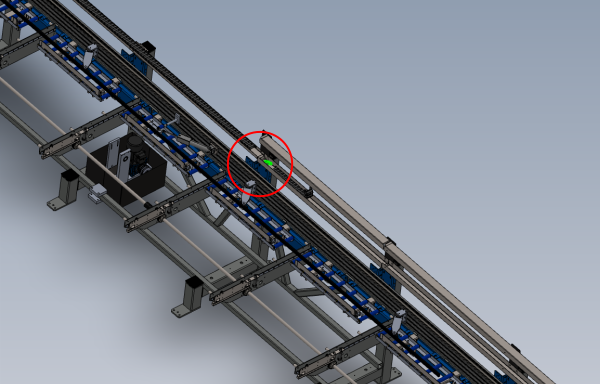

Étape 7 - Fit lower chain trays

Lightly fix these parts, as adjustment will be required later

1 Fit D0015721 to indicate point Using M5 x 16 button hex bolt, M5 penny washer and M5 nyloc nut .

2 Fit D0015724 to indicate point with same fixings as above

3 Fit D0015723to indicate point with same fixings as above

4 Fit D0015725 at indicated position .

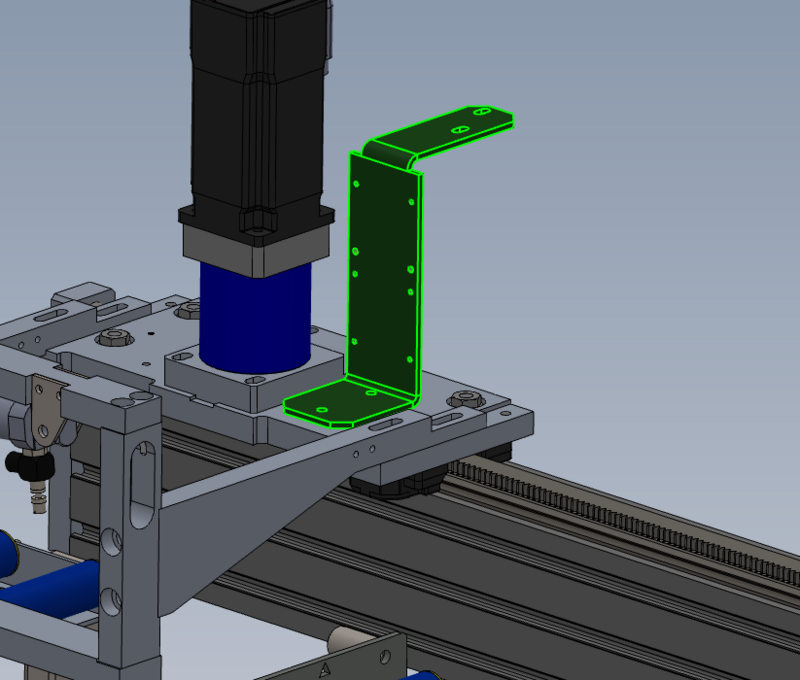

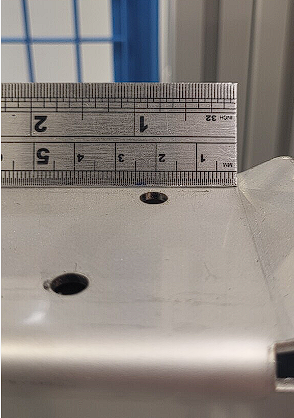

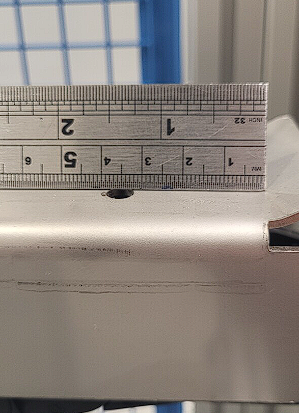

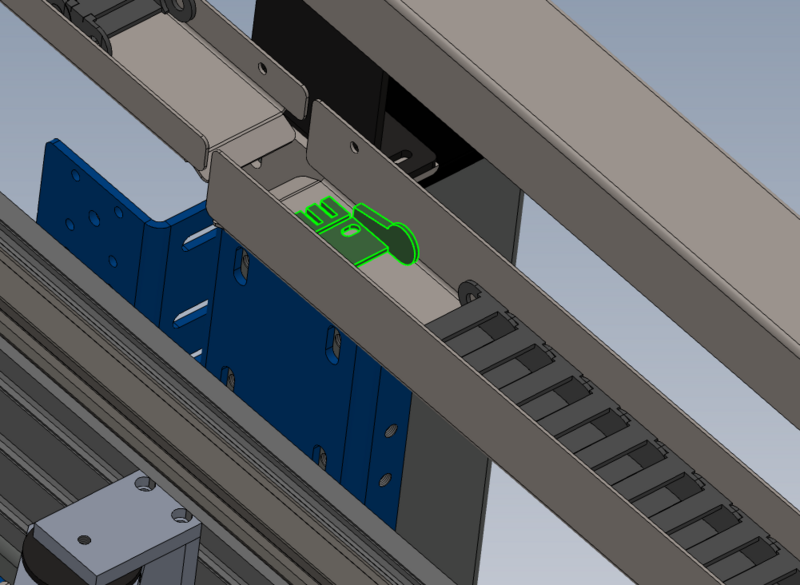

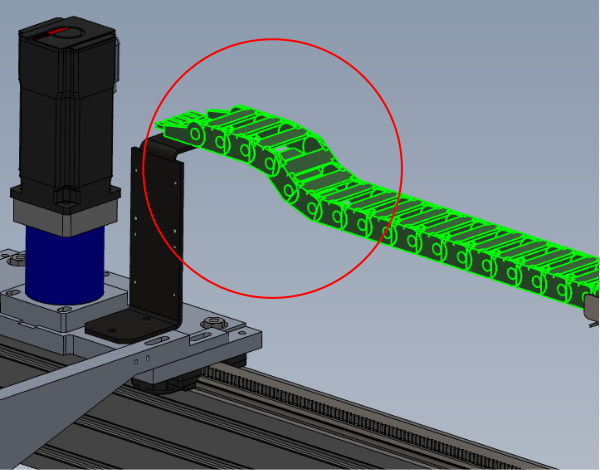

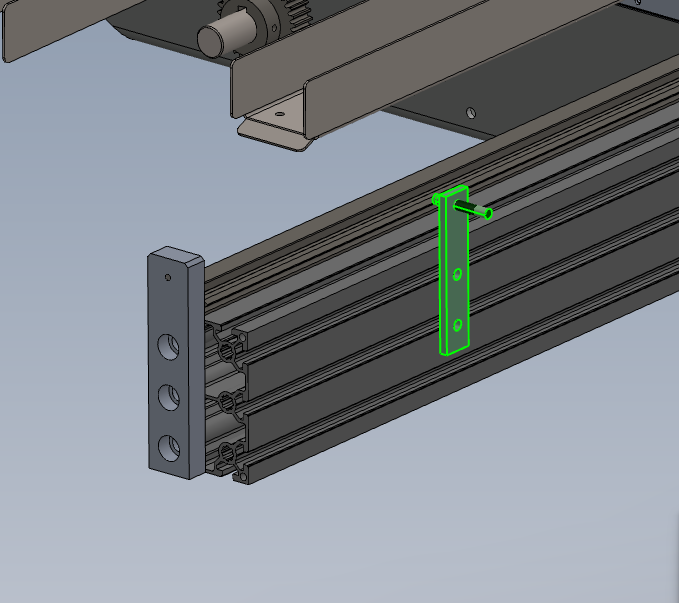

Étape 8 - Fit Carriage bracket

Fit D0015720 carriage bracket as shown using M6 x 16 socket caps and A form washers

Ensure bracket is mounted square on carriage plate

Étape 9 - Fixed end fixing position

Fixed part of energy chain be be at this position on mounting tray

1st hole 20mm from fold

2nd hole 35mm from fold

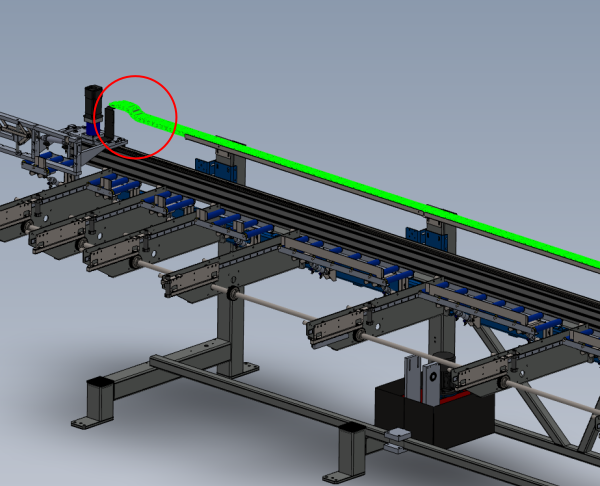

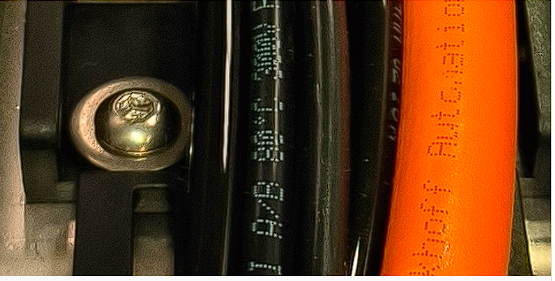

Étape 10 - Attach pre built R0015286 energy chain

Fit pre built energy chain from assembly R0015286 and attach using M5 x 16 button heads, medium washers and M5 nyloc nuts as shown

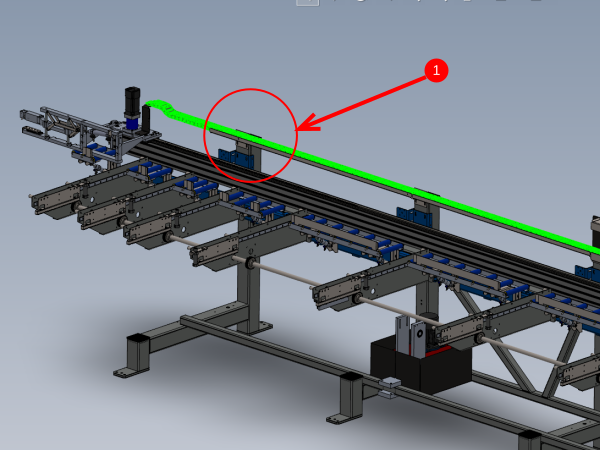

Étape 11 - Adjust lower trays to suit energy chain

1 Move gripper with energy chain attached to point indicated

2 Adjust bracket in indicated direction so that energy chain sits central in the tray

3 Measure indicated distance S

4 Set the next 4 lower tray mounting points to replicate this measurement using the same method of adjustment with the angled bracket

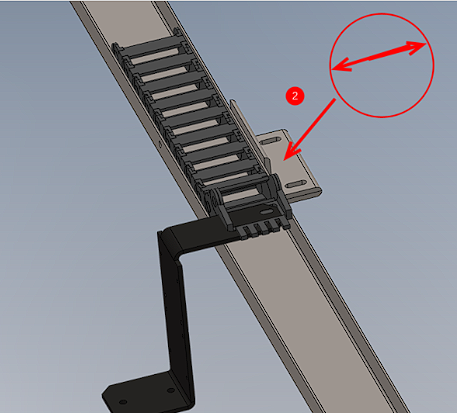

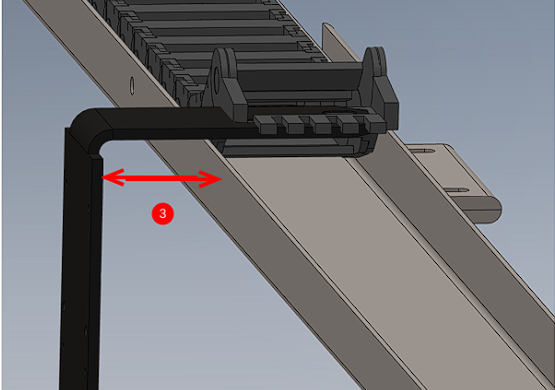

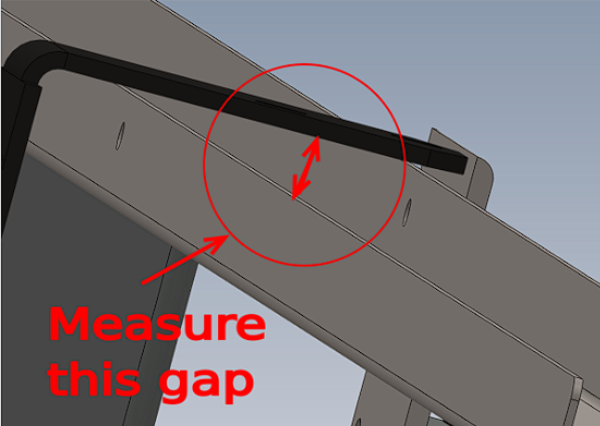

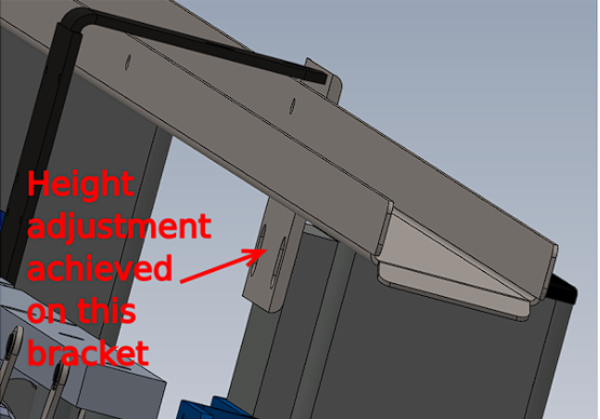

Étape 12 - Adjust lower tray height

Using the first point used to set the brackets , measure the gap indicated and replicate this measurement on the other 4 points . This is adjusted by moving the indicated bracket up or down .

Étape 13 - Quality check

Move Gripper carriage along the complete length of the hepco beam , and monitor the energy chain .

Check that there is no sideways pressure on the chain from misalignment

Check that no snags occur on fixings when energy chain is travelling

Étape 14 - Finalise fixings

Now aligned , ensure all fixings used to assemble the energy trays and brackets have adhesive apllied and final tension added to fasteners and pen marked

Étape 15 - Mount Datum Sensor and bracket

Mount D0015598 with E0000366 as shown. Use M8 d nuts, M8 x 16 socket caps and A form washers

(measurement required for position please)

Set sensor to carriage face. Gap should be no larger than 1mm. Check gap at all points of travel along carriage face

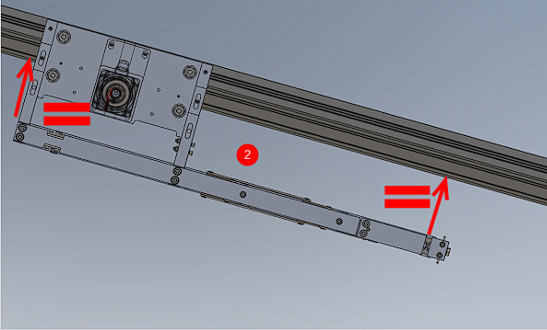

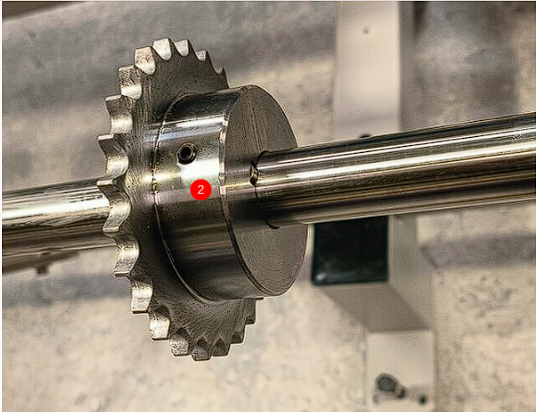

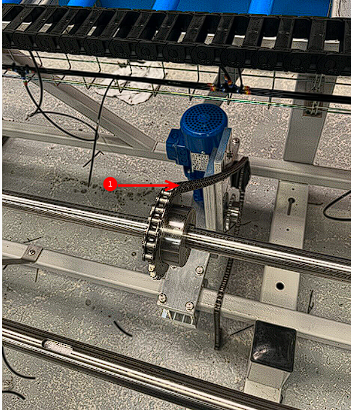

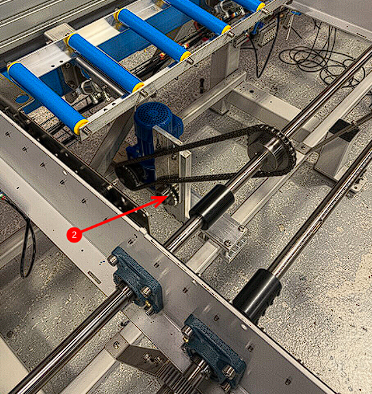

Étape 16 - Mount R0015096 Bench Assemble Transfer Drive Assembly

1 Position 1 off drive assembly in the positions indicated

2 Use a 1000mm steel rule to align indicated sprocket with drive sprocket on drive shaft indicated

Étape 17 - Add drive chain

1 Fit drive chain to shaft sprocket and motor assembly.

2 Adjust tensioner to apply tension to chain. This should be set so chain has minimal slack, but is not under excessive tension.

Étape 18 - Now move to section two

Section two of this dokit must be followed

Found here

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português