| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=Ancil_Saw_Setup_Guidance_Screenshot_2021-03-01_161923.jpg |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.... ») |

|||

| Ligne 6 : | Ligne 6 : | ||

|Tags=Ancil, Cill, Ancilliary | |Tags=Ancil, Cill, Ancilliary | ||

}} | }} | ||

| − | <translate>= Tooling Design = | + | <translate>=Tooling Design= |

Several Cill profile supports have already been designed. | Several Cill profile supports have already been designed. | ||

{{Warning|...All cill support blocks are handed depending on feed of machine}}<br /> | {{Warning|...All cill support blocks are handed depending on feed of machine}}<br /> | ||

| Ligne 12 : | Ligne 12 : | ||

|+ | |+ | ||

!Build Number | !Build Number | ||

| − | !Profile | + | !Profile |

!Profile BMP | !Profile BMP | ||

!Cill Block | !Cill Block | ||

| Ligne 35 : | Ligne 35 : | ||

D0001898-16 Profile Support Block Outfeed SH 100x16mm | D0001898-16 Profile Support Block Outfeed SH 100x16mm | ||

<br /> | <br /> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| − | = Side Clamp Positioner = | + | =Side Clamp Positioner= |

| − | * Ensure Side clamp Positioner stroke length is 100mm to give full range | + | *Ensure Side clamp Positioner stroke length is 100mm to give full range |

| − | * Check range of motion to ensure the side clamp output can grip each profile type using the side clamp output only | + | *Check range of motion to ensure the side clamp output can grip each profile type using the side clamp output only |

| − | = Saw Stroke End Position = | + | =Saw Stroke End Position and 500mm Upgrade= |

| − | Check the widest profile cut at 45 degrees to ensure there is enough travel to complete the cut | + | Cill saws need a 500mm blade upgrade |

| − | + | ||

| + | Check the widest profile cut at 45 degrees to ensure there is enough travel to complete the cut. to get a further 10mm stroke from the saw cut, the mount for the saw stroke cylinder rod end can be modified. {{#annotatedImageLight:Fichier:Ancil Saw Setup Guidance Screenshot 2021-03-02 150400.jpg|0=300px|hash=|jsondata=|mediaClass=Image|type=frameless|align=center|src=https://stuga.dokit.app/images/7/77/Ancil_Saw_Setup_Guidance_Screenshot_2021-03-02_150400.jpg|href=./Fichier:Ancil Saw Setup Guidance Screenshot 2021-03-02 150400.jpg|resource=./Fichier:Ancil Saw Setup Guidance Screenshot 2021-03-02 150400.jpg|caption=|size=300px}} | ||

| + | |||

| + | |||

| + | This has the downside of forcing the start point of the blade up -the blade pokes out 10mm above the slit strips, but this is not a big problem as long as the blade is not above the cut tables | ||

| + | |||

| + | =Saw Stroke Mid Cut Input= | ||

| + | Ancil saws benefit from the mid switch input on the saw stroke, because the stoke speed is inevitably slowed down on the widest profile, which also needs the full stroke range. Adding the mid point switch means narrower and lower profiles do not need the full, slow range of the cut and the cycle time is reduced considerably. | ||

| − | + | See [https://stuga.dokit.app/wiki/Reducing_Saw_Cut_Height_for_Lower_Profiles instructions] on how to set this feature up | |

| − | = Colour Coding Support Blocks and Pusher End = | + | =Colour Coding Support Blocks and Pusher End= |

| + | See instructions for how to set this feature up in a standard way | ||

| − | = BladetoFence Setup = | + | =BladetoFence Setup= |

| + | Bladetofence on an ancil saw should be around 70mm. | ||

| − | = Cill Chute Fill Plate = | + | =Cill Chute Fill Plate= |

| − | <br /></translate> | + | Part number D0005628(-OH) is used to fill in the radius of the chute which helps offcuts of wide cills down the chute{{#annotatedImageLight:Fichier:Ancil Saw Setup Guidance Cill infil.jpg|0=200px|hash=|jsondata=|mediaClass=Image|type=frameless|align=center|src=https://stuga.dokit.app/images/2/29/Ancil_Saw_Setup_Guidance_Cill_infil.jpg|href=./Fichier:Ancil Saw Setup Guidance Cill infil.jpg|resource=./Fichier:Ancil Saw Setup Guidance Cill infil.jpg|caption=|size=200px}}<br /></translate> |

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{AddComments}} | {{AddComments}} | ||

Version du 2 mars 2021 à 16:12

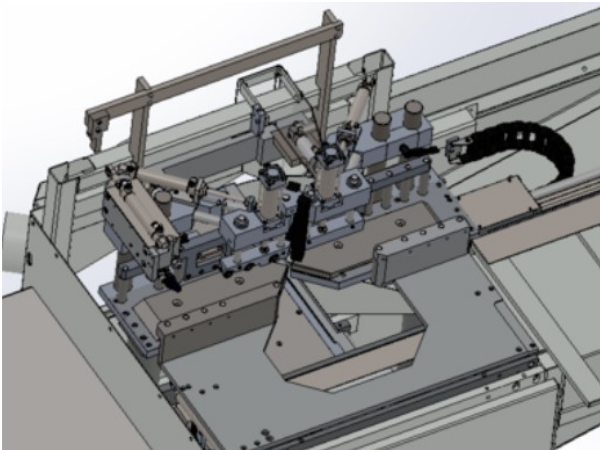

Special guidance for setting up Ancil Saws

Tooling Design

Several Cill profile supports have already been designed.

| Build Number | Profile | Profile BMP | Cill Block |

|---|---|---|---|

| S012 | Rehau 246330 150mm

Rehau 503940 225mm |

D0001897-16 Profile Support Block Infeed SH 100x16mm

D0001898-16 Profile Support Block Outfeed SH 100x16mm

|

Side Clamp Positioner

- Ensure Side clamp Positioner stroke length is 100mm to give full range

- Check range of motion to ensure the side clamp output can grip each profile type using the side clamp output only

Saw Stroke End Position and 500mm Upgrade

Cill saws need a 500mm blade upgrade

Check the widest profile cut at 45 degrees to ensure there is enough travel to complete the cut. to get a further 10mm stroke from the saw cut, the mount for the saw stroke cylinder rod end can be modified.

This has the downside of forcing the start point of the blade up -the blade pokes out 10mm above the slit strips, but this is not a big problem as long as the blade is not above the cut tables

Saw Stroke Mid Cut Input

Ancil saws benefit from the mid switch input on the saw stroke, because the stoke speed is inevitably slowed down on the widest profile, which also needs the full stroke range. Adding the mid point switch means narrower and lower profiles do not need the full, slow range of the cut and the cycle time is reduced considerably.

See instructions on how to set this feature up

Colour Coding Support Blocks and Pusher End

See instructions for how to set this feature up in a standard way

BladetoFence Setup

Bladetofence on an ancil saw should be around 70mm.

Cill Chute Fill Plate

Part number D0005628(-OH) is used to fill in the radius of the chute which helps offcuts of wide cills down the chute

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português