| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 72 : | Ligne 72 : | ||

|Step_Picture_01=R0000299_Stroke_assembly_rebuild_Screenshot_2024-06-04_075806.png | |Step_Picture_01=R0000299_Stroke_assembly_rebuild_Screenshot_2024-06-04_075806.png | ||

|Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":240,"height":497,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":2.5,"scaleY":2.5,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/1/19/R0000299_Stroke_assembly_rebuild_Screenshot_2024-06-04_075806.png","filters":[]},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":297.91,"top":706.36,"width":92.3,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.83,"scaleY":3.83,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"R0000729","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} }],"height":1243,"width":600} | |Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":240,"height":497,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":2.5,"scaleY":2.5,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/1/19/R0000299_Stroke_assembly_rebuild_Screenshot_2024-06-04_075806.png","filters":[]},{"type":"textbox","version":"2.4.6","originX":"center","originY":"center","left":297.91,"top":706.36,"width":92.3,"height":22.6,"fill":"#FF0000","stroke":"#FF0000","strokeWidth":1,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":3.83,"scaleY":3.83,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"text":"R0000729","fontSize":20,"fontWeight":"normal","fontFamily":"sans-serif","fontStyle":"normal","lineHeight":1.16,"underline":false,"overline":false,"linethrough":false,"textAlign":"left","textBackgroundColor":"","charSpacing":0,"minWidth":20,"styles":{} }],"height":1243,"width":600} | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Unless otherwise stated</translate> | ||

| + | |Step_Content=<translate>Always use Loctite 243 on all fasteners fitted unless stated different | ||

| + | |||

| + | |||

| + | All bearings should be an acceptable fit, with Loctite 641 and FE10 solvent used if required | ||

| + | |||

| + | |||

| + | All fasteners should be marked once finalised</translate> | ||

| + | |Step_Picture_00=R0008013_Clacker_assembly_quality.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version du 4 juin 2024 à 11:15

Instructions for correct assembly and setting of stroke assembly gearboxes

Introduction

The following instructions should be followed to ensure that correct assembly and setting are performed

Tools / consumables Required

Standard hex key set

Standard spanner set

Double pin saw flange spanner

Drifts and punches

Ballpein hammer

Soft hammer

Degreasing bath

Parts Required

Kit R0000299 containing

B0000043 Double Angular bearing 15 I?D 35 O?D 15.9 long rubber seal 3 x 2

B0000105 Double Angular Bearing 15 I/D 35 O/D 15.9 Long x 1

B0000335 3ph Brake motor 2 pole 3000rpm x 1

B0000380 Double Angular Bearing 25 I/D 52 O/D 20.6 Long + rubber seal x 2

D0000059 Damper Bridge x 1

D0000062 Damper Bridge Boss x 2

D0007730 ZX4 V Notch Mk1 Spindle Shaft x1

D0007867 Bevel Gear (Left) x 1

D0007868 Bevel Gear (Right ) x 1

D0007873 Motor Gear x 1

D0007874 Pinion Gear x 1

D0007875 Pinion Shaft x 1Étape 1 - Handing clarification

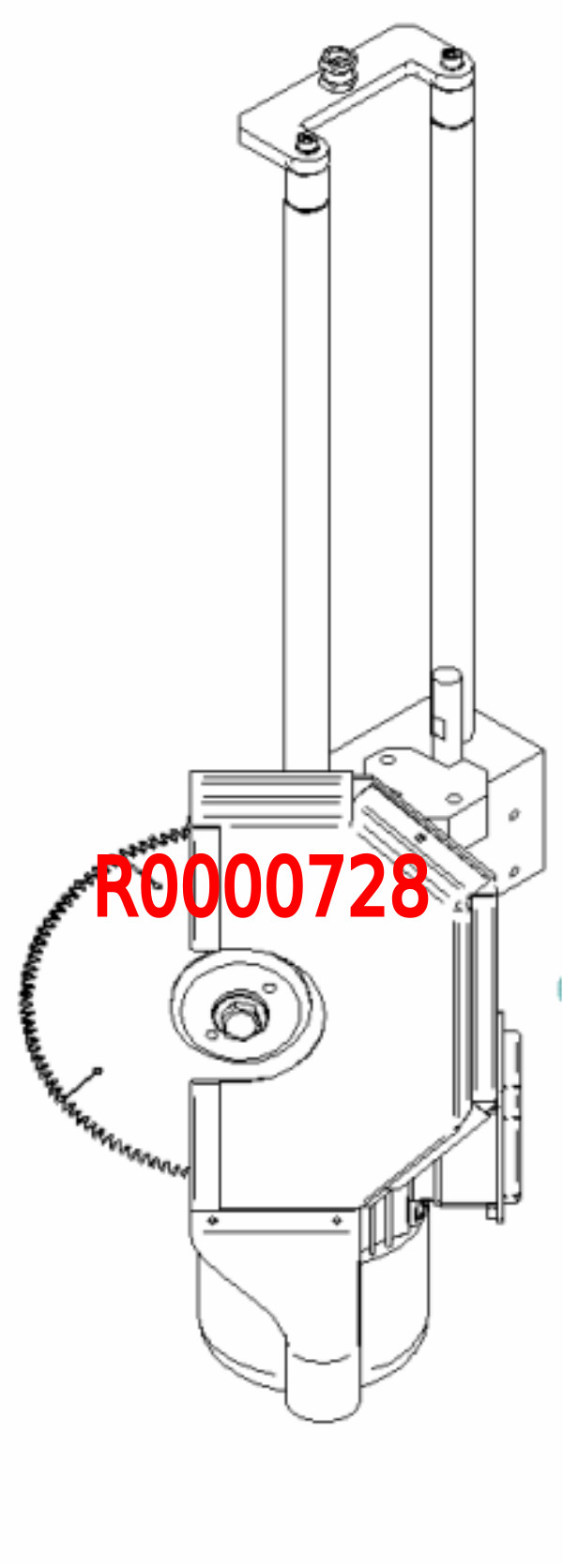

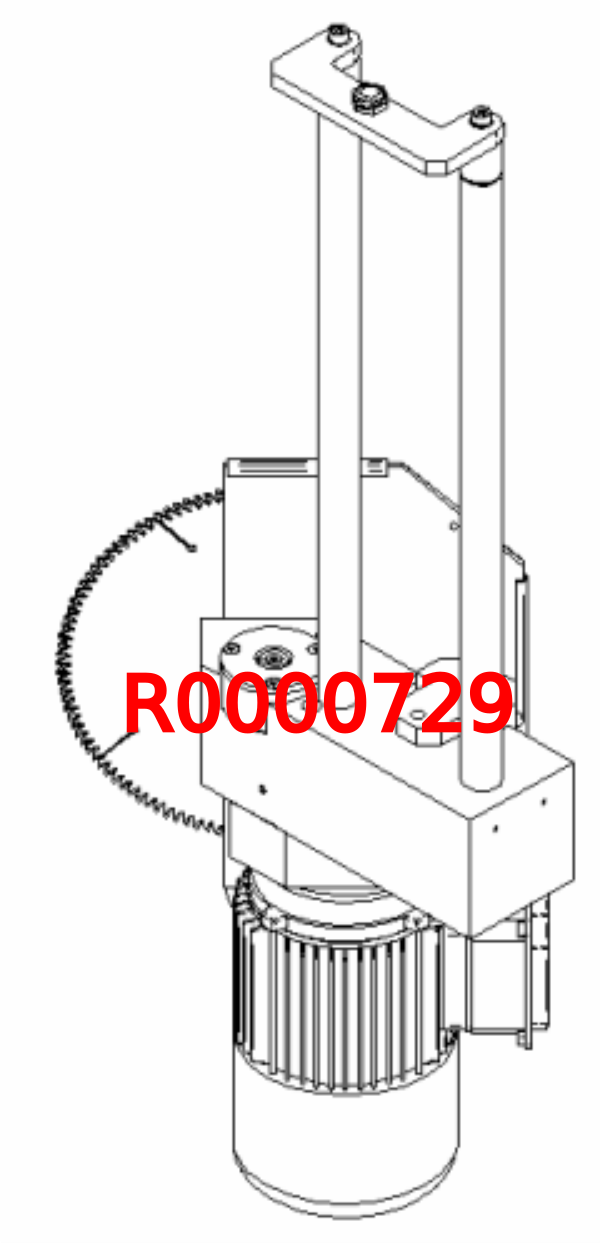

R0000728 and R0000729 are mirror images to each other

Please inspect pictures to clarify and confirm correct hand to be built

(Supplied unit to be refurbished will always be rebuilt as the same hand )

Étape 2 - Unless otherwise stated

Always use Loctite 243 on all fasteners fitted unless stated different

All bearings should be an acceptable fit, with Loctite 641 and FE10 solvent used if required

All fasteners should be marked once finalised

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português