| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 4 : | Ligne 4 : | ||

|Description=<translate>Instructions to mount cut guard</translate> | |Description=<translate>Instructions to mount cut guard</translate> | ||

|Difficulty=Medium | |Difficulty=Medium | ||

| − | |Duration= | + | |Duration=5 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

Version du 3 avril 2024 à 11:41

Instructions to mount cut guard

Introduction

Tools Required

Standard hex key set

Standard HSS drill set

Standard tap set

Cutting disc

Parts Required

C0001275 Printer: ZD421 Direct Thermal (Not Incl. C0001276 P&P)

C0001276 Peel & Present for ZD421 Printer

D0016333 Bruehl Fence panel 1700 x 800 x 2

D0016334 Bruehl Fence panel 650 x 800 x 2

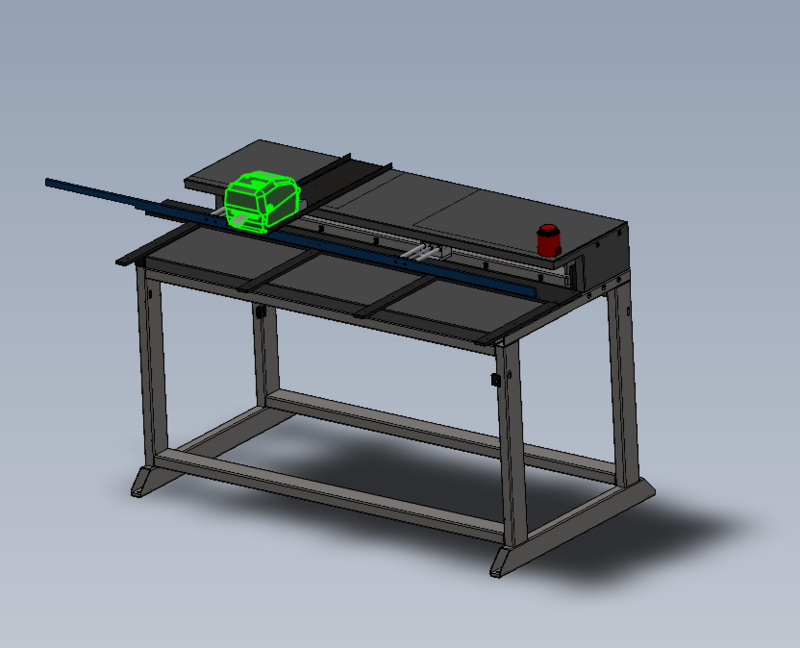

H0005178 Safety Table Extension x 1

M0000033 Frame End Cap 50 x 50 x 1

M0001207 Bruehl Fence Clip x 14

P0000069 Tube to tube fitting 6mm x 1

R0015290 Saw Outfeed Bench Assemble Top guard x 1

Étape 1 - Unless otherwise stated

Use loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

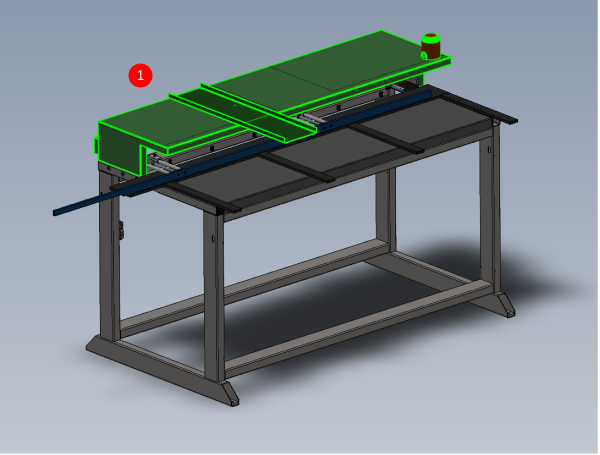

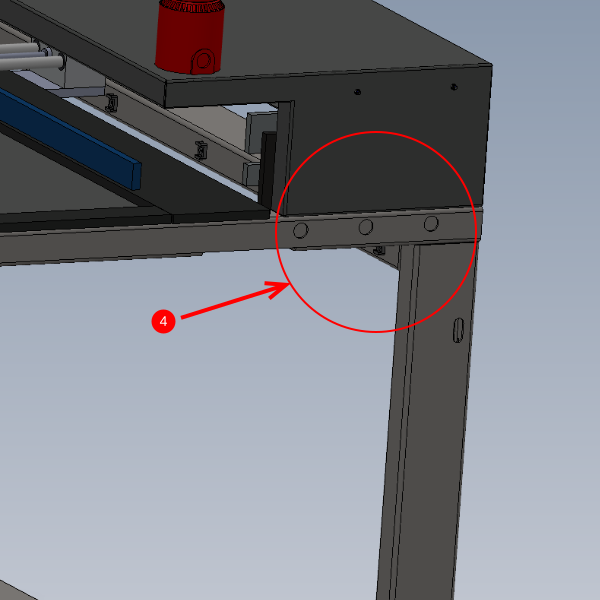

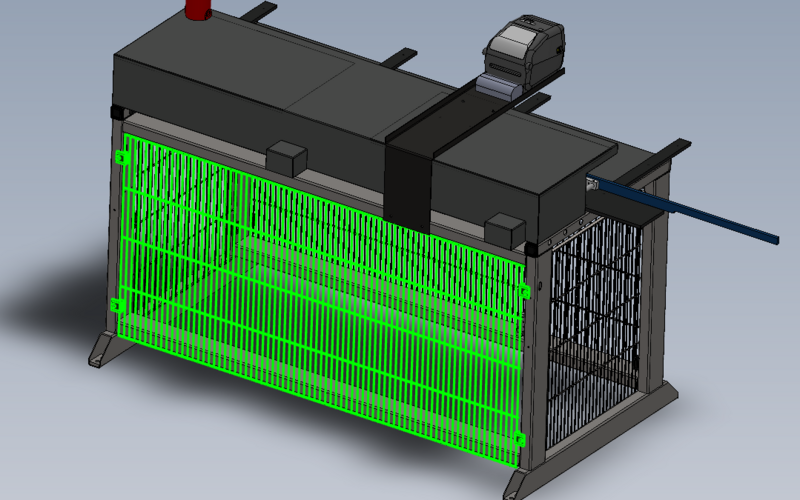

Étape 2 - Fit top Hood

1 Position top hood assembly as shown

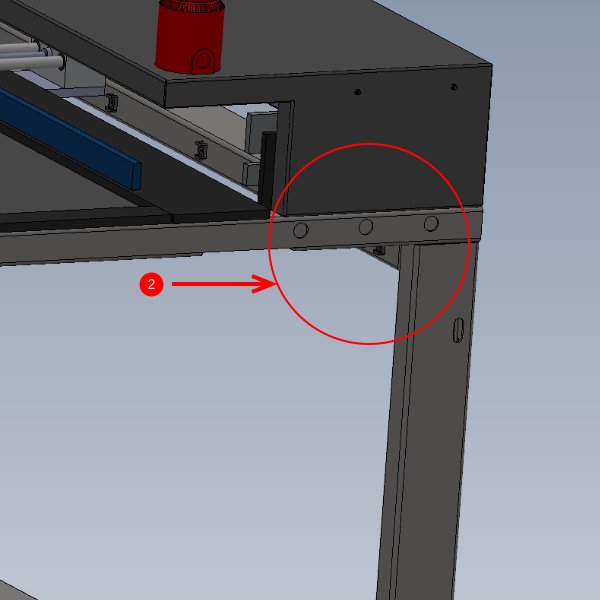

2 Slacken safety gate fixing 3 off M8 to allow access for cut guard mounting points

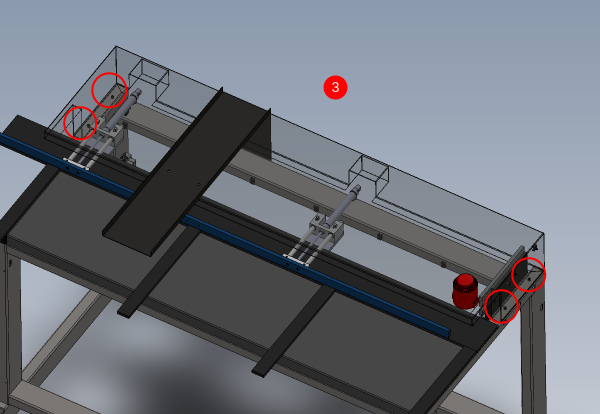

3 Use 4 off M6 x 20 Socket caps with M6 heavy motor washers and fit to indicated positions . Align as best as possible edges of cut guard to frame, then apply final tension to fasteners to complete

4 Finalise 3 off M8 socket caps that hold safety gate to frame

5 Run W00010002 cable into tie bases fitted to cut guard and route to Siren

(pictures please)

6 Add final fixings to printer shelf . Drill and tap to M8 and add 2 off M8 socket caps with A form washers

Étape 3 - Fit Printer

Fit printer to shelf as indicated

Ensure box is left on frame and auto peel is left with box

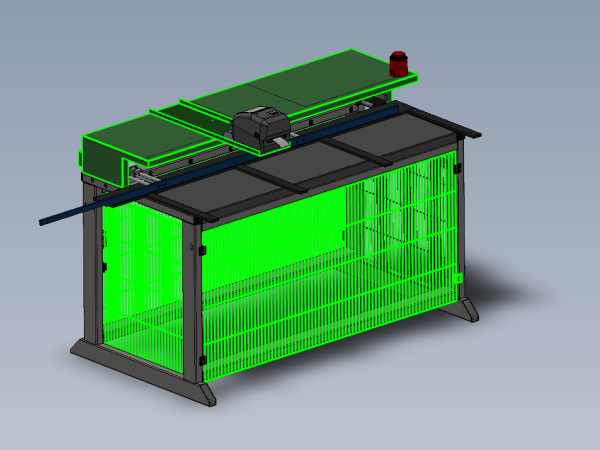

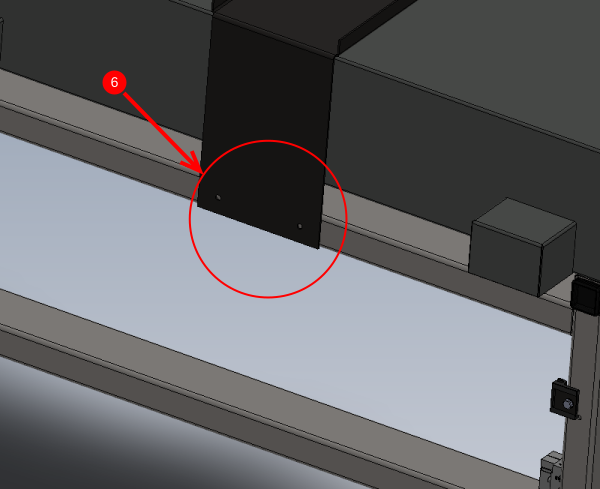

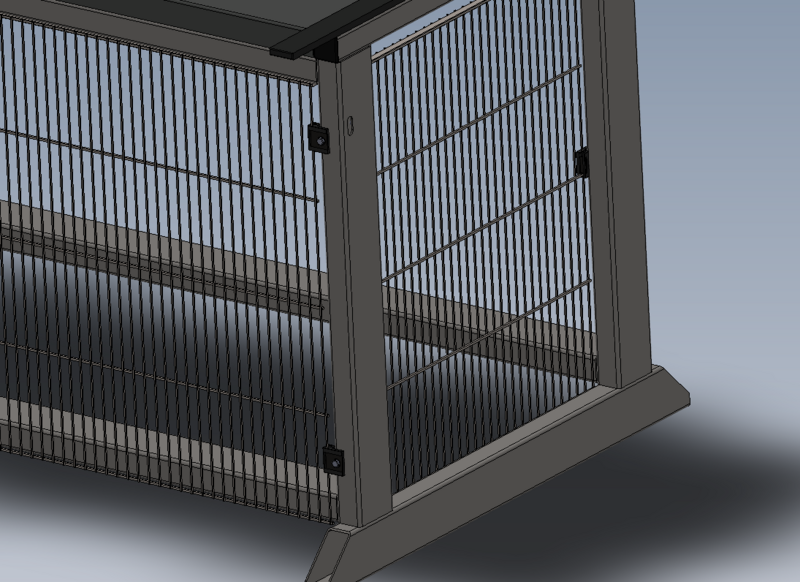

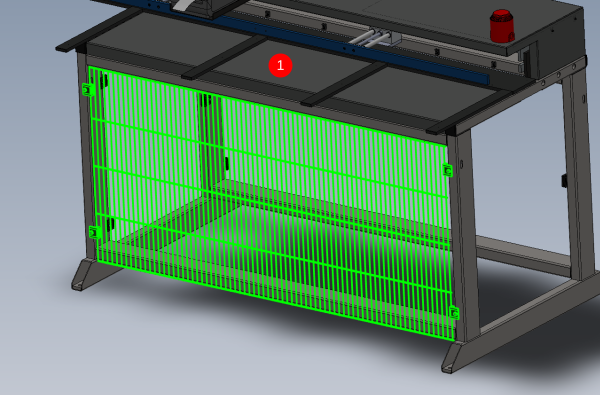

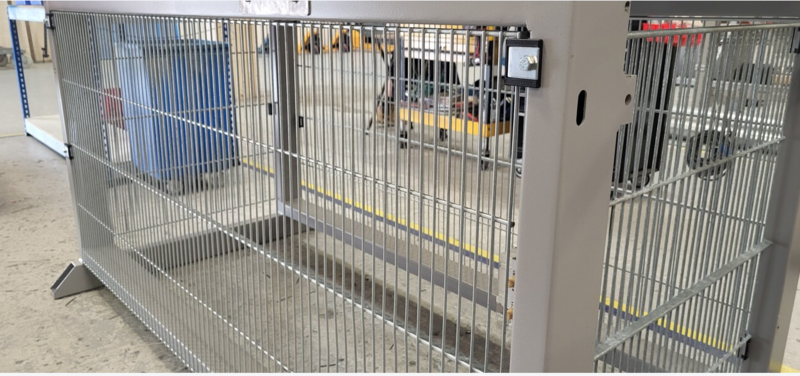

Étape 4 - Cut guard panels

D0016333 Bruehl Fence panel 1730 x 800 x 2

D0016334 Bruehl Fence panel 650 x 800 x 2

These panels will require cutting from sheet , ensure correct orientation of fence slats is obtained when marking out and cutting

See image for orientation

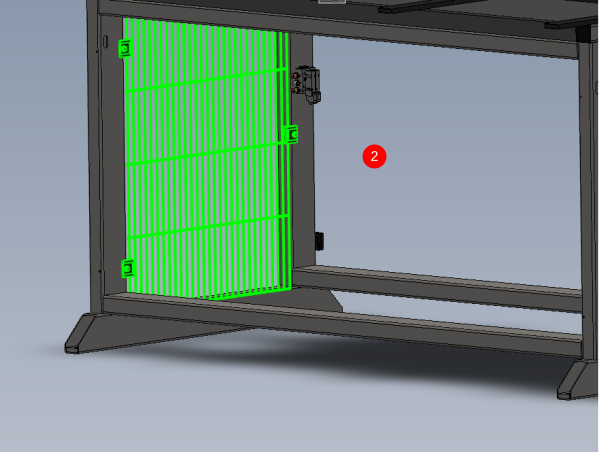

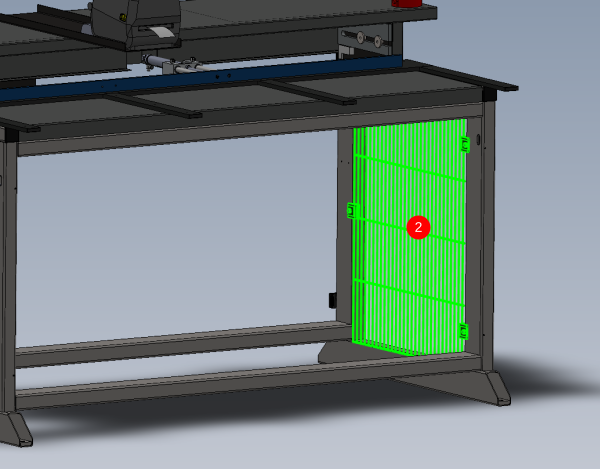

Étape 5 - Guard fitting

When fitting guards use alloy blocks and g clamps to hold guard to make fixing easier

Étape 6 - Attach guards to frame

1 Drill and fix front guard orientated as shown (hole sizes and bolt type required)

2 Drill and fix both side guards as shown (hole sizes and bolt type required)

3 Drill and fix read guard orientated as shown (hole sizes and bolt type required)

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português