| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 165 : | Ligne 165 : | ||

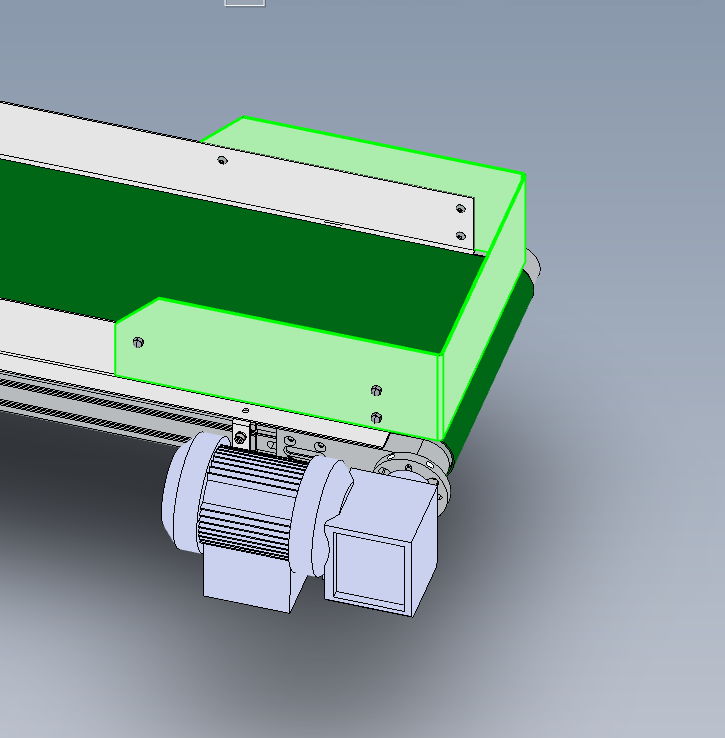

|Step_Picture_00=R0015343_Waste_Guidance_Installation_Screenshot_2023-10-31_150250.png | |Step_Picture_00=R0015343_Waste_Guidance_Installation_Screenshot_2023-10-31_150250.png | ||

|Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png | |Step_Picture_01=ZX5_Production_R0015122_Module_A_to_R0015139_Module_B_alignment_photorequired.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Important</translate> | ||

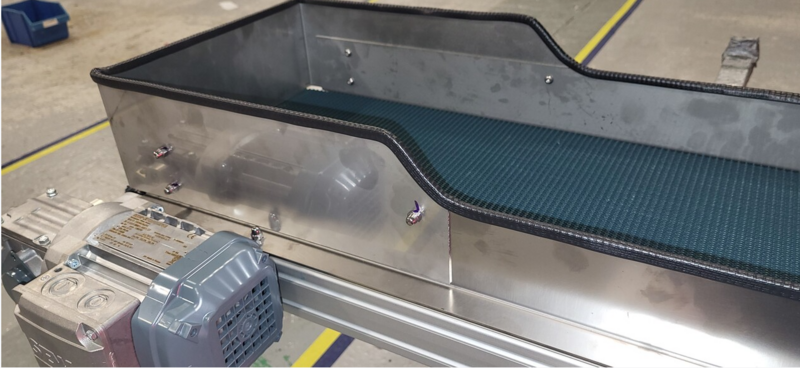

| + | |Step_Content=<translate>When positioning swarf funnel, it is vital that it does not contact the conveyor belt . Please ensure it is set so there is no contact between the two</translate> | ||

| + | |Step_Picture_00=R0015338_Bench_Assemble_Serial_Plate_caution.png | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version du 29 janvier 2024 à 15:27

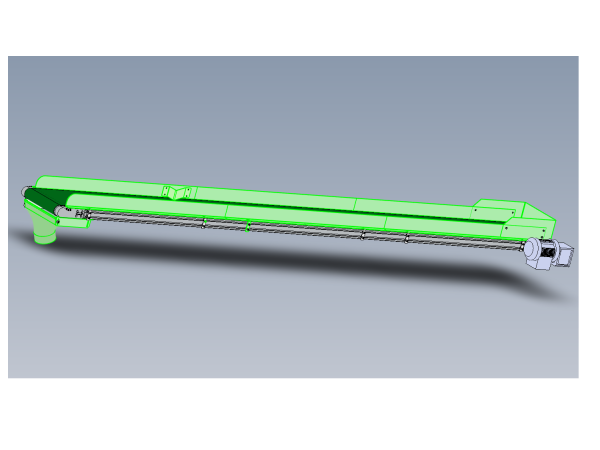

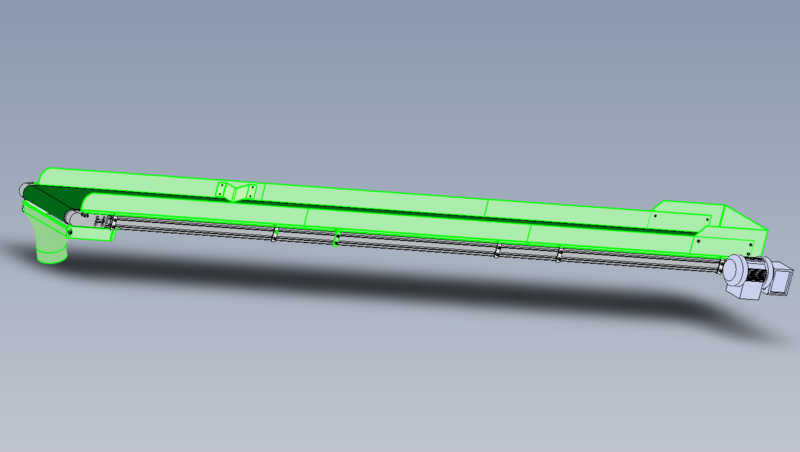

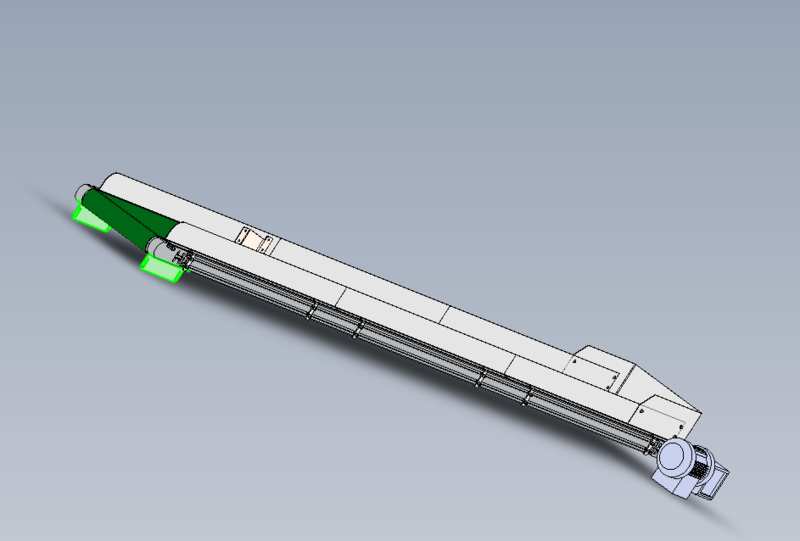

Installation details of waste guidance

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Please note

- 4 Étape 3 - Fit Radius side sheets

- 5 Étape 4 - Fit side sheets

- 6 Étape 5 - Fit deflector

- 7 Étape 6 - Position end plate

- 8 Étape 7 - Drill end plate

- 9 Étape 8 - Fit end plate

- 10 Étape 9 - Fit edging strip

- 11 Étape 10 - Fit lower swarf funnel brackets

- 12 Étape 11 - Add riv nuts

- 13 Étape 12 - Important

- 14 Étape 13 - Fit swarf funnel

- 15 Étape 14 - Drill and pin

- 16 Étape 15 - Check all fasteners

- 17 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Standard HSS drill set

Standard tap set

Parts Required

D0001967 Conveyor End Plate x 1

D0001970 Swarf Funnel Support x 2

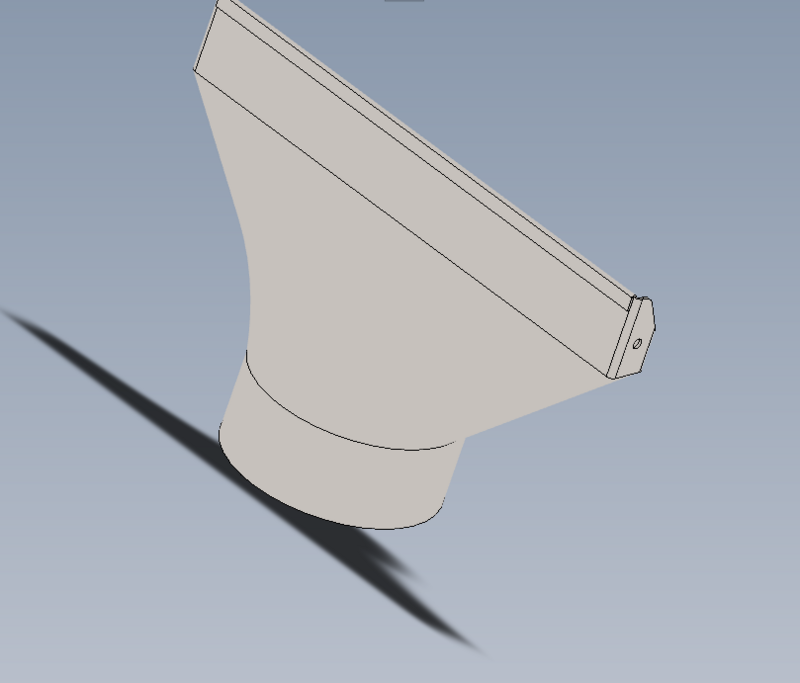

D0005616 Conveyor Swarf Funnel x 1

D0010843 Conveyor Deflector Plate x 1

M0000031 Panel Edging Strip; 9 x 6mm (consumable stock )

R0015344 Bench Assemble Conveyor Parts

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Please note

Drive motor must be removed to allow access to fit side sheets

1 locking grubscrew must be slackened to allow drive motor to be removed.

Ensure drive motor is refitted after installation of waste guidance sheets

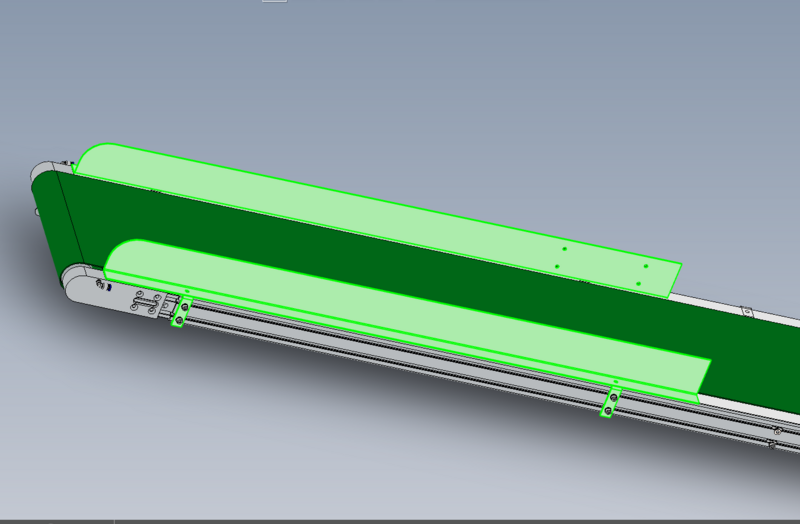

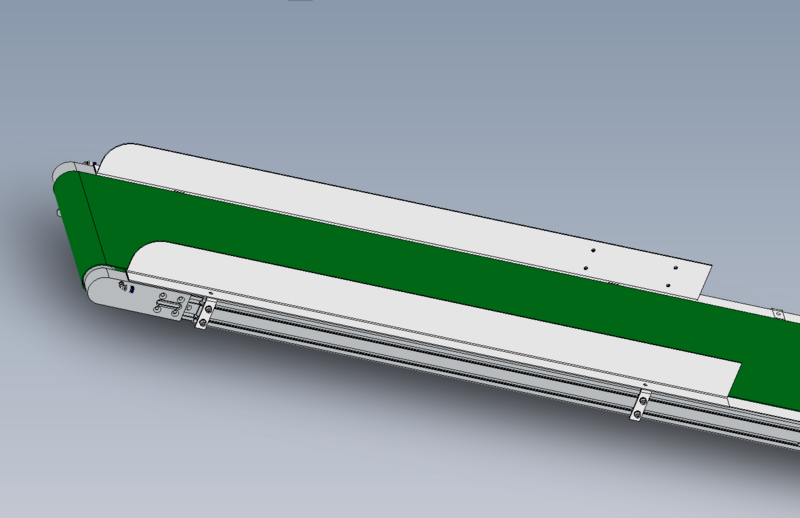

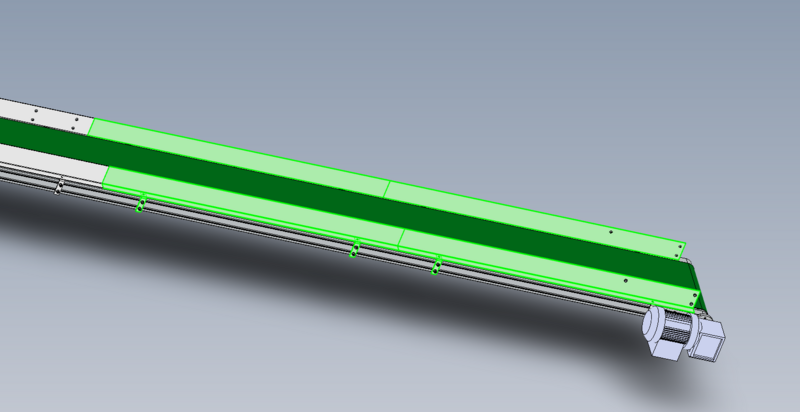

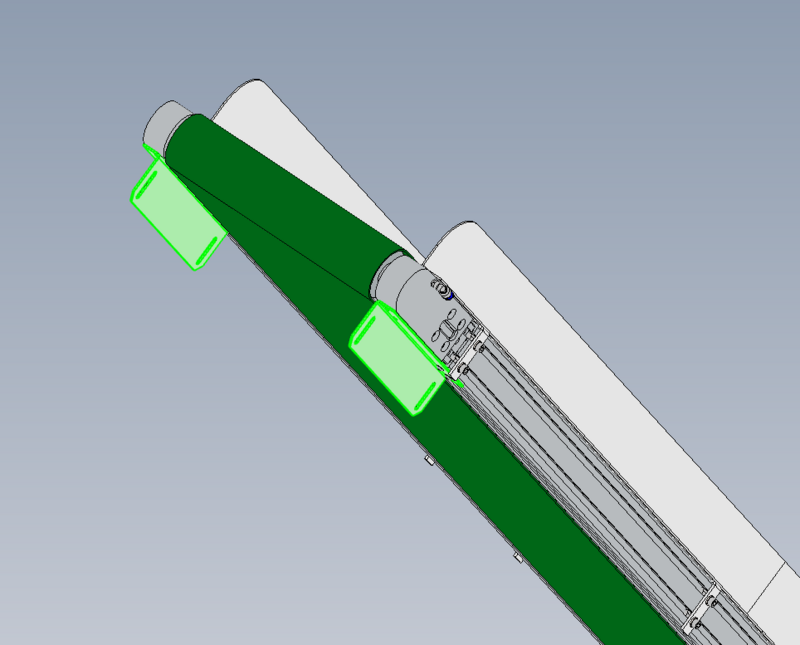

Étape 3 - Fit Radius side sheets

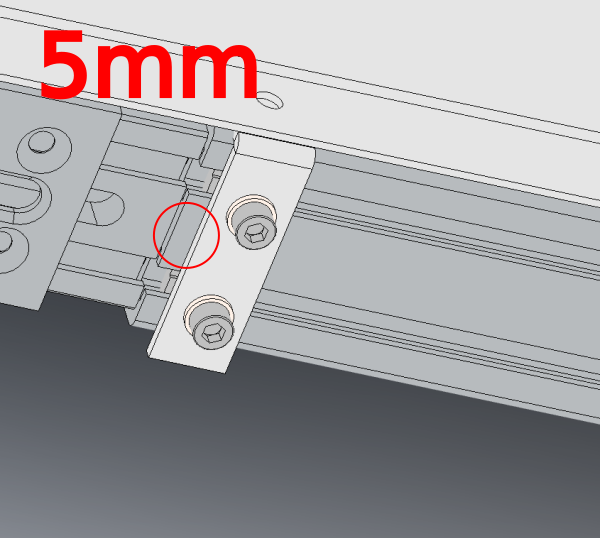

fit 2 off radius side sheets as shown

Secure using m5 slim D nuts , M5 x 10 socket caps and M5 A form washers

Position as shown 5mm from edge frame

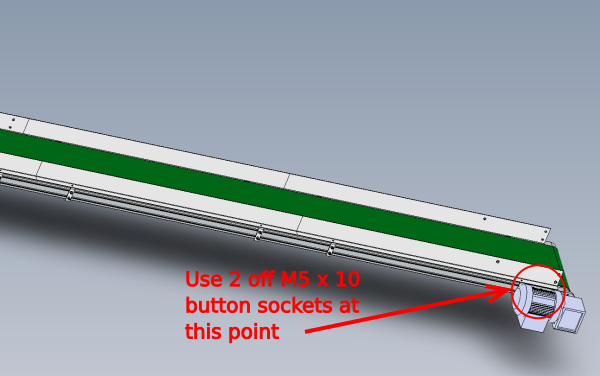

Étape 4 - Fit side sheets

Fit 4 off side sheet as shown

Secure using m5 slim D nuts , M5 x 10 socket caps and M5 A form washers

At position shown, Use 2 off M5 x 10button heads for clearance when motor fitted

Étape 5 - Fit deflector

Drill and fit deflector as shown

Ensure deflector is mounted at a height that clearance is present between conveyor belt and deflector

Provide details to enable ecr to be raised to add mounting holes

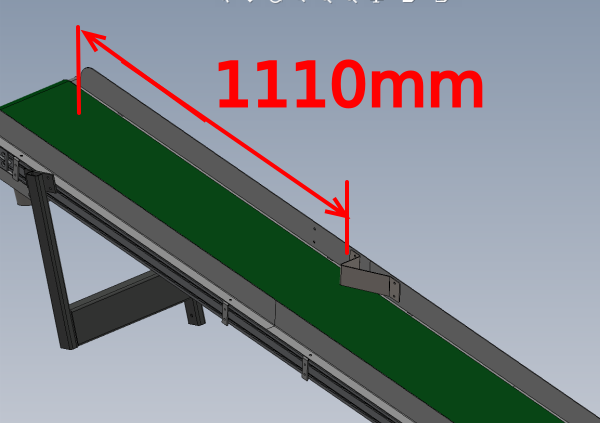

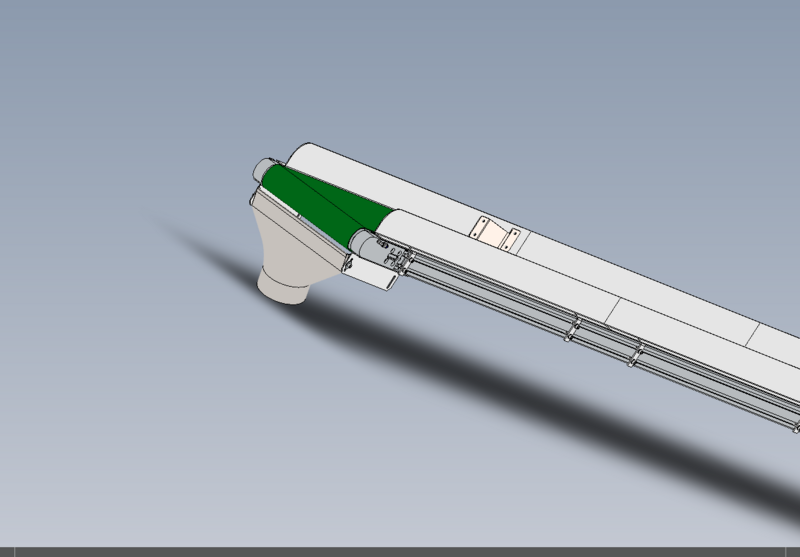

Étape 6 - Position end plate

Position conveyor end plate as shown

Ensure end plate does not touch belt. Needs to be 3mm higher than belt face

Mark positions for mounting holes and remove end plate

Étape 7 - Drill end plate

Drill M6 clearance holes at marked points

Photos and details of this please Drill off cable tie bases for motor cable

Provide all details to enable ECR generation

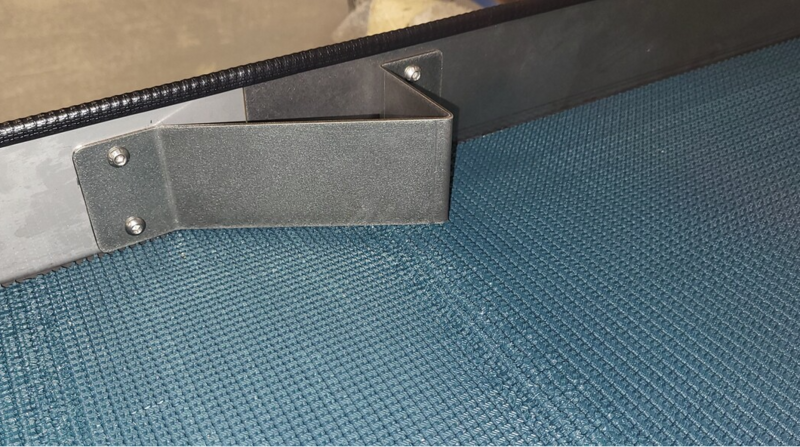

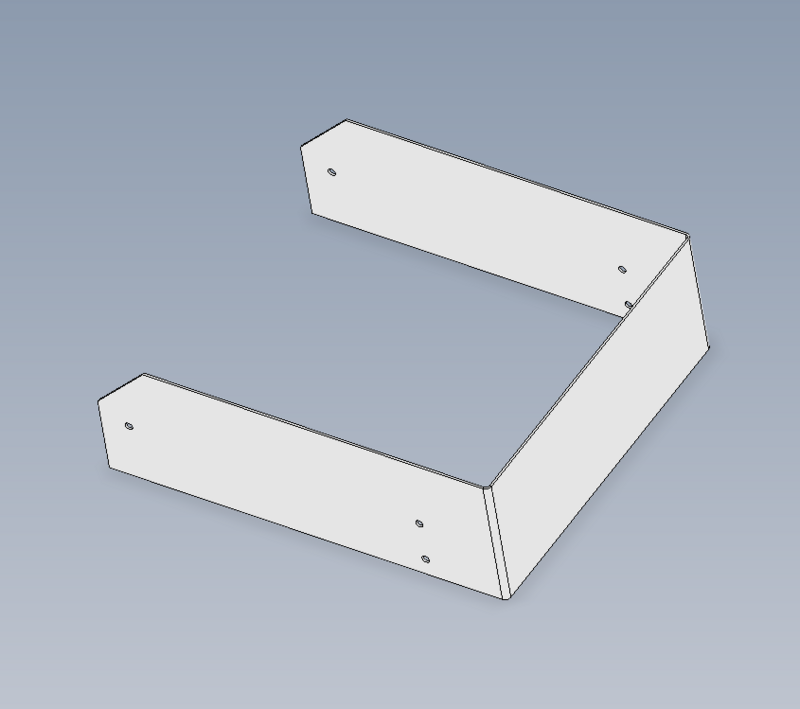

Étape 10 - Fit lower swarf funnel brackets

Pictures Required

Secure with 4 off M5 x 10 socket caps and M5 A form washers

Étape 11 - Add riv nuts

Add 2 off m6 rivnuts to swarf funnel pre drilled holes

Ecr raised to add rivnut to drawing 18/12/23

Étape 12 - Important

When positioning swarf funnel, it is vital that it does not contact the conveyor belt . Please ensure it is set so there is no contact between the two

Étape 13 - Fit swarf funnel

Fit swarf funnel to conveyor brackets

Secure with M6 cap heads and washers

Picture required for correct setting position of funnel

Étape 14 - Drill and pin

Details and pictures Required

Drill and pin funnel in position with 2 off 3 mm spiral pins

Étape 15 - Check all fasteners

Check all fasteners are finalised and marked

Ensure all settings have been finalised

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português