| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 100 : | Ligne 100 : | ||

|Step_Content=<translate>fit 10 off keys to relevant keyways and slide 9 drive pinions and 1 off drive sprockets into approximate positions</translate> | |Step_Content=<translate>fit 10 off keys to relevant keyways and slide 9 drive pinions and 1 off drive sprockets into approximate positions</translate> | ||

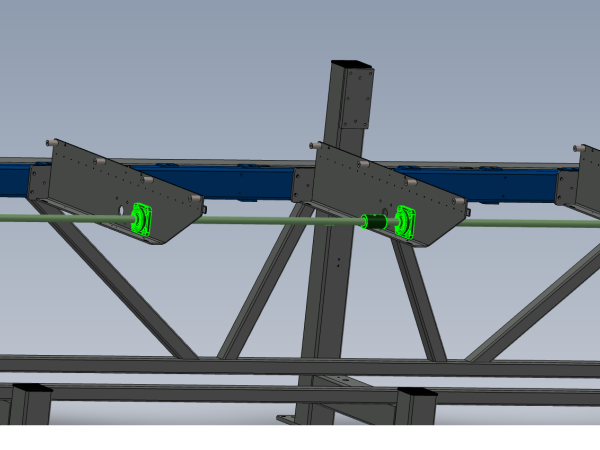

|Step_Picture_00=R0015275_Fit_shafts_and_pinions_Screenshot_2023-07-06_131901.png | |Step_Picture_00=R0015275_Fit_shafts_and_pinions_Screenshot_2023-07-06_131901.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

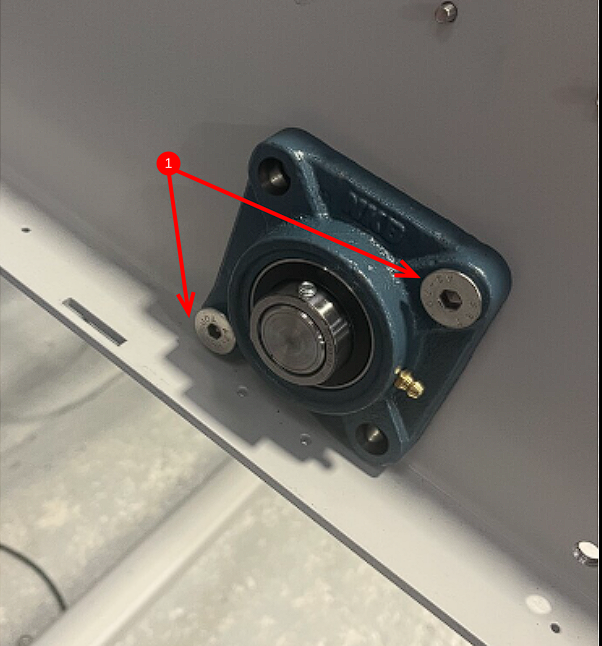

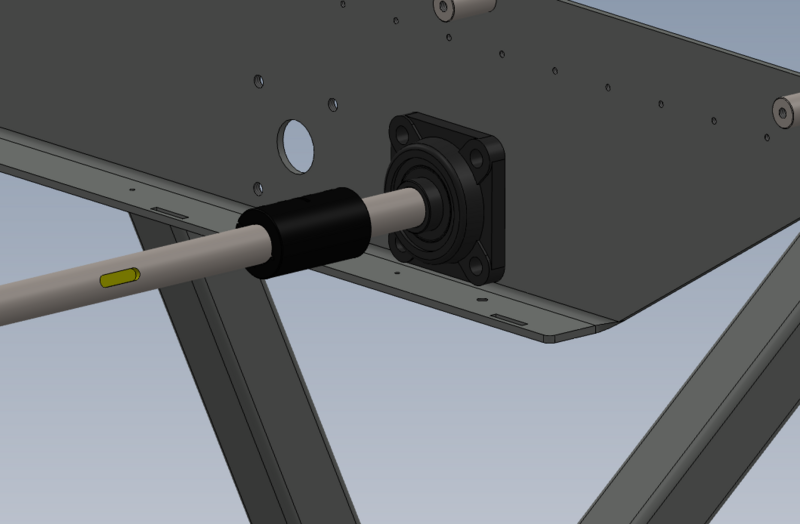

| + | |Step_Title=<translate>Lubrication</translate> | ||

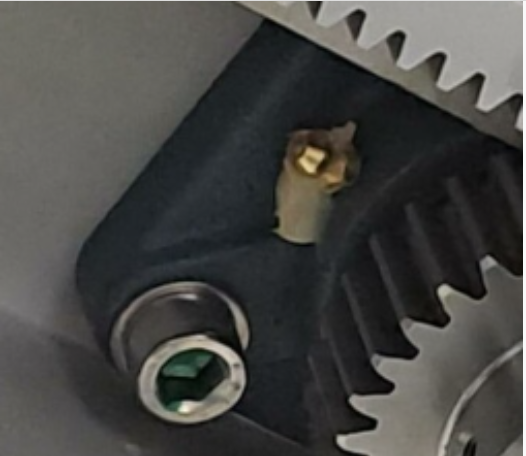

| + | |Step_Content=<translate>all bearings should be lubricated with grease gun and trojan grease</translate> | ||

| + | |Step_Picture_00=R0015275_Fit_shafts_and_pinions_Screenshot_2023-11-08_083649.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

Version actuelle datée du 8 novembre 2023 à 09:37

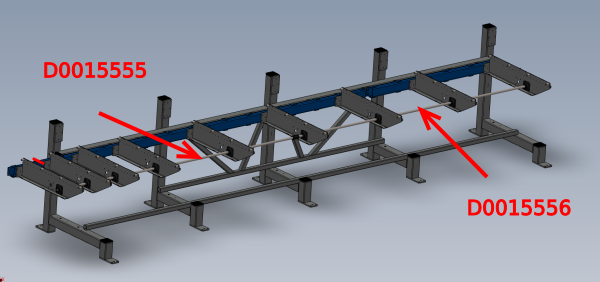

instructions for installing main drive shafts to support arm assembly

Introduction

Tools Required

Standard Hex key set

Parts Required

Previously assembled parts from R0015287 Bench Assemble Shafts, Bearings and Pinions

B0001100 x 12

B0001153 x 1

B0001165 x 1Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connections

Pen mark all bolts to show finalised

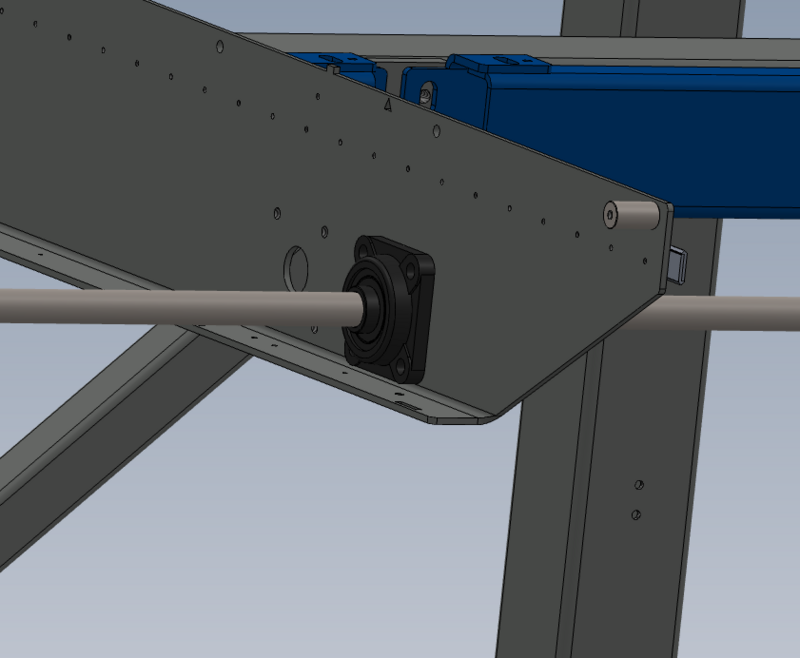

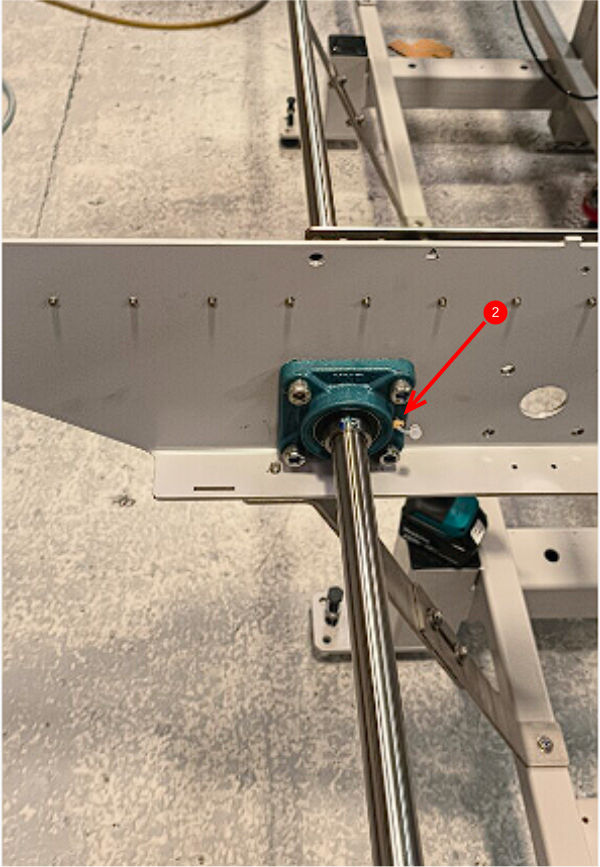

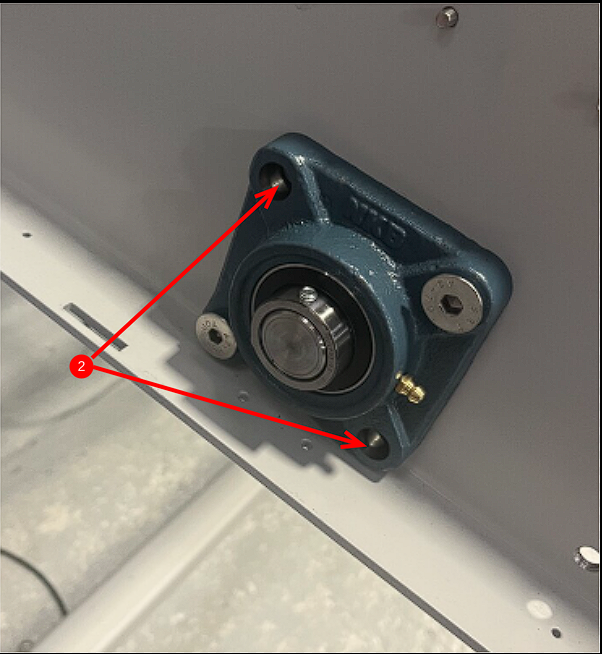

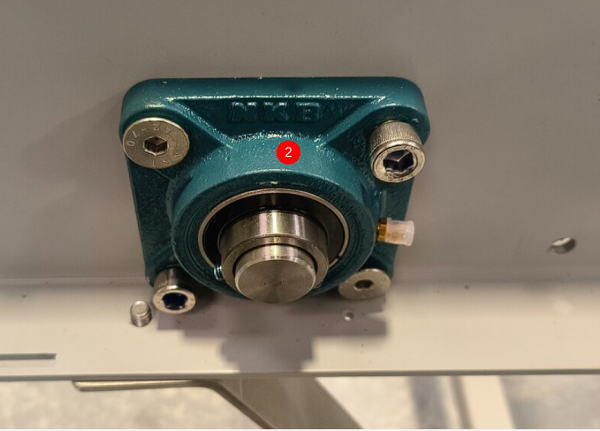

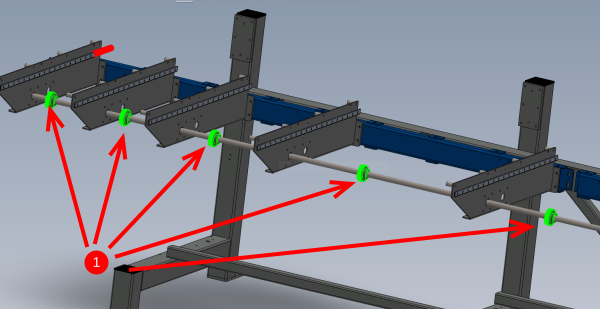

Étape 2 - Bearing position Clarification

1 Bearings should be located as shown on each arm

2 Grease nipples to face as shown

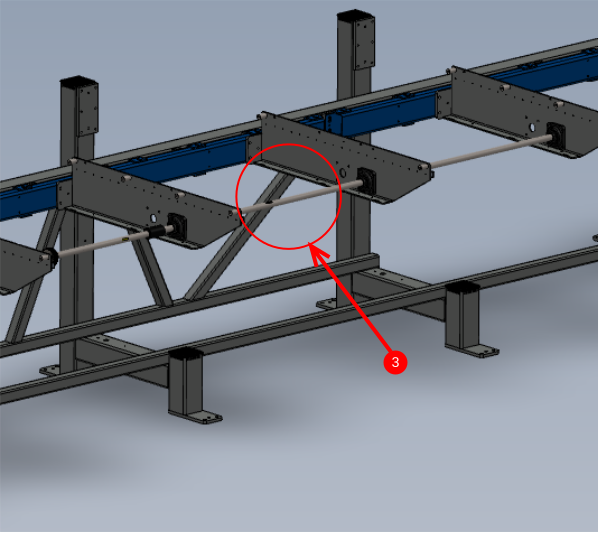

Étape 3 - Attach Bearings

1 Use 2 off M10 x 40 Countersunk bolts to centralise position of bearing block

2 Add 2 off M10 x 20 socket cap and fix in two holes indicated and tighten.

3 Replace M10 counter sunk bolts with another 2 off M10 x 20 socket caps

repeat for all bearing mounting positions

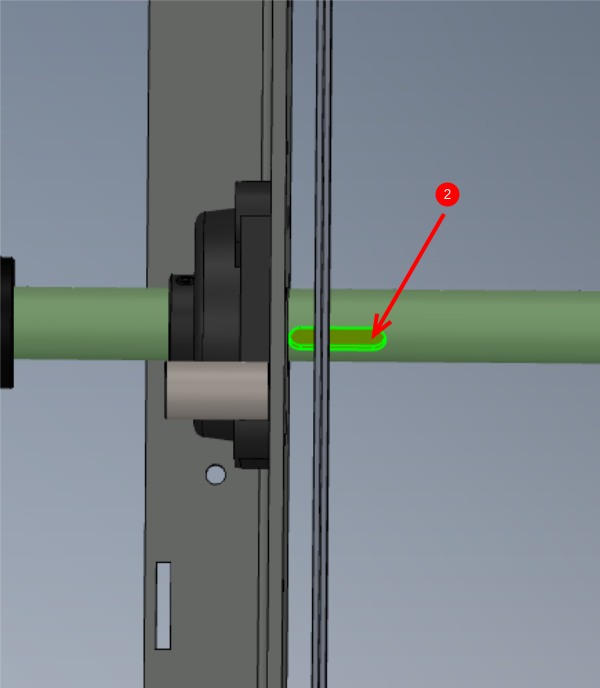

Étape 4 - Location of shafts

1 Shafts need to be correctly orientated

2 Each arm should have a key positioned as shown for drive pinions

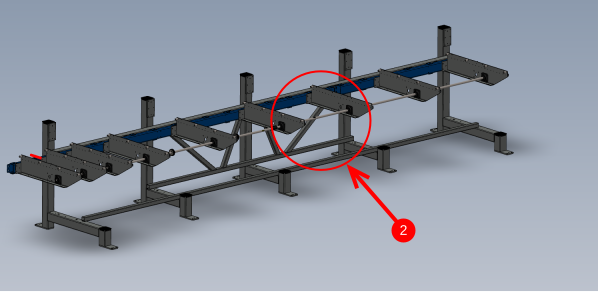

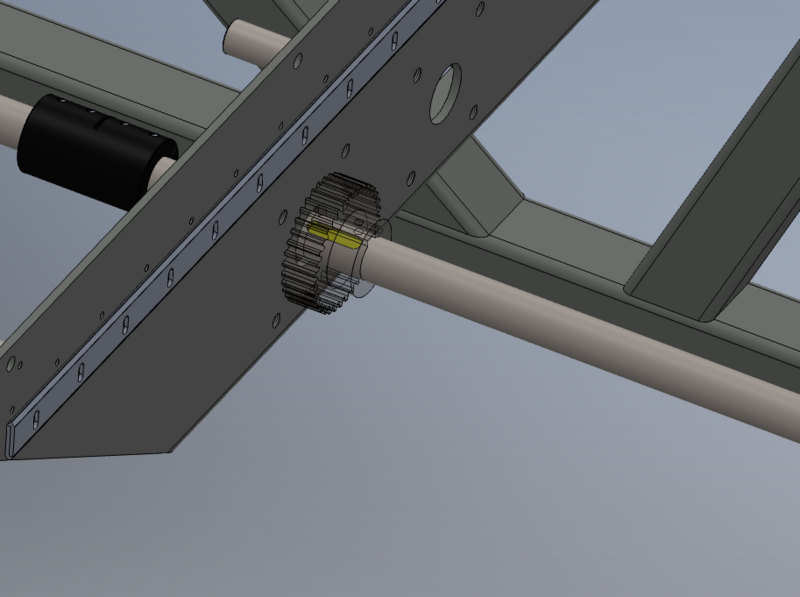

Étape 5 - Fit shafts and pinions

Double check for dokit needed on this section. please take photos and gather ingformation please

1 Shafts should be slid through bearing blocks to install. Drive pinions should be added to shaft between each arm as the shaft is fitted.

2 B0001165 1 off drive sprocket will also require adding to shaft as they are fitted . See images for location

3 B0001165 should be orientated as shown

Étape 6 - Couple shafts

Couple shafts together with 1 off B0001153 shaft coupler and 2 off B0001100 key

Étape 7 - Fit keys

fit 10 off keys to relevant keyways and slide 9 drive pinions and 1 off drive sprockets into approximate positions

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português