| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=R0015358_Conveyor_chassis_Screenshot_2023-10-31_122941.png |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2... ») |

|||

| Ligne 93 : | Ligne 93 : | ||

{{Tuto Step | {{Tuto Step | ||

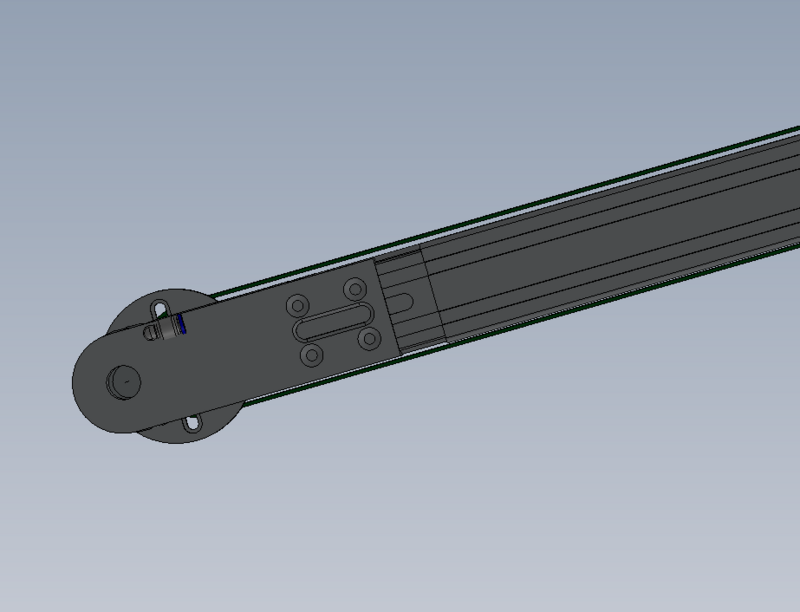

|Step_Title=<translate>Fit Slave roller (non driven)</translate> | |Step_Title=<translate>Fit Slave roller (non driven)</translate> | ||

| − | |Step_Content=<translate>Fit slave roller assembly as shown | + | |Step_Content=<translate>Fit slave roller assembly as shown |

| + | |||

| + | Ensure spacer washers are fitted | ||

| Ligne 102 : | Ligne 104 : | ||

|Step_Title=<translate>Fit drive roller</translate> | |Step_Title=<translate>Fit drive roller</translate> | ||

|Step_Content=<translate>Fit drive roller assembly as shown | |Step_Content=<translate>Fit drive roller assembly as shown | ||

| + | |||

| + | |||

| + | Ensure spacer washers are fitted | ||

| Ligne 127 : | Ligne 132 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate></translate> | + | |Step_Title=<translate>Fit belt</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Fit belt to assembly</translate> |

| + | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133247.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit mid roller</translate> | ||

| + | |Step_Content=<translate>Fit mid roller</translate> | ||

| + | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133333.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

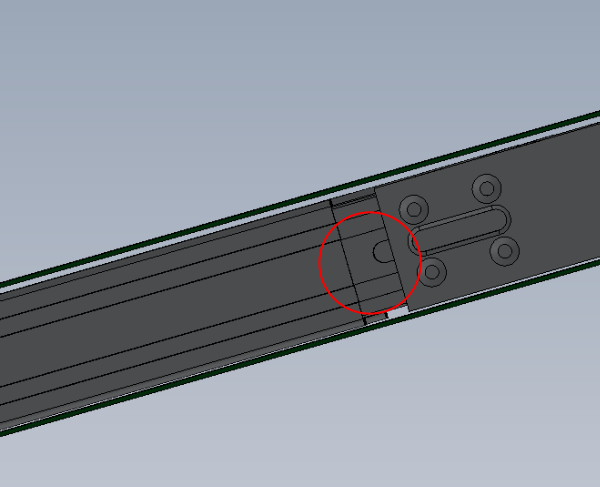

| + | |Step_Title=<translate>Tension slave roller</translate> | ||

| + | |Step_Content=<translate>Set lower roller tension | ||

| + | |||

| + | |||

| + | Measure and set gap to 15mm either side</translate> | ||

| + | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133447.png | ||

| + | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":661,"height":536,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.91,"scaleY":0.91,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/4/44/R0015358_Conveyor_chassis_Screenshot_2023-10-31_133447.png","filters":[]},{"type":"wfellipse","version":"2.4.6","originX":"center","originY":"center","left":370.01,"top":263.01,"width":101.36,"height":101.36,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":2,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"rx":50.68230839379009,"ry":50.68230839379009}],"height":487,"width":600} | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Tension drive roller</translate> | ||

| + | |Step_Content=<translate>Tension drive roller to provide adequate tension to belt | ||

| + | |||

| + | |||

| + | Ensure both sides are set tot he same measurement</translate> | ||

| + | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133536.png | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Check all fasteners</translate> | ||

| + | |Step_Content=<translate>Quality check all fasteners | ||

| + | |||

| + | |||

| + | ensure all fasteners have adhesive applied, are correctly tensioned and are pen marked to indicate finalised</translate> | ||

| + | |Step_Picture_00=R0000711_Rotary_Base_Assembly_quality-assurance-testing.png | ||

| + | }} | ||

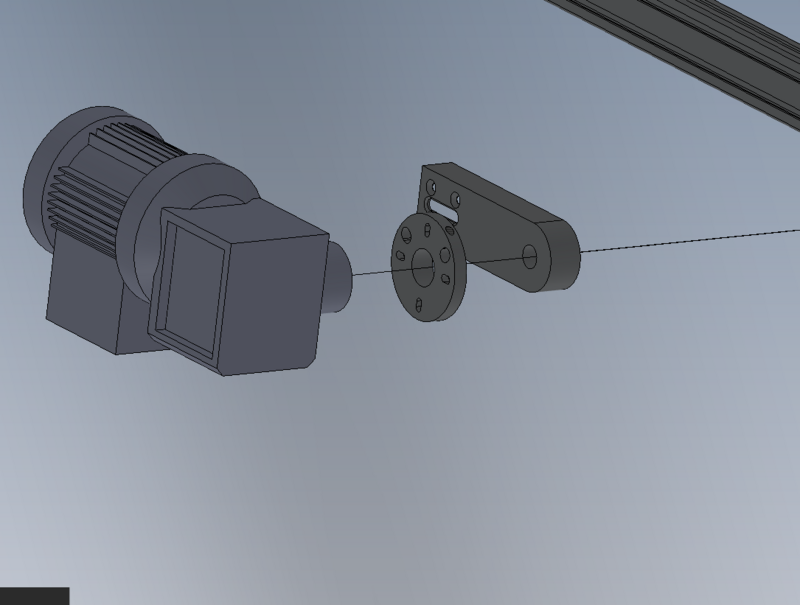

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit drive motor and flange</translate> | ||

| + | |Step_Content=<translate>Fit drive flange to bearing cheek ensuring correct orientation to allow correct fitment of motor | ||

| + | |||

| + | |||

| + | Fit motor to bearing flange</translate> | ||

| + | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_133901.png | ||

| + | }} | ||

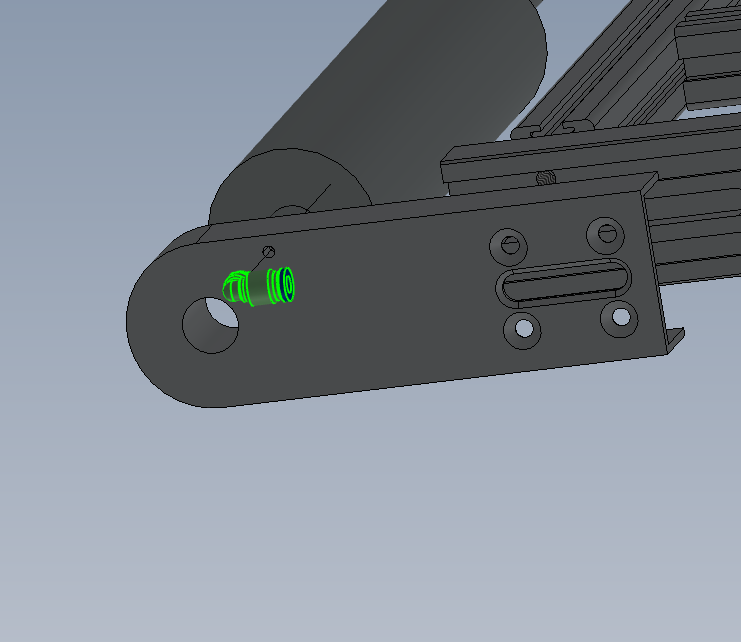

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Fit blower fittings</translate> | ||

| + | |Step_Content=<translate>Fit 3 off blower fittings to mounting points on bearing cheeks</translate> | ||

| + | |Step_Picture_00=R0015358_Conveyor_chassis_Screenshot_2023-10-31_134014.png | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 31 octobre 2023 à 14:40

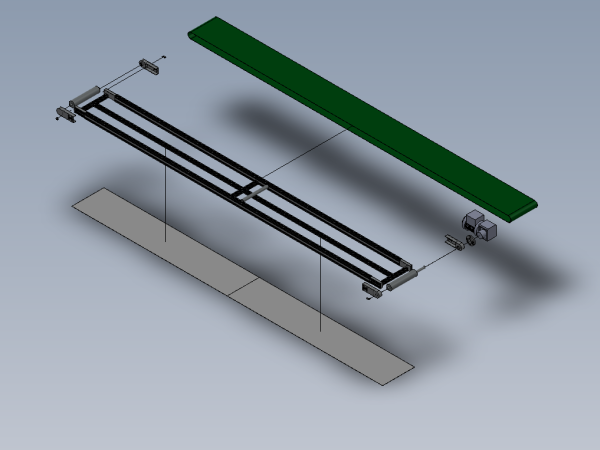

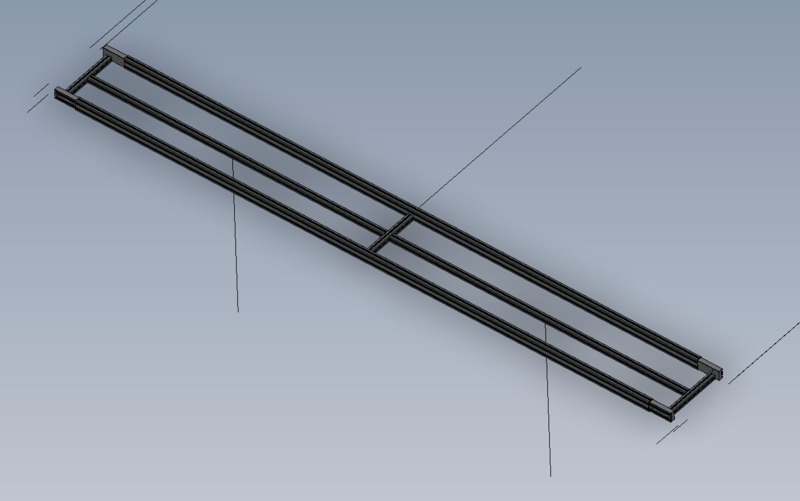

Assembly details for conveyor frame

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Drill blower points on rollers

- 4 Étape 3 - Assemble mounts

- 5 Étape 4 - insert M4 plate nuts

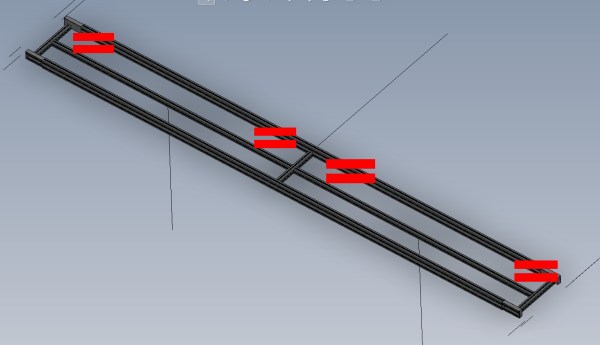

- 6 Étape 5 - Assemble main frame

- 7 Étape 6 - Finalise all fasteners

- 8 Étape 7 - Fit Slave roller (non driven)

- 9 Étape 8 - Fit drive roller

- 10 Étape 9 - Attach adhesive tape

- 11 Étape 10 - Fit stainless top plates

- 12 Étape 11 - Fit belt

- 13 Étape 12 - Fit mid roller

- 14 Étape 13 - Tension slave roller

- 15 Étape 14 - Tension drive roller

- 16 Étape 15 - Check all fasteners

- 17 Étape 16 - Fit drive motor and flange

- 18 Étape 17 - Fit blower fittings

- 19 Commentaires

Introduction

Tools Required

standard hex key set

Standard spanner set

Standard HSS drill set

Standard tap set

Utility knife

Parts Required

B0000441 Conveyor 3580mm x 300mm x 1

B0001013 Conveyor Motor SEW - WA 10 x 1

B0001177 Pair conveyor side cheeks and bearings slave x 2

M0000133 Conveyor Belt XL-AS 7350 x 300 B x 1

P0000200 Elbow Adaptor 6mm - M5 x 3

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Drill blower points on rollers

indicated 3 roller housings will require blower holes adding

Please include all drilling details for this procedure

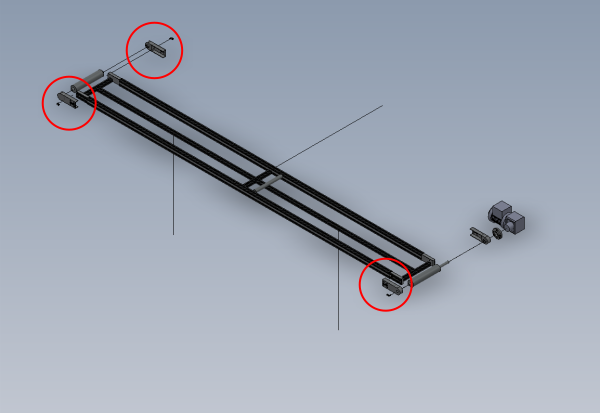

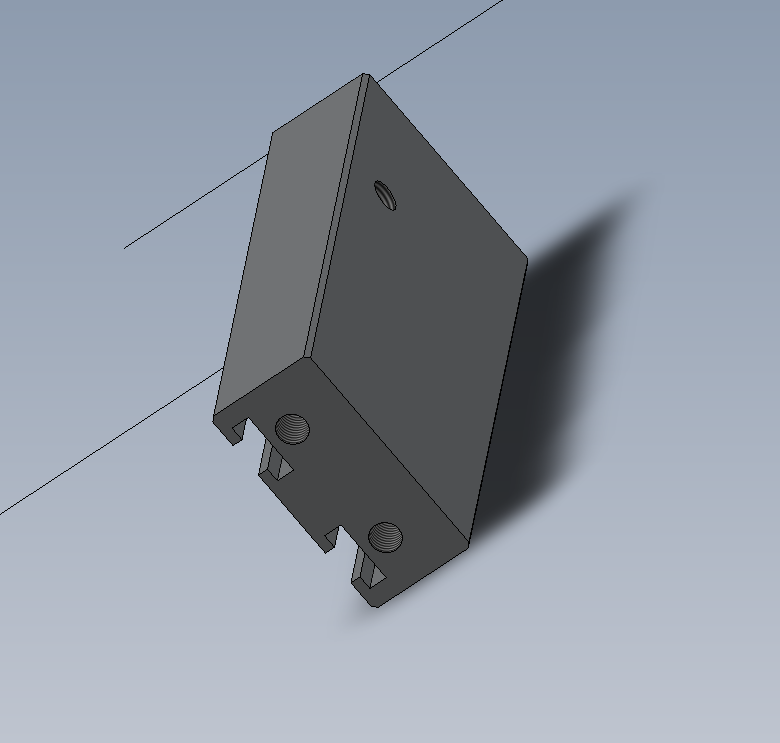

Étape 3 - Assemble mounts

Assemble 4 off mounts

Each mount has 3 off maytec fittings

Ensure maytec fittings are orientated correctly

Étape 4 - insert M4 plate nuts

insert 8 off supplied m4 plate nuts into correct face of long frame sections

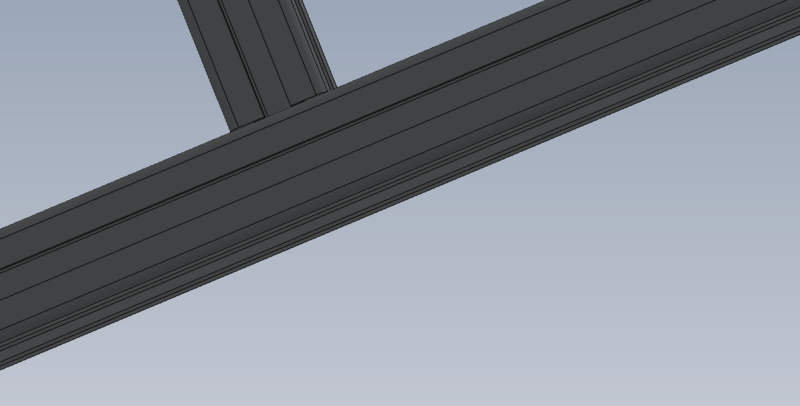

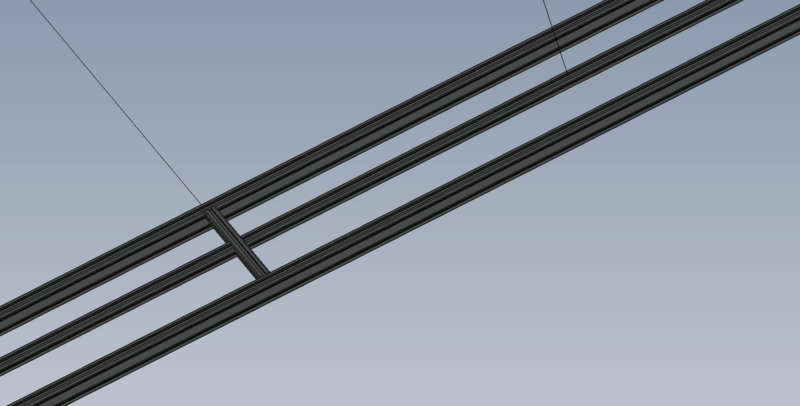

Étape 5 - Assemble main frame

Assemble main maytec frame

Ensure all sections are set in a parallel position

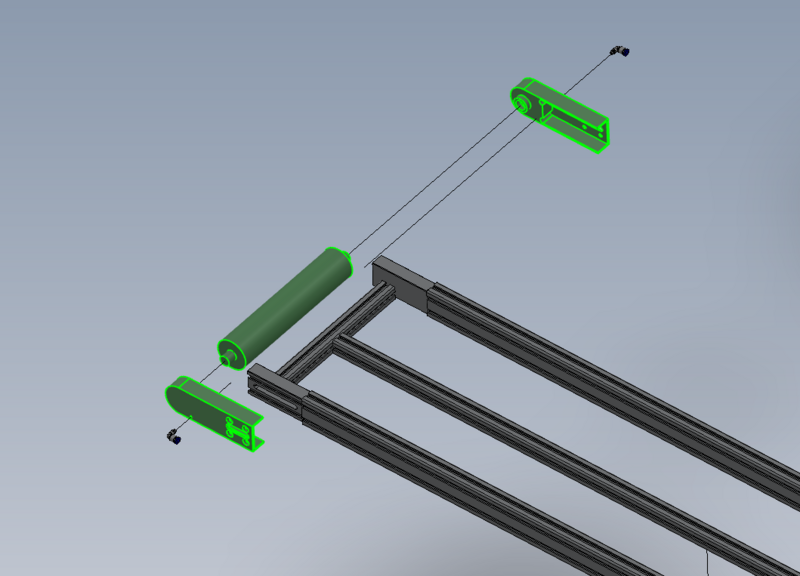

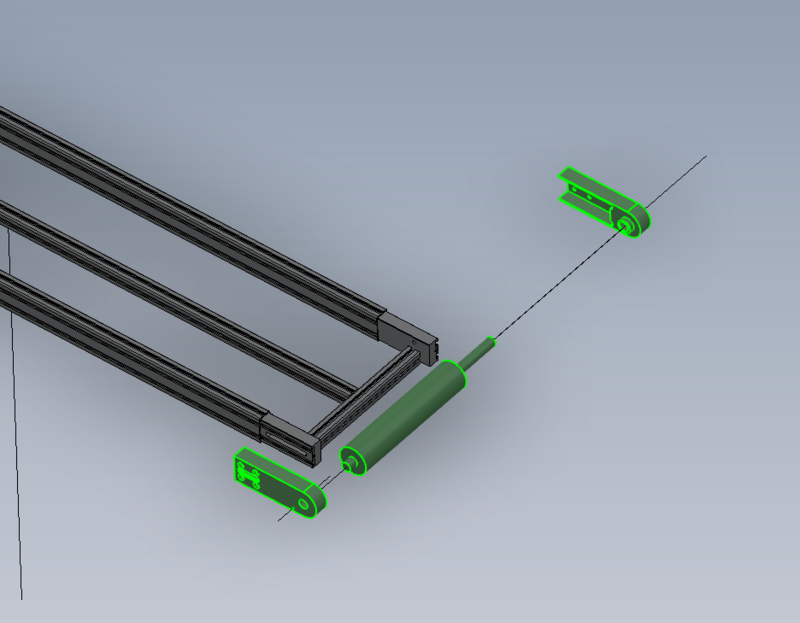

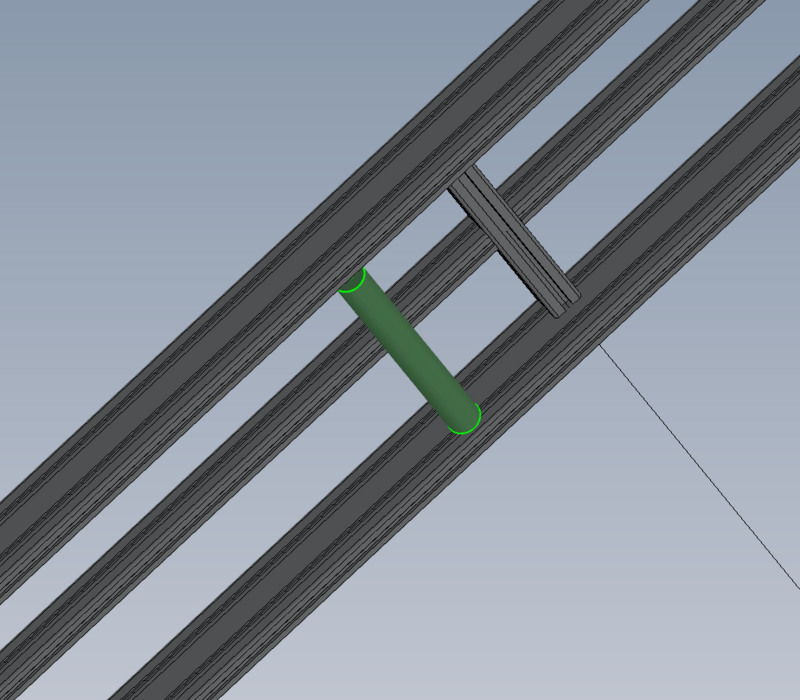

Étape 7 - Fit Slave roller (non driven)

Fit slave roller assembly as shown

Ensure spacer washers are fitted

Ensure blower points are orientated correctly to suit belt rotation direction

Étape 8 - Fit drive roller

Fit drive roller assembly as shown

Ensure spacer washers are fitted

Ensure blower point is orientated correctly to suit belt rotation direction

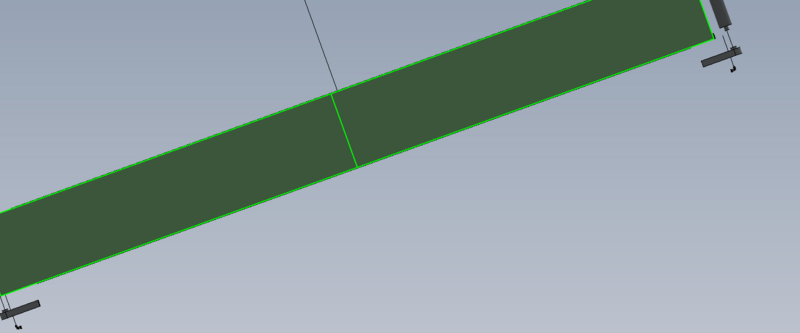

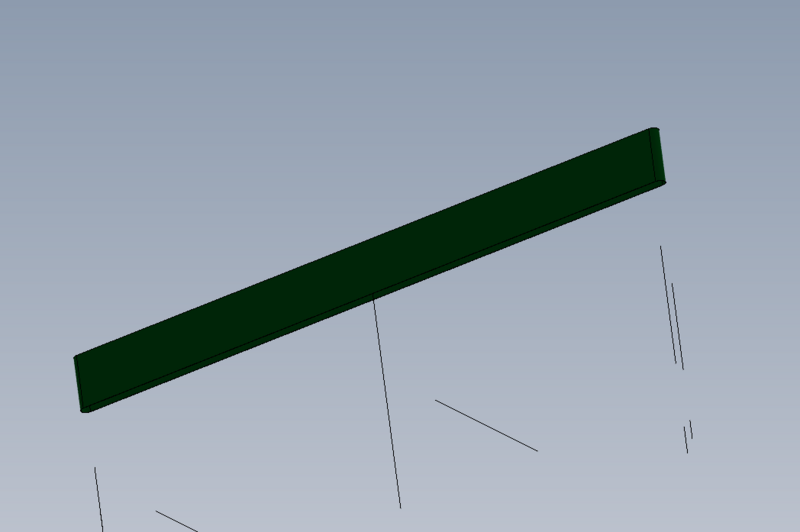

Étape 10 - Fit stainless top plates

Use stainless plates as a guide to align M4 plate nuts before removing adhesive tape backing

Once aligned , remove adhesive tape backing and secure stainless plates into position

Fit 8 off supplied m4 countersunk hex sockets to finalise stainless plate fitting

Étape 14 - Tension drive roller

Tension drive roller to provide adequate tension to belt

Ensure both sides are set tot he same measurement

Étape 15 - Check all fasteners

Quality check all fasteners

ensure all fasteners have adhesive applied, are correctly tensioned and are pen marked to indicate finalised

Étape 16 - Fit drive motor and flange

Fit drive flange to bearing cheek ensuring correct orientation to allow correct fitment of motor

Fit motor to bearing flange

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português