| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 2 : | Ligne 2 : | ||

|Main_Picture=SR_Axis_Torque_Adjustment_TorqueCrib.png | |Main_Picture=SR_Axis_Torque_Adjustment_TorqueCrib.png | ||

|Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":-27,"top":-456,"width":490,"height":862,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.46,"scaleY":1.46,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/d/db/SR_Axis_Torque_Adjustment_TorqueCrib.png","filters":[]}],"height":450,"width":600} | |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":-27,"top":-456,"width":490,"height":862,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.46,"scaleY":1.46,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/d/db/SR_Axis_Torque_Adjustment_TorqueCrib.png","filters":[]}],"height":450,"width":600} | ||

| − | |Description=<translate>For the | + | |Description=<translate>For the Sawing Modules that have a servo motor rather than a piston to rotate the Saw the Torque needs to be reduced significantly</translate> |

|Categories=Maintenance | |Categories=Maintenance | ||

|Difficulty=Medium | |Difficulty=Medium | ||

Version du 6 août 2025 à 16:56

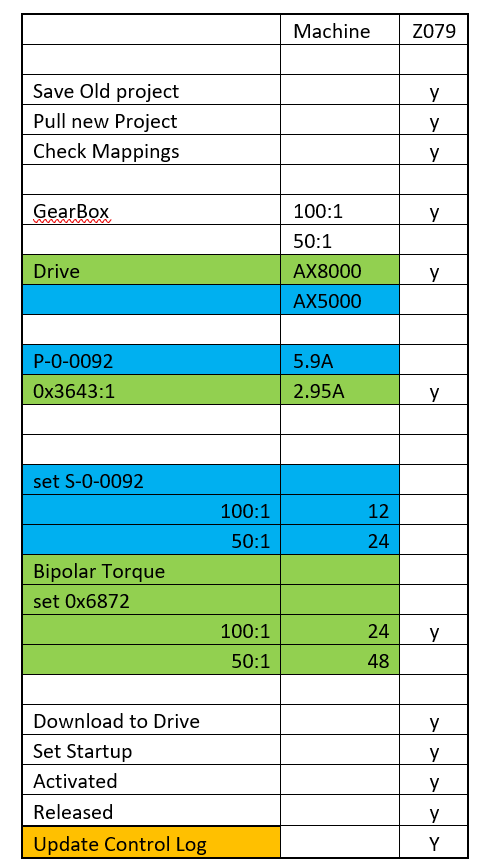

For the Sawing Modules that have a servo motor rather than a piston to rotate the Saw the Torque needs to be reduced significantly

Sommaire

- 1 Étape 1 - Gather Information - Gear Box

- 2 Étape 2 - Gather Information - Drive used

- 3 Étape 3 - Gather Information - Motor Being used

- 4 Étape 4 - Aim

- 5 Étape 5 - Regenerate Projects

- 6 Étape 6 - For a AX5003 Drive

- 7 Étape 7 - For AX8206 Drive

- 8 Étape 8 - For Both Drives

- 9 Étape 9 - Crib Table example

- 10 Commentaires

Étape 1 - Gather Information - Gear Box

Check Axis.mul and look at the line

SR,7,1,1,291833.500,1,200,500,500,125.1,90.0,InF_SRHome,3,20,5,0.0,5.0,10.0,0.000,

Gear ratio

291833.500 100:1

145602.000 50:1

Étape 2 - Gather Information - Drive used

AX8206 Drive

or

AX5003 Drive

Étape 3 - Gather Information - Motor Being used

It should be a AM8032-E

The AM8032-E has torque constant of 0.8 N/A

Étape 4 - Aim

We are aiming to deliver a torque of no more than 56 Nm

For

100:1 the motors maximum delivered torque 0.56 Nm

or

50:1 the motors maximum delivered torque 1.12 Nm

Étape 5 - Regenerate Projects

- Put old projects into a clearly named folder

- Create a new empty folder with the name of the machine.

- Open Project "From Target" to the new folder

- Check the mappings are present

- Add a Drive Manager project

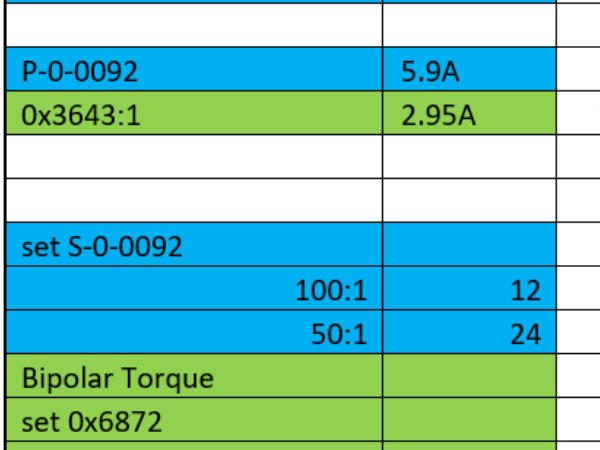

Étape 6 - For a AX5003 Drive

Use drive manager to get to the parameters.

Check the value of P-0-092 this value should be 5.9A (if not seek help)

Change the value of S-0-0092 to

12% for 100:1

or

24% for 50:1

If you have an old drive manager you may have to enter:

The value may be in .1 scale hence factor of 10 and also could be in HEX

120 or 0C00,

240 or F000

Étape 7 - For AX8206 Drive

Check channel B 0x3643:1 s/b 2.95A

Change 0x6872 to

24% for 100:1

or

48% for 50:1

Étape 8 - For Both Drives

- Add to startup parameters

- Download to drive

- Save project

- Activate

- Update control board

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português