| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 25 : | Ligne 25 : | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Check that the clutch is assembled correctly</translate> | ||

| + | |Step_Content=<translate>The clutch should have a friction plate each side of the pulley wheel</translate> | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Select a heavy profile for setting up</translate> | |Step_Title=<translate>Select a heavy profile for setting up</translate> | ||

Version du 6 avril 2023 à 13:57

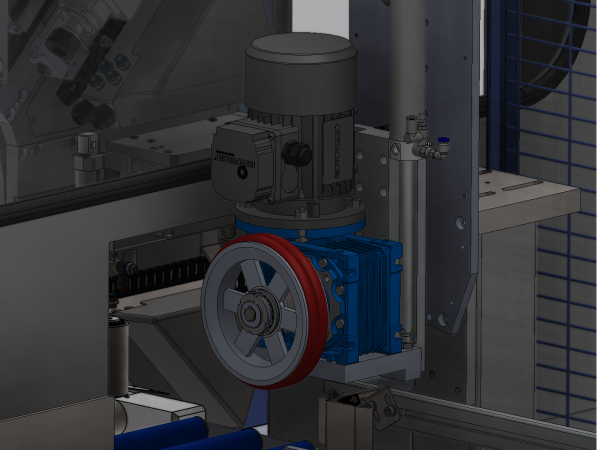

How to correctly set the pressure and clutch settings on the infeed loading wheel

Sommaire

- 1 Introduction

- 2 Video d'introduction

- 3 Étape 1 - Check that the clutch is assembled correctly

- 4 Étape 2 - Select a heavy profile for setting up

- 5 Étape 3 - Move the x axis clear

- 6 Étape 4 - Check the profile can slide to the machine easily

- 7 Étape 5 - Activate the Wheel

- 8 Étape 6 - Set the pressure

- 9 Étape 7 - Attempt to slide the profile by hand

- 10 Étape 8 - Try with power

- 11 Étape 9 - Try with power and infeed clamps on

- 12 Étape 10 - Final manual test with motor off

- 13 Étape 11 - Fold over the castellation locknut

- 14 Commentaires

Introduction

Setting the pressure and clutch tension on the loading wheel is critical for the reliable and accurate running of the machine

If set incorrectly, the profile will slip and not load correctly or will not give an accurate start position for the datum holes

The goal is to set the system to a "goldilocks" zone where there is enough pressure and clutch tension to reliably load a bar, but not too much so the clutch limits any correctional movement from the gripper arm on loading

Vimeo

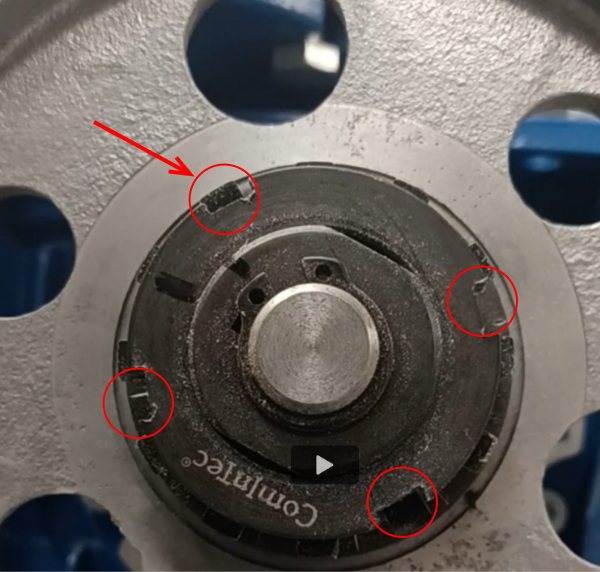

Étape 1 - Check that the clutch is assembled correctly

The clutch should have a friction plate each side of the pulley wheel

Étape 2 - Select a heavy profile for setting up

Use the heaviest profile you can find - a full bar of door T or transom

Place it under the wheel so it can be fed into the machine

Étape 3 - Move the x axis clear

Move the x axis to 4000mm so there is a clear test runway

Étape 4 - Check the profile can slide to the machine easily

Ensure there are no height spots or differences in height between the infeed and outfeed table that prevent the smooth transition of the profile into the machine

Activate the side and top infeed clamps with the profile inside, check again that it slides easily -the top and side clamps should be on 2 bar

Étape 5 - Activate the Wheel

Ensure the top and side infeed clamps are off

Bring the wheel onto the profile

Étape 6 - Set the pressure

Pressure should be set to 1 bar - any more than this creates too much drag for the clutch wheel to overcome

Étape 7 - Attempt to slide the profile by hand

The wheel clutch tension should be set so you can still manually push the profile and out of the machine. The wheel should turn (ie should not not skid on the profile) but there should be obvious tension.

Adjust the clutch tension if to suit

Étape 8 - Try with power

With the wheel on the profile, try the wheel motor on

The bar should drive in.

If the clutch slips, turn motor off, tighten clutch, try again

Étape 9 - Try with power and infeed clamps on

Try same test again with the infeed clamps on.

The clutch needs to just overcome the friction created by the side clamps

Étape 10 - Final manual test with motor off

Now the clutch has been tightened to overcome the infeed clamp forces, see if you can still slide the bar with the wheel done and the infeed clamps on.

It should be more difficult, but it should be possible to overcome the forces.

If this manual test fails, there could be one or more of these problems:

- Too much down pressure on wheel

- Clutch is too tight

- Friction / tightness in a roller

- A non-rolling part of the table or fence sticking out causing friction

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português