| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 82 : | Ligne 82 : | ||

{{Tuto Step | {{Tuto Step | ||

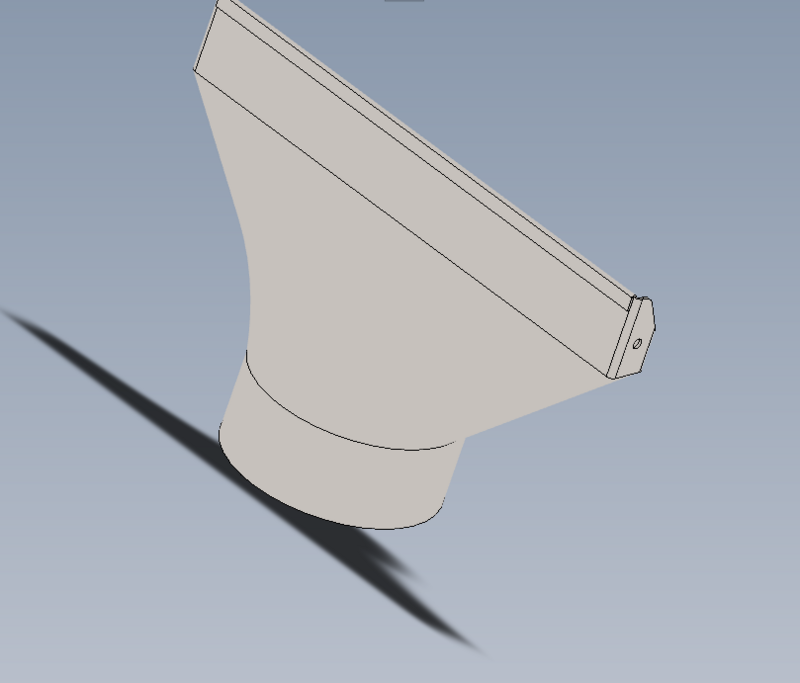

|Step_Title=<translate>Fit deflector</translate> | |Step_Title=<translate>Fit deflector</translate> | ||

| − | |Step_Content=<translate>Drill and fit deflector as shown | + | |Step_Content=<translate>{{Warning|...Ensure holes if drilled by hand are sufficiently deburred and free of sharp edges on both sides}} |

| + | |||

| + | Drill and fit deflector as shown | ||

Ensure deflector is mounted at a height that clearance is present between conveyor belt and deflector | Ensure deflector is mounted at a height that clearance is present between conveyor belt and deflector | ||

Version du 6 décembre 2023 à 09:04

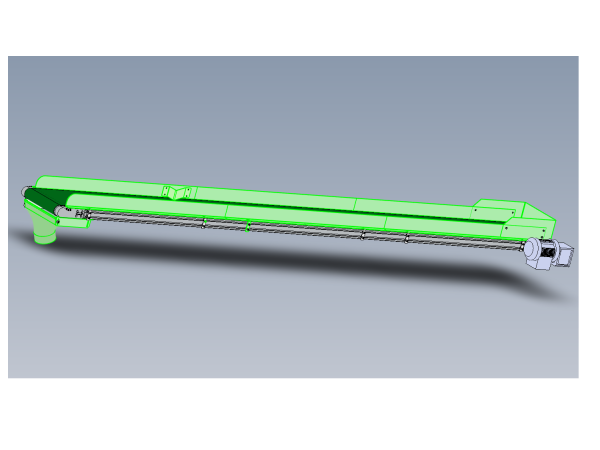

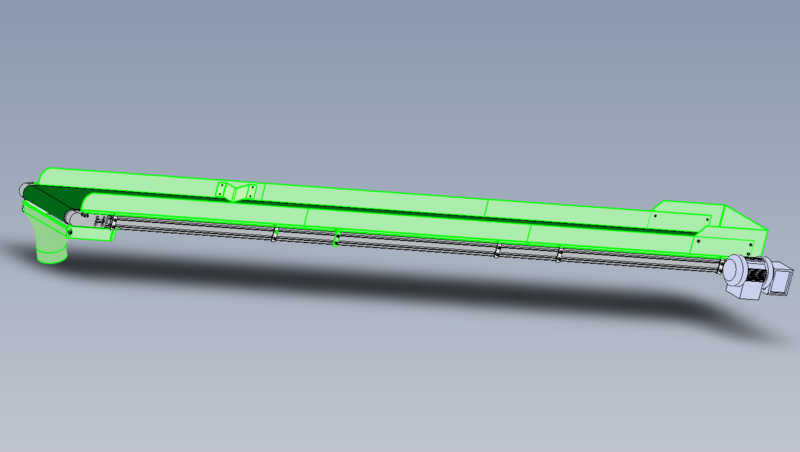

Installation details of waste guidance

Sommaire

- 1 Introduction

- 2 Étape 1 - Unless otherwise stated

- 3 Étape 2 - Please note

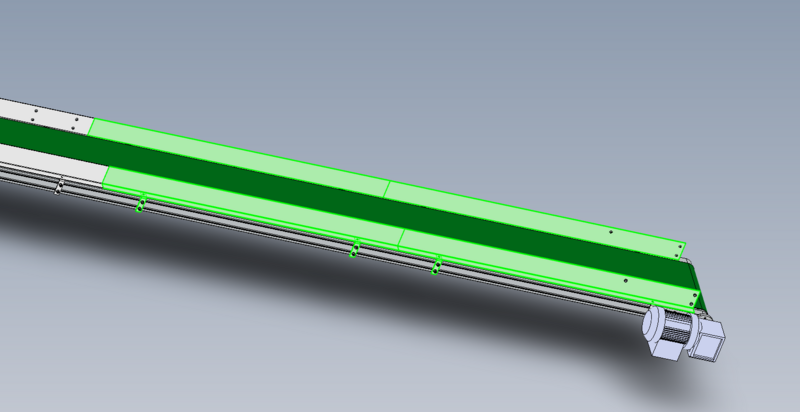

- 4 Étape 3 - Fit Radius side sheets

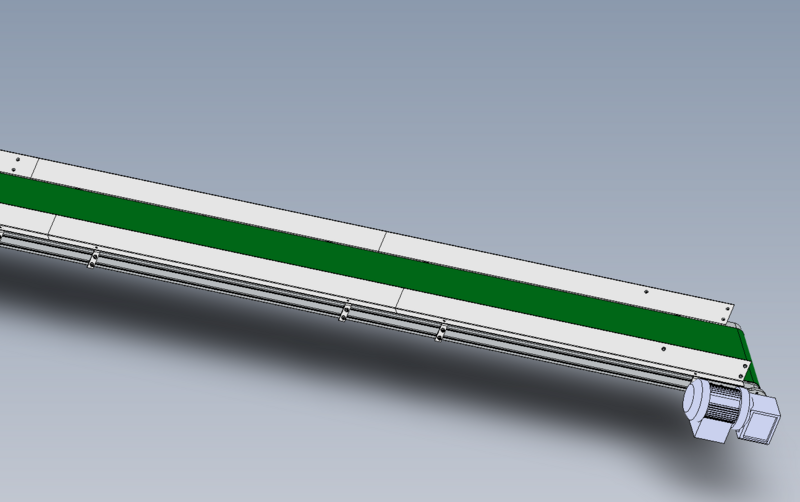

- 5 Étape 4 - Fit side sheets

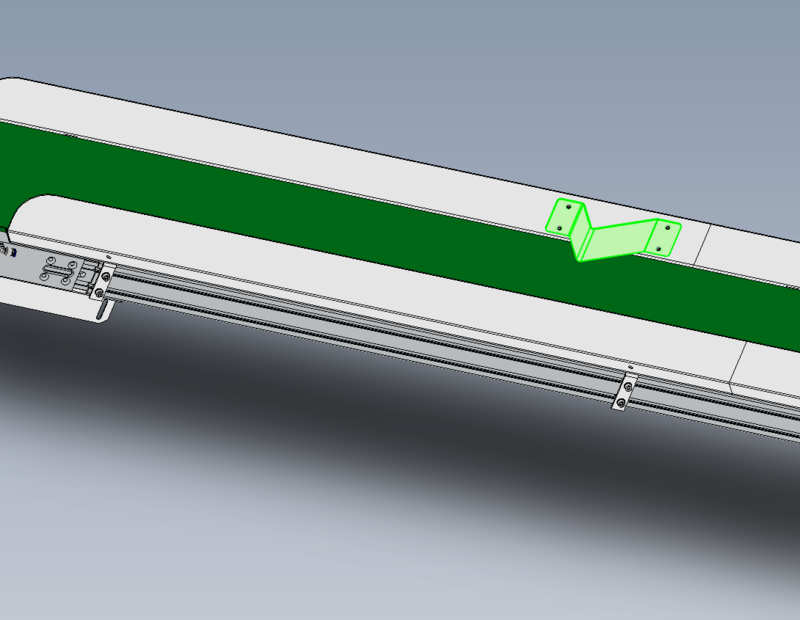

- 6 Étape 5 - Fit deflector

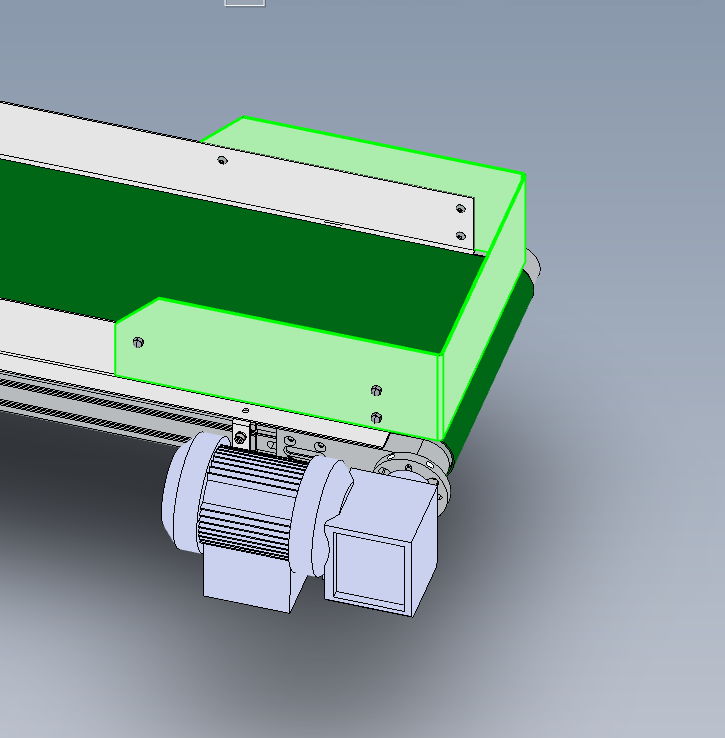

- 7 Étape 6 - Position end plate

- 8 Étape 7 - Drill end plate

- 9 Étape 8 - Fit end plate

- 10 Étape 9 - Fit edging strip

- 11 Étape 10 - Fit lower swarf funnel brackets

- 12 Étape 11 - Add riv nuts

- 13 Étape 12 - Fit swarf funnel

- 14 Étape 13 - Drill and pin

- 15 Étape 14 - Check all fasteners

- 16 Commentaires

Introduction

Tools Required

Standard hex key set

Standard spanner set

Standard HSS drill set

Standard tap set

Parts Required

D0001967 Conveyor End Plate x 1

D0001970 Swarf Funnel Support x 2

D0005616 Conveyor Swarf Funnel x 1

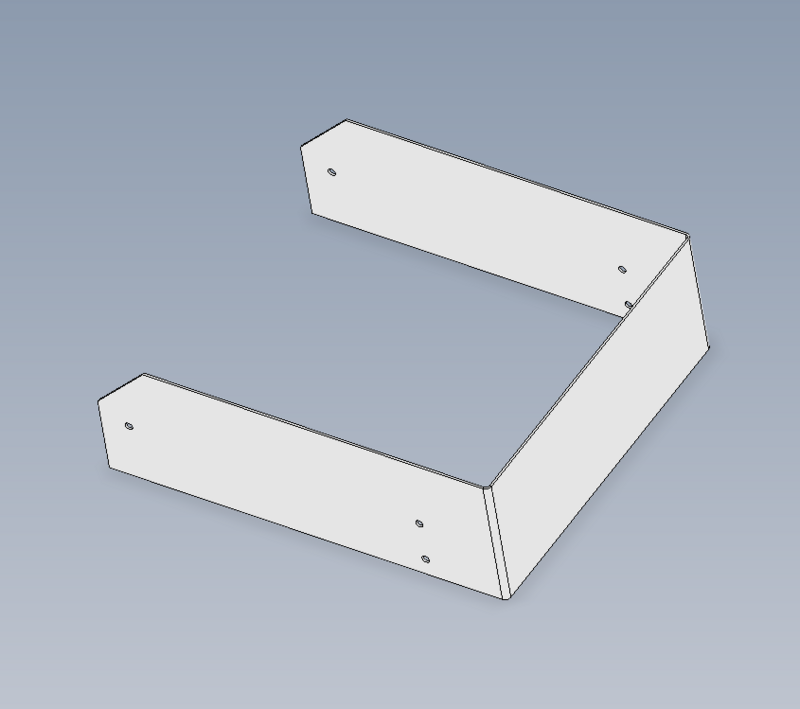

D0010843 Conveyor Deflector Plate x 1

M0000031 Panel Edging Strip; 9 x 6mm (consumable stock )

R0015344 Bench Assemble Conveyor Parts

Étape 1 - Unless otherwise stated

Use Loctite 243 on all fasteners

Use Loctite 572 on all threaded pneumatic connection

Pen mark all fasteners to show finalised

Étape 2 - Please note

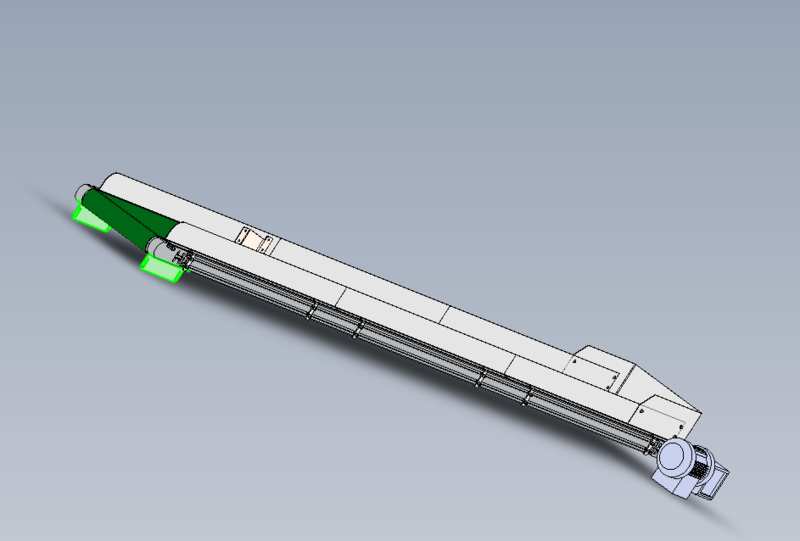

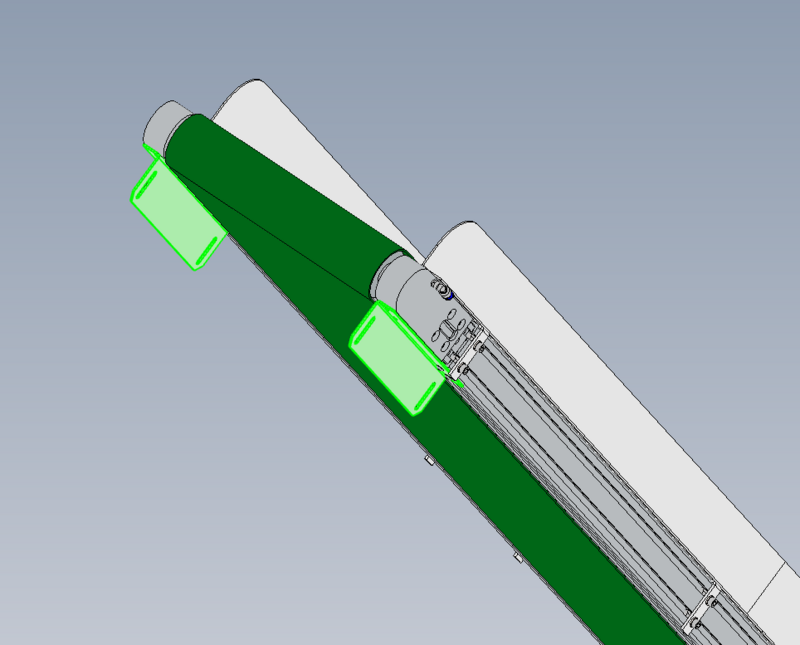

Drive motor must be removed to allow access to fit side sheets

1 locking grubscrew must be slackened to allow drive motor to be removed.

Ensure drive motor is refitted after installation of waste guidance sheets

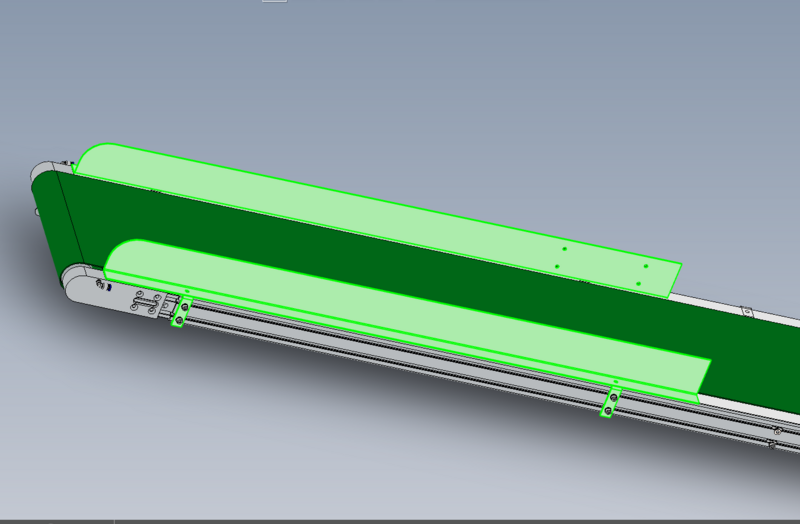

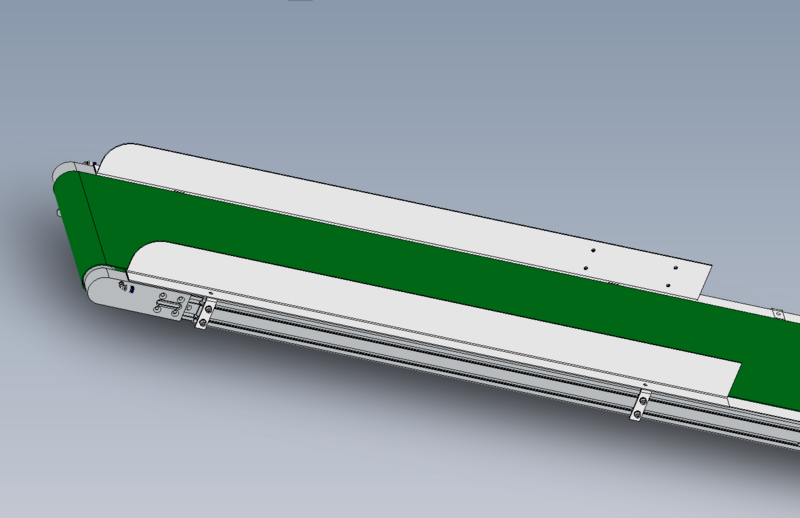

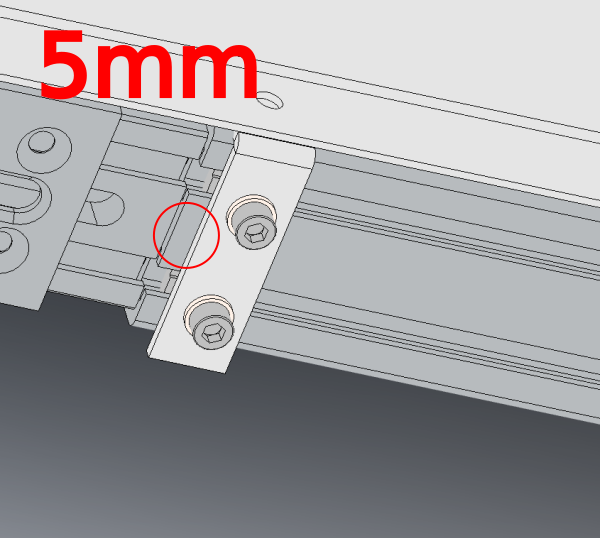

Étape 3 - Fit Radius side sheets

fit 2 off radius side sheets as shown

Secure using m5 d nuts

Position as shown 5mm from edge frame

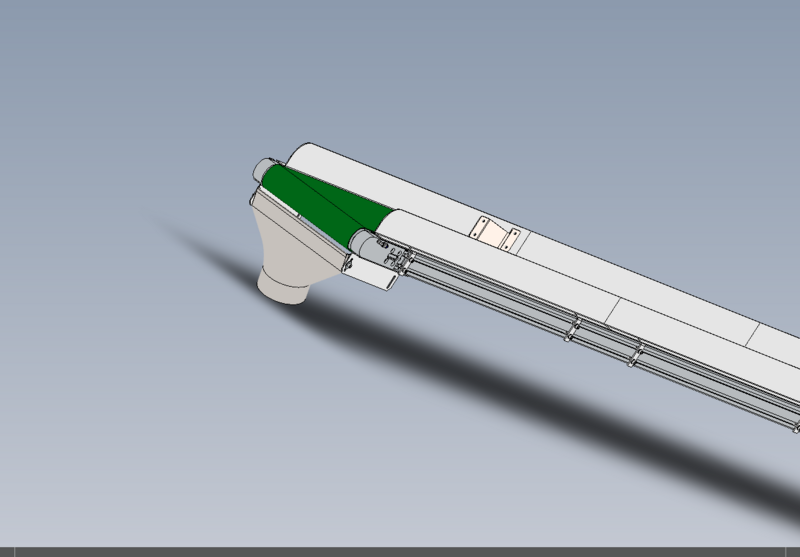

Étape 5 - Fit deflector

Drill and fit deflector as shown

Ensure deflector is mounted at a height that clearance is present between conveyor belt and deflector

Provide details to enable ecr to be raised to add mounting holes

Étape 6 - Position end plate

Position conveyor end plate as shown

Ensure end plate does not touch belt

Mark positions for mounting holes and remove end plate

Étape 7 - Drill end plate

Drill M6 clearance holes at marked points

Drill off cable tie bases for motor cable

Provide all details to enable ecr generation

Étape 12 - Fit swarf funnel

Fit swarf funnel to conveyor brackets

Secure with M6 cap heads and washers

Picture required for correct setting position of funnel

Étape 14 - Check all fasteners

Check all fasteners are finalised and marked

Ensure all settings have been finalised

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português