| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 16 : | Ligne 16 : | ||

|- | |- | ||

|''Description'' | |''Description'' | ||

| − | |''Direct centralising on simple cylinder'' | + | |''Direct centralising'' |

| − | |No mechanical centralising, all on | + | ''on simple cylinder'' |

| − | | | + | |''No mechanical centralising,'' |

| + | ''all on SY axis'' | ||

| + | |''Mechanical Centralising,'' | ||

| + | |||

| + | ''with SY axis offset from centre'' | ||

| | | | ||

|- | |- | ||

| Ligne 25 : | Ligne 29 : | ||

| | | | ||

| | | | ||

| − | | | + | |All saws have the standard centralising mechanics except cill saws where this is removed to enable wider (cill) profiles to be managed |

|- | |- | ||

|Flowline / ZX3 / ZX4 | |Flowline / ZX3 / ZX4 | ||

| Ligne 31 : | Ligne 35 : | ||

| | | | ||

|Optional Refurbished with Y-Drive | |Optional Refurbished with Y-Drive | ||

| − | | | + | |All original flowlines, ZX3 and ZX4 have the standard centralise system, but following the development of the "Y-Drive" on the ZX5, this is offered as an option on refurbished machines |

|- | |- | ||

|Microline | |Microline | ||

| Ligne 37 : | Ligne 41 : | ||

|All | |All | ||

| | | | ||

| − | | | + | |All Microlines have an "A" axis to control the arrow head position |

| + | |||

| + | This axis position affects all cut types so also affects Mitred lengths | ||

|- | |- | ||

|Autoflow | |Autoflow | ||

| Ligne 43 : | Ligne 49 : | ||

|All | |All | ||

| | | | ||

| − | | | + | |All Autoflows use SY axis to control arrow head position |

| + | This axis position affects all cut types so also affects Mitred lengths | ||

|- | |- | ||

|ZX5 | |ZX5 | ||

| Ligne 49 : | Ligne 56 : | ||

| | | | ||

|All | |All | ||

| − | | | + | |The ZX5 uses a hybrid system where mitred cuts will use a fixed bladetofence measurement, coupled with the ability to offset on the SY axis when the centralising is on. This offset allows the blade to offset from centre for Y notching |

|} | |} | ||

| Ligne 69 : | Ligne 76 : | ||

{{Info|...It is important to get consistent inconsistencies to be able to understand what to do about it}}<br /> | {{Info|...It is important to get consistent inconsistencies to be able to understand what to do about it}}<br /> | ||

{| class="wikitable" | {| class="wikitable" | ||

| − | |+Root Cause Table - | + | |+Root Cause Table - Standard Centralising and Y-Drive |

!Symptoms | !Symptoms | ||

!Potential Root Cause | !Potential Root Cause | ||

| Ligne 117 : | Ligne 124 : | ||

|}<br /> | |}<br /> | ||

{| class="wikitable" | {| class="wikitable" | ||

| − | |+Root Cause Table - SY Drive Only (Refurb Flowlines with SY upgrade, All ZX5s) | + | |+Root Cause Table - Full SY Axis and Y Drive Only (Refurb Flowlines with SY upgrade, All ZX5s) |

!Symptoms | !Symptoms | ||

!Potential Root Cause | !Potential Root Cause | ||

!Checks | !Checks | ||

|- | |- | ||

| − | | rowspan=" | + | | rowspan="3" |Arrow heads varying with no pattern, changes after redatum |

SY axis stalling and has following errors | SY axis stalling and has following errors | ||

|SY axis needs lubricating | |SY axis needs lubricating | ||

| Ligne 129 : | Ligne 136 : | ||

|SY axis sensor not functioning correctly | |SY axis sensor not functioning correctly | ||

| | | | ||

| + | |- | ||

| + | |SY Axis Misaligned and stalling | ||

| + | SY Axis coupling slipping | ||

| + | |Check for following error / lag on SY axis | ||

|- | |- | ||

|All arrow heads out by same amount | |All arrow heads out by same amount | ||

|SY Axis Datum is wrong | |SY Axis Datum is wrong | ||

| + | |||

| + | |||

| + | SY Axis Misaligned and stalling | ||

| + | |||

| + | SY Axis coupling slipping | ||

|Check and double check offsets | |Check and double check offsets | ||

Check repeatability of SY axis datum visually (mark a line and repeatedly test datuming) | Check repeatability of SY axis datum visually (mark a line and repeatedly test datuming) | ||

| Ligne 141 : | Ligne 157 : | ||

<br /> | <br /> | ||

{| class="wikitable" | {| class="wikitable" | ||

| − | |+Root Cause Table AFTER T Transoms correct - All | + | |+Root Cause Table AFTER T Transoms correct - All Types |

!Symptoms | !Symptoms | ||

!Potential Root Cause | !Potential Root Cause | ||

Version du 17 août 2023 à 14:52

Additional root causes that can affect arrow head accuracy

Machine Types

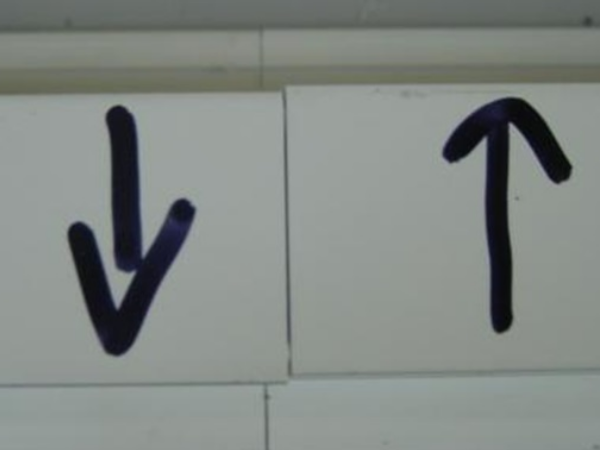

Arrow head setup on a Stuga machine falls into 3 different groups depending on the model of the machine and the centralising options fitted

| Standard | Full SY Axis | Y-Drive | Notes | |

|---|---|---|---|---|

| Description | Direct centralising

on simple cylinder |

No mechanical centralising,

all on SY axis |

Mechanical Centralising,

with SY axis offset from centre |

|

| Standalone Saw | All | All saws have the standard centralising mechanics except cill saws where this is removed to enable wider (cill) profiles to be managed | ||

| Flowline / ZX3 / ZX4 | Optional Refurbished with Y-Drive | All original flowlines, ZX3 and ZX4 have the standard centralise system, but following the development of the "Y-Drive" on the ZX5, this is offered as an option on refurbished machines | ||

| Microline | All | All Microlines have an "A" axis to control the arrow head position

This axis position affects all cut types so also affects Mitred lengths | ||

| Autoflow | All | All Autoflows use SY axis to control arrow head position

This axis position affects all cut types so also affects Mitred lengths | ||

| ZX5 | All | The ZX5 uses a hybrid system where mitred cuts will use a fixed bladetofence measurement, coupled with the ability to offset on the SY axis when the centralising is on. This offset allows the blade to offset from centre for Y notching |

T Transoms First

The first important step is to gather reliable test data. Create test pieces 4 off 400mm of narrow, mid and wide T transoms

- Carefully check that the bars are symmetrical

- Use a test bar long enough to ensure the offcut is not at the start of the bar

- Label them 1, 2 and 3 and 4 as they come off the machine

- Carefully check the dimensions and symmetry of each profile - use the "front to front and back to front method" to check shoulder lengths against each other. This is a quick way to identify discrepancies and compare pieces

- Measure the arrow head location accurately and carefully to get an idea of how the arrow heads perform overall, rather than concentrating on one profile that the operator tells you is wrong.

- If there are any inconsistencies on a profile, repeat the same test - Do you get the same result?

- Test inconsistent profiles again - do you get the same result?

| Symptoms | Potential Root Cause | Checks |

|---|---|---|

No issues found but history of:

|

Swarf or offcut stuck was stopping the centralise getting to position

Centralise cylinder pressure too low (either / both will stop profile getting pushed to backfence)

|

Check the side fence reaches the profile when centralising

|

| First or last arrow head on bar is different to others | Side fences not parallel

Rear fences not aligned |

TM016 Arrow Head Adjustment on Saw#Step 4 - Check Side Fences are Parallel |

| Some profile arrow heads correct, others profiles not. Repeatable results on every test | Arrow head offsets (fiddle factors) historically set | Reset all ofsets to zero before starting |

| Symptoms | Potential Root Cause | Checks |

|---|---|---|

| Arrow heads varying with no pattern, changes after redatum

SY axis stalling and has following errors |

SY axis needs lubricating | Check SY axis moves full range of movement by hand and via drives screen |

| SY axis sensor not functioning correctly | ||

| SY Axis Misaligned and stalling

SY Axis coupling slipping |

Check for following error / lag on SY axis | |

| All arrow heads out by same amount | SY Axis Datum is wrong

SY Axis coupling slipping |

Check and double check offsets

Check repeatability of SY axis datum visually (mark a line and repeatedly test datuming) |

Z Transoms Second

Repeat the same tests for Z shaped profiles

| Symptoms | Potential Root Cause | Checks |

|---|---|---|

| Bottom arrow head is different to top

First or last arrow head on bar is different to others |

Z Support not active for profile

Z support incorrectly set for profile rebate Infeed top clamp pressure not high enough to flatten profile |

Check Z support settings

Manually check how the Z profile is clamped with the Z support out Top Clamp pressure 1bar-2bar |

| One profile incorrect but others ok | Profile not symmetrical | Test Z transom Symmetry (can be difficult!) |

| Some arrow heads correct, others not, but fixed pattern, not varying along bar length | Arrow head offsets (fiddle factors) historically set | Reset all ofsets to zero before starting |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português