| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Main_Picture=TM016_Arrow_Head_Adjustment_on_Saw_image9.jpg |Main_Picture_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","origin... ») |

|||

| Ligne 5 : | Ligne 5 : | ||

|Categories=Maintenance | |Categories=Maintenance | ||

}} | }} | ||

| − | <translate>= Problem = | + | <translate>=Problem= |

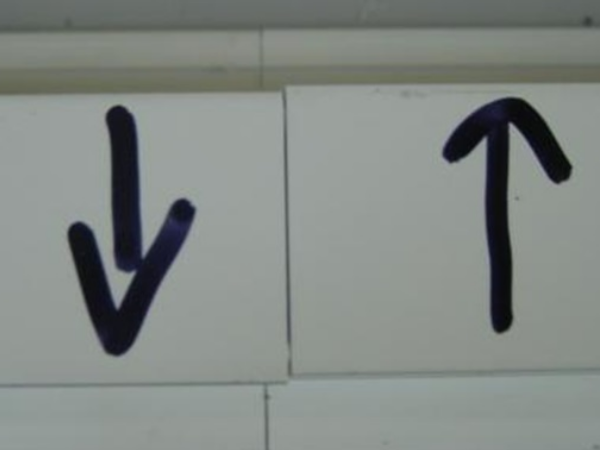

Arrow head setup on a Stuga Sawing centre (not Autoflow) should be simple - the sawing fences centralise around the profile | Arrow head setup on a Stuga Sawing centre (not Autoflow) should be simple - the sawing fences centralise around the profile | ||

| − | {{Pin|...Autoflow and Microline machines have an axis-driven position for the saw blade centralise position, not a mechanical one}}<br /> | + | {{Pin|...Autoflow and Microline machines have an axis-driven position for the saw blade centralise position, not a mechanical one}}<br />If the arrow heads are varying or different on one profile to another, there must be other root causes involved - use this checklist to see if |

{| class="wikitable" | {| class="wikitable" | ||

| − | |+Root Cause Table - Saw, Flowline, ZX3/4/5 | + | |+Root Cause Table - All Saw, Flowline, ZX3/4/5 |

| − | !Root Cause | + | !Potential Root Cause |

!Symptoms | !Symptoms | ||

!Checks | !Checks | ||

|- | |- | ||

|Swarf or offcut stuck stopping the centralise getting to position | |Swarf or offcut stuck stopping the centralise getting to position | ||

| − | |All arrow heads out by the same amount on one bar | + | |All arrow heads out by the same amount on one bar or a set of bars in order, then correct again |

| − | Arrow heads out by a long way (>5mm) | + | Arrow heads out by a long way (>5mm) towards front of machine |

| − | Mitre | + | Mitre cut lengths also short (not long) |

|Check the side fence reaches the profile when centralising | |Check the side fence reaches the profile when centralising | ||

|- | |- | ||

| − | |Z Support not active for profile | + | |Z Support not active for profile |

| − | | | + | Z support incorrectly set for profile rebate |

| − | + | |On Z profiles, Bottom arrow head is different to top | |

| + | First or last arrow head on bar is different to others | ||

|Check Z support settings | |Check Z support settings | ||

| + | Manually check how the Z profile is clamped with the Z support out | ||

|- | |- | ||

|Profile not symmetrical | |Profile not symmetrical | ||

| − | |One profile incorrect | + | |One profile incorrect but others ok |

|See [[TB0395 How To Test T transom Symmetry]] | |See [[TB0395 How To Test T transom Symmetry]] | ||

|- | |- | ||

|Arrow head offsets (fiddle factors) historically set | |Arrow head offsets (fiddle factors) historically set | ||

| − | |Some arrow heads correct, others not | + | |Some arrow heads correct, others not, but fixed pattern, not varying along bar length |

|Reset all ofsets to zero before starting | |Reset all ofsets to zero before starting | ||

| + | |- | ||

| + | |Side Clamps not parallel | ||

| + | |First or last arrow head on bar is different to others | ||

| + | |Check front fences are parallel with the rear | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |} | ||

| + | {| class="wikitable" | ||

| + | |+Root Cause Table - SY Drive Only (Refurb Flowlines with SY upgrade, All ZX5s) | ||

| + | !Potential Root Cause | ||

| + | !Symptoms | ||

| + | !Checks | ||

| + | |- | ||

| + | |SY axis needs lubricating | ||

| + | |Arrow heads varying with no pattern, change after redatum | ||

| + | SY axis stalling and has following errors | ||

| + | |Check SY axis moves full range of movement by hand and via drives screen | ||

| + | |- | ||

| + | |SY axis sensor not functioning correctly | ||

| + | |Arrow heads varying with no pattern, change after redatum | ||

| + | | | ||

| + | |- | ||

| + | |SY Axis Datum is wrong | ||

| + | |All arrow heads out by same amount | ||

| + | |Check and double check offsets | ||

| + | Check repeatability of SY axis datum visually (mark a line and repeatedly | ||

| + | {{Warning|..You have to ask yourself why the SY axis datum position has changed - there has to be a root cause. Simply changing the parameter will mask the real problem and therefore guaranteed to return again minutes or days later}}<br /> | ||

|}</translate> | |}</translate> | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{AddComments}} | {{AddComments}} | ||

Version du 15 août 2023 à 18:32

Additional root causes that can affect arrow head accuracy

Sommaire

Problem

Arrow head setup on a Stuga Sawing centre (not Autoflow) should be simple - the sawing fences centralise around the profile

If the arrow heads are varying or different on one profile to another, there must be other root causes involved - use this checklist to see if

| Potential Root Cause | Symptoms | Checks |

|---|---|---|

| Swarf or offcut stuck stopping the centralise getting to position | All arrow heads out by the same amount on one bar or a set of bars in order, then correct again

Arrow heads out by a long way (>5mm) towards front of machine Mitre cut lengths also short (not long) |

Check the side fence reaches the profile when centralising |

| Z Support not active for profile

Z support incorrectly set for profile rebate |

On Z profiles, Bottom arrow head is different to top

First or last arrow head on bar is different to others |

Check Z support settings

Manually check how the Z profile is clamped with the Z support out |

| Profile not symmetrical | One profile incorrect but others ok | See TB0395 How To Test T transom Symmetry |

| Arrow head offsets (fiddle factors) historically set | Some arrow heads correct, others not, but fixed pattern, not varying along bar length | Reset all ofsets to zero before starting |

| Side Clamps not parallel | First or last arrow head on bar is different to others | Check front fences are parallel with the rear |

| Potential Root Cause | Symptoms | Checks |

|---|---|---|

| SY axis needs lubricating | Arrow heads varying with no pattern, change after redatum

SY axis stalling and has following errors |

Check SY axis moves full range of movement by hand and via drives screen |

| SY axis sensor not functioning correctly | Arrow heads varying with no pattern, change after redatum | |

| SY Axis Datum is wrong | All arrow heads out by same amount | Check and double check offsets

Check repeatability of SY axis datum visually (mark a line and repeatedly |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português