| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 5 : | Ligne 5 : | ||

|Categories=Production | |Categories=Production | ||

|Difficulty=Medium | |Difficulty=Medium | ||

| − | |Duration= | + | |Duration=2 |

|Duration-type=hour(s) | |Duration-type=hour(s) | ||

}} | }} | ||

Version du 1 juin 2023 à 17:11

Installation and routing of control cables and pipes to connection boxes

Sommaire

Introduction

Tools Required

Standard screw driver set

Flush side cutters

Parts Required

A0000344 Energy chain bracket set x 8

Étape 2 - Spindle energy chain assembly

Assembly 8 off spindle energy chains with 27 links of A0000343 and 1 pair of A0000344

Assemble as image

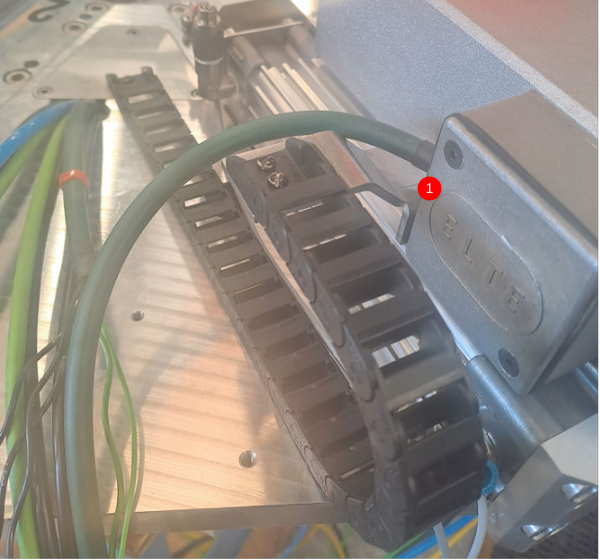

Étape 3 - Mount energy chains

1 Use 4 off m3 x 6 pan head screws and mount energy chains as shown. Ensure energy chain is mounted parallel to the cylinder

2 Disconnect end shown ready for cabling

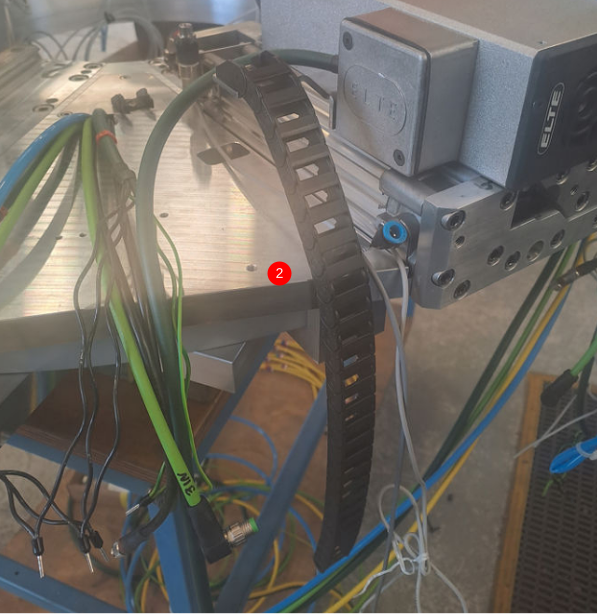

Étape 4 - Double plunge control routing

1 Use small cable wrap to start loom at cylinder end. Incorporate reed switches as passing. Add tie wrap to secure loom

2 Continue loom and fix to tie bases as passing

3 Continue loom over terminal box and secure on Tie base

4 Place looms as shown through energy chains

5 Reconnect energy chain and leave flying tails in centre of the ring

Repeat for 3 other double spindles

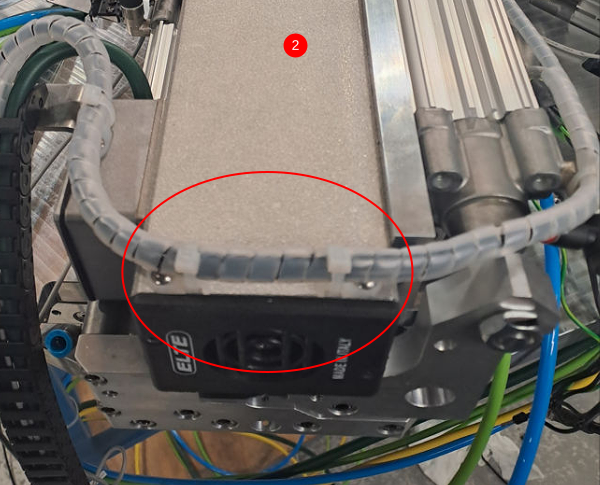

Étape 6 - Mount pre assembled connection boxes

1 Mount connection boxes using M5 x 10 button head at cable end and 2 off M5 x 12 cap heads with washers at other end

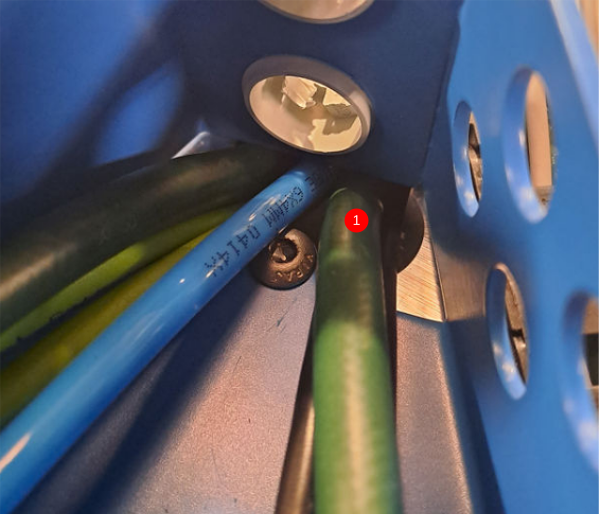

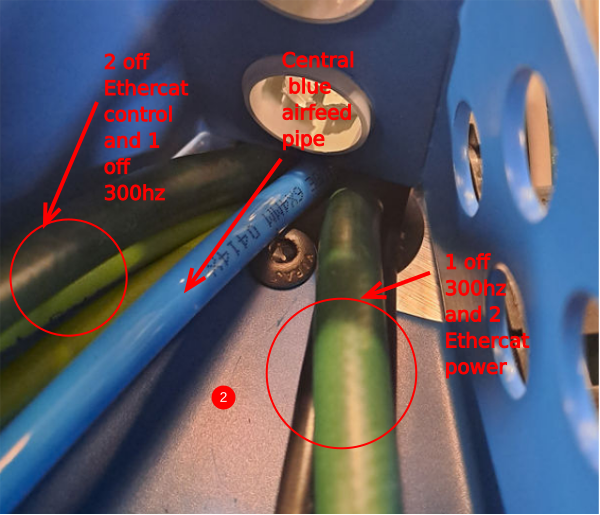

2 Cables should be separated as shown

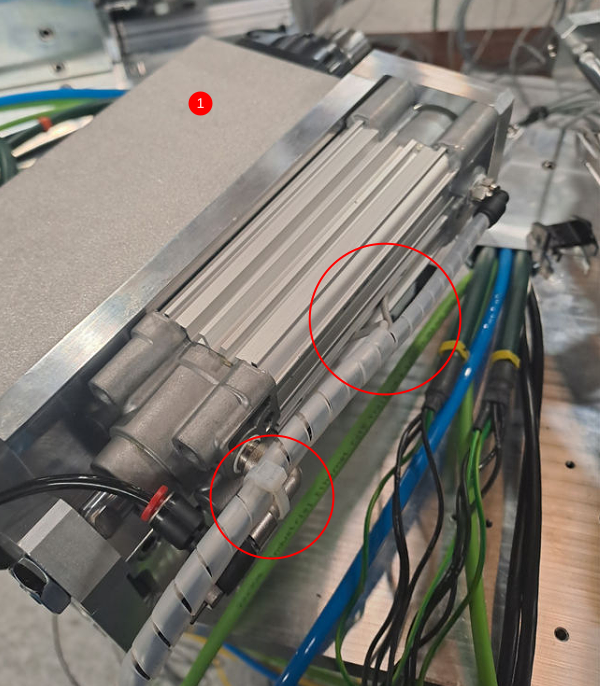

Étape 7 - Clearance checks

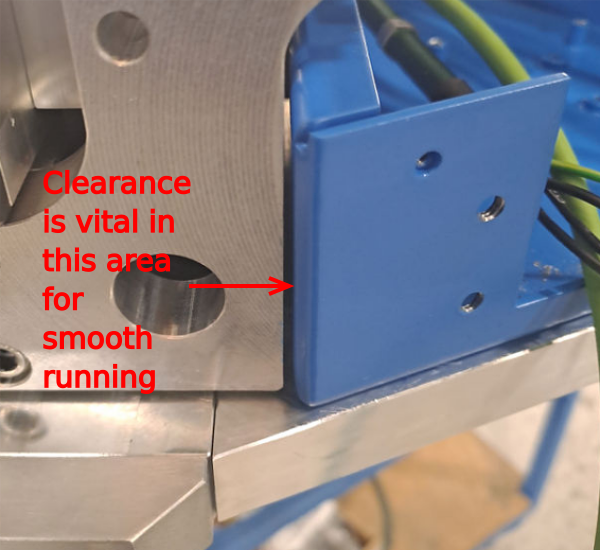

It is vital to check clearance in the following area. There must be no contact in this area when the spindle is plunged forward.

If contact is occurring, the connection box will need adjusting to gain clearance

To Adjust

1 Remove spindle connection box

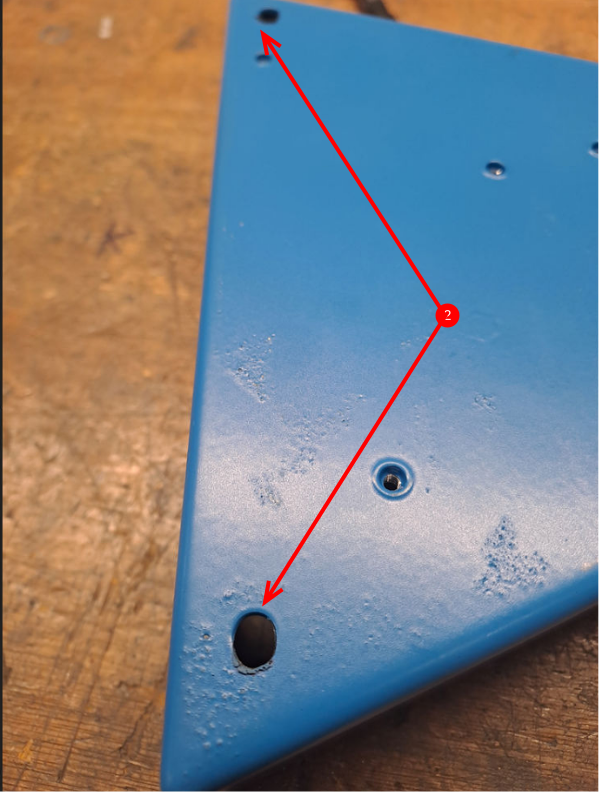

2 Elongate mounting holes to give movement int he direction required

3 Refit and adjust to achieve clearance

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português