| [version en cours de rédaction] | [version en cours de rédaction] |

m (Gareth Green a déplacé la page C0001005MM Micromech Stepper Motor Transition to C0001005 vers C0001005MM Micromech Stepper Motor Assembly) |

|||

| (Une révision intermédiaire par le même utilisateur non affichée) | |||

| Ligne 13 : | Ligne 13 : | ||

{{Materials}} | {{Materials}} | ||

{{EPI}} | {{EPI}} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Supplied 3mm dowel with C0001200 encoder must be fitted to stepper motor</translate> | ||

| + | |Step_Content=<translate></translate> | ||

| + | |Step_Picture_00=C0001005MM_Micromech_Stepper_Motor_Assembly_20221221_142254.jpg | ||

| + | |Step_Picture_01=C0001005MM_Micromech_Stepper_Motor_Assembly_20221221_143910.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Position of dowel</translate> | ||

| + | |Step_Content=<translate>Mark the motor face as the picture to give the correct mounting position | ||

| + | |||

| + | |||

| + | A 3mm hole must be drilled in this position at a depth of 5mm . Caution, damage can be caused to motor if this depth is not adhered to. Increase drill sizes incrementally when drilling, to ensure a good sized 3mm hole | ||

| + | |||

| + | |||

| + | Use masking tape to stop swarf entering the stepper motor housing | ||

| + | |||

| + | |||

| + | Use a drop of Loctite 270 to ensure dowel remains in place when fitted</translate> | ||

| + | |Step_Picture_00=C0001005MM_Micromech_Stepper_Motor_Assembly_20221221_134141.jpg | ||

| + | |Step_Picture_01=C0001005MM_Micromech_Stepper_Motor_Assembly_20221221_135226.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>C0001200 Encoder fitting</translate> | ||

| + | |Step_Content=<translate>Add Loctite 243 to location clasp (pic 3) and refit to encoder. | ||

| + | |||

| + | Add Loctite 243 to 4 off grub screws in encoder collar | ||

| + | |||

| + | Fit encoder to stepper motor ensuring location clasp sits on top of fitted 3mm dowel. | ||

| + | |||

| + | ensure retaining collar with grub screw is against encoder face and then secure the 4 grub screws | ||

| + | |||

| + | |||

| + | Test rotation of stepper motor spindle to check correct running with encoder fitted</translate> | ||

| + | |Step_Picture_00=C0001005MM_Micromech_Stepper_Motor_Assembly_20221221_123453.jpg | ||

| + | |Step_Picture_01=C0001005MM_Micromech_Stepper_Motor_Assembly_20221221_122739.jpg | ||

| + | |Step_Picture_02=C0001005MM_Micromech_Stepper_Motor_Assembly_20221221_122642.jpg | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate></translate> | |Step_Title=<translate></translate> | ||

| Ligne 19 : | Ligne 56 : | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version actuelle datée du 21 décembre 2022 à 16:19

How to convert a C0001292 Motor into a replacement for a Beckhoff C0001005 replacement

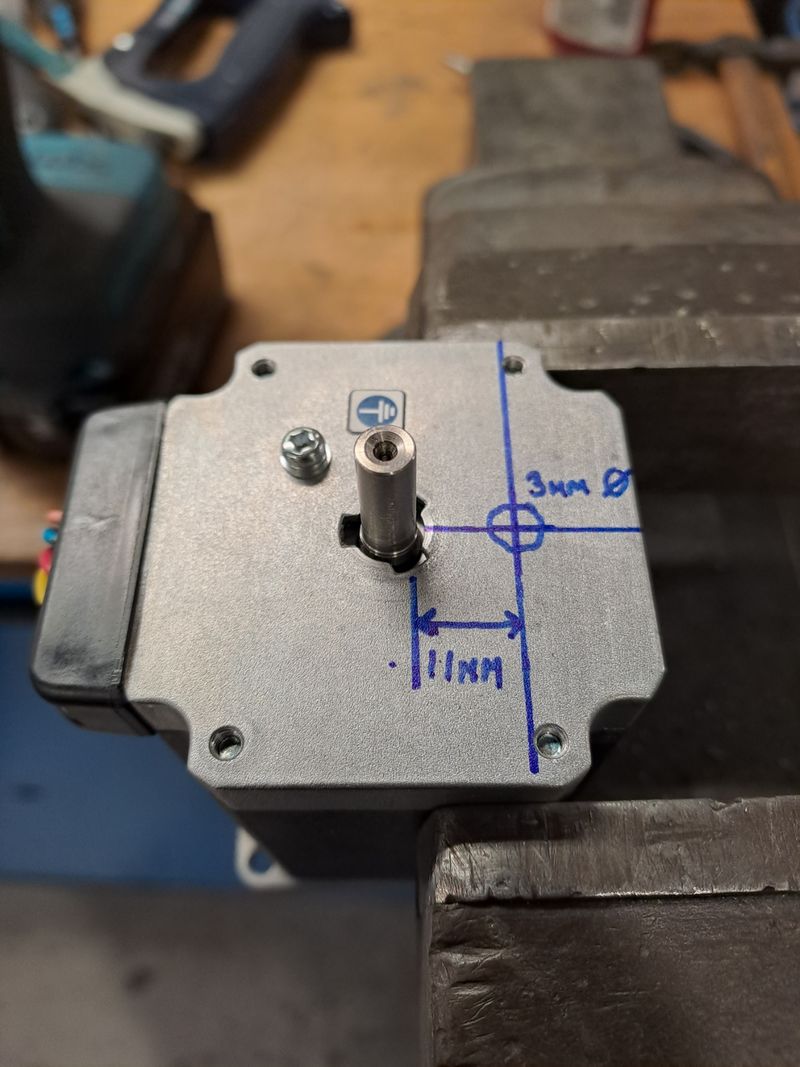

Étape 2 - Position of dowel

Mark the motor face as the picture to give the correct mounting position

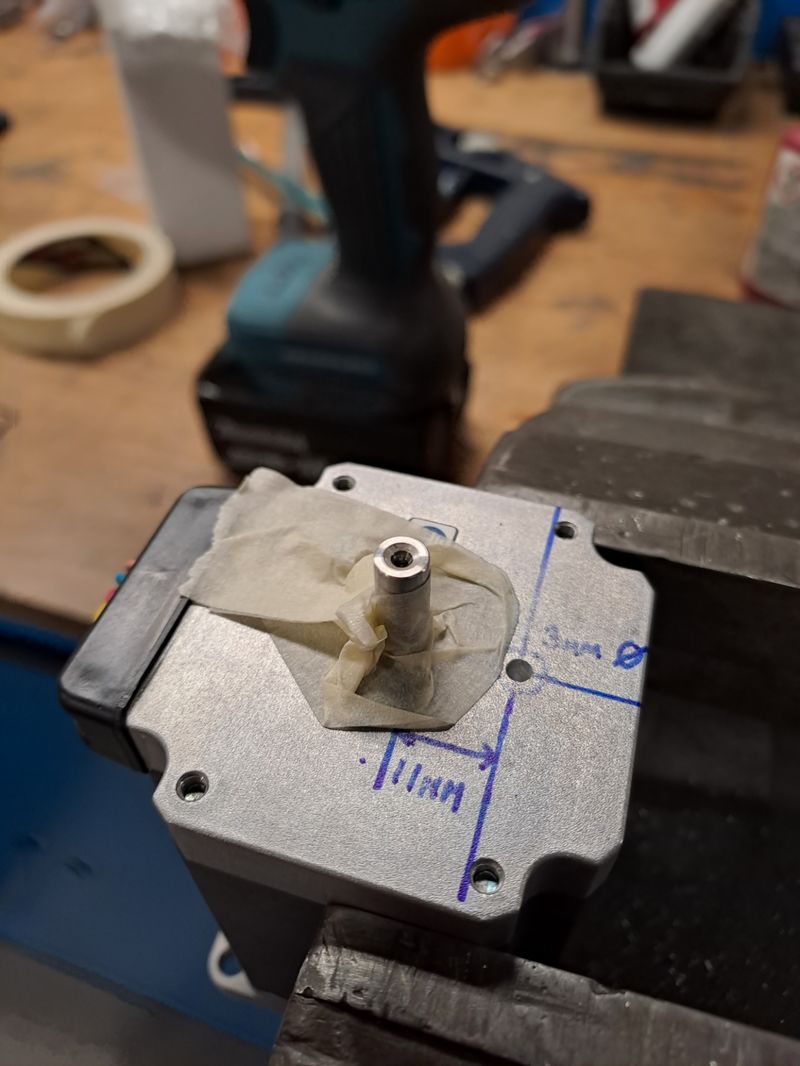

A 3mm hole must be drilled in this position at a depth of 5mm . Caution, damage can be caused to motor if this depth is not adhered to. Increase drill sizes incrementally when drilling, to ensure a good sized 3mm hole

Use masking tape to stop swarf entering the stepper motor housing

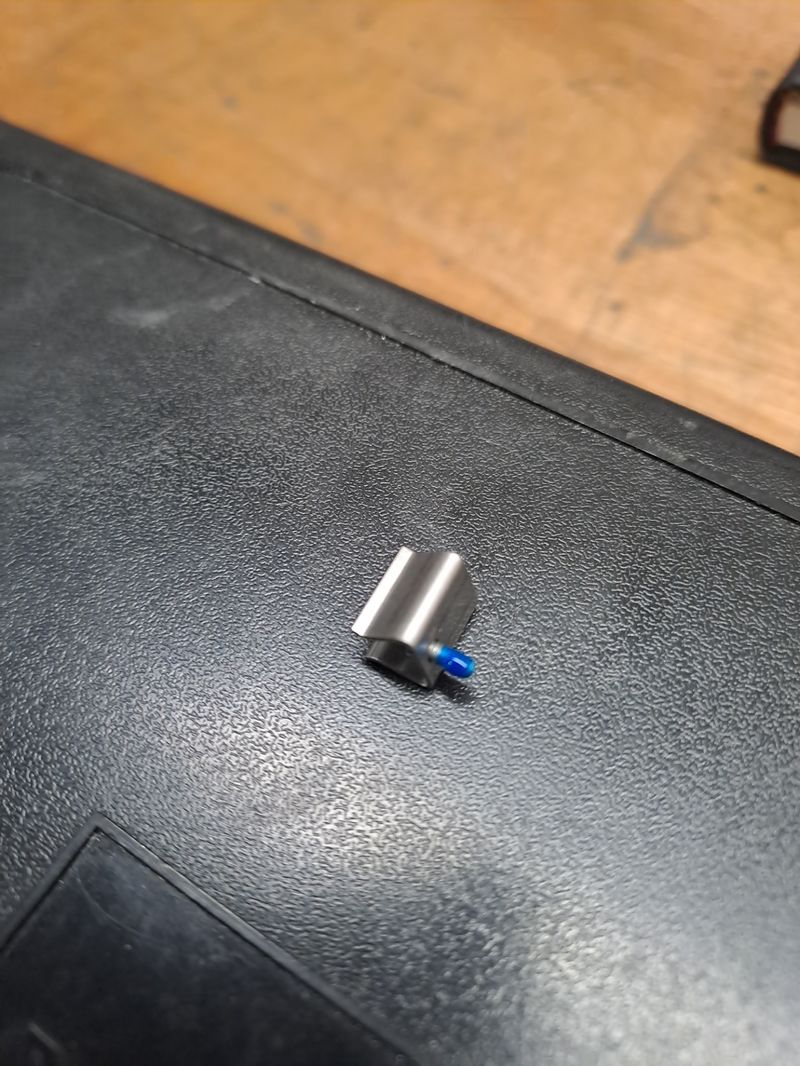

Use a drop of Loctite 270 to ensure dowel remains in place when fitted

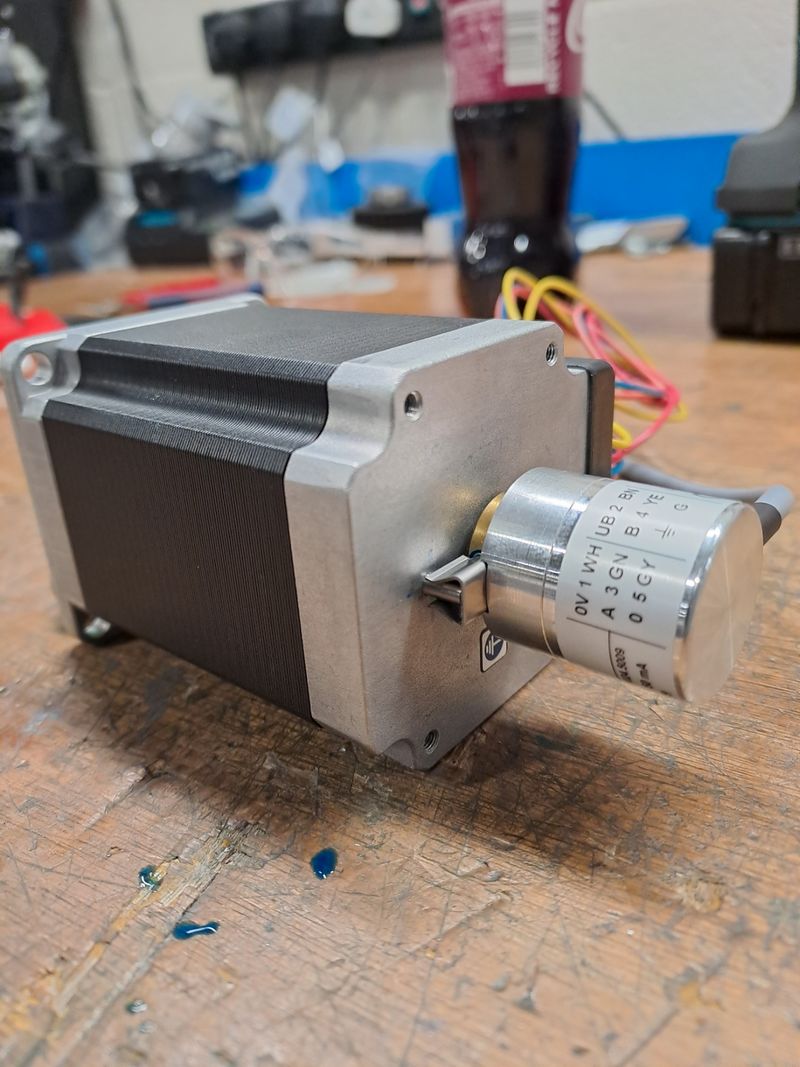

Étape 3 - C0001200 Encoder fitting

Add Loctite 243 to location clasp (pic 3) and refit to encoder.

Add Loctite 243 to 4 off grub screws in encoder collar

Fit encoder to stepper motor ensuring location clasp sits on top of fitted 3mm dowel.

ensure retaining collar with grub screw is against encoder face and then secure the 4 grub screws

Test rotation of stepper motor spindle to check correct running with encoder fitted

Étape 4 -

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português