| [version en cours de rédaction] | [version en cours de rédaction] |

(Page créée avec « {{Tuto Details |Description=<translate>Process for unloading and locating Autoflow Mk4 machine in Saje upvc</translate> |Categories=Maintenance |Difficulty=Hard |Duration=... ») |

|||

| Ligne 1 : | Ligne 1 : | ||

{{Tuto Details | {{Tuto Details | ||

| + | |Main_Picture=Saje_uPVC_Unloading_Process_IMG_7330_1_.jpg | ||

|Description=<translate>Process for unloading and locating Autoflow Mk4 machine in Saje upvc</translate> | |Description=<translate>Process for unloading and locating Autoflow Mk4 machine in Saje upvc</translate> | ||

|Categories=Maintenance | |Categories=Maintenance | ||

| Ligne 11 : | Ligne 12 : | ||

The machine will be delivered in the following modules, that should be unloaded from the lorry in this order | The machine will be delivered in the following modules, that should be unloaded from the lorry in this order | ||

| − | # Machining centre base module (1.8 x 2.2m) | + | #Machining centre base module (1.8 x 2.2m) |

| − | # Machining centre outer guard 2 off (2.0 x 1.5m) | + | #Machining centre outer guard 2 off (2.0 x 1.5m) |

| − | # Infeed module (2.4 x 7.5m) | + | #Infeed module (2.4 x 7.5m) |

| − | # Conveyor modules (4.5 x 0.5m, 2.5 x 0.5m) | + | #Conveyor modules (4.5 x 0.5m, 2.5 x 0.5m) |

| + | |||

<br /></translate> | <br /></translate> | ||

}} | }} | ||

| − | {{Materials}} | + | {{Materials |

| − | {{EPI}} | + | |ItemList={{ItemList}} |

| + | }} | ||

| + | {{EPI | ||

| + | |EPI=use-protective-footwear, use-protective-clothing, use-protective-headgear | ||

| + | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Remove the Soenen Machine</translate> | |Step_Title=<translate>Remove the Soenen Machine</translate> | ||

| − | |Step_Content=<translate>Wed / Thur before unloading, remove the Soenen machine, leaving the large outfeed conveyor tables | + | |Step_Content=<translate>'''Wed / Thur''' before unloading, remove the Soenen machine, leaving the large outfeed conveyor tables |

The Brackets on the outfeed tables will be used for the Stuga conveyors</translate> | The Brackets on the outfeed tables will be used for the Stuga conveyors</translate> | ||

| Ligne 41 : | Ligne 47 : | ||

|Step_Picture_02=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Inner_Feet_Dims.jpg | |Step_Picture_02=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Inner_Feet_Dims.jpg | ||

|Step_Picture_03=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Inner_Feet_Dims.jpg | |Step_Picture_03=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Inner_Feet_Dims.jpg | ||

| + | |Step_Picture_03_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":4,"top":-78,"width":471,"height":732,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1.1,"scaleY":1.1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/a/ae/Saje_uPVC_Unloading_Process_Sturtz_Infeed_Inner_Feet_Dims.jpg","filters":[]}],"height":449.6487119437939,"width":600} | ||

| + | |Step_Picture_04=Saje_uPVC_Unloading_Process_Sturtz_Infeed_All_Pads.jpg | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

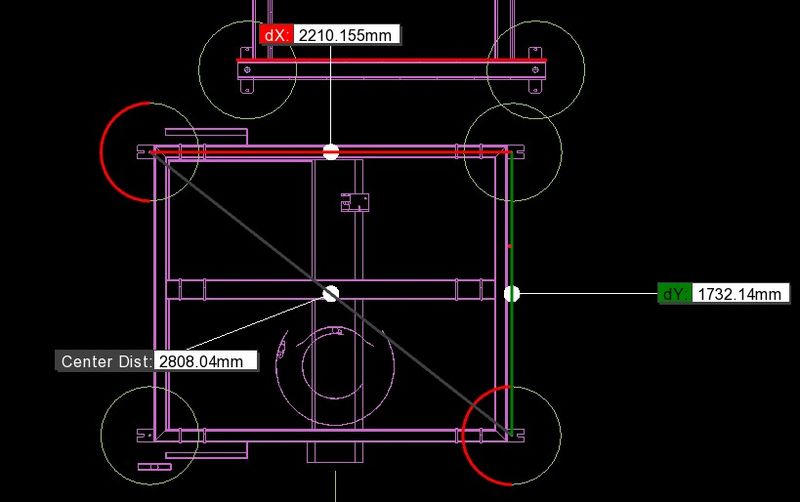

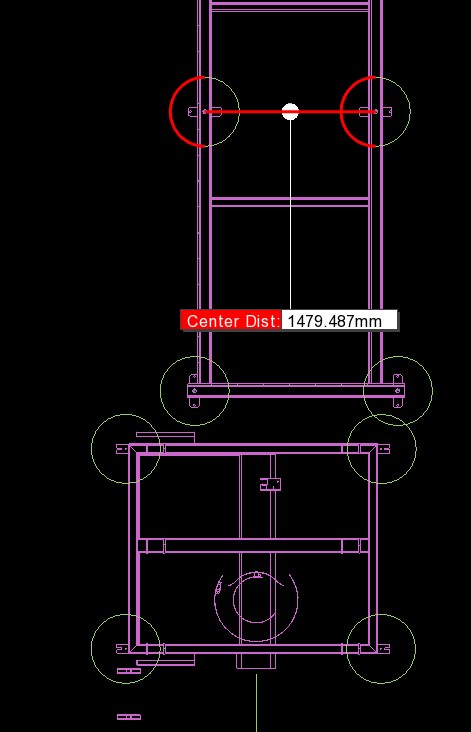

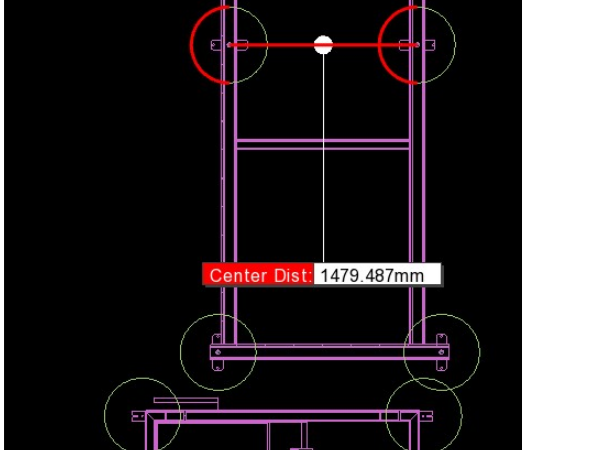

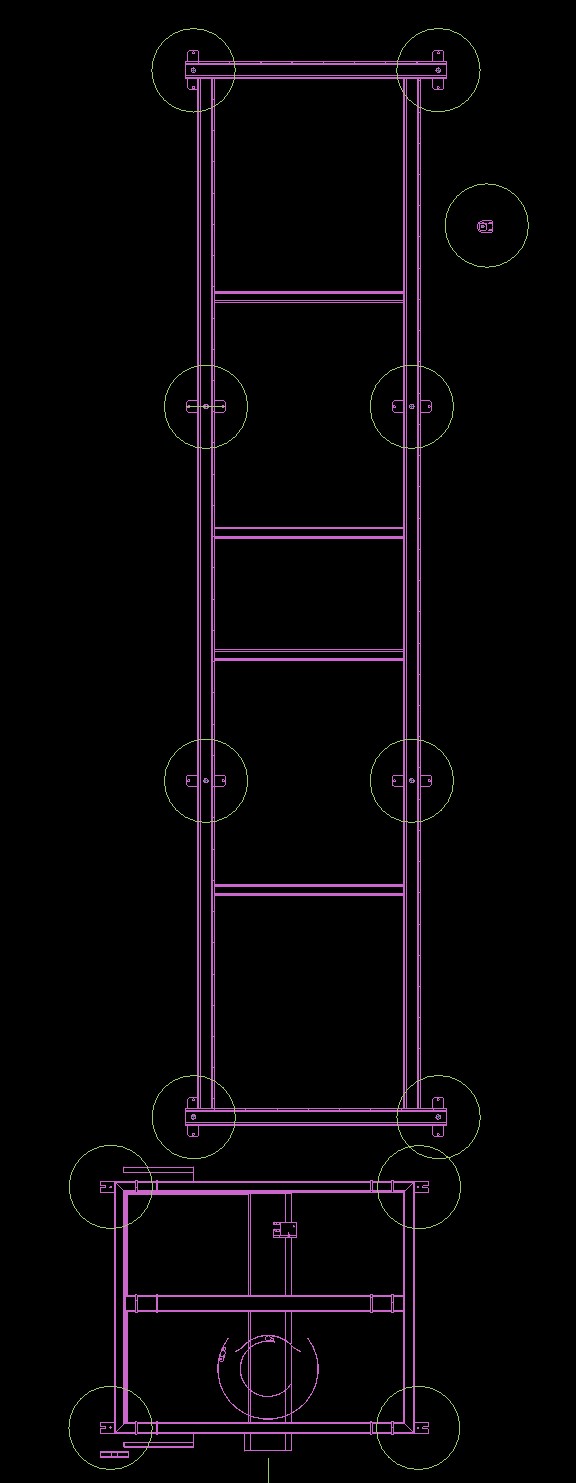

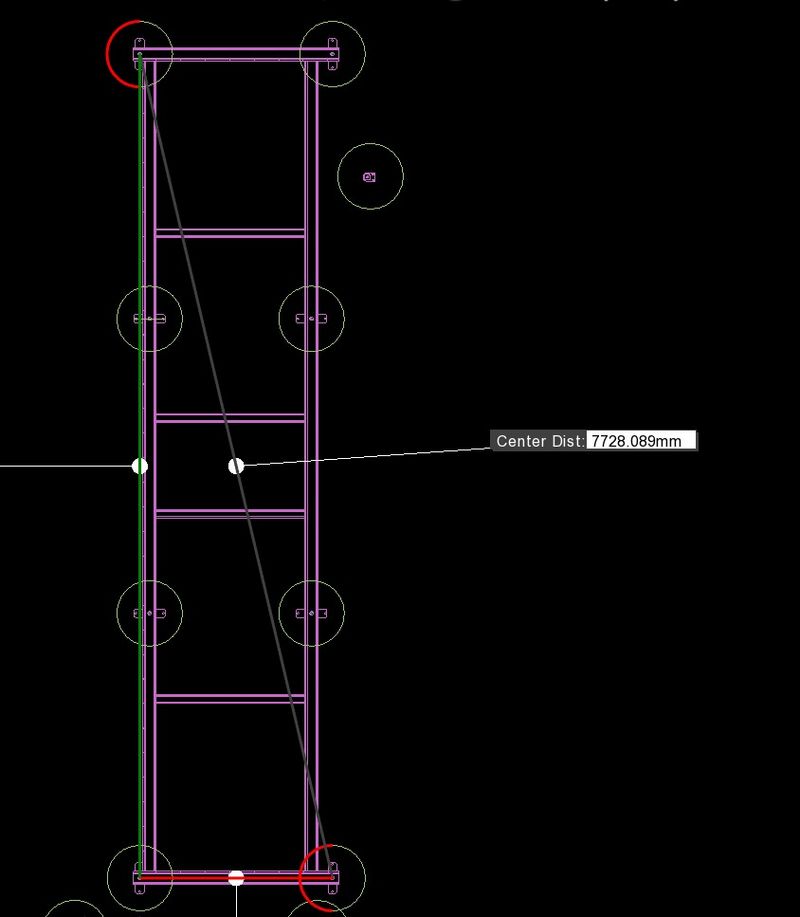

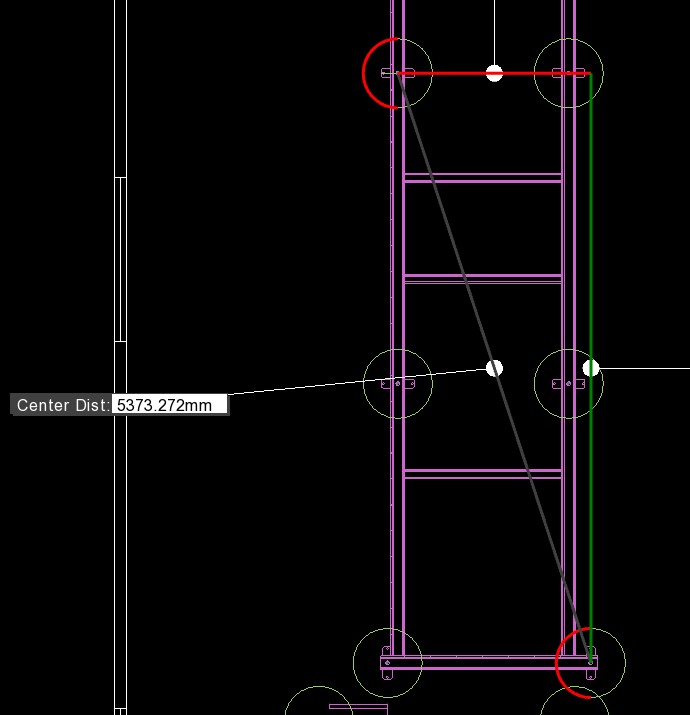

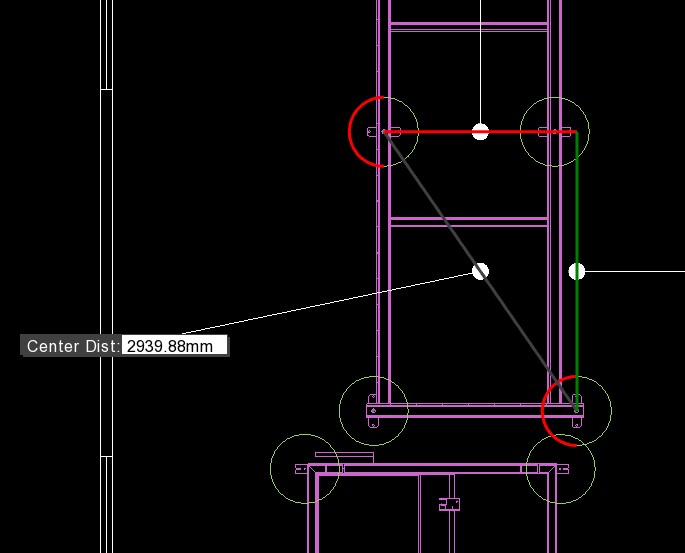

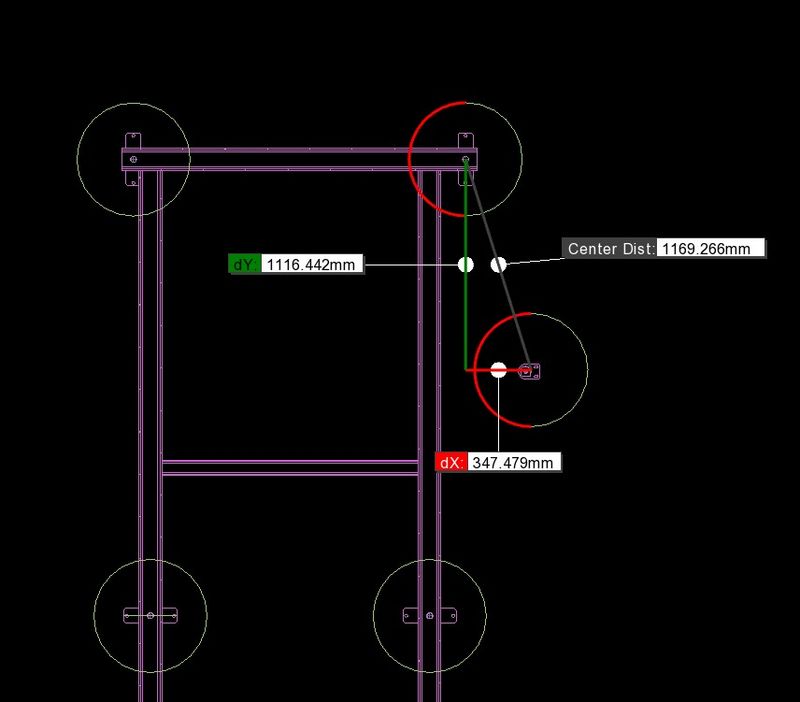

|Step_Title=<translate>Triangulation for Infeed Pads</translate> | |Step_Title=<translate>Triangulation for Infeed Pads</translate> | ||

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>Pictures show triangulation distances.</translate> |

|Step_Picture_00=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Triangulation_1.jpg | |Step_Picture_00=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Triangulation_1.jpg | ||

|Step_Picture_01=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Triangulation_2.jpg | |Step_Picture_01=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Triangulation_2.jpg | ||

|Step_Picture_02=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Triangulation_3.jpg | |Step_Picture_02=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Triangulation_3.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Odd pad</translate> | ||

| + | |Step_Content=<translate>Additional pad needed on infeed "unwrapping" table</translate> | ||

| + | |Step_Picture_00=Saje_uPVC_Unloading_Process_Sturtz_Infeed_Odd_Pad.jpg | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

|Step_Title=<translate>Prepare the Machine Pads / Piles</translate> | |Step_Title=<translate>Prepare the Machine Pads / Piles</translate> | ||

| − | |Step_Content=<translate>{{Idea|...Using shuttering in the pad holes will enable the height of the pad to be increased to correct the "run off" of the floor.}} | + | |Step_Content=<translate>'''Friday''':{{Idea|...Using shuttering in the pad holes will enable the height of the pad to be increased to correct the "run off" of the floor.}} |

| − | * Pad size 300mm x 300mm (or similar) | + | *Pad size 300mm x 300mm (or similar) |

| − | * Pad Depth 300-500mm | + | *Pad Depth 300-500mm |

| − | * Use shuttering or large diameter soil pipe | + | *Use shuttering or large diameter soil pipe |

| − | * Find the highest point, string a level agcross | + | *Find the highest point, string a level agcross to the other pads |

| − | *</translate> | + | *Fill shuttering with quick set cement to +/- 15mm of level |

| + | {{Idea|...The machining table has levelling feet, but the run off of the current cow shed floor may prove challenging for the range of the levelling. Using the shuttering to create taller plies will solve this problem easily and inexpensively}}<br /></translate> | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| Ligne 76 : | Ligne 90 : | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate> | + | |Step_Title=<translate>Clear Outside Unloading Area</translate> |

| − | |Step_Content=<translate></translate> | + | |Step_Content=<translate>The full width of this route will need to be cleared</translate> |

| + | |Step_Picture_00=Saje_uPVC_Unloading_Process_Saje_Rear.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Imporvements to step into building</translate> | ||

| + | |Step_Content=<translate>If possible, improve the access pathway. | ||

| + | |||

| + | Potentially find a ramp system for the step into the unit</translate> | ||

| + | |Step_Picture_00=Saje_uPVC_Unloading_Process_Step_into_Saje_Rear.jpg | ||

| + | |Step_Picture_01=Saje_uPVC_Unloading_Process_Saje_Rear.jpg | ||

| + | |Step_Picture_01_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":-316,"top":-396,"width":4032,"height":3024,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.3,"scaleY":0.3,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/c/c0/Saje_uPVC_Unloading_Process_Saje_Rear.jpg","filters":[]}],"height":449.75922953451044,"width":600} | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Lorry to reverse along LHS of building</translate> | ||

| + | |Step_Content=<translate>'''Monday''': | ||

| + | |||

| + | Lorry to reverse along left side of building (when viewed from front) | ||

| + | |||

| + | This allow easy unloading access for forklift to unload to ground, and align components with door | ||

| + | |||

| + | <br /></translate> | ||

| + | |Step_Picture_00=Saje_uPVC_Unloading_Process_Saje_Rear_LHS.jpg | ||

| + | |Step_Picture_01=Saje_uPVC_Unloading_Process_Saje_Unloading_area.jpg | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Machining Centre</translate> | ||

| + | |Step_Content=<translate>The machining centre</translate> | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Machining Centre Guard</translate> | ||

| + | |Step_Content=<translate>The guar is a clam shell design that encases the machine in 2 pars from front and rear</translate> | ||

}} | }} | ||

{{Notes}} | {{Notes}} | ||

{{PageLang | {{PageLang | ||

| + | |Language=en | ||

|SourceLanguage=none | |SourceLanguage=none | ||

|IsTranslation=0 | |IsTranslation=0 | ||

| − | |||

}} | }} | ||

{{Tuto Status | {{Tuto Status | ||

|Complete=Draft | |Complete=Draft | ||

}} | }} | ||

Version du 3 octobre 2022 à 10:04

Process for unloading and locating Autoflow Mk4 machine in Saje upvc

Sommaire

- 1 Introduction

- 2 Pièces et outils

- 3 Étape 1 - Remove the Soenen Machine

- 4 Étape 2 - Prepare the floor

- 5 Étape 3 - Triangulation for Infeed Pads

- 6 Étape 4 - Odd pad

- 7 Étape 5 - Prepare the Machine Pads / Piles

- 8 Étape 6 - Prepare unloading bogeys

- 9 Étape 7 - Clear the inside area

- 10 Étape 8 - Clear Outside Unloading Area

- 11 Étape 9 - Imporvements to step into building

- 12 Étape 10 - Lorry to reverse along LHS of building

- 13 Étape 11 - Machining Centre

- 14 Étape 12 - Machining Centre Guard

- 15 Commentaires

Introduction

Access for machinery is limited at the Saje factory.

The machine will be delivered in the following modules, that should be unloaded from the lorry in this order

- Machining centre base module (1.8 x 2.2m)

- Machining centre outer guard 2 off (2.0 x 1.5m)

- Infeed module (2.4 x 7.5m)

- Conveyor modules (4.5 x 0.5m, 2.5 x 0.5m)

- Pièces et outils

Pièces et outils

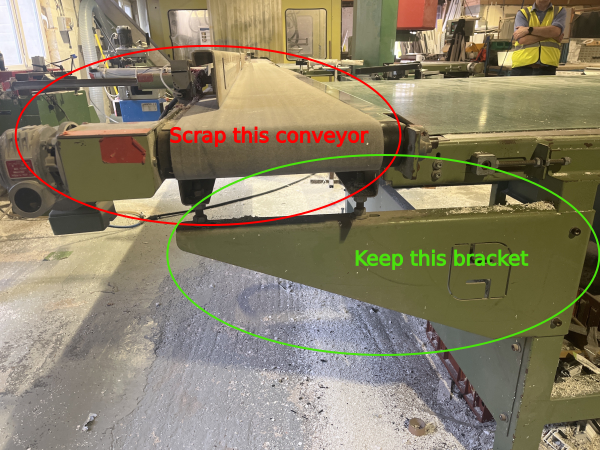

Étape 1 - Remove the Soenen Machine

Wed / Thur before unloading, remove the Soenen machine, leaving the large outfeed conveyor tables

The Brackets on the outfeed tables will be used for the Stuga conveyors

Étape 2 - Prepare the floor

The datum points for loading have already been marked on the floor.

Using these datum points, mark the position of the remainder of the floor pads

Étape 5 - Prepare the Machine Pads / Piles

Friday:- Pad size 300mm x 300mm (or similar)

- Pad Depth 300-500mm

- Use shuttering or large diameter soil pipe

- Find the highest point, string a level agcross to the other pads

- Fill shuttering with quick set cement to +/- 15mm of level

Étape 6 - Prepare unloading bogeys

Window loading bogeys (3 off) to be prepared on a rigid base to allow one end of machine infeed frame to rest on them

The forklift will lift and push from the other end

Étape 7 - Clear the inside area

Including the chop saw table

Leaving a clear route for the 2.4m x 7.5m table to roll in

Étape 9 - Imporvements to step into building

If possible, improve the access pathway.

Potentially find a ramp system for the step into the unit

Étape 10 - Lorry to reverse along LHS of building

Monday:

Lorry to reverse along left side of building (when viewed from front)

This allow easy unloading access for forklift to unload to ground, and align components with door

Étape 11 - Machining Centre

The machining centre

Étape 12 - Machining Centre Guard

The guar is a clam shell design that encases the machine in 2 pars from front and rear

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português