| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 6 : | Ligne 6 : | ||

|Tags=Weekly, Maintenance | |Tags=Weekly, Maintenance | ||

}} | }} | ||

| − | <translate></translate> | + | <translate><br /> |

| + | {| class="wikitable" | ||

| + | !Date | ||

| + | !Build Number | ||

| + | !Completed By | ||

| + | |- | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |} | ||

| + | {| class="wikitable" | ||

| + | |+Infeed Table | ||

| + | !Ref | ||

| + | !Description | ||

| + | ! | ||

| + | !Tick | ||

| + | |- | ||

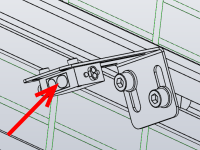

| + | |1.1 | ||

| + | |Clean Material Load and Offcut Sensors | ||

| + | Wipe Lenses. | ||

| + | |||

| + | Check function on LED output | ||

| + | |{{#annotatedImageLight:Fichier:ZX5 Weekly Maintenance Checklist Image 1.11.png|0=200px|hash=eaeed23bbb7413bebb9094432289a12b|jsondata={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":541,"height":407,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.37,"scaleY":0.37,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/3/3a/ZX5_Weekly_Maintenance_Checklist_Image_1.11.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":31.5,"top":111,"width":47,"height":48,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-23.5,"x2":23.5,"y1":24,"y2":-24,"x2a":15.223587559783695,"y2a":-4.112793129264413,"x2b":3.7914207358877876,"y2b":-15.30678981099582},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":8,"top":135,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":55,"top":87,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":150,"width":200}|mediaClass=Image|type=frameless|align=center|src=/images/thumb/3/3a/ZX5_Weekly_Maintenance_Checklist_Image_1.11.png/ia-eaeed23bbb7413bebb9094432289a12b-px-ZX5_Weekly_Maintenance_Checklist_Image_1.11.png.png|href=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.11.png|resource=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.11.png|caption=|size=200px}} | ||

| + | | | ||

| + | |- | ||

| + | |1.2 | ||

| + | |Check Alignment and State of Infeed Pegs | ||

| + | Check that the pegs on each arm all exist and are all aligned with each other. | ||

| + | |{{#annotatedImageLight:Fichier:ZX5 Weekly Maintenance Checklist Image 1.21.png|0=200px|hash=65817db89eb1e7d54dbe2f2303e37d24|jsondata={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":464,"height":281,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.43,"scaleY":0.43,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/f/f2/ZX5_Weekly_Maintenance_Checklist_Image_1.21.png","filters":[]},{"type":"wfline","version":"2.4.6","originX":"center","originY":"center","left":67.5,"top":52.5,"width":5,"height":65,"fill":"rgba(255,0,0,0)","stroke":"#4AE40D","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-2.5,"x2":2.5,"y1":-32.5,"y2":32.5},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":65,"top":20,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":70,"top":85,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":121,"width":200}|mediaClass=Image|type=frameless|align=center|src=/images/thumb/f/f2/ZX5_Weekly_Maintenance_Checklist_Image_1.21.png/ia-65817db89eb1e7d54dbe2f2303e37d24-px-ZX5_Weekly_Maintenance_Checklist_Image_1.21.png.png|href=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.21.png|resource=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.21.png|caption=|size=200px}} | ||

| + | | | ||

| + | |- | ||

| + | |1.3 | ||

| + | |Check State of Infeed Wheel Rubber | ||

| + | |{{#annotatedImageLight:Fichier:ZX5 Weekly Maintenance Checklist Image 1.41.png|0=200px|hash=aed316b6f90b4a3934c967a16a8cb2d3|jsondata={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":203,"height":239,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.99,"scaleY":0.99,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/a/a7/ZX5_Weekly_Maintenance_Checklist_Image_1.41.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":139,"top":148,"width":78,"height":18,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":39,"x2":-39,"y1":-9,"y2":9,"x2a":-17.713300032517537,"y2a":12.29793943158179,"x2b":-21.311052139697672,"y2b":-3.2923196995321273},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":178,"top":139,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":100,"top":157,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":235,"width":200}|mediaClass=Image|type=frameless|align=center|src=/images/thumb/a/a7/ZX5_Weekly_Maintenance_Checklist_Image_1.41.png/ia-aed316b6f90b4a3934c967a16a8cb2d3-px-ZX5_Weekly_Maintenance_Checklist_Image_1.41.png.png|href=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.41.png|resource=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.41.png|caption=|size=200px}} | ||

| + | | | ||

| + | |- | ||

| + | |1.4 | ||

| + | |Load Wheel Slide | ||

| + | Ensure the slide operates up and down freely | ||

| + | |{{#annotatedImageLight:Fichier:ZX5 Weekly Maintenance Checklist Image 1.41.png|0=200px|hash=b21a3cc0a33075e885606e5b62a9ccfa|jsondata={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":203,"height":239,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.99,"scaleY":0.99,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/a/a7/ZX5_Weekly_Maintenance_Checklist_Image_1.41.png","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":177.5,"top":129,"width":3,"height":140,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":-1.5,"x2":1.5,"y1":70,"y2":-70,"x2a":9.06969083166955,"y2a":-49.8332010295898,"x2b":-6.92663696355667,"y2b":-50.175979482344644},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":176,"top":199,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":179,"top":59,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":160,"top":135.5,"width":0,"height":131,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":0,"x2":0,"y1":-65.5,"y2":65.5,"x2a":8,"y2a":45.5,"x2b":-8,"y2b":45.5},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":160,"top":70,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":160,"top":201,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":235,"width":200}|mediaClass=Image|type=frameless|align=center|src=/images/thumb/a/a7/ZX5_Weekly_Maintenance_Checklist_Image_1.41.png/ia-b21a3cc0a33075e885606e5b62a9ccfa-px-ZX5_Weekly_Maintenance_Checklist_Image_1.41.png.png|href=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.41.png|resource=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.41.png|caption=|size=200px}} | ||

| + | | | ||

| + | |- | ||

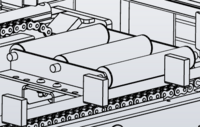

| + | |1.5 | ||

| + | |Roller bed | ||

| + | Check all rollers are free to turn and not flat-spotted | ||

| + | |||

| + | Particularly near entrance to machining centre | ||

| + | |{{#annotatedImageLight:Fichier:ZX5 Weekly Maintenance Checklist Image 1.5.png|0=200px|hash=|jsondata=|mediaClass=Image|type=frameless|align=center|src=https://stuga.dokit.app/images/8/8b/ZX5_Weekly_Maintenance_Checklist_Image_1.5.png|href=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.5.png|resource=./Fichier:ZX5 Weekly Maintenance Checklist Image 1.5.png|caption=|size=200px}} | ||

| + | | | ||

| + | |}</translate> | ||

{{PageLang | {{PageLang | ||

|Language=en | |Language=en | ||

Version du 5 avril 2022 à 18:08

Weekly Maintenance Checklist for ZX5 Machine

Sommaire

| Date | Build Number | Completed By |

|---|---|---|

| Ref | Description | Tick | |

|---|---|---|---|

| 1.1 | Clean Material Load and Offcut Sensors

Wipe Lenses. Check function on LED output |

||

| 1.2 | Check Alignment and State of Infeed Pegs

Check that the pegs on each arm all exist and are all aligned with each other. |

||

| 1.3 | Check State of Infeed Wheel Rubber | ||

| 1.4 | Load Wheel Slide

Ensure the slide operates up and down freely |

||

| 1.5 | Roller bed

Check all rollers are free to turn and not flat-spotted Particularly near entrance to machining centre |

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português